ASTM D4417-20a

(Test Method)Standard Test Methods for Field Measurement of Surface Profile of Blast Cleaned Steel

Standard Test Methods for Field Measurement of Surface Profile of Blast Cleaned Steel

SIGNIFICANCE AND USE

5.1 The height of surface profile has been shown to be a factor in the performance of various coatings applied to steel. For this reason, surface profile should be measured prior to coating application to ensure conformance of a prepared surface to profile requirements specified by the manufacturer of a protective coating or the coating job specification.

Note 2: The peak count/peak density has been shown to be a factor in the performance of various coatings applied to steel. According to research performed by Roper, Weaver and Brandon6, an increase in peak count can improve the adhesion of some coatings to the prepared steel, as well as provide greater resistance to corrosion undercutting once the coating becomes damaged in service.

Note 3: Optical microscope methods serve as a referee method for surface profile measurement methods A and B. Profile depth designations are based on the concept of mean maximum profile (h max); this value is determined by averaging a given number (usually 20) of the highest peak to lowest valley measurements made in the field of view of a standard measuring microscope. This is done because of evidence that coating performance in any one small area is primarily influenced by the highest surface features in that area and not by the average roughness.7

SCOPE

1.1 These test methods cover the description of techniques for measuring the profile of abrasive blast cleaned surfaces in the field, shop, and laboratory. There are other techniques suitable for laboratory use not covered by these test methods.

1.2 Method B may also be appropriate to the measurement of profile produced by using power tools.

Note 1: The Method B procedure in this standard was developed for use on flat surfaces. Depending on the radius of the surface, the results could have greater variability with lower values and averages.

1.3 SSPC standard SSPC-PA 17 provides additional guidance for determining conformance with surface profile requirements.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4417 −20a

Standard Test Methods for

Field Measurement of Surface Profile of Blast Cleaned

1

Steel

This standard is issued under the fixed designation D4417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 These test methods cover the description of techniques

2.1 ASTM Standards:

for measuring the profile of abrasive blast cleaned surfaces in

D7127 Test Method for Measurement of Surface Roughness

the field, shop, and laboratory. There are other techniques

of Abrasive Blast Cleaned Metal Surfaces Using a Por-

suitable for laboratory use not covered by these test methods.

table Stylus Instrument

E177 Practice for Use of the Terms Precision and Bias in

1.2 Method B may also be appropriate to the measurement

ASTM Test Methods

of profile produced by using power tools.

E691 Practice for Conducting an Interlaboratory Study to

NOTE 1—The Method B procedure in this standard was developed for

Determine the Precision of a Test Method

use on flat surfaces. Depending on the radius of the surface, the results

3

2.2 SSPC Standard:

could have greater variability with lower values and averages.

SSPC-PA 17 Procedure for Determining Conformance to

1.3 SSPC standard SSPC-PA 17 provides additional guid-

Steel Profile/Surface Roughness/Peak Count Require-

ance for determining conformance with surface profile require-

ments

ments.

4

2.3 ASME Standard:

1.4 The values stated in SI units are to be regarded as the

ASME B46.1-2002 Surface Texture, Surface Roughness

standard. The values given in parentheses are for information

Waviness and Lay

5

only.

2.4 ISO Standards:

1.5 This standard does not purport to address all of the ISO 4287: 1997 Geometrical Product Specifications

safety concerns, if any, associated with its use. It is the (GPS)—Surface Texture: Profile Method—Terms,

responsibility of the user of this standard to establish appro- Definitions, and Surface Parameters

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accor-

3.1 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Development of International Standards, Guides and Recom-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

mendations issued by the World Trade Organization Technical

Standards volume information, refer to the standard’s Document Summary page on

Barriers to Trade (TBT) Committee. the ASTM website.

3

Available from Society for Protective Coatings (SSPC), 800 Trumbull Dr.,

Pittsburgh, PA 15205, http://www.sspc.org.

