ASTM C1044-98(2003)

(Practice)Standard Practice for Using a Guarded-Hot-Plate Apparatus or Thin-Heater Apparatus in the Single-Sided Mode

Standard Practice for Using a Guarded-Hot-Plate Apparatus or Thin-Heater Apparatus in the Single-Sided Mode

SCOPE

1.1 This practice covers the determination of the steady-state heat flow through the meter section of a specimen when a guarded-hot-plate apparatus or thin-heater apparatus is used in the single-sided mode of operation.

1.2 This practice provides a supplemental procedure for use in conjunction with either Test Method C 177 or C 1114 for testing a single specimen. This practice is limited to only the single-sided mode of operation, and, in all other particulars, the requirements of either Test Method C 177 or C 1114 apply.

Note 1—Test Methods C 177 and C 1114 describe the use of the guarded-hot-plate and thin-heater apparatus, respectively, for determining steady-state heat flux and thermal transmission properties of flat-slab specimens. In principle, these methods cover both the double- and single-sided mode of operation, and at present, do not distinguish between the accuracies for the two modes of operation. When appropriate, thermal transmission properties shall be calculated in accordance with Practice C 1045.

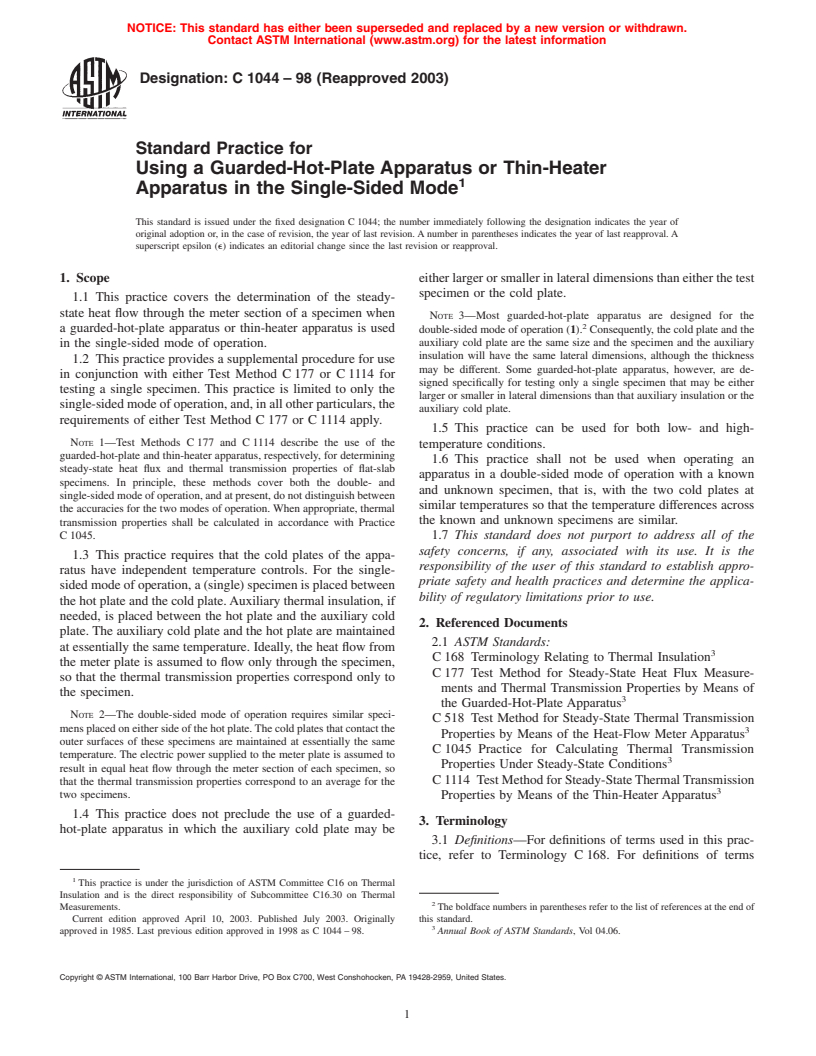

1.3 This practice requires that the cold plates of the apparatus have independent temperature controls. For the single-sided mode of operation, a (single) specimen is placed between the hot plate and the cold plate. Auxiliary thermal insulation, if needed, is placed between the hot plate and the auxiliary cold plate. The auxiliary cold plate and the hot plate are maintained at essentially the same temperature. Ideally, the heat flow from the meter plate is assumed to flow only through the specimen, so that the thermal transmission properties correspond only to the specimen.

Note 2—The double-sided mode of operation requires similar specimens placed on either side of the hot plate. The cold plates that contact the outer surfaces of these specimens are maintained at essentially the same temperature. The electric power supplied to the meter plate is assumed to result in equal heat flow through the meter section of each specimen, so that the thermal transmission properties correspond to an average for the two specimens.

