ASTM G39-99(2011)

(Practice)Standard Practice for Preparation and Use of Bent-Beam Stress-Corrosion Test Specimens

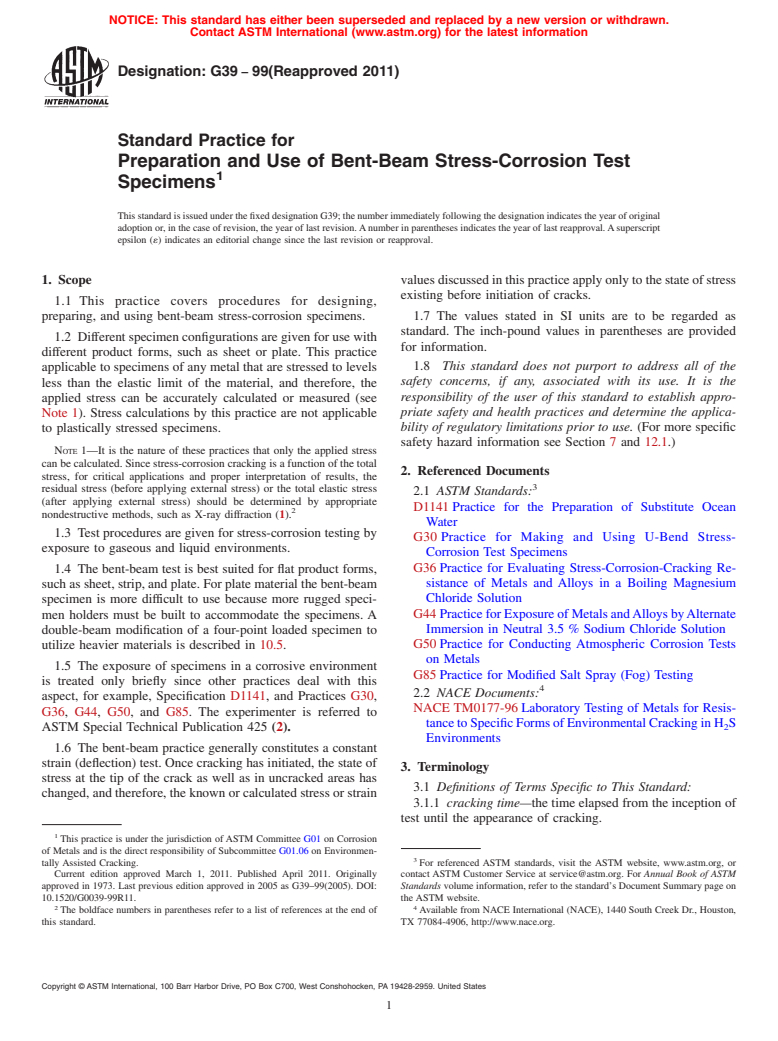

Standard Practice for Preparation and Use of Bent-Beam Stress-Corrosion Test Specimens

