ASTM D5579-09a

(Test Method)Standard Test Method for Evaluating the Thermal Stability of Manual Transmission Lubricants in a Cyclic Durability Test

Standard Test Method for Evaluating the Thermal Stability of Manual Transmission Lubricants in a Cyclic Durability Test

SIGNIFICANCE AND USE

This test method is used to evaluate automotive manual transmission fluids for thermal instability, which results in deterioration of synchronizer performance.

This test method may also be utilized in other specifications and classifications of transmission and gear lubricants such as the following:

(final API designation of PG-1),

Military Specification MIL-L-2105,

SAE Information Report J308 Axle and Manual Transmission Lubricants, and

Mack Truck GO-H Gear Lubricant Specification.

SCOPE

1.1 This test method covers the thermal stability of fluids for use in heavy duty manual transmissions when operated at high temperatures.

1.2 The lubricant performance is measured by the number of shifting cycles that can be performed without failure of synchronization when the transmission is operated while continuously cycling between high and low range.

1.3 Correlation of test results with truck transmission service has not been established. However, the procedure has been shown to appropriately separate two transmission lubricants, which have shown satisfactory and unsatisfactory field performance in the trucks of one manufacturer.

1.4 Changes in this test method may be necessary due to refinements in the procedure, obsolescence of parts, or reagents, and so forth. These changes will be incorporated by Information Letters issued by the ASTM Test Monitoring Center (TMC). The test method will be revised to show the content of all the letters, as issued.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5.1 Exception—When materials, products, or equipment are available only in inch-pound units, SI units are omitted.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 This test method is arranged as follows:

Section Scope 1 Referenced Documents 2 Terminology 3 Summary of Test Method 4 Significance and Use 5 Apparatus 6 Test Transmission 6.2 Transmission Mounts 6.3 Oil-Circulating System 6.4 Oil Return Hole 6.5 Air Pressure Controls 6.6 Drive System 6.7 Instrumentation 6.8 Thermocouple Placement 6.9 Reagents and Materials 7 Safety 8 Preparation of Apparatus 9 Cleaning of Parts 9.1 Assembly 9.2 Calibration 10 Transmission and Test Stand Calibration 10.1 Reference Oils 10.2 Reference Oil Test Frequency 10.3 Instrumentation Calibration 10.4 Shift Time Calibration 10.5 Operating Procedure 11 System Flush and Charge 11.1 Test Operation 11.2 Shut-Down Procedure 11.3 Transmission Disassembly 11.4 Determination of Test Results 12 Failure Criteria 12.1 Shifter Fork Wear 12.2 Test Validity Determination 12.3 Report 14 Precision and Bias 15 Keywords 16 Test Validity Calculations and LimitsAnnex A1 Test Kit PartsAnnex A2 HTCT Test Report Forms and Data DictionaryAnnex A3 Manual Transmission Cyclic Durability Test Parts Inspection and Wear MeasurementsAnnex A4

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D5579 – 09a

Standard Test Method for

Evaluating the Thermal Stability of Manual Transmission

1

Lubricants in a Cyclic Durability Test

This standard is issued under the fixed designation D5579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

