ASTM G139-96

(Test Method)Standard Test Method for Determining Stress-Corrosion Cracking Resistance of Heat-Treatable Aluminum Alloy Products Using Breaking Load Method (Withdrawn 2004)

Standard Test Method for Determining Stress-Corrosion Cracking Resistance of Heat-Treatable Aluminum Alloy Products Using Breaking Load Method (Withdrawn 2004)

SCOPE

1.1 This test method covers procedures for evaluation of stress corrosion cracking (SCC) resistance by the breaking load test method, a concept which uses residual strength as the measure of damage evolution (in this case environmentally assisted cracking).

1.2 This test method covers specimen type and replication , test environment, stress levels, exposure periods, final strength determination, and statistical analysis of the raw residual strength data.

1.3 The test method was developed for use with heat-treatable aluminum alloys. that is, 2XXX alloys and 7XXX with 1.2 to 3 percent Cu, and test specimens oriented in the short-transverse direction relative to grain structure (1,2). However, the residual strength measurements and the statistics used to analyze the data are not specific to heat-treatable aluminum alloys and can be used for other specimen orientations and different types of materials.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers procedures for evaluation of stress corrosion cracking (SCC) resistance by the breaking load test method, a concept which uses residual strength as the measure of damage evolution (in this case environmentally assisted cracking).

Formerly under the jurisdiction of Committee G01 on Corrosion of Metals, this test method was withdrawn in January 2005 for failure to update within the 8-year period.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: G 139 – 96

Standard Test Method for

Determining Stress-Corrosion Cracking Resistance of Heat-

Treatable Aluminum Alloy Products Using Breaking Load

Method

This standard is issued under the fixed designation G139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.5% Sodium Chloride Solution

G47 Test Method for Determining Susceptibility to Stress-

1.1 This test method covers procedures for evaluation of

Corrosion Cracking of High-Strength Aluminum Alloy

stresscorrosioncracking(SCC)resistancebythebreakingload

Products

test method, a concept which uses residual strength as the

G49 Practice for Preparation and Use of Direct Tension

measure of damage evolution (in this case environmentally

Stress-Corrosion Test Specimens

assisted cracking).

G64 Classification of Resistance to Stress-Corrosion

1.2 This test method covers specimen type and replication,

Cracking of Heat-Treatable Aluminum Alloys

test environment, stress levels, exposure periods, final strength

determination, and statistical analysis of the raw residual

3. Terminology

strength data.

3.1 Definitions of Terms Specific to This Standard:

1.3 The test method was developed for use with heat-

3.1.1 censor—a statistical term indicating that the value

treatable aluminum alloys, that is, 2XXX alloys and 7XXX

from an individual observation may fall outside of the range

with 1.2 to 3.0% Cu, and test specimens oriented in the

that can be measured because of test procedures or conditions.

short-transverse direction relative to grain structure (1, 2).

3.1.2 sample—the nominally uniform, bulk material from

However, the residual strength measurements and the statistics

which individual stress-corrosion cracking specimens are ob-

used to analyze the data are not specific to heat-treatable

tained.

aluminum alloys and can be used for other specimen orienta-

tions and different types of materials.

4. Summary of Test Method

1.4 This standard does not purport to address all of the

4.1 This test method describes a procedure for using re-

safety concerns, if any, associated with its use. It is the

sidual strength after exposure to a corrosive environment to

responsibility of the user of this standard to establish appro-

evaluate stress corrosion cracking susceptibility in heat treat-

priate safety and health practices and determine the applica-

able aluminum alloy product forms such as sheet, plate,

bility of regulatory limitations prior to use.

extrusions, forgings, and bar. These products generally are

most susceptible to SCC in the long transverse direction of

2. Referenced Documents

sheet, the short transverse direction of plate, extrusions and

2.1 ASTM Standards:

3 forgings, and the transverse direction of rod and bar stock. In

E8 TestMethodsforTensionTestingofMetallicMaterials

this test, tensile bars or direct tension sheet specimens, pre-

E691 Practice for Conducting an Interlaboratory Study to

4 pared according to PracticeG49, are exposed to 3.5 weight %

Determine the Precision of a Test Method

aqueoussodiumchloridesolution(PracticeG44),areremoved

G44 Practice for Evaluating Stress Corrosion Cracking

before they fail and are tension tested to determine the amount

ResistanceofMetalsandAlloysbyAlternateImmersionin

of corrosion damage that has occurred. The average retained

strength is then calculated and the Box-Cox Transformation

This test method is under the jurisdiction of ASTM Committee G-1 on can be used for statistical analysis of the results.

