ASTM F3043-14e1

(Specification)Standard Specification for “Twist Off” Type Tension Control Structural Bolt/Nut/Washer Assemblies, Alloy Steel, Heat Treated, 200 ksi Minimum Tensile Strength

Standard Specification for “Twist Off” Type Tension Control Structural Bolt/Nut/Washer Assemblies, Alloy Steel, Heat Treated, 200 ksi Minimum Tensile Strength

SIGNIFICANCE AND USE

A2.4 Significance and Use

A2.4.1 This test method describes the testing procedure that shall be used to qualify material for use in ASTM F3043 bolts made of any steel composition permitted by this specification. The test method measures the susceptibility of the material to the influence of an externally applied potential (see A2.7.2.3.2) by testing for the threshold of embrittlement in a salt solution environment.

SCOPE

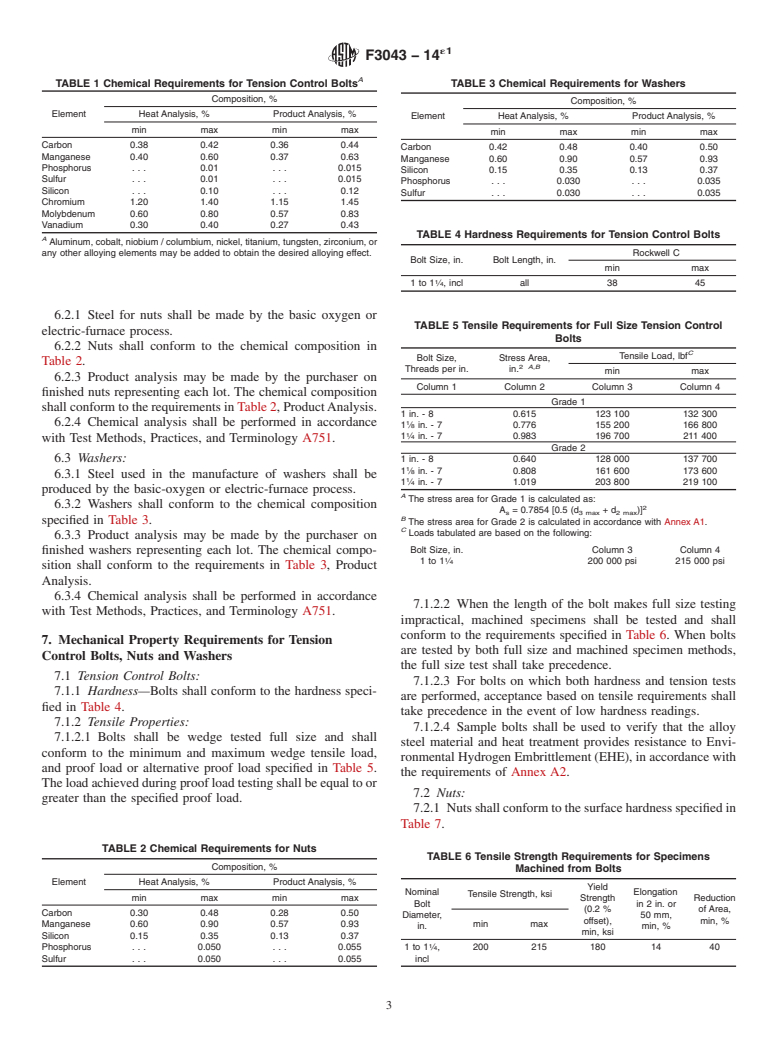

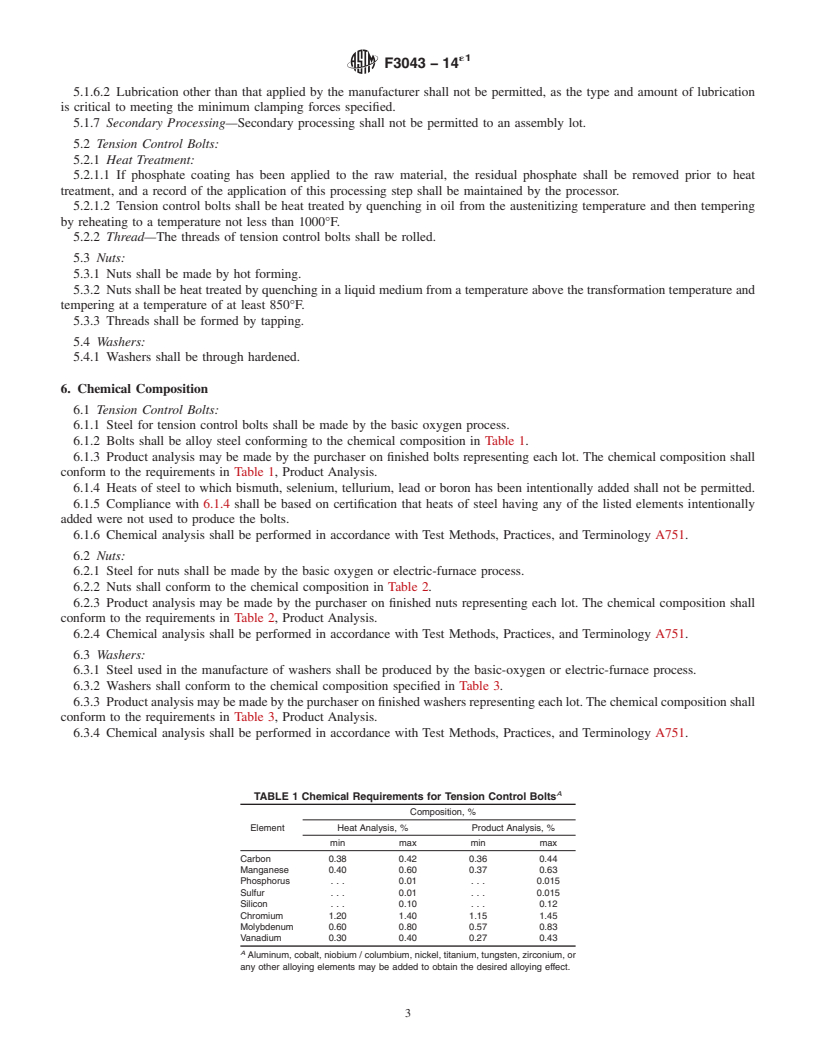

1.1 This specification covers one style of heat treated, alloy steel, tension control bolt-nut-washer assemblies, also referred to as “sets,” having a tensile strength of 200 to 215 ksi. These assemblies are capable of developing a minimum predetermined tension when installed by applying torque to the nut, while at the same time applying a counter torque to separate the spline end from the body of the bolt using an appropriate spline drive installation tool.

1.2 An assembly consists of a tension control bolt with spline end, nut and washer covered by this specification.

1.3 The assemblies are available with round heads described in Section 10, in sizes 1 in. to 11/4 in. inclusive.

1.4 The fastener assemblies are intended for use in structural connections in the following environmental conditions:

1.4.1 Interiors, normally dry, including interiors where structural steel is embedded in concrete, encased in masonry or protected by membrane or noncorrosive contact type fireproofing.

1.4.2 Interiors and exteriors, normally dry, under roof, where the installed assemblies are soundly protected by a shop-applied or field-applied coating to the structural steel system.

1.5 The fastener assemblies are not intended for use in structural connections in the following environments, with or without protection by a shop-applied or field-applied coating to the structural steel system:

1.5.1 Exteriors not under roof.

1.5.2 Chemical environments in which strong concentrations of highly corrosive gases, fumes, or chemicals, either in solution or as concentrated liquids or solids, contact the fasteners or their protective coating.

1.5.3 Heavy industrial environments severe enough to be classified as a chemical environment as described in 1.5.2.

1.5.4 Condensation and high humidity environments maintaining almost continuous condensation, including submerged in water and soil.

1.5.5 Cathodically protected environments, in which current is applied to the structural steel system by the sacrificial anode method or the DC power method.

