ASTM D204-02

(Test Method)Standard Test Methods for Sewing Threads

Standard Test Methods for Sewing Threads

SIGNIFICANCE AND USE

Acceptance Testing—The test methods in Test Methods D 204 for the determination of the properties of sewing thread are considered satisfactory for acceptance testing of commercial shipments of sewing thread, unless specified in the individual test method. These test methods are the best available and are used extensively in the trade.

4.1.1 If there are differences of practical significance between reported test results for two laboratories (or more) comparative test should be performed to determine if there is a statistical bias between them using competent statistical assistance. As a minimum, use the samples for such a comparative tests that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If a bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

SCOPE

1.1 These test methods can be used to evaluate sewing threads of any fiber.

1.1.1 The test methods in this standard are intended to evaluate only sewing thread taken from thread holders.

1.2 These test methods only provide for the measurement of sewing thread physical properties. These test methods do not address any other properties that may be important for the satisfactory performance of sewing threads under particular end use conditions.

1.3 These test methods can be used to measure the following properties:SectionsColorfastness to Drycleaning73-83Colorfastness to Laundering62-72Colorfastness to Water Migration84-94Diameter43-50Length per Thread Holder34-42Shrinkage, Single Strand51-61Dry Heat58.1Boiling Water58.2Strength and Elongation15-21Single Strand-Conditioned19.1.1Single Strand-Wet19.1.2Loop Strength19.2Knot Strength19.3Twist22-27Twist Balance28-33Yarn Number7-14

Note 1—For methods covering tests on prepared seams, refer to Test Methods D 1683 and D 3940.

1.4 The values stated in SI units are to be regarded as standard; the values in English units are provided as information only and are not exact equivalents.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D204–02

Standard Test Methods for

1

Sewing Threads

This standard is issued under the fixed designation D204; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

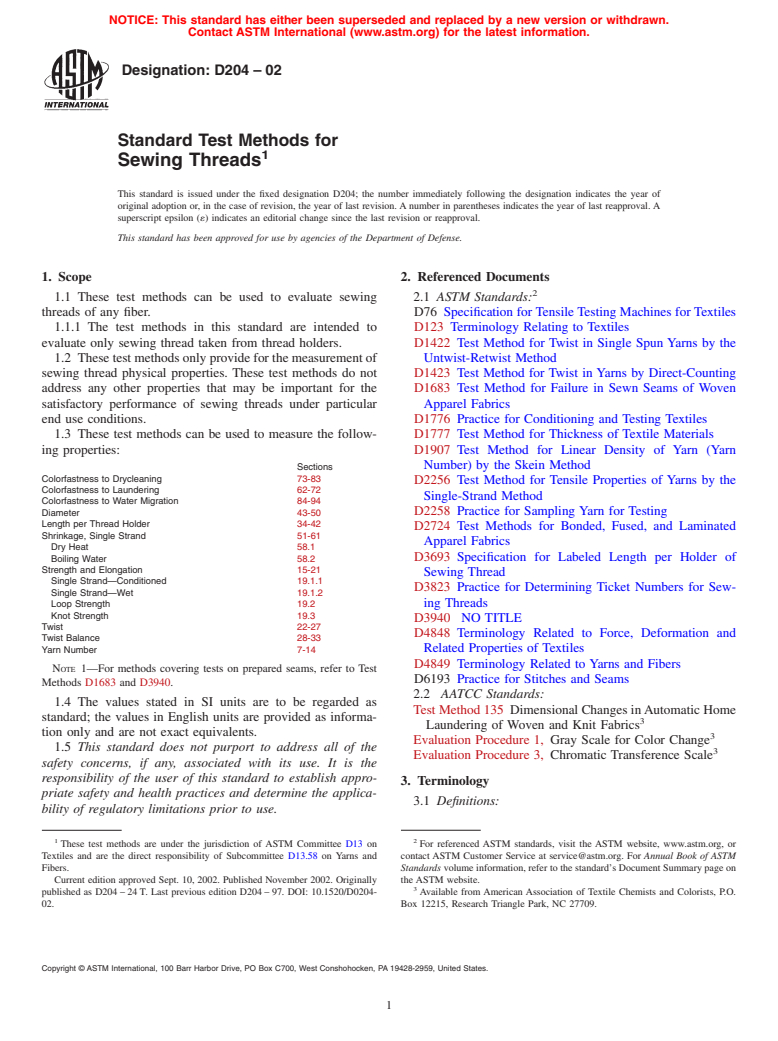

1. Scope 2. Referenced Documents

2

1.1 These test methods can be used to evaluate sewing 2.1 ASTM Standards:

threads of any fiber. D76 Specification for Tensile Testing Machines for Textiles

1.1.1 The test methods in this standard are intended to D123 Terminology Relating to Textiles

evaluate only sewing thread taken from thread holders. D1422 Test Method for Twist in Single Spun Yarns by the