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

4.2 The procedure calls for exposure of unstressed speci-

Stress Corrosion Cracking and Corrosion Fatigue.

mens which are used to factor out the effects of pitting,

Current edition approved April 10, 1996. Published July 1996.

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

the standard.

Annual Book of ASTM Standards, Vol 03.01.

4 5

Annual Book of ASTM Standards, Vol 14.02. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

G139–96

intergranular, and general corrosion. These phenomena de- cluded in this test method can accommodate small numbers of

grade residual strength but do not require applied stress for failed specimens but not large numbers.

their occurrence. 6.2 The breaking load test is applicable to specimens that

have been exposed in natural and service environments.

5. Significance and Use

However, conditions in these environments may not be con-

5.1 The test method was developed for use with high

stant so consideration must be given to the period and timing

strength aluminum alloys (2XXX and Cu containing 7XXX)

ofexposuretoavoidbiasingresults.Forexample,environmen-

that are normally tested in 3.5 weight % NaCl by alternate

tal conditions that vary seasonally such as temperature, mois-

immersion. However, the concept which uses residual strength

ture, and pollutant concentration may affect the corrosivity of

as a measure of damage evolution (in this case

outdoor exposure stations. Direct material comparisons should

environmentally-assistedcracking)can,inprinciple,beapplied

be made using identical environmental conditions.

to any alloy and environmental system.

6.3 Some care is required when comparison samples have

5.2 This test method has been developed for research

different original (uncorroded) tensile strength and fracture

studiesofalloysandtemperswithimprovedresistancetoSCC.

toughness values. Large variations in initial properties can

The test results permit different material variants to be com-

either reduce or increase the apparent differences in SCC

pared with a high degree of confidence and with much more performance of the samples. To avoid bias due to tensile

precision than the results of pass/fail tests. Thus, it is particu-

properties, the statistical procedures incorporated in this test

larly useful for comparing materials with similar levels of method are based on percentages of original strength. How-

resistancetostress-corrosioncracking.Theprocedurecouldbe

ever, to examine the effect of fracture toughness, which affects

modified for use as a quality assurance tool but this has not residual strength, a flaw size calculation must be done using

been a primary purpose during its development.

fracture mechanics techniques (3).

5.3 The exposure periods and conditions that are described

7. Test Specimens

inthistestmethodapplyspecificallytohighstrengthaluminum

alloys, but the statistical techniques should be valid for other 7.1 The breaking load procedure may be conducted using

alloy systems with different exposure conditions. any specimen that can be axially stressed in a fixture that will

5.4 Although this particular procedure was primarily in- sustain an applied displacement. However, results obtained

tended for testing products in the short-transverse stressing using different specimen geometries or stressing methods can

direction, it is useful for other stressing directions, particularly not be directly compared. While the relative susceptibilities of

the long-transverse direction in sheet and thin plate products. the samples will not be changed, the absolute numbers can be

5.5 Determination of the actual serviceability of a material quite different.

requires stress-corrosion testing performed in the intended 7.2 Wheneverthegeometryofthemetalsamplepermits,the

service environment, under conditions relating to the end use, test should be conducted using smooth, round tension speci-

including protective measures such as coatings and inhibitors menspreparedinaccordancewithPracticeG49.Inthecaseof

and is outside the scope of this test method. sheet and other products that may be too thin to yield tensile