1.6 Units—The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 The following precautionary statement pertains only to the test method portions, Section 13, Section 14 and Annex A2 of this Specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F3043 −14

StandardSpecification for

“Twist Off” Type Tension Control Structural Bolt/Nut/Washer

Assemblies, Alloy Steel, Heat Treated, 200 ksi Minimum

1,2

Tensile Strength

This standard is issued under the fixed designation F3043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Section 1.7 and the title of Annex A1 were editorially corrected in February 2015.

1. Scope 1.5.1 Exteriors not under roof.

1.5.2 Chemical environments in which strong concentra-

1.1 This specification covers one style of heat treated, alloy

tions of highly corrosive gases, fumes, or chemicals, either in

steel, tension control bolt-nut-washer assemblies, also referred

solution or as concentrated liquids or solids, contact the

to as “sets,” having a tensile strength of 200 to 215 ksi. These

fasteners or their protective coating.

assemblies are capable of developing a minimum predeter-

1.5.3 Heavy industrial environments severe enough to be

mined tension when installed by applying torque to the nut,

classified as a chemical environment as described in 1.5.2.

whileatthesametimeapplyingacountertorquetoseparatethe

1.5.4 Condensation and high humidity environments main-

splineendfromthebodyoftheboltusinganappropriatespline

taining almost continuous condensation, including submerged

drive installation tool.

in water and soil.

1.2 An assembly consists of a tension control bolt with

1.5.5 Cathodicallyprotectedenvironments,inwhichcurrent

spline end, nut and washer covered by this specification.

is applied to the structural steel system by the sacrificial anode

1.3 Theassembliesareavailablewithroundheadsdescribed method or the DC power method.

1

in Section 10, in sizes 1 in. to 1 ⁄4 in. inclusive.

1.6 Units—The values stated in inch-pound units are to be

1.4 The fastener assemblies are intended for use in struc- regarded as standard. No other units of measurement are

included in this standard.

tural connections in the following environmental conditions:

1.4.1 Interiors, normally dry, including interiors where

1.7 The following precautionary statement pertains only to

structural steel is embedded in concrete, encased in masonry or

the test method portions, Section 13, Section 14 and AnnexA2

protected by membrane or noncorrosive contact type fireproof-

ofthisSpecification: This standard does not purport to address

ing.

all of the safety concerns, if any, associated with its use. It is

1.4.2 Interiors and exteriors, normally dry, under roof,

the responsibility of the user of this standard to establish

where the installed assemblies are soundly protected by a

appropriate safety and health practices and determine the

shop-applied or field-applied coating to the structural steel

applicability of regulatory limitations prior to use.

system.

