ASTM A976-13

(Classification)Standard Classification of Insulating Coatings for Electrical Steels by Composition, Relative Insulating Ability and Application

Standard Classification of Insulating Coatings for Electrical Steels by Composition, Relative Insulating Ability and Application

SIGNIFICANCE AND USE

4.1 This classification establishes categories of insulating coatings based on their chemical nature, relative insulating ability, and typical applications. These categories describe general physical and chemical characteristics of the coatings that are useful in making broad estimates of their insulating ability and suitability for various applications.

SCOPE

1.1 This document classifies insulating coatings for electrical steels according to their composition, relative insulating ability, and functionality. The purpose of this classification is to assist users of insulating coatings by providing general information about the chemical nature and use of the coatings, as well as to provide important data concerning limits to their use, that is, relative insulating ability, punchability, temperature stability, weldability, and fabricability. Specific surface insulation resistivity values for each coating are not included in this classification. The user is referred to the flat-rolled electrical steel specifications noted in 1.2 should more detailed information concerning surface insulation resistivity values be required.

1.2 This classification is to be used in conjunction with the various specifications for flat-rolled electrical steels under the jurisdiction of Committee A06, including Specifications A345, A677, A683, A726, A840, and A876. However, in those instances in which the coating descriptions and characteristics differ between this classification and any of the specifications, this classification shall supersede the specification.

1.3 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A976 −13

Standard Classification of

Insulating Coatings for Electrical Steels by Composition,

1

Relative Insulating Ability and Application

This standard is issued under the fixed designation A976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This document classifies insulating coatings for electri- 2.1 ASTM Standards:

cal steels according to their composition, relative insulating A340 Terminology of Symbols and Definitions Relating to

ability,andfunctionality.Thepurposeofthisclassificationisto Magnetic Testing

assist users of insulating coatings by providing general infor- A345 Specification for Flat-Rolled Electrical Steels for

mation about the chemical nature and use of the coatings, as Magnetic Applications

well as to provide important data concerning limits to their use, A677 Specification for Nonoriented Electrical Steel Fully

that is, relative insulating ability, punchability, temperature Processed Types

stability, weldability, and fabricability. Specific surface insula- A683 Specification for Nonoriented Electrical Steel, Semi-

tion resistivity values for each coating are not included in this processed Types

classification. The user is referred to the flat-rolled electrical A717/A717M TestMethodforSurfaceInsulationResistivity

steel specifications noted in 1.2 should more detailed informa- of Single-Strip Specimens

tion concerning surface insulation resistivity values be re- A726 Specification for Cold-Rolled Magnetic Lamination

quired. Quality Steel, Semiprocessed Types

A840 Specification for Fully Processed Magnetic Lamina-

1.2 This classification is to be used in conjunction with the

3

tion Steel (Withdrawn 2011)

various specifications for flat-rolled electrical steels under the

A876 Specification for Flat-Rolled, Grain-Oriented, Silicon-

jurisdiction of CommitteeA06, including Specifications A345,

Iron, Electrical Steel, Fully Processed Types

A677, A683, A726, A840, and A876. However, in those

A937/A937M Test Method for Determining Interlaminar

instances in which the coating descriptions and characteristics

Resistance of Insulating Coatings Using Two Adjacent

differ between this classification and any of the specifications,

Test Surfaces

this classification shall supersede the specification.

1.3 The values stated in customary (cgs-emu and inch-

3. Terminology

pound) units are to be regarded as standard. The values given

3.1 Definitions of Terms Specific to This Standard:

in parentheses are mathematical conversions to SI units which

3.1.1 interlaminar resistance, n—the average resistance of

are provided for information only and are not considered

two adjacent insulating surfaces in contact with each other, in

standard.

accordance with Test Method A937/A937M.

1.4 This standard does not purport to address all of the

3.1.2 stress-relief anneal, n—heat treatment that improves

safety concerns, if any, associated with its use. It is the

the magnetic properties of electrical steel by relieving internal

responsibility of the user of this standard to establish appro-

stresses which are introduced during fabrication of magnetic

priate safety and health practices and determine the applica-

cores.

bility of regulatory limitations prior to use.

1 2

This classification is under the jurisdiction of ASTM CommitteeA06 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Magnetic Properties and is the direct responsibility of SubcommitteeA06.02 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Material Specifications. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2013. Published November 2013. Originally the ASTM website.

