ASTM D1447-00

(Test Method)Standard Test Method for Length and Length Uniformity of Cotton Fibers by Fibrograph Measurement

Standard Test Method for Length and Length Uniformity of Cotton Fibers by Fibrograph Measurement

SIGNIFICANCE AND USE

This test method is considered satisfactory for acceptance testing when the levels of the laboratories are controlled by the use of the same reference standard cotton samples because the current estimates of between-laboratory precision are acceptable under these conditions. In case of dispute, the statistical bias, if any, between the laboratory of the purchaser and the laboratory of the seller should be determined with each comparison being based on testing randomized specimens from one sample of material.

Fibrograph measurements provide a relatively fast method for determining the length and length uniformity of the fibers in a sample of cotton in a reproducible manner.

Results of the Fibrograph length tests do not necessarily agree with those obtained by other methods for measuring lengths of cotton fibers because of the effect of fiber crimp and other factors.

Fibrograph tests are more objective than commercial staple length classifications and also provide additional information on fiber length uniformity of cotton fibers. The cotton quality information provided by these results is used in research studies and quality surveys, in checking commercial staple length classifications, in assembling bales of cotton into uniform lots, and for other purposes.

Fibrograph measurements are based on the assumptions that a fiber is caught on the comb in proportion to its length as compared to total length of all fibers in the sample and that the point of catch for a fiber is at random along its length.

SCOPE

1.1 This test method covers the measurement of the length and length uniformity of cotton fibers by use of the Fibrograph. The test method is applicable to fibers taken from raw or partially processed cotton or some types of cotton waste, but not to fibers from blends of cotton with other fibers or to fibers recovered from cotton yarns or fabrics.

1.2 This test method covers procedures for all models of the Digital Fibrograph, hereafter referred to as Fibrograph.

Note 1--Instructions for the use of Manual and Servo Fibrograph Models were included in the text of Test Method D1447 in 1971 and previous editions.

Note 2--For other methods covering the measurement of the length of cotton fibers refer to Test Method D1440.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1447–00

Standard Test Method for

Length and Length Uniformity of Cotton Fibers by

1

Fibrograph Measurement

This standard is issued under the fixed designation D 1447; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the measurement of the length 3.1 Definitions:

andlengthuniformityofcottonfibersbyuseoftheFibrograph. 3.1.1 amount, n—cotton length testing with the Fibrograph,

The test method is applicable to fibers taken from raw or n—a measure of the thickness, or optical density, of the test

partially processed cotton or some types of cotton waste, but beard, proportional to the number of fibers present at various

not to fibers from blends of cotton with other fibers or to fibers distances from the comb(s).

recovered from cotton yarns or fabrics. 3.1.2 fibrogram, n—in cotton length testing with the Fib-

1.2 This test method covers procedures for all models of the rograph, the curve representing the second cumulation of the

Digital Fibrograph, hereafter referred to as Fibrograph. length distribution of the fibers sensed by the length measuring

instrument in scanning the fiber board.

NOTE 1—Instructions for the use of Manual and Servo Fibrograph

3.1.3 span length (Fibrograph), n—the distance spanned by

Models were included in the text of Test Method D 1447 in 1971 and

a specified percentage of the fibers in the test beard, taking the

previous editions.

NOTE 2—For other methods covering the measurement of the length of amount reading at the starting point of the scanning as 100 %.

cotton fibers refer to Test Method D 1440.

3.1.4 test beard, n—in length testing of cotton, the portion

of the test specimen that has been combed and brushed into a

1.3 The values stated in SI units are to be regarded as

“beard” which protrudes from the outside of the comb(s) or the

standard. No other units of measurement are included in this

clamp(s).

standard.

3.1.5 test specimen (Fibrograph), n—the cotton fibers

1.4 This standard does not purport to address all of the

placed randomly on a Fibrograph comb(s) for fiber length

safety concerns, if any, associated with its use. It is the

measurements.

responsibility of the user of this standard to establish appro-

3.1.6 uniformity ratio, n—in cotton length testing with the

priate safety and health practices and determine the applica-

Fibrograph, the ratio between two span lengths expressed as a

bility of regulatory limitations prior to use.

percentage of the longer length.

2. Referenced Documents

3.1.6.1 Discussion—various span lengths and measures of

length uniformity may be calculated from the results of the

2.1 ASTM Standards:

2

measured points, but the 2.5 and 50 % span lengths and the

D 123 Terminology Relating to Textiles

50/2.5 uniformity ratio are usually used.

