ASTM G139-05

(Test Method)Standard Test Method for Determining Stress-Corrosion Cracking Resistance of Heat-Treatable Aluminum Alloy Products Using Breaking Load Method

Standard Test Method for Determining Stress-Corrosion Cracking Resistance of Heat-Treatable Aluminum Alloy Products Using Breaking Load Method

SCOPE

1.1 This test method covers procedures for evaluation of stress corrosion cracking (SCC) resistance by the breaking load test method, a concept which uses residual strength as the measure of damage evolution (in this case environmentally assisted cracking).

1.2 This test method covers specimen type and replication, test environment, stress levels, exposure periods, final strength determination, and statistical analysis of the raw residual strength data.

1.3 The test method was developed for use with heat-treatable aluminum alloys, that is, 2XXX alloys and 7XXX with 1.2 to 3.0 % Cu, and test specimens oriented in the short-transverse direction relative to grain structure (, ). However, the residual strength measurements and the statistics used to analyze the data are not specific to heat-treatable aluminum alloys and can be used for other specimen orientations and different types of materials.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G139 – 05

Standard Test Method for

Determining Stress-Corrosion Cracking Resistance of Heat-

Treatable Aluminum Alloy Products Using Breaking Load

1

Method

This standard is issued under the fixed designation G139; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers procedures for evaluation of

G44 Practice for Exposure of Metals and Alloys by Alter-

stresscorrosioncracking(SCC)resistancebythebreakingload

nate Immersion in Neutral 3.5 % Sodium Chloride Solu-

test method, a concept which uses residual strength as the

tion

measure of damage evolution (in this case environmentally

G47 Test Method for Determining Susceptibility to Stress-

assisted cracking).

CorrosionCrackingof2XXXand7XXXAluminumAlloy

1.2 This test method covers specimen type and replication,

Products

test environment, stress levels, exposure periods, final strength

G49 Practice for Preparation and Use of Direct Tension

determination, and statistical analysis of the raw residual

Stress-Corrosion Test Specimens

strength data.

G64 ClassificationofResistancetoStress-CorrosionCrack-

1.3 The test method was developed for use with heat-

ing of Heat-Treatable Aluminum Alloys

treatable aluminum alloys, that is, 2XXX alloys and 7XXX

with 1.2 to 3.0% Cu, and test specimens oriented in the

3. Terminology

2

short-transverse direction relative to grain structure (1, 2).

3.1 Definitions of Terms Specific to This Standard:

However, the residual strength measurements and the statistics

3.1.1 censor—a statistical term indicating that the value

used to analyze the data are not specific to heat-treatable

from an individual observation may fall outside of the range

aluminum alloys and can be used for other specimen orienta-

that can be measured because of test procedures or conditions.

tions and different types of materials.

3.1.2 sample—the nominally uniform, bulk material from

1.4 This standard does not purport to address all of the

which individual stress-corrosion cracking specimens are ob-

safety concerns, if any, associated with its use. It is the

tained.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 This test method describes a procedure for using re-

sidual strength after exposure to a corrosive environment to

2. Referenced Documents

3 evaluate stress corrosion cracking susceptibility in heat treat-

2.1 ASTM Standards:

able aluminum alloy product forms such as sheet, plate,

E8 Test Methods for Tension Testing of Metallic Materials

extrusions, forgings, and bar. These products generally are

most susceptible to SCC in the long transverse direction of

1

This test method is under the jurisdiction of ASTM Committee G01 on

sheet, the short transverse direction of plate, extrusions and

Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on

forgings, and the transverse direction of rod and bar stock. In

Stress Corrosion Cracking and Corrosion Fatigue.

Current edition approved Oct. 1, 2005. Published October 2005. Originally

this test, tensile bars or direct tension sheet specimens, pre-

published as G139–96. DiscontinuedApril 2003 and reinstated as G139–05. Last

pared according to Practice G49, are exposed to 3.5 weight %

previous edition G139–96. DOI: 10.1520/G0139-05.

2 aqueous sodium chloride solution (Practice G44), are removed

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

before they fail and are tension tested to determine the amount

the standard.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of corrosion damage that has occurred. The average retained

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

strength is then calculated and the Box-Cox Transformation

Standards volume information, refer to the standard’s Document Summary page on

can be used for statistical analysis of the results.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G139 – 05

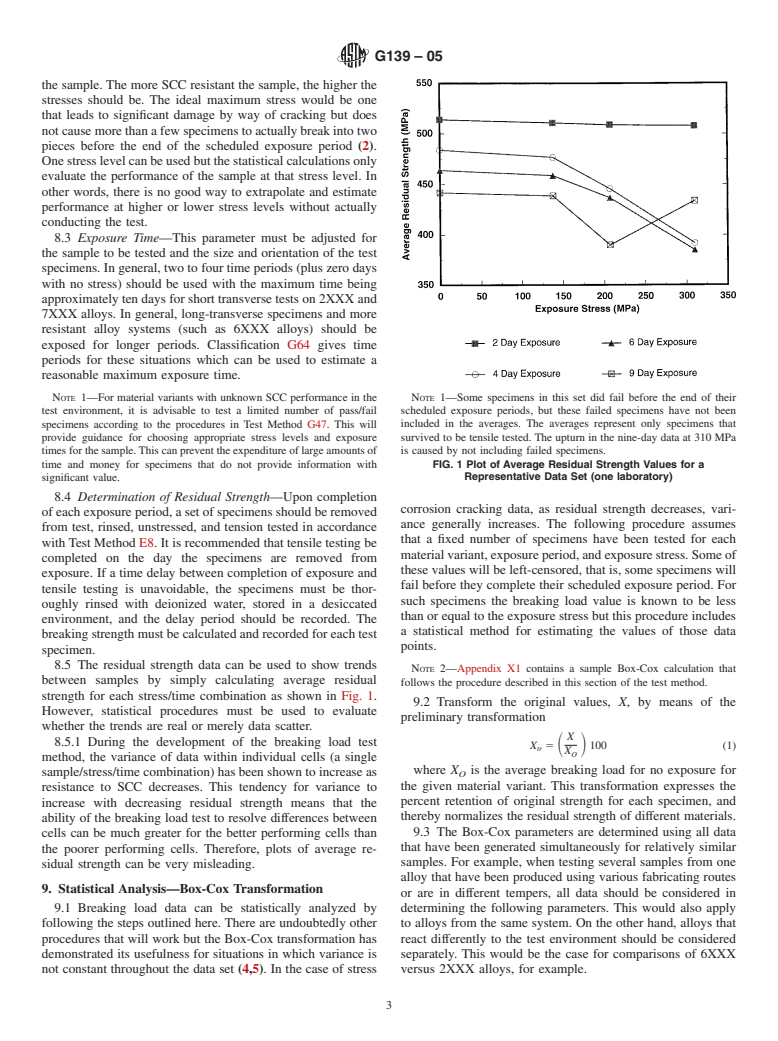

4.2 The procedure calls for exposure of unstressed speci- high many of the specimens will fail before the end of their

mens which are used to factor out the effects of pitting, scheduled exposure periods. The statistical procedures in-

intergranular, and general corrosion. These ph

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.