3

published in 1997. Last previous edition approved in 2008 as A976 – 03 (2008). The last approved version of this historical standard is referenced on

DOI: 10.1520/A0976-13. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

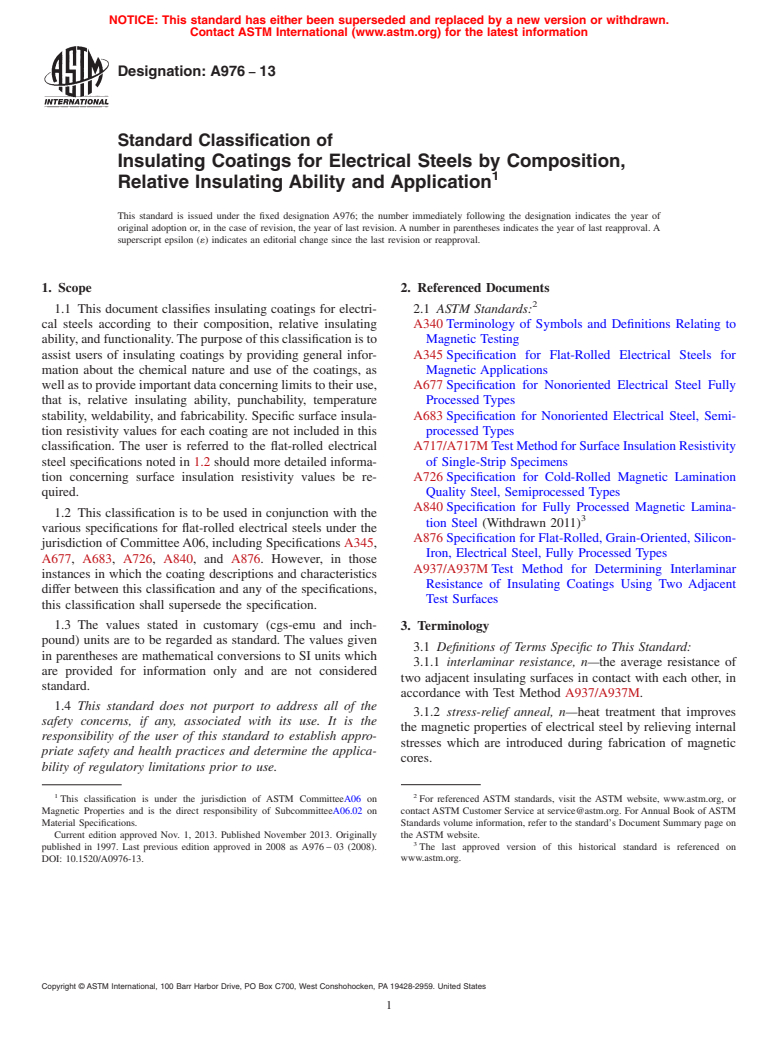

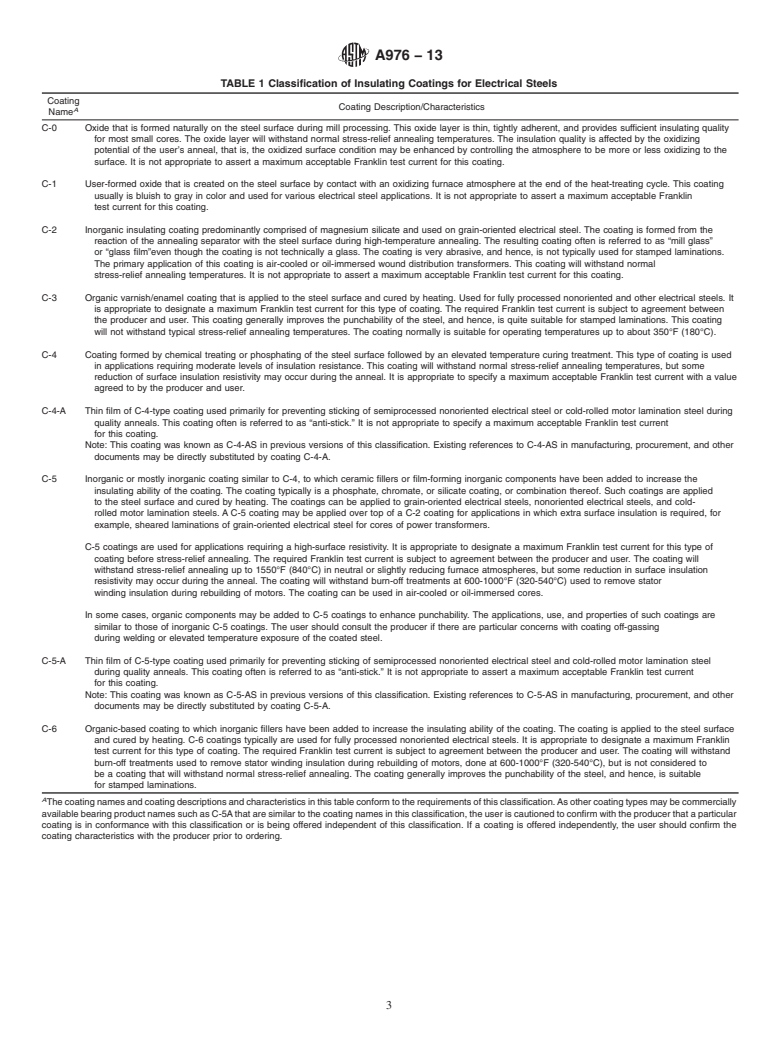

A976−13

3.1.3 surface insulation resistivity, n— the effective resistiv- fied applied voltage. This current value often is referred to as