1 4

These test methods are under the jurisdiction of ASTM Committee D01 on Available from American Society of Mechanical Engineers (ASME), ASME

Paint and Related Coatings, Materials, and Applications and are the direct International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

responsibility of Subcommittee D01.46 on Industrial Protective Coatings. www.asme.org.

5

Current edition approved Dec. 1, 2020. Published December 2020. Originally Available from International Organization for Standardization (ISO), ISO

approved in 1984. Last previous edition approved in 2020 as D4417 – 20. DOI: Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

10.1520/D4417-20A. Geneva, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

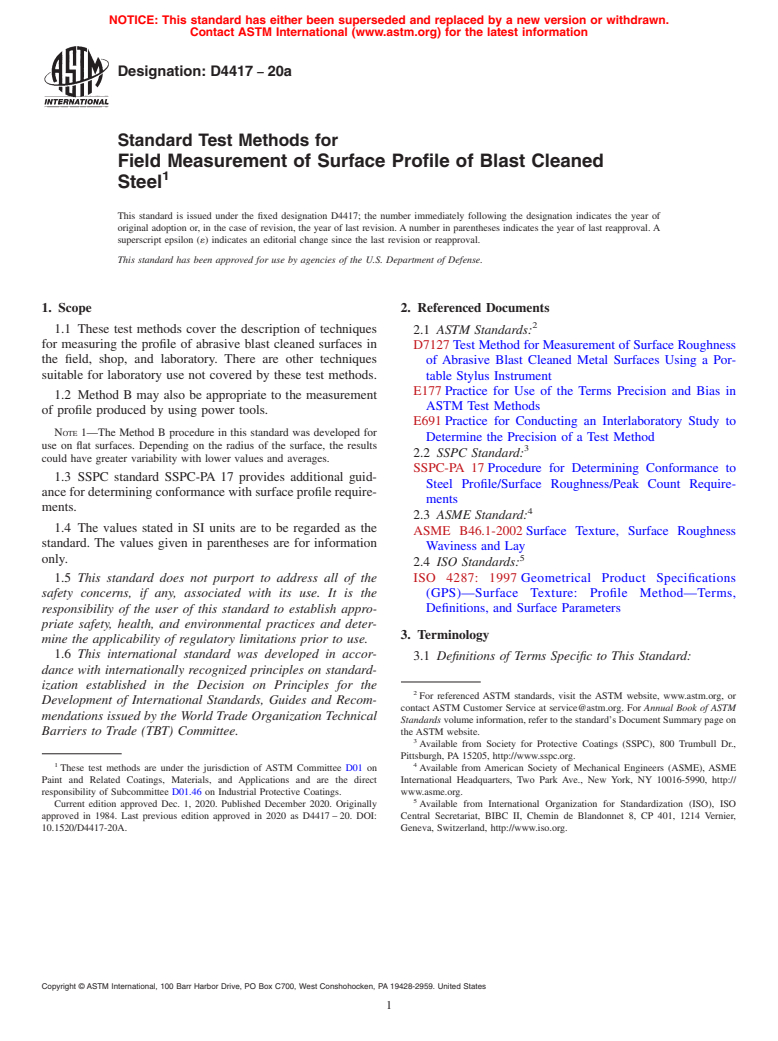

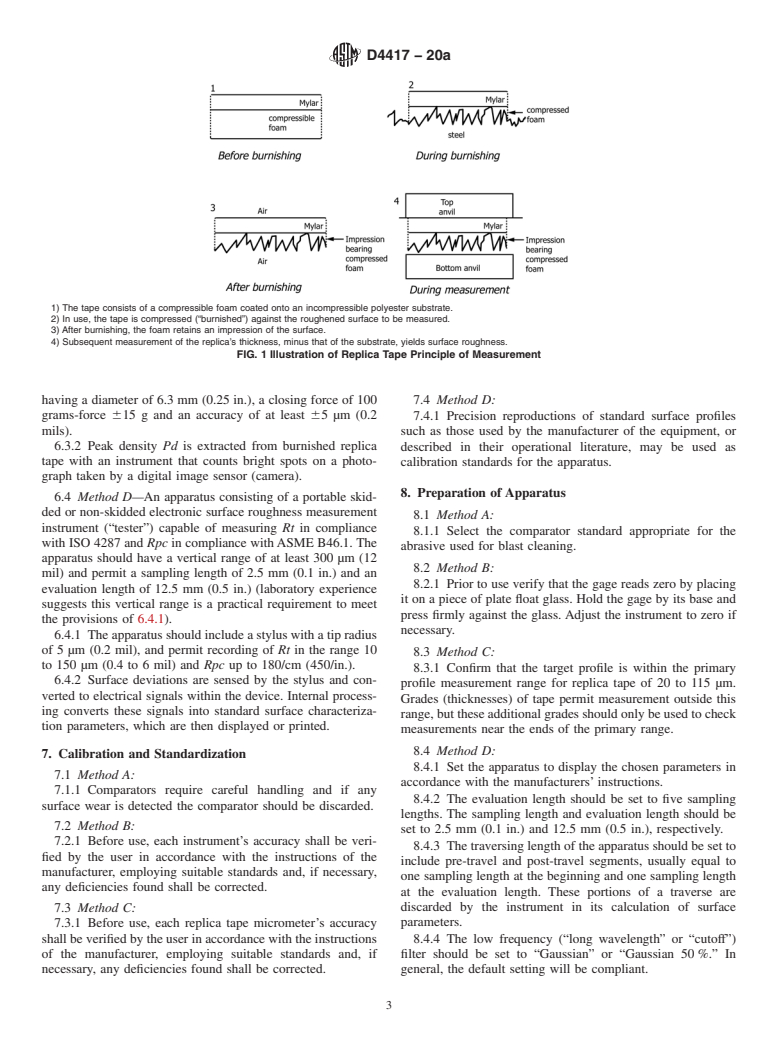

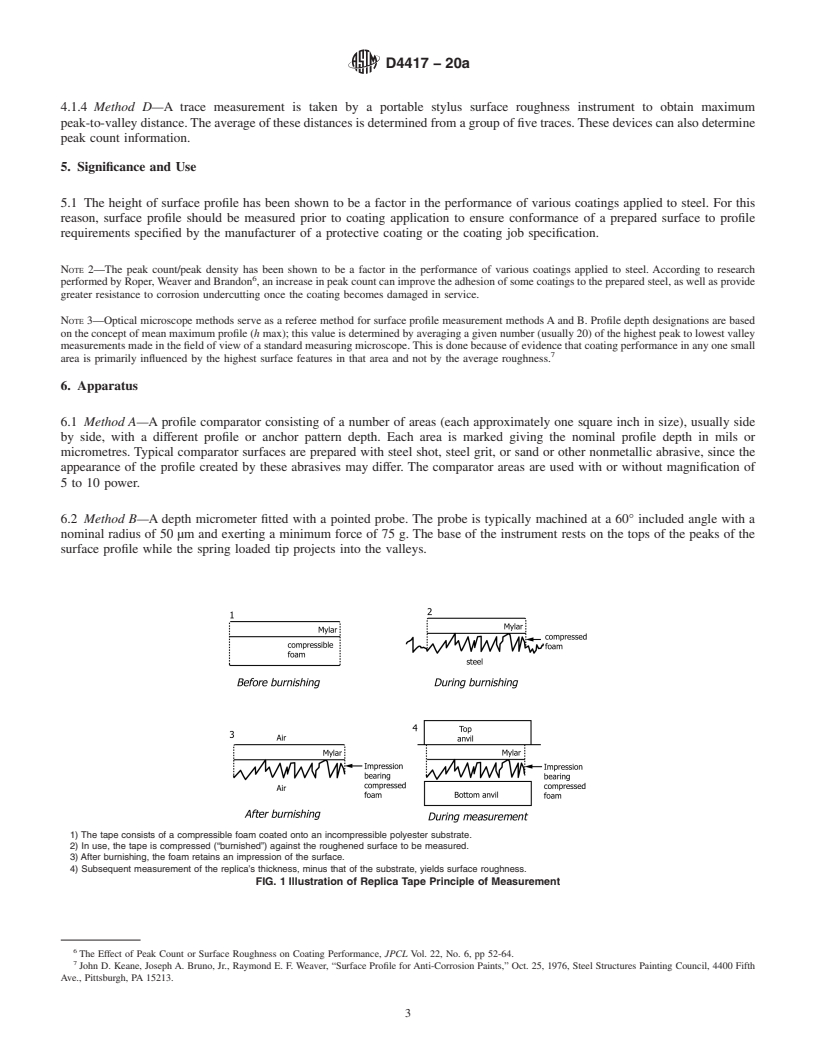

D4417−20a

3.1.1 deadband, n—that distance above and below the mean 5. Significance and Use

line that a continuous stylus trace line must cross in both

5.1 The height of surface profile has been shown to be a

directions (up and down) to count as a single peak.

factor in the performance of various coatings applied to steel.

3.1.2 evaluation length, n—a sequence of five consecutive For this reason, surface profile should be measured prior to

stylus sampling lengths. coating application to ensure conformance of a prepared

surfacetoprofilerequirementsspecifiedbythemanufacturerof

3.1.3 H, n—the average of the maximum peak-to-valley

a protective coating or the coating job specification.