1.4 This practice does not preclude the use of a guarded-hot-plate apparatus in which the auxiliary cold plate may be either larger or smaller in lateral dimensions than either the test specimen or the cold plate.

Note 3—Most guarded-hot-plate apparatus are designed for the double-sided mode of operation (). Consequently, the cold plate and the auxiliary cold plate are the same size and the specimen and the auxiliary insulation will have the same lateral dimensions, although the thickness may be different. Some guarded-hot-plate apparatus, however, are designed specifically for testing only a single specimen that may be either larger or smaller in lateral dimensions than that auxiliary insulation or the auxiliary cold plate.

1.5 This practice can be used for both low- and high-temperature conditions.

1.6 This practice shall not be used when operating an apparatus in a double-sided mode of operation with a known and unknown specimen, that is, with the two cold plates at similar temperatures so that the temperature differences across the known and unknown specimens are similar.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1044 – 98 (Reapproved 2003)

Standard Practice for

Using a Guarded-Hot-Plate Apparatus or Thin-Heater

Apparatus in the Single-Sided Mode

This standard is issued under the fixed designation C 1044; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope either larger or smaller in lateral dimensions than either the test

specimen or the cold plate.

1.1 This practice covers the determination of the steady-

state heat flow through the meter section of a specimen when

NOTE 3—Most guarded-hot-plate apparatus are designed for the

a guarded-hot-plate apparatus or thin-heater apparatus is used

double-sided mode of operation (1). Consequently, the cold plate and the

auxiliary cold plate are the same size and the specimen and the auxiliary

in the single-sided mode of operation.

insulation will have the same lateral dimensions, although the thickness

1.2 This practice provides a supplemental procedure for use

may be different. Some guarded-hot-plate apparatus, however, are de-

in conjunction with either Test Method C 177 or C 1114 for

signed specifically for testing only a single specimen that may be either

testing a single specimen. This practice is limited to only the

larger or smaller in lateral dimensions than that auxiliary insulation or the

single-sidedmodeofoperation,and,inallotherparticulars,the

auxiliary cold plate.

requirements of either Test Method C 177 or C 1114 apply.

1.5 This practice can be used for both low- and high-

NOTE 1—Test Methods C 177 and C 1114 describe the use of the

temperature conditions.

guarded-hot-plate and thin-heater apparatus, respectively, for determining

1.6 This practice shall not be used when operating an

steady-state heat flux and thermal transmission properties of flat-slab

apparatus in a double-sided mode of operation with a known

specimens. In principle, these methods cover both the double- and

and unknown specimen, that is, with the two cold plates at

single-sided mode of operation, and at present, do not distinguish between

similar temperatures so that the temperature differences across

the accuracies for the two modes of operation. When appropriate, thermal

the known and unknown specimens are similar.

transmission properties shall be calculated in accordance with Practice

C 1045. 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.3 This practice requires that the cold plates of the appa-

responsibility of the user of this standard to establish appro-

ratus have independent temperature controls. For the single-

priate safety and health practices and determine the applica-

sidedmodeofoperation,a(single)specimenisplacedbetween

bility of regulatory limitations prior to use.

the hot plate and the cold plate.Auxiliary thermal insulation, if

needed, is placed between the hot plate and the auxiliary cold

2. Referenced Documents

plate. The auxiliary cold plate and the hot plate are maintained

2.1 ASTM Standards:

at essentially the same temperature. Ideally, the heat flow from

C 168 Terminology Relating to Thermal Insulation

the meter plate is assumed to flow only through the specimen,

C 177 Test Method for Steady-State Heat Flux Measure-

so that the thermal transmission properties correspond only to

ments and Thermal Transmission Properties by Means of

the specimen.

the Guarded-Hot-Plate Apparatus

NOTE 2—The double-sided mode of operation requires similar speci-

C 518 Test Method for Steady-State Thermal Transmission

mensplacedoneithersideofthehotplate.Thecoldplatesthatcontactthe

Properties by Means of the Heat-Flow Meter Apparatus

outer surfaces of these specimens are maintained at essentially the same

C 1045 Practice for Calculating Thermal Transmission

temperature. The electric power supplied to the meter plate is assumed to

Properties Under Steady-State Conditions

result in equal heat flow through the meter section of each specimen, so

C 1114 TestMethodforSteady-StateThermalTransmission

that the thermal transmission properties correspond to an average for the

two specimens.

