ASTM C204-07

(Test Method)Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus

Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus

ABSTRACT

This test method covers determination of the fineness of hydraulic cement, using the Blaine air-permeability apparatus, in terms of the specific surface expressed as total surface area in square centimetres per gram, or square metres per kilogram, of cement. Two test methods are given: test method A is the reference test method using the manually operated standard Blaine apparatus, while test method B permits the use of automated apparatus that has in accordance with the qualification requirements of this test method demonstrated acceptable performance. The Blaine air-permeability apparatus consists essentially of a means of drawing a definite quantity of air through a prepared bed of cement of definite porosity. The permeability cell shall consist of a rigid cylinder, constructed of austenitic stainless steel. The disk shall be constructed of noncorroding metal, and shall fit the inside of the cell snugly. The plunger shall be constructed of austenitic stainless steel and shall fit into the cell. The filter paper disks shall be circular, with smooth edges, and shall have the same diameter as the inside of the cell. The U-tube manometer shall be constructed according to the design indicated. The manometer shall be filled to the midpoint line with a nonvolatile, nonhygroscopic liquid of low viscosity and density. The timer shall have a positive starting and stopping mechanism. The calibration of the air permeability apparatus shall be made using the standard reference material. The automated test method shall employ apparatus designed either on the principles of the Blaine air-permeability method or apparatus based on the air-permeability principles of the Lea and Nurse method. When the specific surface values determined by an automated apparatus are to be used for acceptance or rejection of cement, the method used shall comply with the qualification requirements. When standardization is required in order to achieve agreement between test method A and test method B, the apparatus shall be standardized according to the requirements prescribed.

SCOPE

1.1 This test method covers determination of the fineness of hydraulic cement, using the Blaine air-permeability apparatus, in terms of the specific surface expressed as total surface area in square centimetres per gram, or square metres per kilogram, of cement. Two test methods are given: Test Method A is the Reference Test Method using the manually operated standard Blaine apparatus, while Test Method B permits the use of automated apparatus that has in accordance with the qualification requirements of this test method demonstrated acceptable performance. Although the test method may be, and has been, used for the determination of the measures of fineness of various other materials, it should be understood that, in general, relative rather than absolute fineness values are obtained.

1.1.1 This test method is known to work well for portland cements. However, the user should exercise judgement in determining its suitability with regard to fineness measurements of cements with densities, or porosities that differ from those assigned to Standard Reference Material No. 114.

1.2 The values stated in SI units are to be regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation: C204 – 07 Highway and Transportation Officials Standard

AASHTO No.: T 153

Standard Test Methods for

Fineness of Hydraulic Cement by Air-Permeability

1

Apparatus

This standard is issued under the fixed designation C204; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E832 Specification for Laboratory Filter Papers

