ASTM D4065-95

(Practice)Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures

Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures

SCOPE

1.1 This practice is for general use in gathering and reporting dynamic mechanical data. It incorporates laboratory practice for determining dynamic mechanical properties of specimens subjected to various oscillatory deformations on a variety of instruments of the type commonly called dynamic mechanical analyzers or dynamic thermomechanical analyzers.

1.2 This practice is intended to provide means of determining the transition temperatures, elastic, and loss moduli of plastics over a range of temperatures, frequencies, or time, by free vibration and resonant or nonresonant forced vibration techniques. Plots of elastic and loss moduli are indicative of the viscoelastic characteristics of a plastic. These moduli are functions of temperature or frequency in plastics, and change rapidly at particular temperatures or frequencies. The regions of rapid moduli change are normally referred to as transition regions.

1.3 The practice is primarily useful when conducted over a range of temperatures from -160°C to polymer degradation and is valid for frequencies from 0.01 to 1000 Hz.

1.4 This practice is intended for materials that have an elastic modulus in the range from 0.5 MPa to 100 GPa (73 psi to 1.5 x 10 7 psi).

1.5 Apparent discrepancies may arise in results obtained under differing experimental conditions. Without changing the observed data, reporting in full (as described in this practice) the conditions under which the data were obtained will enable apparent differences observed in another study to be reconciled.

1.6 Test data obtained by this practice are relevant and appropriate for use in engineering design.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this practice to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazards statements are given in Section 8.

Note 1—This practice is technically equivalent to ISO 6721, Part 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4065 – 95 An American National Standard

Standard Practice for

Determining and Reporting Dynamic Mechanical Properties

of Plastics

This standard is issued under the fixed designation D 4065; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Specific hazards

1.1 This practice is for general use in gathering and report-

statements are given in Section 8.

ing dynamic mechanical data. It incorporates laboratory prac-

tice for determining dynamic mechanical properties of speci-

2. Referenced Documents

mens subjected to various oscillatory deformations on a variety

2.1 ASTM Standards:

of instruments of the type commonly called dynamic mechani-

D 618 Practice for Conditioning Plastics and Electrical

cal analyzers or dynamic thermomechanical analyzers.

Insulating Materials for Testing

1.2 This practice is intended to provide means of determin-

D 4000 Classification System for Specifying Plastic Mate-

ing the transition temperatures, elastic, and loss moduli of

rials

plastics over a range of temperatures, frequencies, or time, by

D 4092 Terminology Relating to Dynamic Mechanical

free vibration and resonant or nonresonant forced vibration

Measurements on Plastics

techniques. Plots of elastic and loss moduli are indicative of the

viscoelastic characteristics of a plastic. These moduli are

3. Terminology

functions of temperature or frequency in plastics, and change

3.1 Definitions—For definitions of terms relating to this

rapidly at particular temperatures or frequencies. The regions

practice, see Terminology D 4092.

of rapid moduli change are normally referred to as transition

regions.

4. Summary of Practice

1.3 The practice is primarily useful when conducted over a

4.1 A specimen of known geometry is placed in mechanical

range of temperatures from −160°C to polymer degradation

oscillation either at fixed or natural resonant frequencies.

and is valid for frequencies from 0.01 to 1000 Hz.

Elastic or loss moduli, or both of the specimen are measured

1.4 This practice is intended for materials that have an

while varying time, temperature of the specimen or frequency,

elastic modulus in the range from 0.5 MPa to 100 GPa (73 psi

7 or both, of the oscillation. Plots of the elastic or loss moduli, or

to 1.5 3 10 psi).

both, are indicative of viscoelastic characteristics of the speci-

1.5 Apparent discrepancies may arise in results obtained

men. Rapid changes in viscoelastic properties at particular

under differing experimental conditions. Without changing the

temperatures, times, or frequency are normally referred to as

observed data, reporting in full (as described in this practice)

transition regions.

the conditions under which the data were obtained will enable

apparent differences observed in another study to be recon- NOTE 1—The particular method for measurement of elastic and loss

moduli depends upon the operating principle of the instrument used.

ciled.

1.6 Test data obtained by this practice is relevant and

5. Significance and Use

appropriate for use in engineering design.