ity of a single insulating layer tested between applied bare the“FranklinCurrent”andmaybeuseddirectlyasanindicator

metal contacts and the base metal of the insulated test of the quality of the insulation. Specifically, a Franklin Current

specimen, in accordance with Test Method A717/A717M. ofzerocorrespondstoaperfectinsulator.AFranklinCurrentof

1 ampere co

...

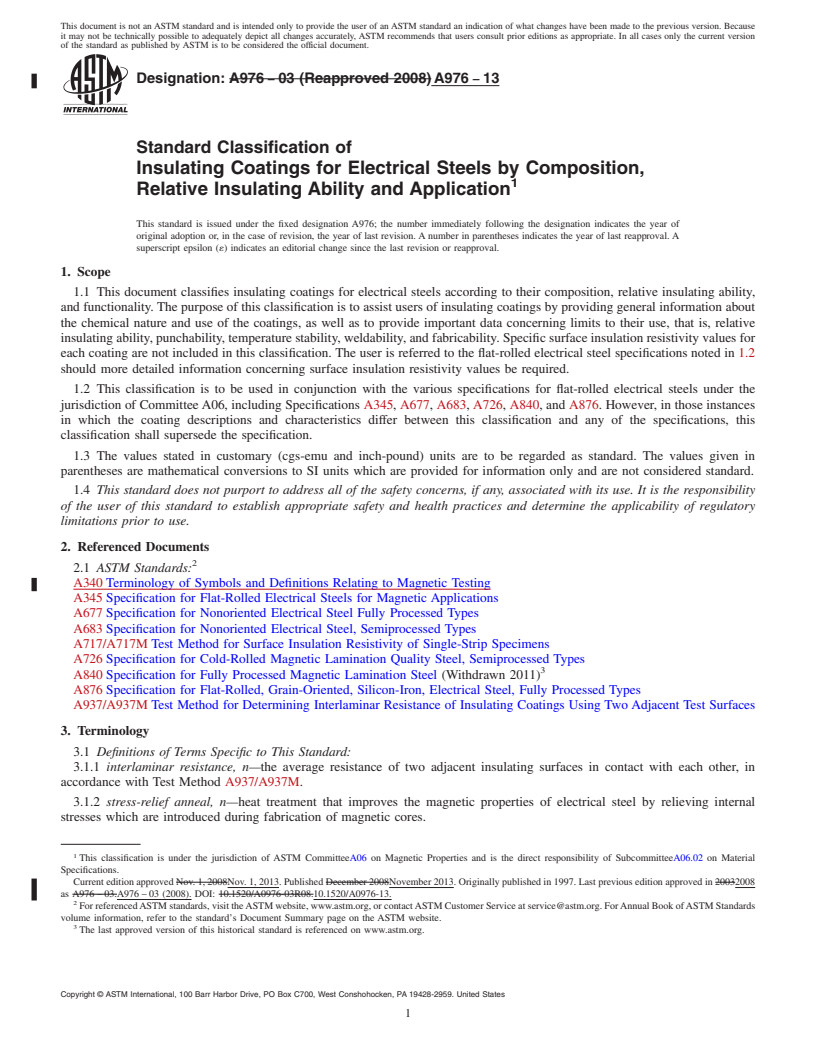

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A976 − 03 (Reapproved 2008) A976 − 13

Standard Classification of

Insulating Coatings for Electrical Steels by Composition,

1

Relative Insulating Ability and Application

This standard is issued under the fixed designation A976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This document classifies insulating coatings for electrical steels according to their composition, relative insulating ability,

and functionality. The purpose of this classification is to assist users of insulating coatings by providing general information about

the chemical nature and use of the coatings, as well as to provide important data concerning limits to their use, that is, relative

insulating ability, punchability, temperature stability, weldability, and fabricability. Specific surface insulation resistivity values for

each coating are not included in this classification. The user is referred to the flat-rolled electrical steel specifications noted in 1.2

should more detailed information concerning surface insulation resistivity values be required.

1.2 This classification is to be used in conjunction with the various specifications for flat-rolled electrical steels under the

jurisdiction of Committee A06, including Specifications A345, A677, A683, A726, A840, and A876. However, in those instances

in which the coating descriptions and characteristics differ between this classification and any of the specifications, this

classification shall supersede the specification.