Terminology 3

Summary of Test Method 4

1.1 Thistestmethodcoversthethermalstabilityoffluidsfor

Significance and Use 5

use in heavy duty manual transmissions when operated at high

Apparatus 6

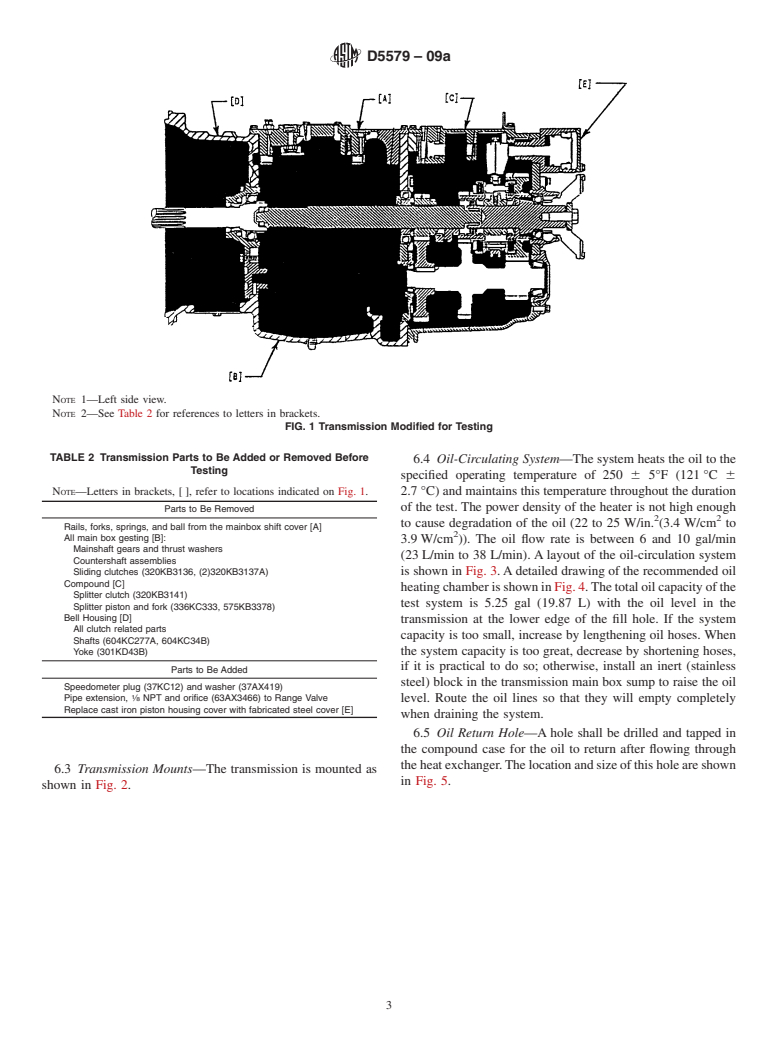

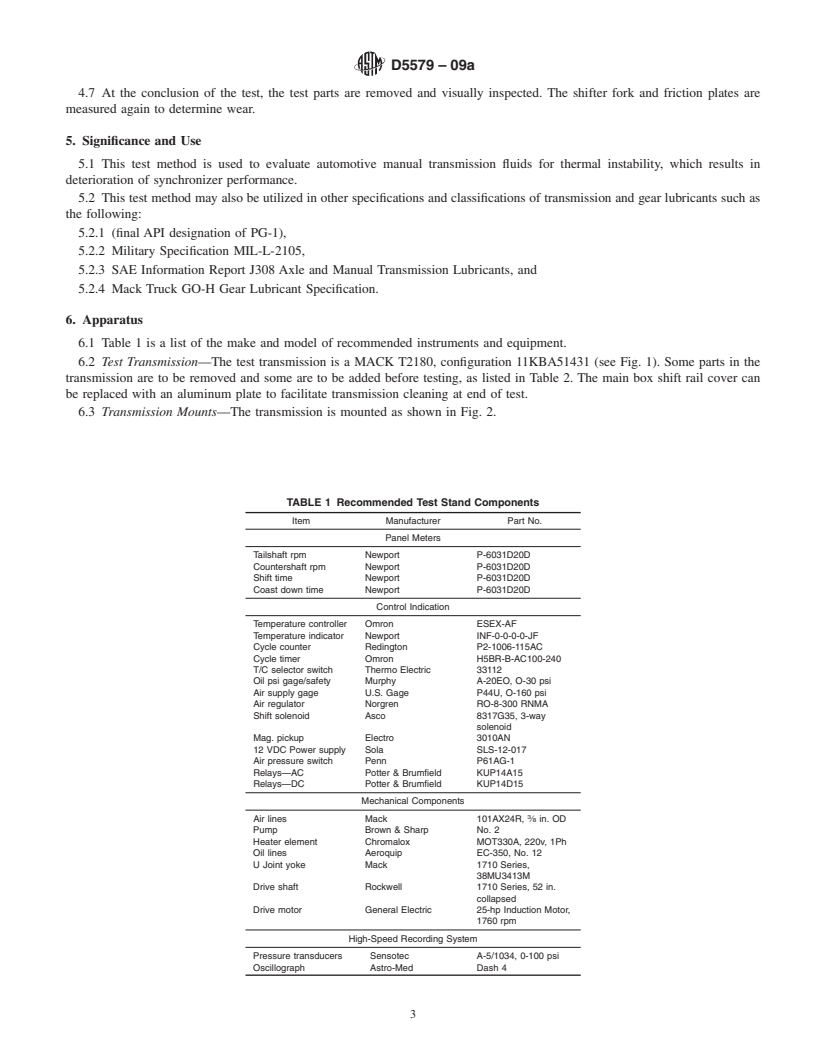

Test Transmission 6.2

temperatures.

Transmission Mounts 6.3

1.2 The lubricant performance is measured by the number

Oil-Circulating System 6.4

of shifting cycles that can be performed without failure of

Oil Return Hole 6.5

Air Pressure Controls 6.6

synchronization when the transmission is operated while con-

Drive System 6.7

tinuously cycling between high and low range.

Instrumentation 6.8

1.3 Correlation of test results with truck transmission ser- Thermocouple Placement 6.9

Reagents and Materials 7

vicehasnotbeenestablished.However,theprocedurehasbeen

Safety 8

shown to appropriately separate two transmission lubricants,

Preparation of Apparatus 9

which have shown satisfactory and unsatisfactory field perfor- Cleaning of Parts 9.1

Assembly 9.2

mance in the trucks of one manufacturer.

Calibration 10

1.4 Changes in this test method may be necessary due to

Transmission and Test Stand Calibration 10.1

refinements in the procedure, obsolescence of parts, or re- Reference Oils 10.2

Reference Oil Test Frequency 10.3

agents, and so forth. These changes will be incorporated by

Instrumentation Calibration 10.4

Information Letters issued by the ASTM Test Monitoring

Shift Time Calibration 10.5

2