2. Referenced Documents

1.5 The fastener assemblies are not intended for use in

3

structural connections in the following environments, with or

2.1 ASTM Standards:

withoutprotectionbyashop-appliedorfield-appliedcoatingto A751 Test Methods, Practices, and Terminology for Chemi-

the structural steel system:

cal Analysis of Steel Products

E709 Guide for Magnetic Particle Testing

E1444 Practice for Magnetic Particle Testing

1 F606 Test Methods for Determining the Mechanical Proper-

This specification is under the jurisdiction of ASTM Committee F16 on

Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, ties of Externally and Internally Threaded Fasteners,

Nuts, Rivets and Washers.

Washers, and Rivets (Metric) F0606_F0606M

Current edition approved Oct. 1, 2014. Published December 2014. DOI:

F788/F788M Specification for Surface Discontinuities of

10.1520/F3043-14E01.

2

The "Twist Off" Type Tension Control Structural Bolt/Nut/WasherAssemblies,

Alloy Steel, Heat Treated, 200 ksi Minimum Tensile Strength of Grade 2 is covered

3

byUSpatentnumber7070664,July4,2006.Interestedpartiesareinvitedtosubmit For referenced ASTM standards, visit the ASTM website, www.astm.org, or

information regarding the identification of an alternative(s) to this patented item to contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the ASTM International Headquarters. Your comments will receive careful consid- Standards volume information, refer to the standard’s Document Summary page on

eration at a meeting of the responsible technical committee, which you may attend. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F3043−14

Bolts, S

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: F3043 − 14 F3043 − 14

Standard Specification for

“Twist Off” Type Tension Control Structural Bolt/Nut/Washer

Assemblies, Alloy Steel, Heat Treated, 200 ksi Minimum

1,2

Tensile Strength

This standard is issued under the fixed designation F3043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Section 1.7 and the title of Annex A1 were editorially corrected in February 2015.

1. Scope

1.1 This specification covers one style of heat treated, alloy steel, tension control bolt-nut-washer assemblies, also referred to

as “sets,” having a tensile strength of 200 to 215 ksi. These assemblies are capable of developing a minimum predetermined tension

when installed by applying torque to the nut, while at the same time applying a counter torque to separate the spline end from the

body of the bolt using an appropriate spline drive installation tool.

1.2 An assembly consists of a tension control bolt with spline end, nut and washer covered by this specification.

1

1.3 The assemblies are available with round heads described in Section 10, in sizes 1 in. to 1 ⁄4 in. inclusive.

1.4 The fastener assemblies are intended for use in structural connections in the following environmental conditions:

1.4.1 Interiors, normally dry, including interiors where structural steel is embedded in concrete, encased in masonry or protected

by membrane or noncorrosive contact type fireproofing.

1.4.2 Interiors and exteriors, normally dry, under roof, where the installed assemblies are soundly protected by a shop-applied

or field-applied coating to the structural steel system.

1.5 The fastener assemblies are not intended for use in structural connections in the following environments, with or without

protection by a shop-applied or field-applied coating to the structural steel system:

1.5.1 Exteriors not under roof.

1.5.2 Chemical environments in which strong concentrations of highly corrosive gases, fumes, or chemicals, either in solution

or as concentrated liquids or solids, contact the fasteners or their protective coating.

1.5.3 Heavy industrial environments severe enough to be classified as a chemical environment as described in 1.5.2.

1.5.4 Condensation and high humidity environments maintaining almost continuous condensation, including submerged in

water and soil.

1.5.5 Cathodically protected environments, in which current is applied to the structural steel system by the sacrificial anode

method or the DC power method.

1.6 Units—The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included

in this standard.

1.7 The following precautionary statement pertains only to the test method portions, Section 1513, Section 1614 and Annex A2

of this Specification:Specification: This standard does not purport to address all of the safety concerns, if any, associated with its

use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use.

1

This specification is under the jurisdiction of ASTM Committee F16 on Fasteners and is the direct responsibility of Subcommittee F16.02 on Steel Bolts, Nuts, Rivets

and Washers.

Current edition approved Oct. 1, 2014. Published December 2014. DOI: 10.1520/F3043-14.10.1520/F3043-14E01.

2

The "Twist Off" Type Tension Control Structural Bolt/Nut/Washer Assemblies, Alloy Steel, Heat Treated, 200 ksi Minimum Tensile Strength of Grade 2 is covered by

US patent number 7 070 664, July 4, 2006. Interested parties are invited to submit information regarding the identification of an alternative(s) to this patented item to the

ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F3043 − 14

2. Referenced Documents

3

2.1 ASTM Standards:

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E709 Guide for Magnetic Particle Testing

E1444 Practice for Magnetic Particle Testing

F606 Test Methods for Determining the Mechanical Properties of Externally and Internall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.