height distances obtained by measuring the thickness of replica

tape.

NOTE 2—The peak cou

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4417 − 20 D4417 − 20a

Standard Test Methods for

Field Measurement of Surface Profile of Blast Cleaned

1

Steel

This standard is issued under the fixed designation D4417; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 These test methods cover the description of techniques for measuring the profile of abrasive blast cleaned surfaces in the field,

shop, and laboratory. There are other techniques suitable for laboratory use not covered by these test methods.

1.2 Method B may also be appropriate to the measurement of profile produced by using power tools.

NOTE 1—The Method B procedure in this standard was developed for use on flat surfaces. Depending on the radius of the surface, the results could have

greater variability with lower values and averages.

1.3 SSPC standard SSPC-PA 17 provides additional guidance for determining conformance with surface profile requirements.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D7127 Test Method for Measurement of Surface Roughness of Abrasive Blast Cleaned Metal Surfaces Using a Portable Stylus

Instrument

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 SSPC Standard:

SSPC-PA 17 Procedure for Determining Conformance to Steel Profile/Surface Roughness/Peak Count Requirements

1

These test methods are under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and are the direct responsibility of

Subcommittee D01.46 on Industrial Protective Coatings.

Current edition approved Aug. 1, 2020Dec. 1, 2020. Published August 2020December 2020. Originally approved in 1984. Last previous edition approved in 20192020

as D4417 – 19.D4417 – 20. DOI: 10.1520/D4417-20.10.1520/D4417-20A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Society for Protective Coatings (SSPC), 800 Trumbull Dr., Pittsburgh, PA 15205, http://www.sspc.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4417 − 20a

4

2.3 ASME Standard:

ASME B46.1-2002 Surface Texture, Surface Roughness Waviness and Lay

5

2.4 ISO Standards:

ISO 4287: 1997 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions, and Surface

Parameters

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 deadband, n—that distance above and below the mean line that a continuous stylus trace line must cross in both directions

(up and down) to count as a single peak.

3.1.2 evaluation length, n—a sequence of five consecutive stylus sampling lengths.

3.1.3 H, n—the average of the maximum peak-to-valley height distances obtained by measuring the thickness of replica tape.

3.1.3.1 Discussion—

H is the thickness measurement adjusted for tape non-linearity.

L

3.1.4 Pd (peak density), n—the number of peaks per unit area obtained from burnished replica tape.

3.1.5 peak, n—a high point in a surface profile.

3.1.6 Rpc (peak count), n—the number of peak/valley pairs, per unit of length, extending outside a “deadband” centered on the

mean line of a stylus trace.

3.1.6.1 Discussion—

F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.