1.3 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in

parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A340 Terminology of Symbols and Definitions Relating to Magnetic Testing

A345 Specification for Flat-Rolled Electrical Steels for Magnetic Applications

A677 Specification for Nonoriented Electrical Steel Fully Processed Types

A683 Specification for Nonoriented Electrical Steel, Semiprocessed Types

A717/A717M Test Method for Surface Insulation Resistivity of Single-Strip Specimens

A726 Specification for Cold-Rolled Magnetic Lamination Quality Steel, Semiprocessed Types

3

A840 Specification for Fully Processed Magnetic Lamination Steel (Withdrawn 2011)

A876 Specification for Flat-Rolled, Grain-Oriented, Silicon-Iron, Electrical Steel, Fully Processed Types

A937/A937M Test Method for Determining Interlaminar Resistance of Insulating Coatings Using Two Adjacent Test Surfaces

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 interlaminar resistance, n—the average resistance of two adjacent insulating surfaces in contact with each other, in

accordance with Test Method A937/A937M.

3.1.2 stress-relief anneal, n—heat treatment that improves the magnetic properties of electrical steel by relieving internal

stresses which are introduced during fabrication of magnetic cores.

1

This classification is under the jurisdiction of ASTM CommitteeA06 on Magnetic Properties and is the direct responsibility of SubcommitteeA06.02 on Material

Specifications.

Current edition approved Nov. 1, 2008Nov. 1, 2013. Published December 2008November 2013. Originally published in 1997. Last previous edition approved in 20032008

as A976 – 03.A976 – 03 (2008). DOI: 10.1520/A0976-03R08.10.1520/A0976-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

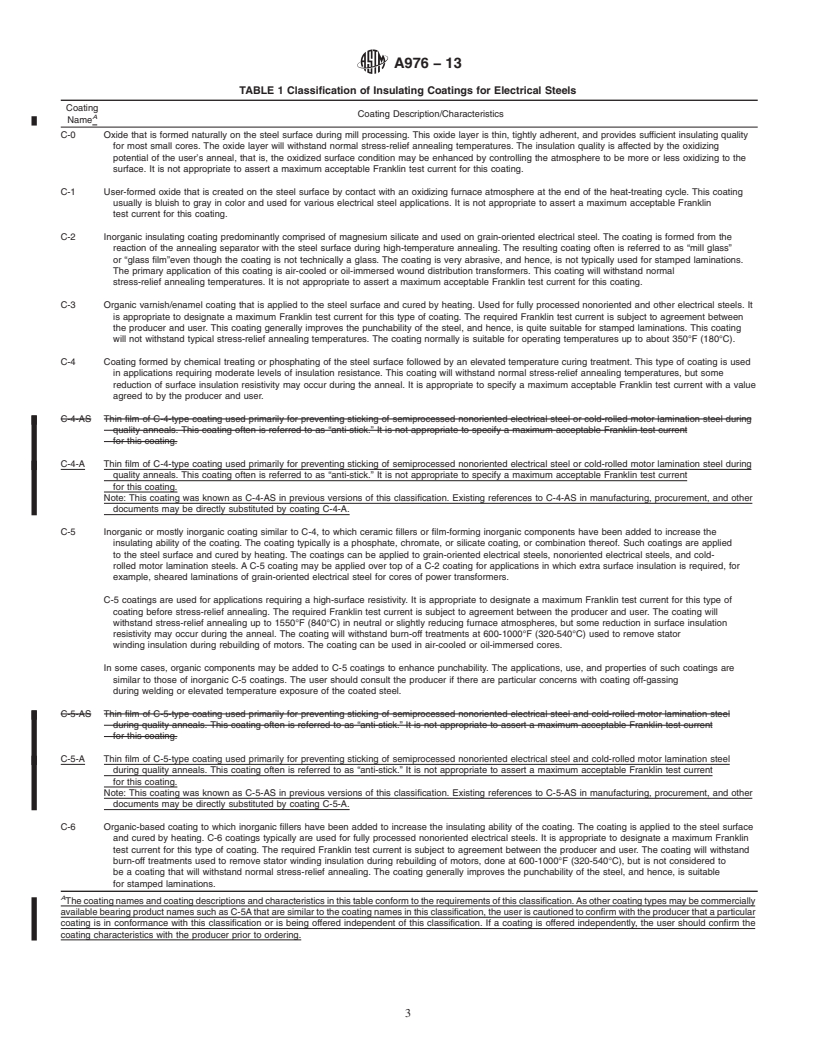

---------------------- Page: 1 ----------------------

A976 − 13

3.1.3 surface insulation resistivity, n— the effective resistivity of a single insulating layer tested between applied ba

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.