Center (TMC). The test method will be revised to show the Operating Procedure 11

System Flush and Charge 11.1

content of all the letters, as issued.

Test Operation 11.2

1.5 The values stated in inch-pound units are to be regarded

Shut-Down Procedure 11.3

as standard. The values given in parentheses are mathematical Transmission Disassembly 11.4

Determination of Test Results 12

conversions to SI units that are provided for information only

Failure Criteria 12.1

and are not considered standard.

Shifter Fork Wear 12.2

Test Validity Determination 12.3

1.5.1 Exception—When materials, products, or equipment

Report 13

are available only in inch-pound units, SI units are omitted.

Precision and Bias 14

1.6 This standard does not purport to address all of the

Keywords 15

safety concerns, if any, associated with its use. It is the Test Validity Calculations and Limits Annex A1

Test Kit Parts Annex A2

responsibility of the user of this standard to establish appro-

HTCT Test Report Forms and Data Dictionary Annex A3

priate safety and health practices and determine the applica-

Manual Transmission Cyclic Durability Test Parts Annex A4

Inspection and Wear Measurements

bility of regulatory limitations prior to use.

1.7 This test method is arranged as follows:

2. Referenced Documents

Section

3

2.1 ASTM Standards:

Scope 1

Referenced Documents 2

D235 Specification for Mineral Spirits (Petroleum Spirits)

(Hydrocarbon Dry Cleaning Solvent)

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.B0.03 on Automotive Gear Lubricants & Fluids.

