ASTM A314-08

(Specification)Standard Specification for Stainless Steel Billets and Bars for Forging

Standard Specification for Stainless Steel Billets and Bars for Forging

ABSTRACT

This specification covers stainless steel billets and bars for forging. The steel materials shall be annealed and conditioned by chipping or grinding. The steel specimens shall conform to the required chemical compositions of carbon, manganese, phosphorus, sulfur, silicon, chromium, nickel, molybdenum, nitrogen, and other elements.

SCOPE

1.1 This specification covers stainless steel billets and bars intended only for forging.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A314 −08

StandardSpecification for

1

Stainless Steel Billets and Bars for Forging

This standard is issued under the fixed designation A314; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3.1.9 Marking (see Specification A484/A484M), and

3.1.10 Exceptions to the specification or special require-

1.1 This specification covers stainless steel billets and bars

ments.

intended only for forging.

3.2 If possible, the intended use of the item should be given

2. Referenced Documents

on the purchase order especially when the item is ordered for

2

a specific end use or uses.

2.1 ASTM Standards:

A484/A484M Specification for General Requirements for

NOTE 1—A typical ordering description is as follows: 10 000 lb, Type

Stainless Steel Bars, Billets, and Forgings

420, annealed, round-cornered square billets, ASTM A314 dated

A751 Test Methods, Practices, and Terminology for Chemi- for valve parts.

cal Analysis of Steel Products

4. Manufacture

E527 Practice for Numbering Metals and Alloys in the

4.1 Annealing—Blooms and billets of the 400 series of

Unified Numbering System (UNS)

stainlesssteeltypeswhicharehighlyhardenable,suchasTypes

2.2 Other Document:

414, 420, 431, 440A, 440B, and 440C, are commonly annealed

SAE J1086 Recommended Practice for Numbering Metals

3

prior to shipment and so specified in order to avoid the

and Alloys

possibility of thermal cracking. Those grades are not normally

3. Ordering Information furnished in the as-rolled or as-forged condition. Other hard-

enable grades, such as Types 403, 410, 416, and 416 Se, which

3.1 It is the responsibility of the purchaser to specify all

may also require annealing, depending on their composition

requirements that are necessary for material ordered under this

and size, are furnished suitable for cold cutting when so

specification. Such requirements may include but are not

specified on the purchase order.

limited to the following:

4.2 Conditioning—Material may be conditioned by chip-

3.1.1 Quantity (weight or number of pieces),

ping or grinding to remove injurious surface defects provided

3.1.2 Name of material: type or UNS designation (Table 1),

3.1.3 Condition, thedepthofconditioningdoesnotexceedthatwhichwillaffect

the surface condition or dimensions of the article to be forged

3.1.4 Cross section (round, round-cornered square, etc.),

3.1.5 Form: bar or forging billet, from the bar or billet.

3.1.6 Applicable dimensions, including size, thickness,

5. Chemical Composition

width, and length,

5.1 The steel shall conform to the chemical composition

3.1.7 ASTM designation and date of issue,

3.1.8 Preparation for delivery (see Specification A484/ prescribed in Table 1 for the respective grades.

A484M),

5.2 Methods and practices relating to chemical analysis

required by this specification shall be in accordance with Test

Methods, Practices, and Terminology A751.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

6. Dimensions

A01.17 on Flat-Rolled and Wrought Stainless Steel.

Current edition approved Oct. 1, 2008. Published October 2008. Originally

6.1 Billets and bars shall conform to the shape and dimen-

approved in 1947. Last previous edition approved in 2002 as A314 – 97 (2002).

sions specified by the purchaser within a permissible variation

DOI: 10.1520/A0314-08.

2

of 65%.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 7. General Requirements

the ASTM website.

3

7.1 In addition to the requirements of this specification, all

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096-0001, http://www.sae.org. requirements of the current edition of Specification A484/