Properties by Means of the Thin-Heater Apparatus

1.4 This practice does not preclude the use of a guarded-

3. Terminology

hot-plate apparatus in which the auxiliary cold plate may be

3.1 Definitions—For definitions of terms used in this prac-

tice, refer to Terminology C 168. For definitions of terms

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurements. The boldface numbers in parentheses refer to the list of references at the end of

Current edition approved April 10, 2003. Published July 2003. Originally this standard.

approved in 1985. Last previous edition approved in 1998 as C 1044 – 98. Annual Book of ASTM Standards, Vol 04.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1044 – 98 (2003)

relating to the guarded-hot-plate apparatus or thin-heater ap- the auxiliary insulation is small; determining Q8; and, calcu-

paratus refer to Test Methods C 177 or C 1114, respectively, lating the heat flow, Q, through the meter section of the

specimen.

3.2 Definitions of Terms Specific to This Standard:

4.2 This practice requires that the apparatus have indepen-

3.2.1 auxiliary cold plate, n—the plate that provides an

dent temperature controls in order to operate the cold plate and

isothermal boundary at the outside surface of the auxiliary

auxiliary cold plate at different temperatures. In the single-

insulation.

sides mode, the apparatus is operated with the temperature of

3.2.2 auxiliary insulation, n—thermal insulation used in

the auxiliary cold plate maintained, as close as possible, to the

placeofasecondtestspecimen,whenthesingle-sidedmodeof

temperatureofthesideofthehotplateadjacenttotheauxiliary

operation is used (syn. dummy specimen).

insulation.

3.2.3 cold plate, n—the plate that provides an isothermal

boundary at the cold surface of the specimen.

NOTE 4—Ideally, if the temperature difference across the auxiliary

3.2.4 double-sided mode, n—operation of the apparatus, insulation is zero and there are no edge heat losses or gains, all of the

power input to the meter plate will flow through the specimen. In practice,

suchthattheheatinputtothemeterplateflowsequallythrough

a small correction is made for heat flow, Q8, through the auxiliary

two specimens, each specimen placed on either side of the hot

insulation.

plate (see also single-sided mode).

3.2.5 gap, n—separation between the meter plate and guard 4.3 The thermal conductance, C8, of the auxiliary insulation

plate, usually filled with a gas or thermal insulation. must be determined from one or more separate tests using

3.2.6 guard plate, n—the outer (rectangular or circular) ring either Test Method C 177, C 1114, or as indicated in 5.4. The

values of C8 should be checked periodically, particularly if

of the guarded hot plate, that encompasses the meter plate and

promotes one-dimensional heat flow normal to the meter plate. during regular testing it is not possible to keep the temperature

drop across the auxiliary insulation less than 1 % of the

3.2.7 guarded hot plate, n—an assembly, consisting of a

temperature drop across the test specimen.

meter plate and a co-planar, concentric guard plate, that

4.4 This practice can be used when it is desirable to

provides the heat input to the specimen(s).

determine the thermal properties of a single specimen. For

3.2.8 meter plate, n—the inner (rectangular or circular)

example, the thermal properties of a single specimen are used

plate of the guarded hot plate, that provides the heat input to

to calibrate a heat-flow-meter apparatus for Test Method

the meter section of the specimen(s).

C 518. In other cases, there may be only one specimen

3.2.9 meter section, n—the portion of the specimen (or

available.

auxiliary insulation) through which the heat input to the meter

plate flows under ideal guarding conditions.

5. Procedure for Single-Sided Mode of Operation

3.2.10 single-sided mode, n—operation of the apparatus

5.1 Refer to Fig. 1 for a schematic diagram of the single-

such that essentially all of the heat input to the meter plate

flows through a specimen placed on one side of the hot plate sided mode of operation of the guarded-hot-plate apparatus.

(see also double-sided mode).

NOTE 5—The schematic diagram for a thin-heater apparatus (not

3.2.11 thin heater, n—an assembly, consisting of a unparti-

shown) in similar, except the hot plate is much thinner and is not

tioned thin-screen heater or thin-foil, that provides the heat

partitioned by a gap.

input to the specimen(s).

5.2 Follow the procedure of either Test Method C 177 or

3.3 Symbols—The symbols used in this practice have the

C 1114 with the following modifications.

following significance. The prime (8) denotes quantities asso-

5.3 Select a semi-rigid material for the auxiliary insulation

ciated with the auxiliary insulation used to control heat from

having a low thermal conductance so that heat gains or losses

the other side of the hot plate.

from the back side of the meter plate will be small. The

3.3.1 A—metre area of hot plate, m .

thickness and lateral conductance of the auxiliary insulation

3.3.2 C8—thermal conductance of auxiliary insulation,

should be small enough to avoid significant effects on the heat

W/(m • K).

transfer through the meter section of the auxiliary insulation

3.3.3 Q—heat flow through meter section of specimen, W.

due to heat transfer at the edge of the auxiliary insulation.