5.1 Dynamic mechanical testing provides a method for

1.7 The values stated in SI units are to be regarded as the

determining elastic and loss moduli as a function of tempera-

standard. The values given in parentheses are for information

ture, frequency or time, or both. A plot of the elastic modulus

only.

and loss modulus of material versus temperature provides a

1.8 This standard does not purport to address all of the

graphical representation of elasticity and damping as a function

safety concerns, if any, associated with its use. It is the

of temperature or frequency.

responsibility of the user of this practice to establish appro-

5.2 This procedure can be used to locate transition tempera-

tures of plastics, that is, changes in the molecular motions of a

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics polymer. In the temperature ranges where significant changes

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

Current edition approved Oct. 10, 1995. Published December 1995. Originally

published as D 4065 – 82. Last previous edition D 4065 – 94. Annual Book of ASTM Standards, Vol 08.01.

This edition includes revisions to Table 1 and the addition of 1.6. Annual Book of ASTM Standards, Vol 08.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 4065

occur, elastic modulus decreases rapidly with increasing tem- 7.2.4 Temperature Controller and Oven—A device for con-

perature (at constant or near constant frequency) or increases trolling the specimen temperature, either by heating (in steps or

with increasing frequency (at constant temperature). A maxi- ramps), cooling (in steps or ramps), or maintaining a constant

mum is observed for the loss modulus. specimen environment. Any temperature programmer should

5.3 This procedure can be used, for example, to evaluate by be sufficiently stable to permit measurement of sample tem-

comparison to known reference materials: perature to 60.5°C.

5.3.1 Degree of phase separation in multicomponent sys- 7.3 Nitrogen or other gas supply for purging purposes.

tems, 7.4 Calipers or other length-measuring device capable of

5.3.2 Filler type, amount, pretreatment, and dispersion, and measuring to an accuracy of 0.01 mm.

5.3.3 Effects of certain processing treatment.

8. Hazards

5.4 This procedure can be used to determine the following:

5.4.1 Stiffness of polymer composites, especially as a func-

8.1 Precautions:

tion of temperature,

8.1.1 Toxic or corrosive effluents, or both, may be released

5.4.2 Degree of polymer crystallinity, and

when heating the specimen near its decomposition point and

5.4.3 Magnitude of triaxial stress state in the rubber phase of

can be harmful to personnel or to the apparatus.

rubber modified polymers.

8.1.2 Take care to prevent buckling of the clamped speci-

5.4.4 This procedure is useful for quality control, specifica-

men due to thermal expansion during the test.

tion acceptance, and research.

5.5 For many materials, there may be a specification that

9. Test Specimens

requires the use of this practice, but with some procedural

9.1 Specimens may be any uniform size or shape but are

modifications that take precedence when adhering to the

ordinarily analyzed in rectangular form. If some heat treatment

specification. Therefore, it is advisable to refer to that material

is applied to the specimen to obtain this preferred analytical

specification before using this practice. Table 1 of Classifica-

form, this treatment should be noted in the report.

tion System D 4000 lists the ASTM materials standards that

9.2 Due to the numerous types of dynamic mechanical

currently exist.

instruments, specimen size is not fixed by this practice. In

many cases, a specimen of 0.75 by 9.4 by 50 mm (0.03 by 0.38

6. Interferences

by 2.0 in.) is found to be usable and convenient.

6.1 Since small quantities of specimen are used, it is

NOTE 2—It is important to select a specimen size consistent with the

essential that the specimens be homogeneous or representative,

modulus of the material under test and capabilities of the measuring

or both.

apparatus. For example, thick specimens of low modulus materials may be

suitable for measurement, while thin specimens of high modulus materials

7. Apparatus

may be required.

7.1 The function of the apparatus is to hold a plastic

9.3 Condition the specimen at 23 6 2°C (736 4°F) and 50

specimen of uniform cross section, so that the specimen acts as

6 5 % relative humidity for not less than 40 h prior to test in

the elastic and dissipative element in a mechanically oscillated

accordance to Procedure A of Practice D 618, for those tests

system. Instruments of this type are commonly called dynamic

where conditioning is required. If other specimen conditioning

mechanical or dynamic thermomechanical analyzers. They

is used, it should be noted in the report.

typically operate in one of seven oscillatory modes: (1) freely

decaying torsional oscillation, (2) forced constant amplitude,

10. Calibration

resonant, flexural oscillation, (3) forced constant amplitude,

10.1 Using the same heating rate or schedule to be used for

fixed frequency, compressive oscillation, (4) forced constant

specimens, calibrate the instrument temperature axis, using the

amplitude, fixed frequency, flexural oscillation, (5) forced,

instrument manufacturer’s procedures with either or both of the

constant amplitude, fixed frequency, tensile oscillation, (6)

following substances.

forced constant amplitude, fixed frequency, torsional oscilla-

Standard Transition Temperature, °C Type of Transition

tion and (7) forced constant amplitude, fixed frequency, or

Water 0.0 fusion

variable frequency dual cantilever.