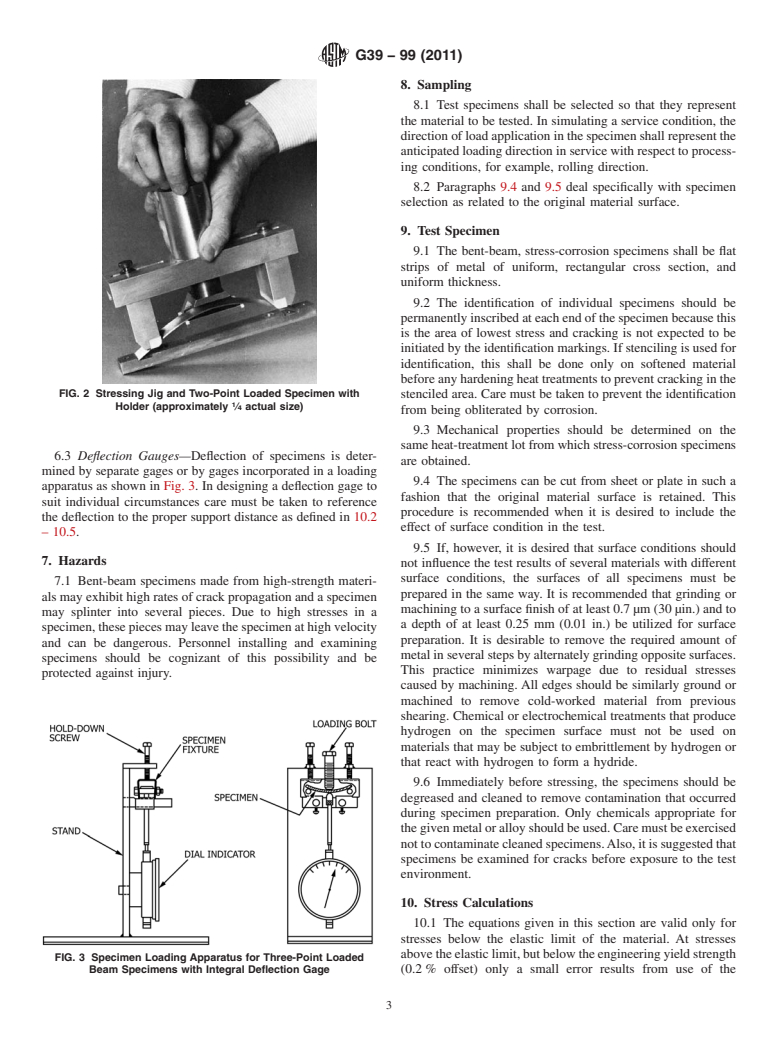

SIGNIFICANCE AND USE

The bent-beam specimen is designed for determining the stress-corrosion behavior of alloy sheets and plates in a variety of environments. The bent-beam specimens are designed for testing at stress levels below the elastic limit of the alloy. For testing in the plastic range, U-bend specimens should be employed (see Practice G30). Although it is possible to stress bent-beam specimens into the plastic range, the stress level cannot be calculated for plastically-stressed three- and four-point loaded specimens as well as the double-beam specimens. Therefore, the use of bent-beam specimens in the plastic range is not recommended for general use.

SCOPE

1.1 This practice covers procedures for designing, preparing, and using bent-beam stress-corrosion specimens.

1.2 Different specimen configurations are given for use with different product forms, such as sheet or plate. This practice applicable to specimens of any metal that are stressed to levels less than the elastic limit of the material, and therefore, the applied stress can be accurately calculated or measured (see Note 1). Stress calculations by this practice are not applicable to plastically stressed specimens.

Note 1—It is the nature of these practices that only the applied stress can be calculated. Since stress-corrosion cracking is a function of the total stress, for critical applications and proper interpretation of results, the residual stress (before applying external stress) or the total elastic stress (after applying external stress) should be determined by appropriate nondestructive methods, such as X-ray diffraction (1).

1.3 Test procedures are given for stress-corrosion testing by exposure to gaseous and liquid environments.

1.4 The bent-beam test is best suited for flat product forms, such as sheet, strip, and plate. For plate material the bent-beam specimen is more difficult to use because more rugged specimen holders must be built to accommodate the specimens. A double-beam modification of a four-point loaded specimen to utilize heavier materials is described in 10.5.

1.5 The exposure of specimens in a corrosive environment is treated only briefly since other practices deal with this aspect, for example, Specification D1141, and Practices G30, G36, G44, G50, and G85. The experimenter is referred to ASTM Special Technical Publication 425 (2).

1.6 The bent-beam practice generally constitutes a constant strain (deflection) test. Once cracking has initiated, the state of stress at the tip of the crack as well as in uncracked areas has changed, and therefore, the known or calculated stress or strain values discussed in this practice apply only to the state of stress existing before initiation of cracks.