3.3.4 Q8—heat flow through meter section of auxiliary

NOTE 6—The influence of edge effects for a particular apparatus and

insulation, W.

test configuration can be determined experimentally as described in Test

3.3.5 Q —power input to meter plate, W.

m

Method C 177 or by computation using one of the procedures referenced

3.3.6 T —surface temperature of cold plate, K.

in Test Method C 177 or described by Peavy and Rennex (2).

c

3.3.7 T8 —surface temperature of auxiliary cold plate, K.

c

5.4 Determine C8 of the auxiliary insulation over the tem-

3.3.8 T —surface temperature of hot plate in contact with

h

perature range of interest using one of the following proce-

specimen, K.

dures. Either Test Method C 177 or C 1114 in a separate test

3.3.9 T8 —surface temperature of hot plate in contact with

h

setup for a matched pair of similar specimens, or in-situ as

auxiliary insulation, K.

described in Annex A1 will be used.

5.4.1 In the first instance using either Test Method C 177 or

4. Significance and Use

C 1114, a match pair of similar specimens is required so that

4.1 This practice provides a procedure for operating the either single specimen subsequently can be used as the

apparatussothattheheatflow, Q8,throughthemetersectionof auxiliary insulation specimen.

C 1044 – 98 (2003)

FIG. 1 Diagram Illustrating Single-Sided Mode of Operation of the Guarded-Hot-Plate Apparatus

5.4.2 In the second instance using in-situ as described in 6. Calculation

Annex A1, pairs of test are required, one with a small

6.1 Calculate the heat flow through the auxiliary insulation

temperature difference across the test specimen and one with a

as follows:

small temperature difference across the auxiliary insulation.

Q8 5 C8 A ~T8 2 T8 ! (1)

h c

NOTE 7—In5.4itisnotintendedfortheusertodeterminevaluesfor C8 where:

for every test that is to be conducted. Rather determine C8 as a function of

C8 is the thermal conductance of the auxiliary insulation at a

temperature over the temperature range of interest so that a corresponding

temperaturecorrespondingto(T8 +T8 )/2,asobtainedaccord-

h c

regression curve may be developed and used for subsequent testing.

ing to 5.4.

5.5 When using a compressible material as the auxiliary

6.2 Calculatetheheatflowthroughthespecimenasfollows:

insulation, determine C8 either at the same thickness as that

Q 5 Q 2 Q8 (2)

m

usedinthesingle-sidedmodeofoperationorcompressedto(at

least) two slightly different thicknesses, thus allowing interpo- 6.3 Use the value of Q, thus obtained to calculate steady-

state thermal transmission properties, in accordance with either

lation for the thickness actually used in the single-sided mode

of operation. Test Method C 177 or C 1114. When appropriate, consult

Practice C 1045 to calculate steady-state thermal transmission

5.6 For an apparatus without a separate provision for

determiningtheindividualthicknessesofthetwospecimenson properties. For reference, calculation equations are provided in

Appendix X1.

opposite sides of the hot plate, place three or more low-

conductance rigid spacers near the outer periphery of the guard

7. Sources of Experimental Error

platebetweenthehotplateandthesurfaceoftheauxiliarycold

7.1 Errorsinthedeterminationof Q,canbeintroducedfrom

plate(seeTestMethodC 177).Computetheeffectivethickness

several sources, including measurement of the power input Q

m

of the test specimen by subtracting the thickness of the rigid

to the meter plate; estimation of the heat flow, Q8, through the

spacers (corrected for thermal expansion, if necessary) from

auxiliary insulation and, for guarded hot plates, estimation of

the thickness that is determined for the test specimen plus the

the heat flow across the gap between the meter and guard

auxiliary insulation. In this case, the separate tests of thermal

plates, that is, gap error.

conductance according to 5.4 compression also should be

7.2 Refer to either Test Method C 177 or C 1114 for

conducted with rigid spacers.

discussion on the uncertainty in the measurement of the

5.7 Maintain the cold plate at the desired temperature T .

c

metered-area power (Q ).

Provide power input to the hot plate to attain the desired m

7.3 Estimatetheuncertainty(DQ8)in Q8byapropagationof

temperature T on the hot side of the test specimen.

h

error using the terms in Eq 1. Refer to Ku (3) for using error

5.8 Maintain the temperature T8 of the auxiliary cold plate

c

propagation formulas.

as closely as practical to the temperature T8 on the back side

h

of the hot plate.

NOTE 8—The terms, Q and Q8 in Eq 2 should be different by at least

m

5.9 Establish thermal steady-state conditions in accordance

two orders of magnitude, if possible. Thus, a large uncertainty in Q8 may

result in a small uncertainty in Q. For example, suppose that the ratio

with either Test Method C 177 or C 1114.

Q /Q8 is 100 and suppose that the ratio DQ’/Q’ is 0.1. The p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.