Indium 156.6 fusion

7.2 The apparatus shall consist of the following:

10.2 Calibrate the instrument using procedures recom-

7.2.1 Clamps—A clamping arrangement that permits grip-

mended by the manufacturer.

ping of the sample.

7.2.2 Oscillatory Deformation (Strain)—A device for ap-

11. Procedure

plying an oscillatory deformation (strain) to the specimen. The

deformation (strain) may be applied and then released, as in 11.1 Measure the length, width, and thickness of the speci-

free-vibration devices, or continuously applied, as in forced- men to an accuracy of 61%.

vibration devices (see Table 1). 11.2 Maximum strain amplitude should be within the linear

7.2.3 Detectors—A device or devices for determining de- viscoelastic range of the material. Strains of less than 1 % are

pendent and independent experimental parameters, such as recommended.

force (stress or strain), frequency, and temperature. Tempera- 11.3 If temperature is to be the independent variable:

ture should be measureable with an accuracy of 61°C, 11.3.1 The test frequency may be from 0.01 to 500 Hz, fixed

frequency to 61 %, and force to 61%. or changing as the dependent variable.

D 4065

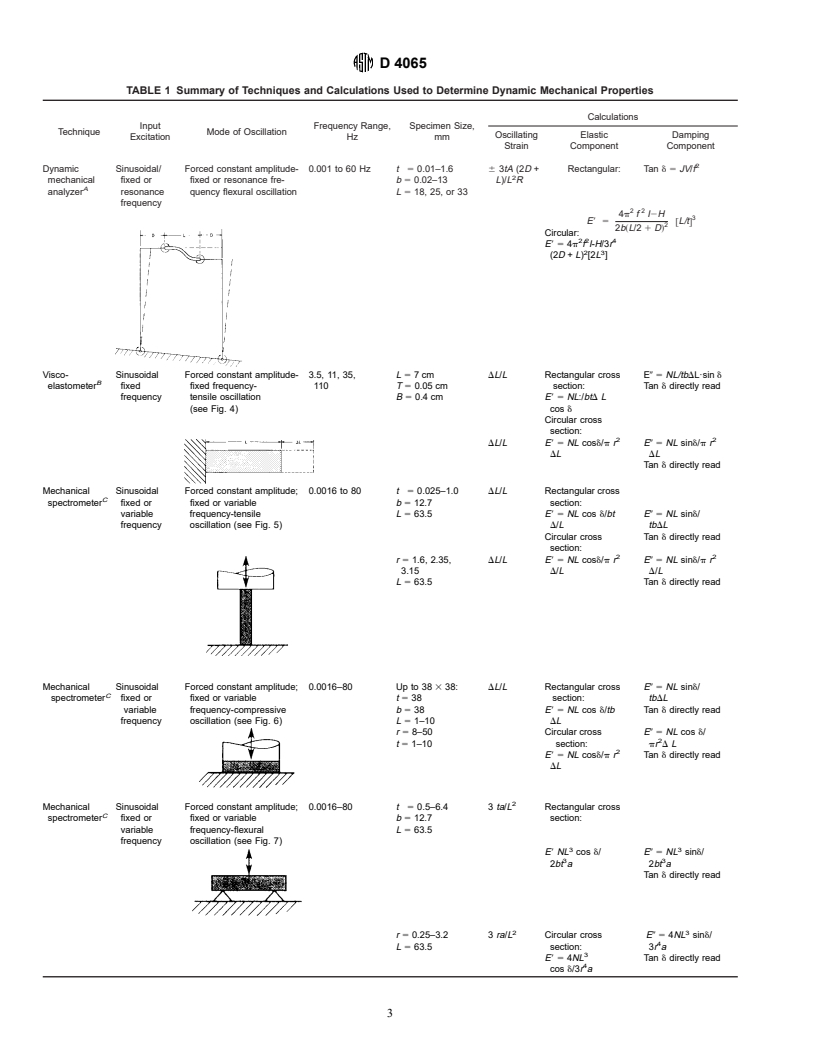

TABLE 1 Summary of Techniques and Calculations Used to Determine Dynamic Mechanical Properties

Calculations

Input Frequency Range, Specimen Size,

Technique Mode of Oscillation

Oscillating Elastic Damping

Excitation Hz mm

Strain Component Component

Dynamic Sinusoidal/ Forced constant amplitude- 0.001

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.