D 1440 Test Method for Length and Length Distribution of

2

3.1.7 For definitions of other textile terms used in this

Cotton Fibers (Array Method)

2

method, refer to Terminology D 123.

D 1441 Practice for Sampling Cotton Fibers for Testing

2

D 1776 Practice for Conditioning and Testing Textiles

4. Summary of Test Method

D 3025 PracticeforStandardizingCottonFiberTestResults

2

4.1 Fibers are placed on comb(s) in such a way that they are

by Use of Calibration Cotton Standards

caught at random points along their lengths to form a beard.

The beard is scanned photoelectrically from base to tip, the

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles,

amount of light passing through the beard being used as a

and is the direct responsibility of Subcommittee D13.11 on Cotton Fibers.

measure of the number of fibers that extend various distances

Current edition approved November 10, 2000. Published February 2001.

from the comb(s).

Originally published as D 1447 – 55. Last previous edition D 1447 – 89 (Reap-

e1

proved 1994) .

2

Annual Book of ASTM Standards, Vol 07.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D1447

4.2 The Fibrograph shows the amount and the length compared to total length of all fibers in the sample and that the

readings from the Fibrogram being sensed on separate dials. point of catch for a fiber is at random along its length.

The instrument can show percent, the distance spanned by

6. Apparatus

predetermined percentages of the cotton fibers in the beard.

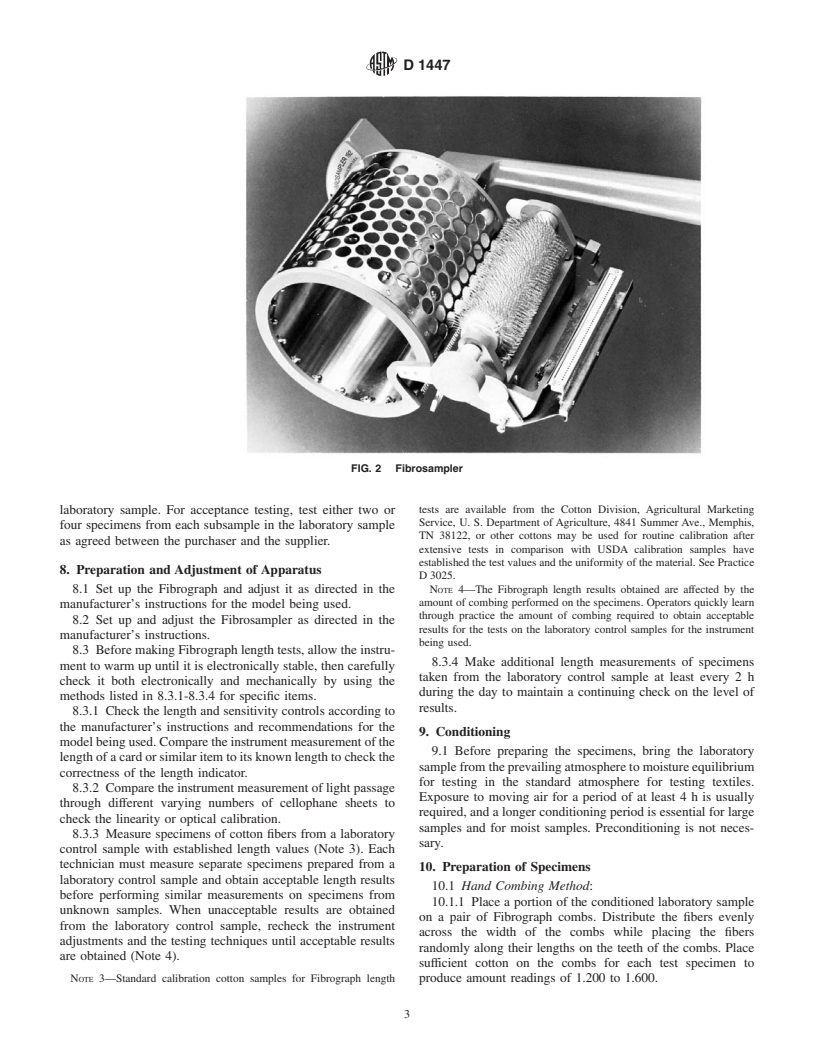

FIG. 1 Digital Fibrograph, Model 530

3

5. Significance and Use 6.1 Fibrograph, Digital model, with accessory equipment

as shown in Fig. 1.

5.1 This test method is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.