ASTM D2343-17(2023)

(Test Method)Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics

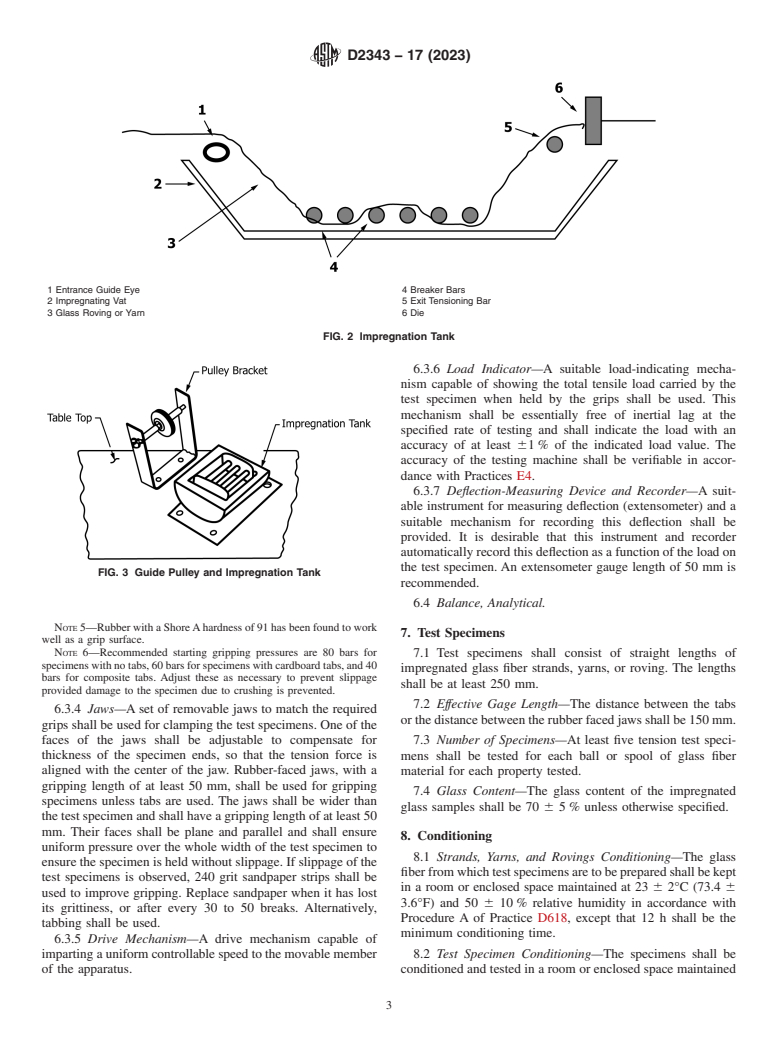

Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics

SIGNIFICANCE AND USE

5.1 Tensile properties determined by this test method are of value for identifying and characterizing materials for control and specification purposes as well as for providing data for research and development studies.

5.2 This test method is intended for use in testing resin-compatible sized glass fiber materials that have been designed specifically for use with certain generic types of plastics. The use of a resin system that is compatible with the reinforcement material under test produces results that are most representative of the actual strength that is available in the material when used as intended in an end item. Premature reinforcement failures occur if the elongation of the resin system is less than that of the reinforcement being tested. It is critical to select a resin system that does not lead to premature reinforcement failure. Use of compatible resin system and complete resin impregnation is recommended to avoid invalid failures and misleading results.

5.3 This test method is useful for testing pretreated specimens for which comparative results are desired. Gage length, gripping system, testing speed, and the resin impregnation ratio of the specimen affects the values obtained by this test method.

SCOPE

1.1 This test method covers the determination of the comparative tensile properties of glass fiber strands, yarns, and rovings in the form of impregnated rod test specimens when tested under defined conditions of pretreatment, temperature, humidity, and tension testing machine speed. This test method is applicable to continuous filament, glass fiber materials that have been coated with a resin compatible sizing. This method is intended for use in quality control and R & D, and is not intended to be used to develop composites design data.

Note 1: This method is technically equivalent to the short method described in ISO 9163.

Note 2: Prime consideration should be given to the use of a polymeric binder that produces specimens that yield the highest consistent values for the glass fiber material under test. Tensile properties vary with specimen preparation, resin impregnation system, and speed and environment of testing. Consider these factors where precise comparative results are desired.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2343 − 17 (Reapproved 2023)

Standard Test Method for

Tensile Properties of Glass Fiber Strands, Yarns, and

1

Rovings Used in Reinforced Plastics

This standard is issued under the fixed designation D2343; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method covers the determination of the com-

D618 Practice for Conditioning Plastics for Testing

parative tensile properties of glass fiber strands, yarns, and

D883 Terminology Relating to Plastics

rovings in the form of impregnated rod test specimens when

E4 Practices for Force Calibration and Verification of Test-

tested under defined conditions of pretreatment, temperature,

ing Machines

humidity, and tension testing machine speed. This test method

E6 Terminology Relating to Methods of Mechanical Testing

is applicable to continuous filament, glass fiber materials that

2.2 ISO Standard:

have been coated with a resin compatible sizing. This method

ISO 9163 Textile Glass—Rovings—Manufacture of Test

is intended for use in quality control and R & D, and is not

Specimens and Determination of Tensile Strength of

intended to be used to develop composites design data.

Impregnated Rovings

NOTE 1—This method is technically equivalent to the short method

described in ISO 9163. 3. Terminology

NOTE 2—Prime consideration should be given to the use of a polymeric

3.1 Definitions:

binder that produces specimens that yield the highest consistent values for

3.1.1 Definitions of terms and symbols relating to this test

the glass fiber material under test. Tensile properties vary with specimen

method appear in Terminologies E6 and D883.

preparation, resin impregnation system, and speed and environment of

testing. Consider these factors where precise comparative results are

4. Summary of Test Method

desired.

4.1 This test method consists of impregnating glass fiber

1.2 The values stated in SI units are to be regarded as the

strands, yarns, or rovings with a suitable polymeric binder

standard. The values given in parentheses are for information

material and loading the resulting test specimens to failure in a

only.

tension testing machine having a constant-rate-of crosshead

1.3 This standard does not purport to address all of the

movement. The cross sectional area is determined from skeins

safety concerns, if any, associated with its use. It is the

of glass fiber taken before and after each set of test specimens.

responsibility of the user of this standard to establish appro-

After impregnation and curing, the specimens shall either be

priate safety, health, and environmental practices and deter-

tabbed using glass fiber mat or cardboard and tested with

mine the applicability of regulatory limitations prior to use.

standard grips; or the ends shall be sanded with 240 grit

sandpaper or fine emery cloth and tested using rubber faced

1.4 This international standard was developed in accor-

grips.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

5. Significance and Use

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical 5.1 Tensile properties determined by this test method are of

Barriers to Trade (TBT) Committee. value for identifying and characterizing materials for control

and specification purposes as well as for providing data for

research and development studies.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

2

ting Plastics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2023. Published August 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1965. Last previous edition approved in 2017 as D2343–17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2343-17R23. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2343 − 17 (2023)

5.2 This test method is intended fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.