5.5.1 Thereisnogoodwaytocomparetestenvironmentsto bars, sheet tensile specimens may be used. The test sensitivity

actual service because most service environments have large increases with the ratio of surface area to volume in the

inherent variability with respect to a single structure that may specimengagesection;howevertestsmadeusingroundtensile

experience many different environments or with respect to two specimens have shown that the same relative rankings can be

identical structures that serve in different locations. Unless a achieved with different size specimens (1).

sample can be tested in the actual service environment for the

8. Exposure Procedure

expected life of the component, no conclusive determination

8.1 Stressing Procedure and Exposure Conditions—The

can be made about the suitability of a particular material for a

particular application. Designers must therefore make judg- specimens shall be stressed by axially loading in constant

deflection-type fixtures as in Figure 1 of Practice G49 and

ments on the suitability of particular materials for applications

based on knowledge of the material and of the service exposed to the 3.5% NaCl alternate immersion test per

Practice G44. The number of specimens for each stress

environment. To avoid service failures, the environment used

level/exposure time combination should be a minimum of

for preliminary evaluations is often chosen based on a worst

three; five or more are preferable.

case scenario leading to intentional overestimations of corro-

8.2 Stress Level—The minimum number of stress levels is

sion damage.

two,oneofwhichisacompletesetofspecimensexposedwith

6. Interferences

noappliedstress.ForsampleswithunknownSCCresistanceit

6.1 The breaking load test factors out pitting corrosion that is preferable to start with two or three stress levels in addition

occurs in environments such as the 3.5% NaCl solution used to the unstressed specimens. The unstressed specimens allow

in alternate immersion testing per PracticeG44. The primary the damage caused by general, pitting and intergranular corro-

concerninusingthebreakingloadtestischoiceofappropriate siontobecalculatedandseparatedfromdamagecausedbythe

exposure stress. If the exposure stress is too low no damage appliedstress.Theotherstresslevel(s)mustbechosenforeach

will accumulate. On the other hand, if the applied stress is too individual sample by considering the expected performance of

high many of the specimens will fail before the end of their the sample.The more SCC resistant the sample, the higher the

scheduled exposure periods. The statistical procedures in- stresses should be. The ideal maximum stress would be one

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

G139–96

that leads to significant damage by way of cracking but does

notcausemorethanafewspecimenstoactuallybreakintotwo

pieces before the end of the scheduled exposure period (2).

Onestresslevelcanbeusedbutthestatisticalcalculationsonly

evaluate the performance of the sample at that stress level. In

other words, there is no good way to extrapolate and estimate

performance at higher or lower stress levels without actually

conducting the test.

8.3 Exposure Time—This parameter must be adjusted for

the sample to be tested and the size and orientation of the test

specimens.Ingeneral,twotofourtimeperiods(pluszerodays

with no stress) should be used with the maximum time being

approximatelytendaysforshorttransversetestson2XXXand

7XXX alloys. In general, long-transverse specimens and more

resistant alloy systems (such as 6XXX alloys) should be

exposed for longer periods. Classification G64 gives time

periods for these situations which can be used to estimate a

reasonable maximum exposure time.