Current edition approved Oct. 1, 2009. Published November 2009. Originally

3

approved in 1994. Last previous edition approved in 2009 as D5579–09. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/D5579-09a. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 15206-4489. Standards volume information, refer to the standard’s Document Summary page on

This edition incorporates revisions in all Information Letters through No. 09-1. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5579 – 09a

2.2 SAE Standard: 4.7 At the conclusion of the test, the test parts are removed

4

SAE J308 Axle and Manual Transmission Lubricants and visually inspected. The shifter fork and friction plates are

2.3 Military Standard: measured again to determine wear.

5

MIL-L-2105 Lubricating Oil, Gear, Multipurpose

5. Significance and Use

2.4 Other Standard:

6

5.1 This test method is used to evaluate automotive manual

GO-H Mack Trucks Oil,

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard Designation: D5579 – 09a

Designation:D5579–09

Standard Test Method for

Evaluating the Thermal Stability of Manual Transmission

1

Lubricants in a Cyclic Durability Test

This standard is issued under the fixed designation D5579; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the thermal stability of fluids for use in heavy duty manual transmissions when operated at high

temperatures.

1.2 The lubricant performance is measured by the number of shifting cycles that can be performed without failure of

synchronization when the transmission is operated while continuously cycling between high and low range.

1.3 Correlation of test results with truck transmission service has not been established. However, the procedure has been shown

to appropriately separate two transmission lubricants, which have shown satisfactory and unsatisfactory field performance in the

trucks of one manufacturer.

1.4 Changes in this test method may be necessary due to refinements in the procedure, obsolescence of parts, or reagents, and

2

so forth.These changes will be incorporated by Information Letters issued by theASTMTest Monitoring Center (TMC). The test

method will be revised to show the content of all the letters, as issued.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5.1 Exception—When materials, products, or equipment are available only in inch-pound units, SI units are omitted.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.7 This test method is arranged as follows:

Section

Scope 1

Referenced Documents 2

Terminology 3

Summary of Test Method 4

Significance and Use 5

Apparatus 6

Test Transmission 6.2

Transmission Mounts 6.3

Oil-Circulating System 6.4

Oil Return Hole 6.5

Air Pressure Controls 6.6

Drive System 6.7

Instrumentation 6.8

Thermocouple Placement 6.9

Reagents and Materials 7

Safety 8

Preparation of Apparatus 9

Cleaning of Parts 9.1

Assembly 9.2

Calibration 10

Transmission and Test Stand Calibration 10.1

Reference Oils 10.2

Reference Oil Test Frequency 10.3

Instrumentation Calibration 10.4

Shift Time Calibration 10.5

Operating Procedure 11

1

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.B0.03

on Automotive Gear Lubricants & Fluids.

Current edition approved April 15,Oct. 1, 2009. Published JuneNovember 2009. Originally approved in 1994. Last previous edition approved in 20062009 as

D5579–06.D5579–09. DOI: 10.1520/D5579-09a.

2

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 15206-4489. This edition incorporates revisions in all Information Letters through No. 05-2.09-1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5579 – 09a

System Flush and Charge 11.1

Test Operation 11.2

Shut-Down Procedure 11.3

Transmission Disassembly 11.4

Determination of Test Results 12

Failure Criteria 12.1

Shifter Fork Wear 12.2

Test Validity Determination 12.3

Report 13

Precision and Bias 14

Keywords 15

Test Validity Calculations and Limits Annex A1

Test Kit Parts Annex A2

HTCT Test Report Forms and Data Dictionary Annex A3

Manual Transmission Cyclic Durability Test Parts Annex A4

Inspection and Wear Measurements

2. Referenced Documents

3

2.1 ASTM Standards:

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

2.2 SAE Standard:

4

SAE J308 Axle and Manual Transmission Lubricants

2.3 Military Standard:

5

MIL-L-2105 Lubricating Oil, Gear, Multipurpose

2.4 Other Standard:

6

GO-H Mack Trucks Oil,Gear: Multi-Purpose

3. Terminology

3.1 Definitions:

3.1.1 wear—the loss of material from two or more surfaces in relative motion.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.