1.7 The values stated in SI units are to be regarded as standard. The inch-pound values in parentheses are provided for information.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (For more specific safety hazard information see Section 7 and 12.1.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G39 −99(Reapproved 2011)

Standard Practice for

Preparation and Use of Bent-Beam Stress-Corrosion Test

1

Specimens

ThisstandardisissuedunderthefixeddesignationG39;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope valuesdiscussedinthispracticeapplyonlytothestateofstress

existing before initiation of cracks.

1.1 This practice covers procedures for designing,

preparing, and using bent-beam stress-corrosion specimens. 1.7 The values stated in SI units are to be regarded as

standard. The inch-pound values in parentheses are provided

1.2 Differentspecimenconfigurationsaregivenforusewith

for information.

different product forms, such as sheet or plate. This practice

1.8 This standard does not purport to address all of the

applicable to specimens of any metal that are stressed to levels

safety concerns, if any, associated with its use. It is the

less than the elastic limit of the material, and therefore, the

responsibility of the user of this standard to establish appro-

applied stress can be accurately calculated or measured (see

priate safety and health practices and determine the applica-

Note 1). Stress calculations by this practice are not applicable

bility of regulatory limitations prior to use. (For more specific

to plastically stressed specimens.

safety hazard information see Section 7 and 12.1.)

NOTE 1—It is the nature of these practices that only the applied stress

canbecalculated.Sincestress-corrosioncrackingisafunctionofthetotal

2. Referenced Documents

stress, for critical applications and proper interpretation of results, the

3

residual stress (before applying external stress) or the total elastic stress

2.1 ASTM Standards:

(after applying external stress) should be determined by appropriate

D1141Practice for the Preparation of Substitute Ocean

2

nondestructive methods, such as X-ray diffraction (1).

Water

1.3 Test procedures are given for stress-corrosion testing by

G30 Practice for Making and Using U-Bend Stress-

exposure to gaseous and liquid environments.

Corrosion Test Specimens

G36Practice for Evaluating Stress-Corrosion-Cracking Re-

1.4 The bent-beam test is best suited for flat product forms,

sistance of Metals and Alloys in a Boiling Magnesium

suchassheet,strip,andplate.Forplatematerialthebent-beam

specimen is more difficult to use because more rugged speci- Chloride Solution

G44PracticeforExposureofMetalsandAlloysbyAlternate

men holders must be built to accommodate the specimens. A

double-beam modification of a four-point loaded specimen to Immersion in Neutral 3.5 % Sodium Chloride Solution

G50Practice for Conducting Atmospheric Corrosion Tests

utilize heavier materials is described in 10.5.

on Metals

1.5 The exposure of specimens in a corrosive environment

G85Practice for Modified Salt Spray (Fog) Testing

is treated only briefly since other practices deal with this

4

2.2 NACE Documents:

aspect, for example, Specification D1141, and Practices G30,

NACE TM0177-96Laboratory Testing of Metals for Resis-

G36, G44, G50, and G85. The experimenter is referred to

tancetoSpecificFormsofEnvironmentalCrackinginH S

ASTM Special Technical Publication 425 (2). 2

Environments

1.6 The bent-beam practice generally constitutes a constant

strain (deflection) test. Once cracking has initiated, the state of

3. Terminology

stress at the tip of the crack as well as in uncracked areas has

3.1 Definitions of Terms Specific to This Standard:

changed,andtherefore,theknownorcalculatedstressorstrain

3.1.1 cracking time—the time elapsed from the inception of

test until the appearance of cracking.

1

This practice is under the jurisdiction ofASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

3

tally Assisted Cracking. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2011. Published April 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1973. Last previous edition approved in 2005 as G39–99(2005). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0039-99R11. the ASTM website.

2 4

The boldface numbers in parentheses refer to a list of references at the end of Available from NACE International (NACE), 1440 South Creek Dr., Houston,

this standard. TX 77084-4906, http://www.nace.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G39−99 (2011)

3.1.1.1 Discussion—The test begins when the stress is

applied

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.