NOTE 1—For material variants with unknown SCC performance in the

test environment, it is advisable to test a limited number of pass/fail

specimens according to the procedures in Test Method G47. This will

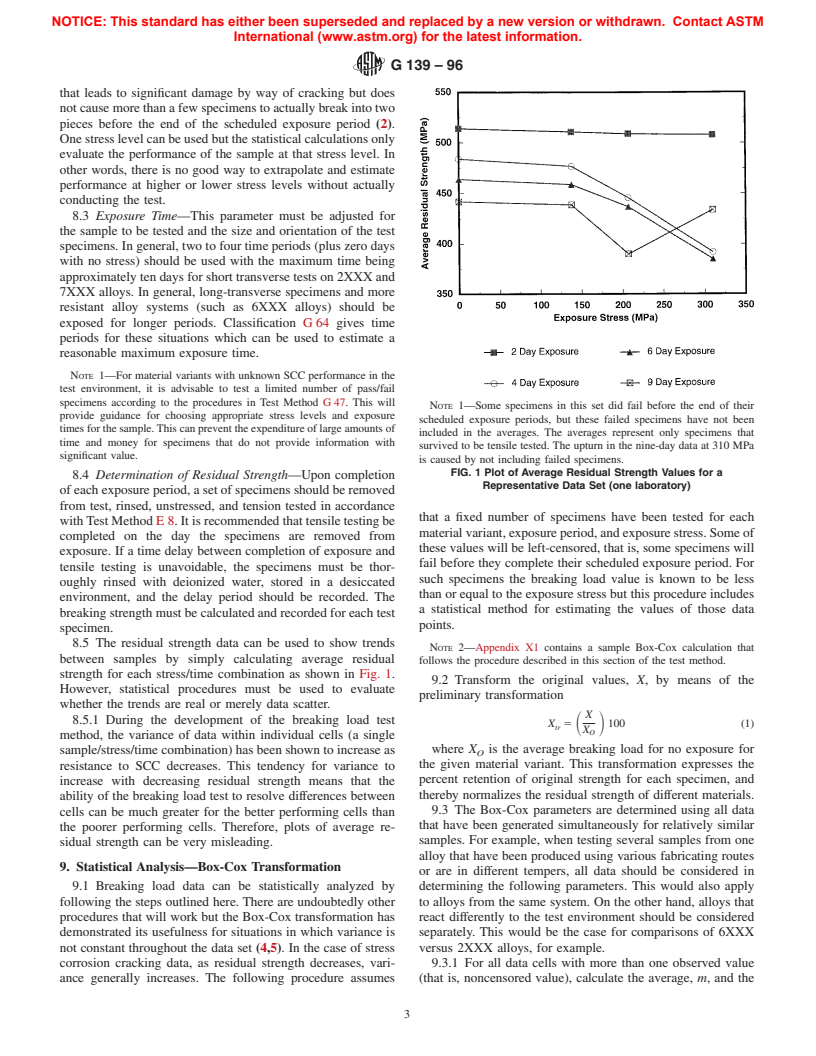

NOTE 1—Some specimens in this set did fail before the end of their

provide guidance for choosing appropriate stress levels and exposure

scheduled exposure periods, but these failed specimens have not been

timesforthesample.Thiscanpreventtheexpenditureoflargeamountsof

included in the averages. The averages represent only specimens that

time and money for specimens that do not provide information with

survived to be tensile tested. The upturn in the nine-day data at 310 MPa

significant value.

is caused by not including failed specimens.

FIG. 1 Plot of Average Residual Strength Values for a

8.4 Determination of Residual Strength—Upon completion

Representative Data Set (one laboratory)

ofeachexposureperiod,asetofspecimensshouldberemoved

from test, rinsed, unstressed, and tension tested in accordance

that a fixed number of specimens have been tested for each

withTestMethodE8.Itisrecommendedthattensiletestingbe

materialvariant,exposureperiod,andexposurestress.Someof

completed on the day the specimens are removed from

these values will be left-censored, that is, some specimens will

exposure. If a time delay between completion of exposure and

fail before they complete their scheduled exposure period. For

tensile testing is unavoidable, the specimens must be thor-

such specimens the breaking load value is known to be less

oughly rinsed with deionized water, stored in a desiccated

thanorequaltotheexposurestressbutthisprocedureincludes

environment, and the delay period should be recorded. The

a statistical method for estimating the values of those data

breakingstrengthmustbecalculatedandrecordedforeachtest

points.

specimen.

8.5 The residual strength data can be used to show trends

NOTE 2—Appendix X1 contains a sample Box-Cox calculation that

between samples by simply calculating average residual

follows the procedure described in this section of the test method.

strength for each stress/time combination as shown in Fig. 1.

9.2 Transform the original values, X, by means of the

However, statistical procedures must be used to evaluate

preliminary transformation

whether the trends are real or merely data scatter.

X

8.5.1 During the development of the breaking load test

X 5 100 (1)

S D

tr

X

O

method, the variance of data within individual cells (a single

where X is the average breaking load for no exposure for

sample/stress/timecombination)hasbeenshowntoincreaseas

O

the given material variant. This transformation expresses the

resistance to SCC

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.