1.2 These test methods only provide for the measurement of Untwist-Retwist Method

sewing thread physical properties. These test methods do not D1423 Test Method for Twist in Yarns by Direct-Counting

address any other properties that may be important for the D1683 Test Method for Failure in Sewn Seams of Woven

satisfactory performance of sewing threads under particular Apparel Fabrics

end use conditions. D1776 Practice for Conditioning and Testing Textiles

1.3 These test methods can be used to measure the follow- D1777 Test Method for Thickness of Textile Materials

ing properties: D1907 Test Method for Linear Density of Yarn (Yarn

Number) by the Skein Method

Sections

Colorfastness to Drycleaning 73-83

D2256 Test Method for Tensile Properties of Yarns by the

Colorfastness to Laundering 62-72

Single-Strand Method

Colorfastness to Water Migration 84-94

D2258 Practice for Sampling Yarn for Testing

Diameter 43-50

Length per Thread Holder 34-42

D2724 Test Methods for Bonded, Fused, and Laminated

Shrinkage, Single Strand 51-61

Apparel Fabrics

Dry Heat 58.1

Boiling Water 58.2 D3693 Specification for Labeled Length per Holder of

Strength and Elongation 15-21

Sewing Thread

Single Strand—Conditioned 19.1.1

D3823 Practice for Determining Ticket Numbers for Sew-

Single Strand—Wet 19.1.2

Loop Strength 19.2 ing Threads

Knot Strength 19.3

D3940 NO TITLE

Twist 22-27

D4848 Terminology Related to Force, Deformation and

Twist Balance 28-33

Related Properties of Textiles

Yarn Number 7-14

D4849 Terminology Related to Yarns and Fibers

NOTE 1—For methods covering tests on prepared seams, refer to Test

D6193 Practice for Stitches and Seams

Methods D1683 and D3940.

2.2 AATCC Standards:

1.4 The values stated in SI units are to be regarded as

Test Method 135 Dimensional Changes inAutomatic Home

standard; the values in English units are provided as informa-

3

Laundering of Woven and Knit Fabrics

tion only and are not exact equivalents.

3

Evaluation Procedure 1, Gray Scale for Color Change

1.5 This standard does not purport to address all of the

3

Evaluation Procedure 3, Chromatic Transference Scale

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions:

bility of regulatory limitations prior to use.

1 2

These test methods are under the jurisdiction of ASTM Committee D13 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Textiles and are the direct responsibility of Subcommittee D13.58 on Yarns and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fibers. Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Current edition approved Sept. 10, 2002. Published November 2002. Originally

3

Available from American Association of Textile Chemists and Colorists, P.O.

published as D204 – 24 T. Last previous edition D204 – 97. DOI: 10.1520/D0204-

02. Box 12215, Research Triangle Park, NC 27709.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

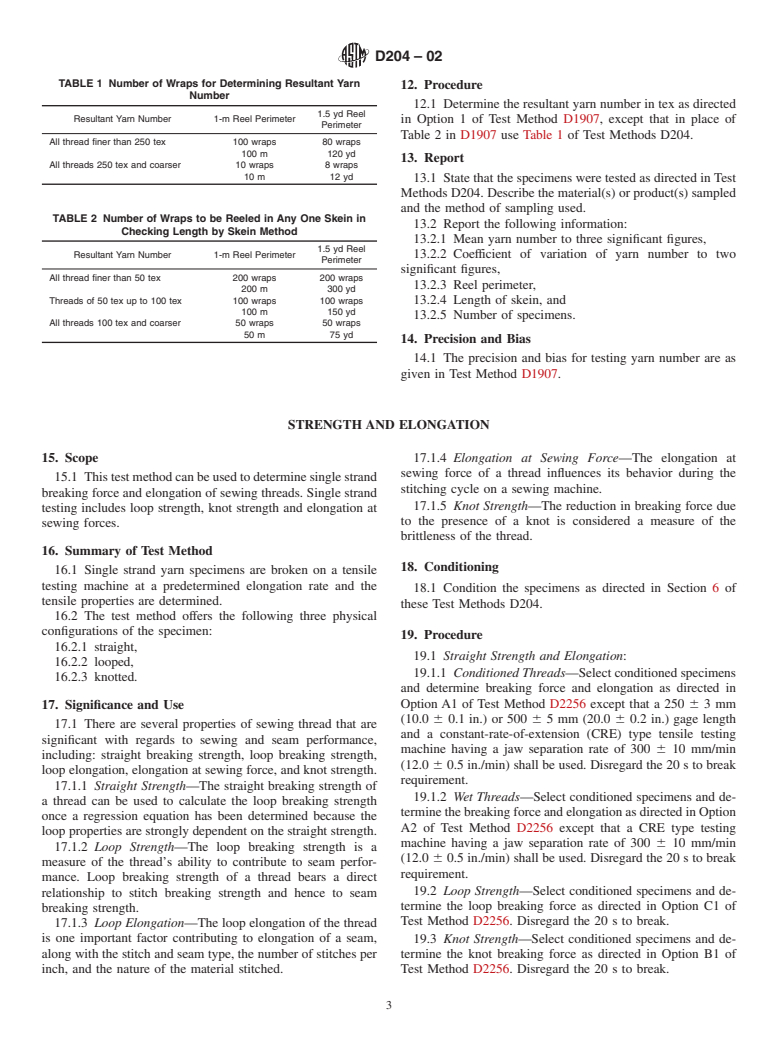

D204–02

3.1.1 Refer to Terminology D4848 for definitions of the the purchaser and the supplier, such as an agreement to use

following terms used in this standard elongation; force and Practice D2258. Consider shipping cases or other shipping

loop-breaking force. units to be the primary sampling units.

3.1.2 Refer to Terminology D4849 for definitions of the

NOTE 2—An adequate specification or other agreement between the

following terms used in this standard colorfastness; covered

purchaserandthesupplierrequirestakingintoaccountvariabilitybetween

yarn, greige thread, growth, sew, sewing force, sewing thread,

shipping units, between packages, or ends within a shipping unit, and

tex, thread holder, t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.