ASTM C1054-13

(Practice)Standard Practice for Pressing and Drying Refractory Plastic and Ramming Mix Specimens

Standard Practice for Pressing and Drying Refractory Plastic and Ramming Mix Specimens

SIGNIFICANCE AND USE

3.1 This practice is useful for producing uniform specimens of refractory plastics and ramming mixes for use in standard ASTM tests. Samples thus formed may be used for referee testing when setting specifications between producer and user. Establish by mutual agreement and specify in the report the forming parameters such as sample size, workability, and forming pressure when referee testing.

3.2 This practice is applicable for preparing test specimens of various sizes. Note that 9 by 41/2 by 21/2 in. (228 by 114 by 64-mm) samples, because of their large cross-section, have a greater tendency to form flaws during pressing, handling, and drying than smaller cross-sectional samples.

3.3 The purpose of this practice is to minimize flaws in pressed specimens. It is not intended to duplicate all field installation conditions.

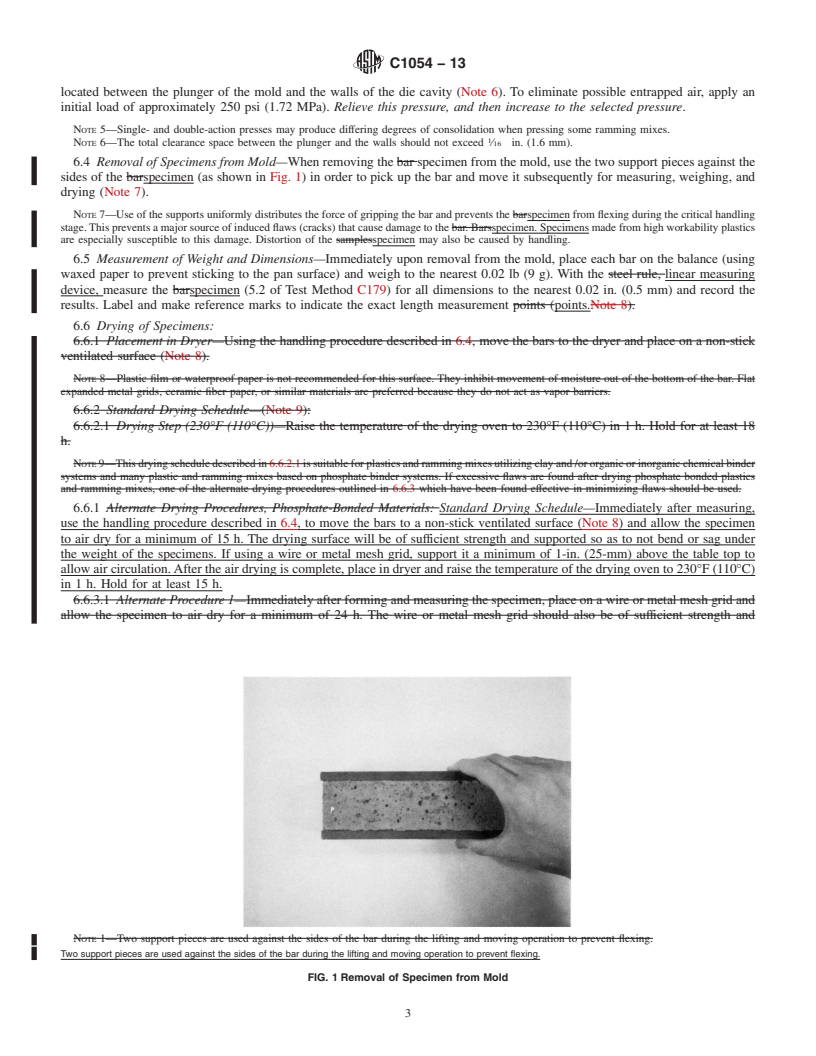

3.4 Variations in workability as determined by Test Method C181 can significantly affect the number of flaws contained in a specimen. Establish by mutual agreement the workability level when comparing tests between two laboratories.

3.5 This practice is not intended for preparing specimens of basic ramming mixes, anhydrous tap-hole mixes, nor resin bonded mixes.

SCOPE

1.1 This practice covers the pressing and drying of chemically and non-chemically bonded alumin-silicate and high alumina plastic and ramming mix refractory specimens classified in accordance with Classification C673.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1054 − 13

Standard Practice for

Pressing and Drying Refractory Plastic and Ramming Mix

1

Specimens

This standard is issued under the fixed designation C1054; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 64-mm) samples, because of their large cross-section, have a

greater tendency to form flaws during pressing, handling, and

1.1 This practice covers the pressing and drying of chemi-

drying than smaller cross-sectional samples.

cally and non-chemically bonded alumin-silicate and high

alumina plastic and ramming mix refractory specimens classi-

3.3 The purpose of this practice is to minimize flaws in

fied in accordance with Classification C673.

pressed specimens. It is not intended to duplicate all field

installation conditions.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

3.4 Variations in workability as determined by Test Method

information only.

C181 can significantly affect the number of flaws contained in

1.3 This standard does not purport to address all of the a specimen. Establish by mutual agreement the workability

safety concerns, if any, associated with its use. It is the level when comparing tests between two laboratories.

responsibility of the user of this standard to establish appro-

3.5 This practice is not intended for preparing specimens of

priate safety and health practices and determine the applica-

basic ramming mixes, anhydrous tap-hole mixes, nor resin

bility of regulatory limitations prior to use.

bonded mixes.

