ASTM D56-05

(Test Method)Standard Test Method for Flash Point by Tag Closed Cup Tester

Standard Test Method for Flash Point by Tag Closed Cup Tester

SIGNIFICANCE AND USE

Flash point measures the tendency of the specimen to form a flammable mixture with air under controlled laboratory conditions. It is only one of a number of properties that shall be considered in assessing the overall flammability hazard of a material.

Flash point is used in shipping and safety regulations to define flammable and combustible materials. One should consult the particular regulation involved for precise definitions of these classes.

Flash point can indicate the possible presence of highly volatile and flammable materials in a relatively nonvolatile or nonflammable material. For example, an abnormally low flash point on a sample of kerosene can indicate gasoline contamination.

SCOPE

1.1 This test method covers the determination of the flash point, by tag manual and automated closed testers, of liquids with a viscosity below 5.5 mm2/s (cSt) at 40°C (104°F), or below 9.5 mm2/s (cSt) at 25°C (77°F), and a flash point below 93°C (200°F).

1.1.1 For the closed-cup flash point of liquids with the following properties: a viscosity of 5.5 mm2/s (cSt) or more at 40°C (104°F); a viscosity of 9.5 mm2/s (cSt) or more at 25°C (77°F); a flash point of 93°C (200°F) or higher; a tendency to form a surface film under test conditions; or containing suspended solids, Test Method D 93 can be used.

1.1.2 For cut-back asphalts refer to Test Methods D 1310 and D 3143.

Note 1—The U.S. Department of Transportation (RSTA) and U.S. Department of Labor (OSHA) have established that liquids with a flash point under 37.8°C (100°F) are flammable as determined by this test method for those liquids that have a viscosity less than 5.5 mm2/s (cSt) at 40°C (104°F) or 9.5 mm2/s (cSt) or less at 25°C (77°F), or do not contain suspended solids or do not have a tendency to form a surface film while under test. Other flash point classifications have been established by these departments for liquids using this test method.

1.2 This test method can be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions and cannot be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test method can be used as elements of fire risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.3 Related Standards are Test Methods D 93, D 1310, D 3828, D 3278, and D 3941.

1.4 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see 8.2 and 8.3 and refer to Material Safety Data Sheets.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D56–05

Standard Test Method for

1

Flash Point by Tag Closed Cup Tester

ThisstandardisissuedunderthefixeddesignationD56;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

To ensure an acceptable precision, this dynamic flash point test method employs a prescribed rate

of temperature rise for the material under test. The rate of heating may not in all cases give the

precision quoted in the test method because of the low thermal conductivity of certain materials. To

improve the prediction of flammability, Test Method D3941, which utilizes a slower heating rate, was

developed. Test Method D3941 provides conditions closer to equilibrium where the vapor above the

liquid and the liquid are at about the same temperature. If a specification requires Test Method D56,

do not change to Test Method D3941 or other test method without permission from the specifier.