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A314−08

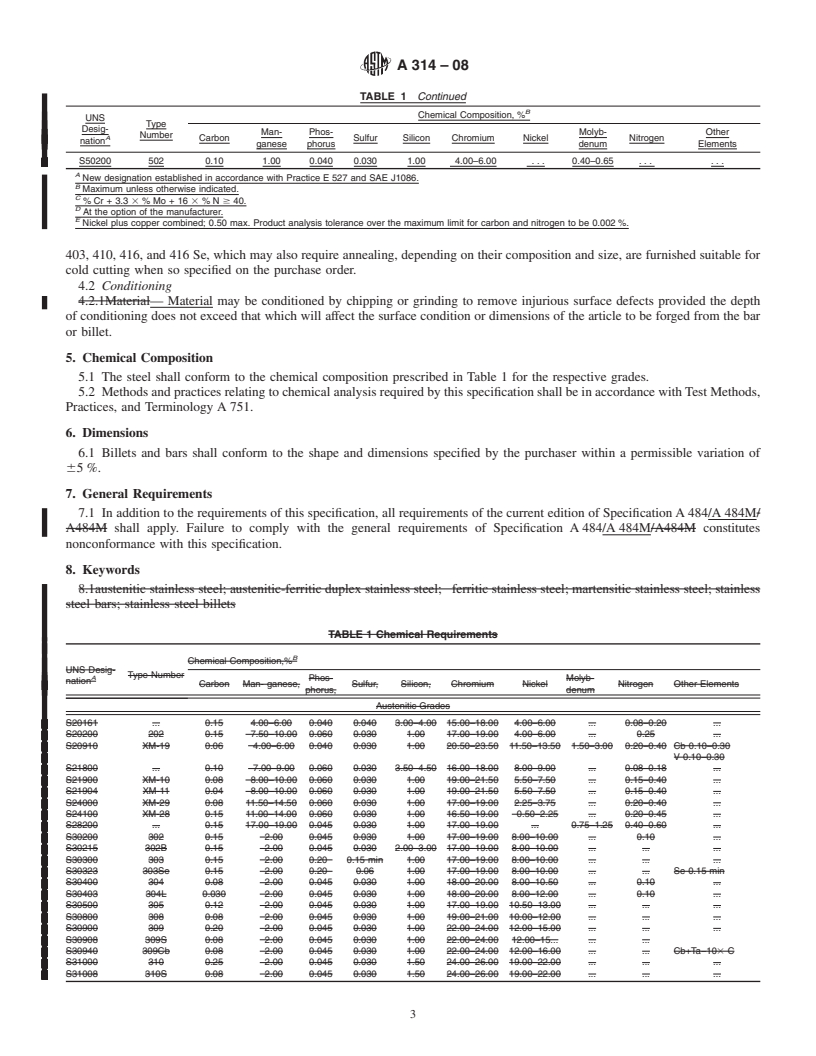

TABLE 1 Chemical Requirements

B

Chemical Composition, %

UNS

Type

Desig-

Man- Phos- Molyb- Other

Number

A Carbon Sulfur Silicon Chromium Nickel Nitrogen

nation

ganese phorus denum Elements

Austenitic Grades

S20161 . . . 0.15 4.00–6.00 0.040 0.040 3.00–4.00 15.00–18.00 4.00–6.00 . . . 0.08–0.20 . . .

S20200 202 0.15 7.50–10.00 0.060 0.030 1.00

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 314–97 (Reapproved 2002) Designation: A 314 – 08

Standard Specification for

1

Stainless Steel Billets and Bars for Forging

This standard is issued under the fixed designation A 314; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification covers stainless steel billets and bars intended only for forging.

2. Referenced Documents

2

2.1 ASTM Standards:

A 484/A 484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A 751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E 527Practice for Numbering Metals and Alloys (UNS) Practice for Numbering Metals and Alloys in the Unified Numbering

System (UNS)

2.2 Other Document:

3

SAE J1086 Recommended Practice for Numbering Metals and Alloys

3. Ordering Information

3.1 It is the responsibility of the purchaser to specify all requirements that are necessary for material ordered under this

specification. Such requirements may include but are not limited to the following:

3.1.1 Quantity (weight or number of pieces),

3.1.2 Name of material: type or UNS designation (Table 1),

3.1.3 Condition,

3.1.4 Cross section (round, round-cornered square, etc.),

3.1.5 Form: bar or forging billet,

3.1.6 Applicable dimensions, including size, thickness, width, and length,

3.1.7 ASTM designation and date of issue,

3.1.8 Preparation for delivery (see Specification A 484/A 484M/A484M),),

3.1.9 Marking (see Specification A 484/A 484M/A484M),), and

3.1.10 Exceptions to the specification or special requirements.

3.2 If possible, the intended use of the item should be given on the purchase order especially when the item is ordered for a

specific end use or uses.

NOTE 1—Atypicalorderingdescriptionisasfollows:10 000lb,Type420,annealed,round-corneredsquarebillets,ASTMA314dated———

for valve parts.

4. Manufacture

4.1 Annealing

4.1.1Blooms—Blooms and billets of the 400 series of stainless steel types which are highly hardenable, such asTypes 414, 420,

431, 440A, 440B, and 440C, are commonly annealed prior to shipment and so specified in order to avoid the possibility of thermal

cracking. Those grades are not normally furnished in the as-rolled or as-forged condition. Other hardenable grades, such as Types

1

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onSteel,StainlessSteel,andRelatedAlloys,andisthedirectresponsibilityofSubcommitteeA01.17

on Flat Stainless Steel Products.

Current edition approved Sept. 10, 1997. Published September 1998. Originally published as A314–47T. Last previous edition A314–95.

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.17

on Flat-Rolled and Wrought Stainless Steel.

Current edition approved Oct. 1, 2008. Published October 2008. Originally approved in 1947. Last previous edition approved in 2002 as A 314 – 97 (2002).

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

, Vol 01.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Annual Book of ASTM Standards, Vol 01.03.

3

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A314–08

TABLE 1 Chemical Requirements

B

Chemical Composition, %

UNS

Type

Desig-

Man- Phos- Molyb- Other

Number

A

Carbon Sulfur Silicon Chromium Nickel Nitrogen

nation

ganese phorus denum Elements

Austenitic Grades

S20161 . 0.15 4.00–6.00 0.040 0.040 3.00–4.00 15.00–18.00 4.00–6.00 . 0.08–0.20 .

S20200 202 0.15 7.50–10.00 0.060 0.030 1.00 17.00–19.00 4.00–6.00 . 0.25 .

S20910 XM-19 0.06 4.00–6.00 0.040 0.030 1.00 20.50–23.50 11.50–13.50 1.50–3.00 0.20–0.40 Cb 0.10–0.30

V 0.10–0.30

S21800 . 0.10 7.00–9.00 0.060 0.030 3.50–4.50 16.00–18.00 8.00–9.00 . 0.08–0.18 .

S21900 XM-10 0.08 8.00–10.00 0.060 0.030 1.00 19.00–21.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.