ASTM F72-95(2001)

(Specification)Standard Specification for Gold Wire for Semiconductor Lead Bonding

Standard Specification for Gold Wire for Semiconductor Lead Bonding

SCOPE

1.1 This specification covers round drawn/extruded gold wire for internal semiconductor device electrical connections. Four classifications of wire are distinguished, (1) copper-modified wire, (2) beryllium-modified wire, ( 3) high-strength wire, and (4) special purpose wire.

Note 1--Trace metallic elements have a significant effect upon the mechanical properties and thermal stability of high-purity gold wire. It is customary in manufacturing to add controlled amounts of selected impurities to gold to modify or stabilize bonding wire properties or both. This practice is known variously as "modifying,"" stabilizing," or "doping." The first two wire classifications denoted in this specification refer to wire made with either of two particular modifiers, copper or beryllium, in general use. In the third and fourth wire classifications, "high-strength" and "special purpose" wire, the identity of modifying additives is not restricted.

1.2 The values stated in SI units shall be regarded as the standard.

1.2.1 A mixed system of metric and inch-pound units is in widespread use for specifying semiconductor lead-bonding wire. SI-equivalent values of other commonly used units are denoted by parentheses in text and tables.

1.3 The following hazard caveat pertains only to the test method portion, Section 9, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 72 – 95 (Reapproved 2001)

Standard Specification for

Gold Wire for Semiconductor Lead Bonding

ThisstandardisissuedunderthefixeddesignationF72;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope F 219 Test Methods of Testing Fine Round and Flat Wire

for Electron Devices and Lamps

1.1 This specification covers round drawn/extruded gold

F 584 Practice for Visual Inspection of Semiconductor

wire for internal semiconductor device electrical connections.

Lead-Bonding Wire

Four classifications of wire are distinguished, (1) copper-

modified wire, (2) beryllium-modified wire, ( 3) high-strength

3. Ordering Information

wire, and (4) special purpose wire.

3.1 Orders for material under this specification shall include

NOTE 1—Trace metallic elements have a significant effect upon the

the following information:

mechanical properties and thermal stability of high-purity gold wire. It is

3.1.1 Classification: copper-modified, beryllium-modified,

customary in manufacturing to add controlled amounts of selected

high strength, or special purpose,

impurities to gold to modify or stabilize bonding wire properties or both.

3.1.2 Quantity,

This practice is known variously as “modifying,”“ stabilizing,” or

3.1.3 Purity (Section 4),

“doping.” The first two wire classifications denoted in this specification

refer to wire made with either of two particular modifiers, copper or 3.1.4 Type, hard, stress relieved, or annealed (Section 5),

beryllium, in general use. In the third and fourth wire classifications,

3.1.5 Breaking load and percentage elongation range (Sec-

“high-strength” and “special purpose” wire, the identity of modifying

tion 5),

additives is not restricted.

3.1.6 Wire diameter (Section 6),

1.2 The values stated in SI units shall be regarded as the

3.1.7 Spool type, length of wire per spool, and type of wind

standard.

(Section 11),

1.2.1 A mixed system of metric and inch-pound units is in

3.1.8 Despooling, left-handed unwind or right-handed un-

widespread use for specifying semiconductor lead-bonding

wind (Section 11), and,

wire. SI-equivalent values of other commonly used units are

3.1.9 Packaging and marking (Section 12).

denoted by parentheses in text and tables.

4. Chemical Composition

1.3 The following hazard caveat pertains only to the test

method portion, Section 9, of this specification. This standard

4.1 Copper-modified material shall conform to the chemical

does not purport to address all of the safety concerns, if any,

requirements specified in Table 1.

associatedwithitsuse.Itistheresponsibilityoftheuserofthis

4.2 Beryllium-modified material shall conform to the

standard to establish appropriate safety and health practices

chemical requirements specified in Table 2.

and determine the applicability of regulatory limitations prior

4.3 High-strength material shall conform to the chemical

to use.

requirements specified in Table 3.

4.4 Special purpose material shall be in accordance with

2. Referenced Documents

Table 4.