2. Referenced Documents

4. Apparatus

2

2.1 ASTM Standards:

4.1 Power Press, preferably of the hydraulic type, equipped

C179 Test Method for Drying and Firing Linear Change of

Refractory Plastic and Ramming Mix Specimens with suitable molds for forming specimens of the required size

(Note 1) and capable of pressing to a minimum of 1500 psi

C181 Test Method for Workability Index of Fireclay and

High-Alumina Refractory Plastics (10.34 MPa) pressure when forming the largest cross-sectional

area specimen.

C673 Classification of Fireclay and High-Alumina Plastic

Refractories and Ramming Mixes

NOTE 1—It may be advisable to have the molds slightly oversized so

that, after drying, the specimens will be close to the required size for the

3. Significance and Use

specific test.

3.1 This practice is useful for producing uniform specimens

4.2 Drying Oven, preferably forced-draft rather than natural

of refractory plastics and ramming mixes for use in standard

convection, capable of maintaining 230°F (110°C) with a

ASTM tests. Samples thus formed may be used for referee

capacity to hold the specimens.

testing when setting specifications between producer and user.

Establish by mutual agreement and specify in the report the 4.3 Balance, sufficient capacity to measure specimens with

forming parameters such as sample size, workability, and sensitivity of 0.02 lb (9 g).

forming pressure when referee testing.

4.4 Thermometer, with a range of 0° to 180 6 0.1°F (–18°

3.2 This practice is applicable for preparing test specimens

to 80°C 6 0.05°C).

1 1

of various sizes. Note that 9 by 4 ⁄2 by 2 ⁄2 in. (228 by 114 by

4.5 Linear Measuring Device, capable of being read to

0.02-in. (0.5-mm) .

1

ThispracticeisunderthejurisdictionofASTMCommitteeC08onRefractories

and is the direct responsibility of Subcommittee C08.09 on Monolithics. 4.6 Mold Lubricant—Either paraffin or silicone-based oils

Current edition approved April 1, 2013. Published June 2013. Originally

can be used as a parting agent for coating mold and die

approved in 1985. Last previous edition approved in 2008 as C1054 – 03 (2008).

surfaces.

DOI: 10.1520/C1054-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

4.7 Two Non-Porous Blocks, approximately ⁄2-in. (13-mm)

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

thick.The cross-sectional dimensions of these pieces will vary,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. depending on the side dimensions of the bar being pressed.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1054 − 13

5. Sampling

5.1 Keep the container or package unopened until testing to

ensure the sample does not dry out.

5.2 The ideal sample test temperature is between 65 and

75°F (18 and 24°C). Measure the temperature by inserting the

full length of the thermometer stem into the material. Note and

record t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1054 − 03 (Reapproved 2008) C1054 − 13

Standard Practice for

Pressing and Drying Refractory Plastic and Ramming Mix

1

Specimens

This standard is issued under the fixed designation C1054; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the pressing and drying of chemically and nonchemicallynon-chemically bonded aluminum-

silicatealumin-silicate and high alumina plastic and ramming mix refractory specimens classified in accordance with Classification

C673.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C16 Test Method for Load Testing Refractory Shapes at High Temperatures

C20 Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory

Brick and Shapes by Boiling Water

C113 Test Method for Reheat Change of Refractory Brick

C133 Test Methods for Cold Crushing Strength and Modulus of Rupture of Refractories

C179 Test Method for Drying and Firing Linear Change of Refractory Plastic and Ramming Mix Specimens

C181 Test Method for Workability Index of Fireclay and High-Alumina Refractory Plastics

C288 Test Method for Disintegration of Refractories in an Atmosphere of Carbon Monoxide

C417 Test Method for Thermal Conductivity of Unfired Monolithic Refractories

C577 Test Method for Permeability of Refractories

C583 Test Method for Modulus of Rupture of Refractory Materials at Elevated Temperatures

C673 Classification of Fireclay and High-Alumina Plastic Refractories and Ramming Mixes

C704 Test Method for Abrasion Resistance of Refractory Materials at Room Temperature

C830 Test Methods for Apparent Porosity, Liquid Absorption, Apparent Specific Gravity, and Bulk Density of Refractory Shapes

by Vacuum Pressure

C832 Test Method of Measuring Thermal Expansion and Creep of Refractories Under Load

C874 Test Method for Rotary Slag Testing of Refractory Materials

C885 Test Method for Young’s Modulus of Refractory Shapes by Sonic Resonance

C914 Test Method for Bulk Density and Volume of Solid Refractories by Wax Immersion

3. Significance and Use

3.1 This practice is useful for producing uniform specimens of refractory plastics and ramming mixes for use in standard ASTM

tests. Samples thus formed may be used for referee testing when setting specifications between producer and user. Forming

Establish by mutual agreement and specify in the report the forming parameters such as sample size, workability, and forming

pressure should be agreed upon and specified in the report when referee testing.

1

This practice is under the jurisdiction of ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.09 on Monolithics.

Current edition approved March 1, 2008April 1, 2013. Published March 2008June 2013. Originally approved in 1985. Last previous edition approved in 20032008 as

C1054 – 03.C1054 – 03 (2008). DOI: 10.1520/C1054-03R08.10.1520/C1054-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1054 − 13

1 1

3.2 This practice is applicable for preparing test specimens of various sizes. Note that 9 by 4 ⁄2 by 2 ⁄2 in. (228 by 114 by

64-mm) samples, because of their large cross-section, have a greater tendency to form flaws during pressing, handling, and drying

than smaller cross-sectional samples.

3.3 Other tests for which these specimens may be used encompass, but are not limited to, the following ASTM standards:

Method C16, Test Methods C20, Test Method C113, Test Methods C133, Test Method C179, Test Method C288, Test Method

C417, Test Method C577,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.