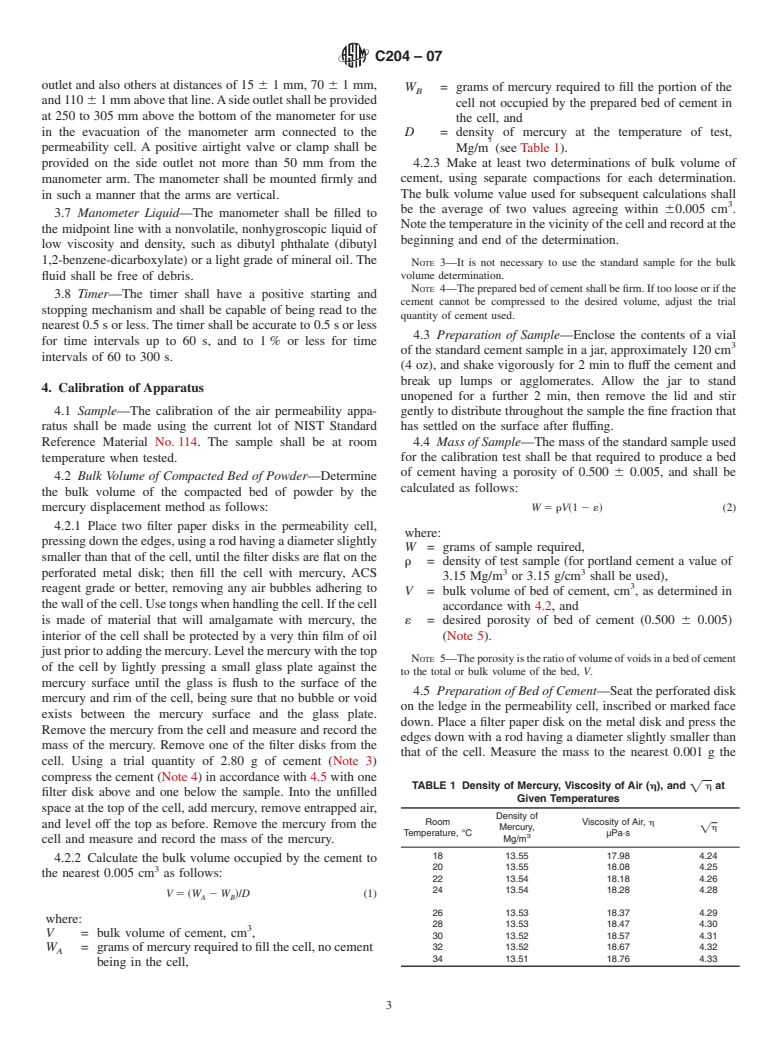

2.2 Other Document:

1.1 This test method covers determination of the fineness of

No. 114 National Institute of Standards and Technology

hydraulic cement, using the Blaine air-permeability apparatus,

3

Standard Reference Material

in terms of the specific surface expressed as total surface area

BS 4359: 1971 British Standard Method for the Determina-

in square centimetres per gram, or square metres per kilogram,

tion of Specific Surface of Powders: Part 2: Air Perme-

of cement. Two test methods are given: Test Method A is the

4

ability Methods

Reference Test Method using the manually operated standard

Blaine apparatus, while Test Method B permits the use of

TEST METHOD A: REFERENCE METHOD

automated apparatus that has in accordance with the qualifica-

tion requirements of this test method demonstrated acceptable

3. Apparatus

performance. Although the test method may be, and has been,

3.1 Nature of Apparatus—The Blaine air-permeability ap-

used for the determination of the measures of fineness of

paratus consists essentially of a means of drawing a definite

various other materials, it should be understood that, in

quantity of air through a prepared bed of cement of definite

general, relative rather than absolute fineness values are

porosity.The number and size of the pores in a prepared bed of

obtained.

definite porosity is a function of the size of the particles and

1.1.1 This test method is known to work well for portland

determines the rate of airflow through the bed. The apparatus,

cements. However, the user should exercise judgement in

illustrated in Fig. 1, shall consist specifically of the parts

determining its suitability with regard to fineness measure-

described in 3.2-3.8.

ments of cements with densities, or porosities that differ from

3.2 Permeability Cell—The permeability cell shall consist

those assigned to Standard Reference Material No. 114.

of a rigid cylinder 12.70 6 0.10 mm in inside diameter,

1.2 The values stated in SI units are to be regarded as the

constructed of austenitic stainless steel. The interior of the cell

standard.

shallhaveafinishof0.81µm(32µin.).Thetopofthecellshall

1.3 This standard does not purport to address all of the

be at right angles to the principal axis of the cell. The lower

safety concerns, if any, associated with its use. It is the

portion of the cell must be able to form an airtight fit with the

responsibility of the user of this standard to establish appro-

upper end of the manometer, so that there is no air leakage

priate safety and health practices and determine the applica-

1

between the contacting surfaces. A ledge ⁄2 to 1 mm in width

bility of regulatory limitations prior to use.

shall be an integral part of the cell or be firmly fixed in the cell

55 6 10 mm from the top of the cell for support of the

2. Referenced Documents

perforated metal disk. The top of the permeability cell shall be

2

2.1 ASTM Standards:

fitted with a protruding collar to facilitate the removal of the

A582/A582M Specification for Free-Machining Stainless

cell from the manometer.

Steel Bars

NOTE 1—Specification A582/A582M Type 303 stainless steel (UNS

C670 Practice for Preparing Precision and Bias Statements

designation S30300) has been found to be suitable for the construction of

for Test Methods for Construction Materials

the permeability cell and the plunger.

3.3 Disk—The disk shall be constructed of noncorroding

1

metal and shall be 0.9 6 0.1 mm in thickness, perforated with

This test method is under the jurisdiction ofASTM Committee C01 on Cement

and is the direct responsibility of Subcommittee C01.25 on Fineness. 30 to 40 holes 1 mm in diameter equally distributed over its

Current edition approved Aug. 1, 2007. Published September 2007. Originally

approved in 1946. Last previous edition approved in 2005 as C204 – 05. DOI:

10.1520/C0204-07.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from National Institute of Standards and Technology (NIST), 100

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

4

Standards volume information, refer to the standard’s Document Summary page on Available from British

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.