2.1 ASTM Standards:

NOTE 2—Copper-modified wire is used on thermocompression wire

F 16 TestMethodsforMeasuringDiameterorThicknessof

bonding machines. Beryllium-modified material is often preferred on

Wire and Ribbon for Electronic Devices and Lamps

high-speed automated thermocompression or thermosonic bonding equip-

F 205 Test Method for Measuring Diameter of Fine Wire

ment. High-strength wire was developed for use on some very high speed

by Weighing

automated thermosonic bonders.

5. Mechanical Properties

This specification is under the jurisdiction of ASTM Committee F01 on

5.1 Material specified by this standard may be either of two

Electronics and is the direct responsibility of Subcommittee F01.07 on Wire

Bonding.

types:

Current edition approved April 15, 1995. Published June 1995. Originally

5.1.1 Hard—Wire, as drawn/as extruded.

published as F 72 – 66 T. Last previous edition F 72 – 94.

5.1.2 Annealed—Wire, annealed after drawing/extruding.

Annual Book of ASTM Standards, Vol 10.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F72

TABLE 1 Chemical Requirements, Copper-Modified Gold TABLE 6 Breaking Load and Elongation of Hard Wire—

Bonding Wire Beryllium-Modified Gold and High-Strength Gold

Element Composition, Weight, % Nominal Diameter, Breaking Load, min, N Elongation in 254 mm

µm (in.) (gf) 10.0 in.), %

Gold, min 99.99

Beryllium, max 0.0001 13 (0.00050) 0.039 (4.0) 0.5 to 2.0, incl

Copper 0.003–0.006 18 (0.00070) 0.069 (7.0) 0.5 to 2.0, incl

Silver, max 0.006 20 (0.00080) 0.088 (9.0) 0.5 to 2.0, incl

Other impurities, max each 0.003 23 (0.00090) 0.147 (15.0) 1.0 to 2.5, incl

Total of all detectable elements, max 0.01 25 (0.0010) 0.177 (18.0) 1.0 to 2.5, incl

28 (0.0011) 0.216 (22.0) 1.0 to 2.5, incl

30 (0.0012) 0.265 (27.0) 1.0 to 2.5, incl

31.8 (0.00125) 0.284 (29.0) 1.0 to 2.5, incl

TABLE 2 Chemical Requirements, Beryllium-Modified Gold

33 (0.0013) 0.314 (32.0) 1.0 to 2.5, incl

Bonding Wire

38 (0.0015) 0.392 (40.0) 1.0 to 2.5, incl

51 (0.0020) 0.736 (75.0) 1.0 to 3.0, incl

Element Composition, Weight, %

Gold, min 99.99

Beryllium 0.0003–0.0010

TABLE 7 Breaking Load and Elongation of Stress Relieved/

Other impurities, max each 0.003

Total of all detectable impurities, max 0.01 Annealed Wire—Copper-Modified Gold

Nominal Breaking Load, Elongation in 254 mm

Diameter, min, (10.0 in.), %

µm (in.) N(gf)

TABLE 3 Chemical Requirements, High-Strength Gold Bonding A

Min Max Range

Wire

13 (0.00050) 0.0098 (1.0) 0.5 3.0 2

Element Composition, Weight, %

18 (0.00070) 0.020 (2.0) 0.5 7.0 3

20 (0.00080) 0.029 (3.0) 0.5 8.0 3

Gold, min 99.99

23 (0.00090) 0.049 (5.0) 0.5 8.0 3

Total of all detectable impurities, max 0.01

25 (0.0010) 0.059 (6.0) 0.5 10.0 3

28 (0.0011) 0.069 (7.0) 0.5 10.0 3

30 (0.0012) 0.078 (8.0) 0.5 10.0 3

31.8 (0.00125) 0.088 (9.0) 0.5 10.0 3

TABLE 4 Chemical Requirements, Special Purpose Gold

33 (0.0013) 0.0981 (10.0) 0.5 10.0 3

Bonding Wire

38 (0.0015) 0.118 (12.0) 0.5 12.0 4

Element Composition, Weight, %

51 (0.0020) 0.196 (20.0) 0.5 15.0 4

A

Gold Not restricted

A range of permissible elongation of at least the number of percentage points

Other principal elements Not restricted

shown shall be selected from within the overall range designated by the minimum

Total of all detectable elements Not restricted

and maximum values for the given diameter. For example, for wire of 25-µm

(0.0010-in.) diameter, copper-modified gold wire, permissible elongation of 4.0 to

7.0, 6.0 to 9.0, 7.0 to 10.0 %, etc., may be selected.