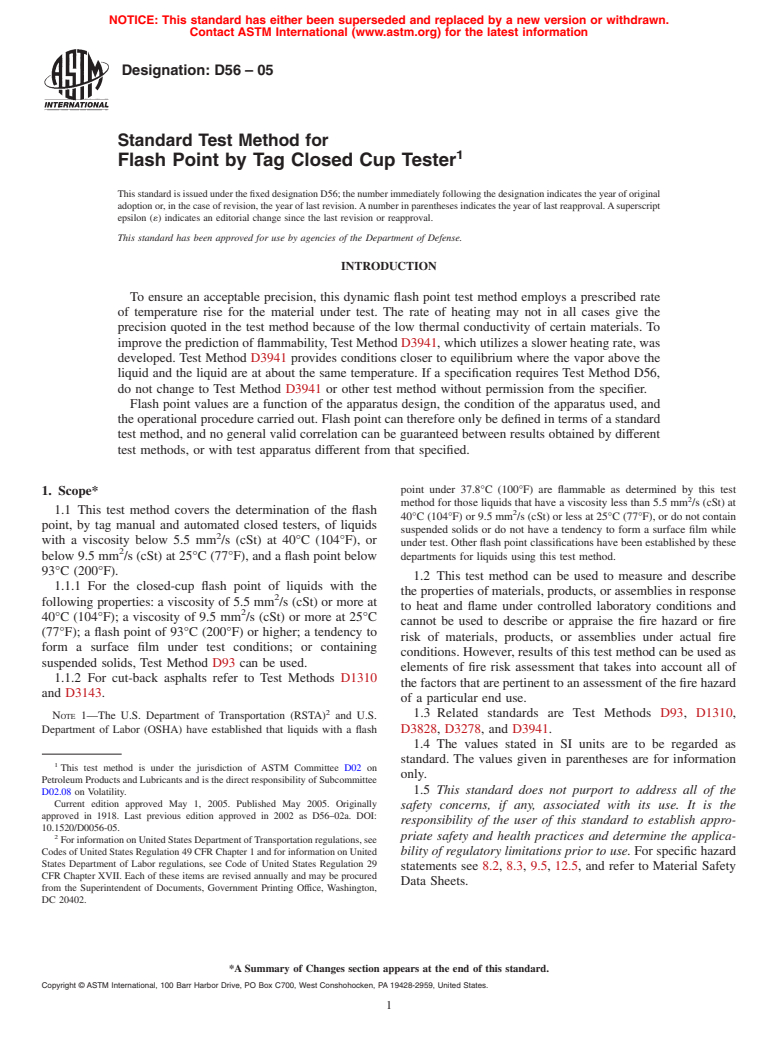

Flash point values are a function of the apparatus design, the condition of the apparatus used, and

the operational procedure carried out. Flash point can therefore only be defined in terms of a standard

test method, and no general valid correlation can be guaranteed between results obtained by different

test methods, or with test apparatus different from that specified.

point under 37.8°C (100°F) are flammable as determined by this test

1. Scope*

2

method for those liquids that have a viscosity less than 5.5 mm /s (cSt) at

1.1 This test method covers the determination of the flash

2

40°C (104°F) or 9.5 mm /s (cSt) or less at 25°C (77°F), or do not contain

point, by tag manual and automated closed testers, of liquids

suspended solids or do not have a tendency to form a surface film while

2

with a viscosity below 5.5 mm /s (cSt) at 40°C (104°F), or

under test. Other flash point classifications have been established by these

2

below 9.5 mm /s (cSt) at 25°C (77°F), and a flash point below departments for liquids using this test method.

93°C (200°F).

1.2 This test method can be used to measure and describe

1.1.1 For the closed-cup flash point of liquids with the

the properties of materials, products, or assemblies in response

2

following properties: a viscosity of 5.5 mm /s (cSt) or more at

to heat and flame under controlled laboratory conditions and

2

40°C (104°F); a viscosity of 9.5 mm /s (cSt) or more at 25°C

cannot be used to describe or appraise the fire hazard or fire

(77°F); a flash point of 93°C (200°F) or higher; a tendency to

risk of materials, products, or assemblies under actual fire

form a surface film under test conditions; or containing

conditions. However, results of this test method can be used as

suspended solids, Test Method D93 can be used.

elements of fire risk assessment that takes into account all of

1.1.2 For cut-back asphalts refer to Test Methods D1310

the factors that are pertinent to an assessment of the fire hazard

and D3143.

of a particular end use.

2

1.3 Related standards are Test Methods D93, D1310,

NOTE 1—The U.S. Department of Transportation (RSTA) and U.S.

Department of Labor (OSHA) have established that liquids with a flash D3828, D3278, and D3941.

1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

1

This test method is under the jurisdiction of ASTM Committee D02 on

only.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

1.5 This standard does not purport to address all of the

D02.08 on Volatility.

Current edition approved May 1, 2005. Published May 2005. Originally

safety concerns, if any, associated with its use. It is the

approved in 1918. Last previous edition approved in 2002 as D56–02a. DOI:

responsibility of the user of this standard to establish appro-

10.1520/D0056-05.

2

priate safety and health practices and determine the applica-

ForinformationonUnitedStatesDepartmentofTransportationregulations,see

Codes of United States Regulation 49 CFR Chapter 1 and for information on United bility of regulatory limitations prior to use. For specific hazard

States Department of Labor regulations, see Code of United States Regulation 29

statements see 8.2, 8.3, 9.5, 12.5, and refer to Material Safety

CFR Chapter XVII. Each of these items are revised annually and may be procured

Data Sheets.

from the Superintendent of Documents, Government Printing Office, Washington,

DC 20402.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.