ASTM E117-64 (1989)

(Test Method)Method for Spectrographic Analysis of Pig-Lead by the Point-To-Plane Technique (Withdrawn 1995)

Method for Spectrographic Analysis of Pig-Lead by the Point-To-Plane Technique (Withdrawn 1995)

General Information

Standards Content (Sample)

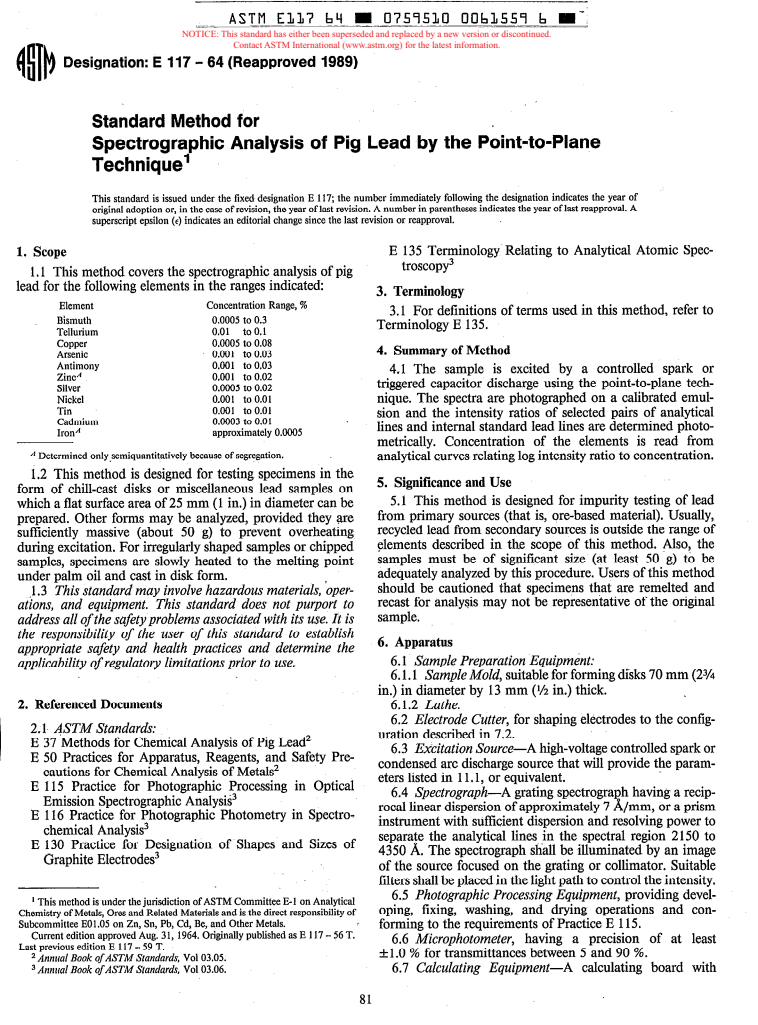

Designation: E 117 - 64 (Reapproved 1969)

@

Standard Method for

Spectrographic Analysis of Pig Lead by the Point-to-Plane

Technique’

This standard is issued under the fixed designation E 117; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (c) indicates an editorial change since the last revision or reapproval.

1. Scope E 135 Terminology Relating to Analytical Atomic Spec-

troscopy3

1.1 This method covers the spectrographic analysis of pig

lead for the following elements in the ranges indicated:

3. Terminology

Concentration Range, %

Element

3.1 For definitions of terms used in this method, refer to

0.0005 to 0.3

Bismuth

Terminology E 135.

Tellurium 0.01 too.1

0.0005 to 0.08

Copper

4. Summary of Method

Arsenic 0.001 to 0.03

Antimony 0.001 to 0.03

4.1 The sample is excited by a controlled spark or

ZincA 0.001 to 0.02

triggered capacitor discharge using the point-to-plane tech-

Silver o.ooo5 to 0.02

Nickel 0.001 to 0.01 nique. The spectra are photographed on a calibrated emul-

0.001 to 0.01

Tin

sion and the intensity ratios of selected pairs of analytical

Cadmium 0.0003 to 0.01

lines and internal standard lead lines are determined photo-

IronA approximately 0.0005

metrically. Concentration of the elements is read from

n Determined only.semiquantitatively because of segregation.

analytical curves relating log intensity ratio to concentration.

1.2 This method is designed for testing specimens in the

5. Significance and Use

form of chill-cast disks or miscellaneous lead samples on

5.1 This method is designed for impurity testing of lead

which a flat surface area of 25 mm (1 in.) in diameter can be

from primary sources (that is, ore-based material). Usually,

prepared. Other forms may be analyzed, provided they are

recycled lead from secondary sources is outside the range of

sufficiently massive (about 50 g) to prevent overheating

elements described in the scope of this method. Also, the

during excitation. For irregularly shaped samples or chipped

samples must be of significant size (at least 50 g) to be

samples, specimens are slowly heated to the melting point

adequately analyzed by this procedure. Users of this method

under palm oil and cast in disk form.

should be cautioned that specimens that are remelted and

1.3 This standard may involve hazardous materials, oper-

recast for analysis may not be representative of the original

ations, and equipment. This standard does not purport to

sample.

address all of the safety problems associated with its use. It is

the responsibility of the user of this standard to establish

6. Apparatus

appropriate safety and health practices and determine the

6.1 Sample Preparation Equipment:

applicability of regulatory limitations prtor to use.

6.1.1 Sample Mold, suitable for forming disks 70 mm (2x/4

in.) in diameter by 13 mm (r/2 in.) thick.

2. Referenced Documents

6.1.2 Lathe.

6.2 Electrode Cutter, for shaping electrodes to the config-

2.1. ASTA4 Standards:

uration described in 7.2.

E 37 Methods for Chemical Analysis of Pig Lead2

6.3 Efcitation Source-A high-voltage controlled spark or

E 50 Practices for Apparatus, Reagents, and Safety Pre-

condensed arc discharge source that will provide the param-

cautions for Chemical Analysis of Metals’

eters listed in 11.1, or equivalent.

E 115 Practice for Photographic Processing in Optical

6.4 Spectrograph-A grating spectrograph having a recip-

Emission Spectrographic Analysis3

rocal linear dispersion of approximately 7 A/mm, or a prism

E 116 Practice for Photographic Photometry in Spectro-

instrument with sufficient dispersion and resolving power to

chemical Analysis3

separate the analytical lines in the spectral region 2150 to

E 130 Practice for Designation of Shapes and Sixes of

4350 A. The spectrograph shall be ilhuninated by an image

Graphite Electrodes3

of the source focused on the grating or collimator. Suitable

filters shall be placed in the light path to control the intensity.

6.5 Photographic Processing Equipment, providing devel-

t This method is under the jurisdiction of ASTM Committee E-l on Analytical

oping, futing, washing, and drying operations and con-

Chemistry of Metals, Ores and Related Materials and is the direct responsibility of

Subcommittee E01.05 on Zn, Sn, Pb, Cd, Be, and Other Metals.

forming to the requirements of Practice E 115.

Current edition approved Aug. 31, 1964. Originally published as E 117 - 56 T.

6.6 Microphotometer, having a precision of at least

Last previous edition E 117 - 59 T.

f 1 .O % for transmittances between 5 and 90 %.

2 Annrral Book of ASTM Standards. VolO3.05.

3 Annual Book ofASTM Standards, VolO3.06. 6.7 Calculating Equipment-A calculating board with

81

---------------------- Page: 1 ----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.