5.2 Breaking Load and Elongation—The tension test shall

TABLE 8 Breaking Load and Elongation of Stress Relieved/

be the standard test for determining the mechanical properties,

Annealed Wire—Beryllium-Modified Gold

and acceptance or rejection shall depend on the breaking load

Nominal Breaking Load, Elongation in 254 mm

and percent elongation at failure of a 254-mm (10.0-in.) length

Diameter, min, (10.0 in.), %

of wire.

µm (in.) N(gf)

A

Min Max Range

5.2.1 Hard wire shall conform to the requirements of Table

13 (0.00050) 0.020 (2.0) 0.5 3.0 2

5 for copper-modified gold wire and to the requirements of

18 (0.00070) 0.029 (3.0) 0.5 7.0 3

Table 6 for beryllium-modified gold wire.

20 (0.00080) 0.039 (4.0) 0.5 8.0 3

5.2.2 Stress relieved/annealed wire shall conform to the 23 (0.00090) 0.059 (6.0) 0.5 8.0 3

25 (0.0010) 0.069 (7.0) 0.5 10.0 3

requirements of Table 7 for copper-modified gold wire, the

28 (0.0011) 0.078 (8.0) 0.5 10.0 3

requirements of Table 8 for beryllium-modified gold wire, to

30 (0.0012) 0.0981 (10.0) 0.5 10.0 3

31.8 (0.00125) 0.108 (11.0) 0.5 10.0 3

the requirements of Table 9 for high-strength wire, and to the

33 (0.0013) 0.118 (12.0) 0.5 10.0 3

requirements of Table 10 for special purpose wire.

38 (0.0015) 0.147 (15.0) 0.5 12.0 4

51 (0.0020) 0.245 (25.0) 0.5 15.0 4

A

TABLE 5 Breaking Load and Elongation of Hard Wire—Copper-

A range of permissible elongation of at least the number of percentage points

Modified Gold

shown shall be selected from within the overall range designated by the minimum

and maximum values for the given diameter. For example, for wire of 25-µm

Nominal Diameter, Breaking Load, min, N Elongation in 254 mm

(0.0010-in.) diameter, permissible elongation of 4.0 to 7.0, 6.0 to 9.0, 7.0 to 10.0 %,

µm (in.) (gf) (10.0 in.), %

etc., may be selected.

13 (0.00050) 0.029 (3.0) 0.5 to 2.0, incl

18 (0.00070) 0.059 (6.0) 0.5 to 2.0, incl

20 (0.00080) 0.078 (8.0) 0.5 to 2.0, incl

23 (0.00090) 0.127 (13.0) 1.0 to 2.5, incl

NOTE 3—Hard wire is generally used for ultrasonic wire bonding.

25 (0.0010) 0.157 (16.0) 1.0 to 2.5, incl

Annealed wire is used for thermocompression and thermosonic bonding.

28 (0.0011) 0.196 (20.0) 1.0 to 2.5, incl

30 (0.0012) 0.235 (24.0) 1.0 to 2.5, incl

6. Dimensions and Permissible Variations

31.8 (0.00125) 0.255 (26.0) 1.0 to 2.5, incl

33 (0.0013) 0.275 (28.0) 1.0 to 2.5, incl

6.1 Wire diameters shall be expressed in µm (or equivalent

38 (0.0015) 0.343 (35.0) 1.0 to 2.5, incl

decimal fractions of an inch). Tolerances for the various size

51 (0.0020) 0.686 (70.0) 1.0 to 3.0, incl

ranges are specified in Table 11.

F72

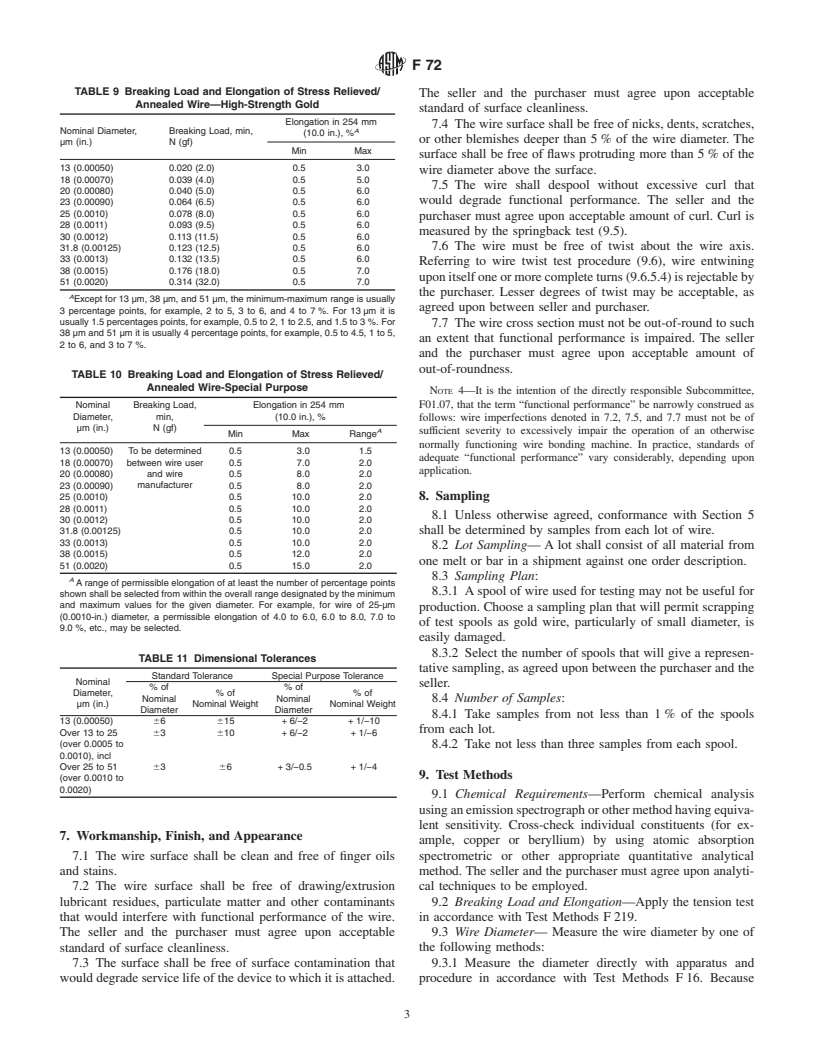

TABLE 9 Breaking Load and Elongation of Stress Relieved/

The seller and the purchaser must agree upon acceptable

Annealed Wire—High-Strength Gold

standard of surface cleanliness.

Elongation in 254 mm

7.4 The wire surface shall be free of nicks, dents, scratches,

A

Nominal Diameter, Breaking Load, min,

(10.0 in.), %

or other blemishes deeper than 5 % of the wire diameter. The

µm (in.) N(gf)

Min Max

surface shall be free of flaws protruding more than 5 % of the

13 (0.00050) 0.020 (2.0) 0.5 3.0

wire diameter above the surface.

18 (0.00070) 0.039 (4.0) 0.5 5.0

7.5 The wire shall despool without excessive curl that

20 (0.00080) 0.040 (5.0) 0.5 6.0

would degrade functional performance. The seller and the

23 (0.00090) 0.064 (6.5) 0.5 6.0

25 (0.0010) 0.078 (8.0) 0.5 6.0

purchaser must agree upon acceptable amount of curl. Curl is

28 (0.0011) 0.093 (9.5) 0.5 6.0

measured by the springback test (9.5).

30 (0.0012) 0.113 (11.5) 0.5 6.0

7.6 The wire must be free of twist about the wire axis.

31.8 (0.00125) 0.123 (12.5) 0.5 6.0

33 (0.0013) 0.132 (13.5) 0.5 6.0

Referring to wire twist test procedure (9.6), wire entwining

38 (0.0015) 0.176 (18.0) 0.5 7.0

uponitselfoneormorecompleteturns(9.6.5.4)isrejectableby

51 (0.0020) 0.314 (32.0) 0.5 7.0

the purchaser. Lesser degrees of twist may be acceptable, as

A

Except for 13 µm, 38 µm, and 51 µm, the minimum-maximum range is usually

agreed upon between seller and purchaser.

3 percentage points, for example, 2 to 5, 3 to 6, and 4 to 7 %. For 13 µm it is

usually 1.5 percentages points, for example, 0.5 to 2, 1 to 2.5, and 1.5 to 3 %. For

7.7 The wire cross section must not be out-of-round to such

38 µm and 51 µm it is usually 4 percentage points, for example, 0.5 to 4.5, 1 to 5,

an extent that functional performance is impaired. The seller

2to6,and3to7%.

and the purchaser must agree upon acceptable amount of

out-of-roundness.

TABLE 10 Breaking Load and Elongation of Stress Relieved/

Annealed Wire-Special Purpose

NOTE 4—It is the intention of the directly responsible Subcommittee,

F01.07, that the term “functional performance” be narrowly construed as

Nominal Breaking Load, Elongation in 254 mm

Diameter, min, (10.0 in.), %

follows: wire imperfections denoted in 7.2, 7.5, and 7.7 must not be of

µm (in.) N(gf)

A sufficient severity to excessively impair the operation of an otherwise

Min Max Range

normally functioning wire bonding machine. In practice, standards of

13 (0.00050) To be determined 0.5 3.0 1.5

adequate “functional performance” vary considerably, depending upon

18 (0.00070) between wire user 0.5 7.0 2.0

application.

20 (0.00080) and wire 0.5 8.0 2.0

23 (0.00090) manufacturer 0.5 8.0 2.0

8. Sampling

25 (0.0010) 0.5 10.0 2.0

28 (0.0011) 0.5 10.0 2.0

8.1 Unless otherwise agreed, conformance with Section 5

30 (0.0012) 0.5 10.0 2.0

31.8 (0.00125) 0.5 10.0 2.0 shall be determined by samples from each lot of wire.

33 (0.0013) 0.5 10.0 2.0

8.2 Lot Sampling— A lot shall consist of all material from

38 (0.0015) 0.5 12.0 2.0

one melt or bar in a shipment against one order description.

51 (0.0020) 0.5 15.0 2.0

8.3 Sampling Plan:

A

A range of permissible elongation of at least the number of percentage points

8.3.1 Aspool of wire used for testing may not be useful for

shown shall be selected from within the overall range designated by the minimum

and maximum values for the given diameter. For example, for wire of 25-µm

production. Choose a sampling plan that will permit scrapping

(0.0010-in.) diameter, a permissible elongation of 4.0 to 6.0, 6.0 to 8.0, 7.0 to

of test spools as gold wire, particularly of small diameter, is

9.0 %, etc., may be selected.

easily damaged.

8.3.2 Select the number of spools that will give a represen-

TABLE 11 Dimensional Tolerances

tative sampling, as agreed upon between the purchaser and the

Standard Tolerance Special Purpose Tolerance

Nominal

seller.

%of %of

Diameter, %of %of

Nominal Nominal 8.4 Number of Samples:

µm (in.) Nominal Weight Nominal Weight

Diameter Diameter

8.4.1 Take samples from not less than 1 % of the spools

13 (0.00050) 66 615 + 6/−2 + 1/−10

from each lot.

Over 13 to 25 63 610 + 6/−2 + 1/−6

(over 0.0005 to

8.4.2 Take not less than three samples from each spool.

0.0010), incl

Over 25 to 51 63 66 + 3/−0.5 + 1/−4

9. Test Methods

(over 0.0010 to

0.0020)

9.1 Chemical Requirements—Perform chemical analysis

usinganemissionspectrographorothermethodhavingequiva-

lent sensitivity. Cross-check individual constituents (for ex-

7. Workmanship, Finish, and Appearance

ample, copper or beryllium) by using atomic absorption

7.1 The wire surface shall be clean and free of finger oils spectrometric or other appropriate quantitative analytical

and stains. method. The seller and the purchaser must agree upon analyti-

7.2 The wire surface shall be free of drawing/extrusion cal techniques to be employed.

lubricant residues, particulate matter and other contaminants 9.2 Breaking Load and Elongation—Apply the tension test

that would interfere with functional performance of the wire. in accordance with Test Methods F 219.

The seller and the purchaser must agree upon acceptable 9.3 Wire Diameter— Measure the wire diameter by one of

standard of surface cleanliness. the following methods:

7.3 The surface shall be free of surface contamination that 9.3.1 Measure the diameter directly with apparatus and

would degrade

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.