ASTM D1044-99

(Test Method)Standard Test Method for Resistance of Transparent Plastics to Surface Abrasion

Standard Test Method for Resistance of Transparent Plastics to Surface Abrasion

SCOPE

1.1 This test method describes a procedure for estimating the resistance of transparent plastics to one kind of surface abrasion by measurement of its optical effects.

1.2 Abrasive damage is judged by that percentage of transmitted light which, in passing through the abraded track, deviates from the incident beam by forward scattering. For the purpose of this test method, only light flux deviating more than 0.044 rad (2.5°) on the average is considered in this assessment of abrasive damage.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only. Note 1-Recent attempts to employ the Taber Abraser for volume loss determinations of various plastics, like earlier ones, have been unsuccessful because of excessively large coefficients of variation attributed to the data. Insufficient agreement among the participating laboratories has rendered the use of volume loss procedure inadvisable as an ASTM test method. Note 2-For determining resistance to abrasion of plastics by measurement of volume loss, reference should be made to Test Methods D1242. Note 3-For determining the resistance to abrasion of organic coatings by weight loss, reference is made to Test Method D4060. This test uses more aggressive CS-10 or CS-17 abrasive wheels. It suffers from poor reproducibility between laboratories when numerical abrasion resistance values are used. Interlaboratory agreement improves significantly when ranking a series of coatings for their abrasion resistance. Note 4-This test method is similar to ISO 3444, and ISO 4586/2. Their technical content is somewhat different.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For a specific precautionary statement, see 7.1.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1044 – 99

Standard Test Method for

Resistance of Transparent Plastics to Surface Abrasion

This standard is issued under the fixed designation D 1044; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * 2. Referenced Documents

1.1 This test method describes a procedure for estimating 2.1 ASTM Standards:

the resistance of transparent plastics to one kind of surface D 618 Practice for Conditioning Plastics and Electrical

abrasion by measurement of its optical effects. Insulating Materials for Testing

1.2 Abrasive damage is judged by that percentage of trans- D 1003 Test Method for Haze and Luminous Transmittance

mitted light which, in passing through the abraded track, of Transparent Plastics

deviates from the incident beam by forward scattering. For the D 1242 Test Methods for Resistance of Plastic Materials to

purpose of this test method, only light flux deviating more than Abrasion

0.044 rad (2.5°) on the average is considered in this assessment D 2240 Test Method for Rubber Property—Durometer

of abrasive damage. Hardness

1.3 The values stated in SI units are to be regarded as the D 4000 Classification System for Specifying Plastic Mate-

standard. The values given in parentheses are for information rials

only. D 4060 Test Method for Abrasion Resistance of Organic

Coatings by the Taber Abraser

NOTE 1—Recent attempts to employ the TaberAbraser for volume loss

2 E 691 Practice for Conducting an Interlaboratory Study to

determinations of various plastics, like earlier ones, have been unsuc-

Determine the Precision of a Test Method

cessful because of excessively large coefficients of variation attributed to

the data. Insufficient agreement among the participating laboratories has 2.2 ISO Standards:

rendered the use of volume loss procedure inadvisable as an ASTM test

ISO 3444 Paper and Board Determination of Abrasion

method.

Resistance

NOTE 2—For determining resistance to abrasion of plastics by mea-

ISO 4586/2 Abrasion Resistance of Decorative Laminated

surement of volume loss, reference should be made to Test Methods

Sheets

D 1242.

ISO 9352–89 Plastics—Determination of Resistance to

NOTE 3—For determining the resistance to abrasion of organic coatings

Wear Abrasive Wheels

byweightloss,referenceismadetoTestMethodD 4060.Thistestmethod

uses more aggresive CS-10 or CS-17 abrasive wheels. It suffers from poor

3. Terminology

reproducibility between laboratories when numerical abrasion resistance

values are used. Interlaboratory agreement improves significantly when

3.1 Definitions:

ranking a series of coatings for their abrasion resistance.

3.1.1 abrasion—abrasive wear caused by displacement or

NOTE 4—ThistestmethodissimilartoISO3444andISO4586/2.Their

rearrangement of a softer material due to rubbing or scuffing

technicalcontentissomewhatdifferent.ThistestmethodandISO9352-89

against hard sharp particles.

are not technically equivalent.

3.1.2 haze—See definitions in Test Method D 1003.

1.4 This standard does not purport to address all of the

3.1.3 reface—preparation of an abrasive wheel on a condi-

safety concerns, if any, associated with its use. It is the

tioning stone prior to use in testing.

responsibility of the user of this standard to establish appro-

3.1.4 wheel—an abrasive wheel consisting of hard particles

priate safety and health practices and determine the applica-

(aluminum oxide) embedded in rubber.

bility of regulatory limitations prior to use. For a specific

precautionary statement, see 8.1.2.

Annual Book of ASTM Standards, Vol 08.01.

1 4

ThistestmethodisunderthejurisdictionofASTMCommitteeD-20onPlastics Annual Book of ASTM Standards, Vol 09.01.

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. Annual Book of ASTM Standards, Vol 08.02.

Current edition approved July 10, 1999. Published October 1999. Originally Annual Book of ASTM Standards, Vol 06.01.

published as D 1044 – 49. Last previous edition D 1044 – 94. Annual Book of ASTM Standards, Vol 14.02.

2 8

Supporting data are available from ASTM Headquarters. Request RR:D20-48 Available from American National Standards Institute, 11 W. 42nd St., 13th

and RR:D20-1090. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 1044

4. Significance and Use

4.1 Transparent plastic materials, when used as windows or

enclosures, are subject to wiping and cleaning; hence the

maintenance of optical quality of a material after abrasion is

important. It is the purpose of this test method to provide a

meansofestimatingtheresistanceofsuchmaterialstothistype

and degree of abrasion.

4.2 Although this test method does not provide fundamental

data, it is suitable for grading materials relative to this type of

abrasion in a manner which correlates with service.

4.3 Comparison of interlaboratory data or the specification

of a “haze” value has no significance if the hazemeter

requirements given in Section 4 are not used. This is because

light diffused from the surface of a Taber track is scattered at

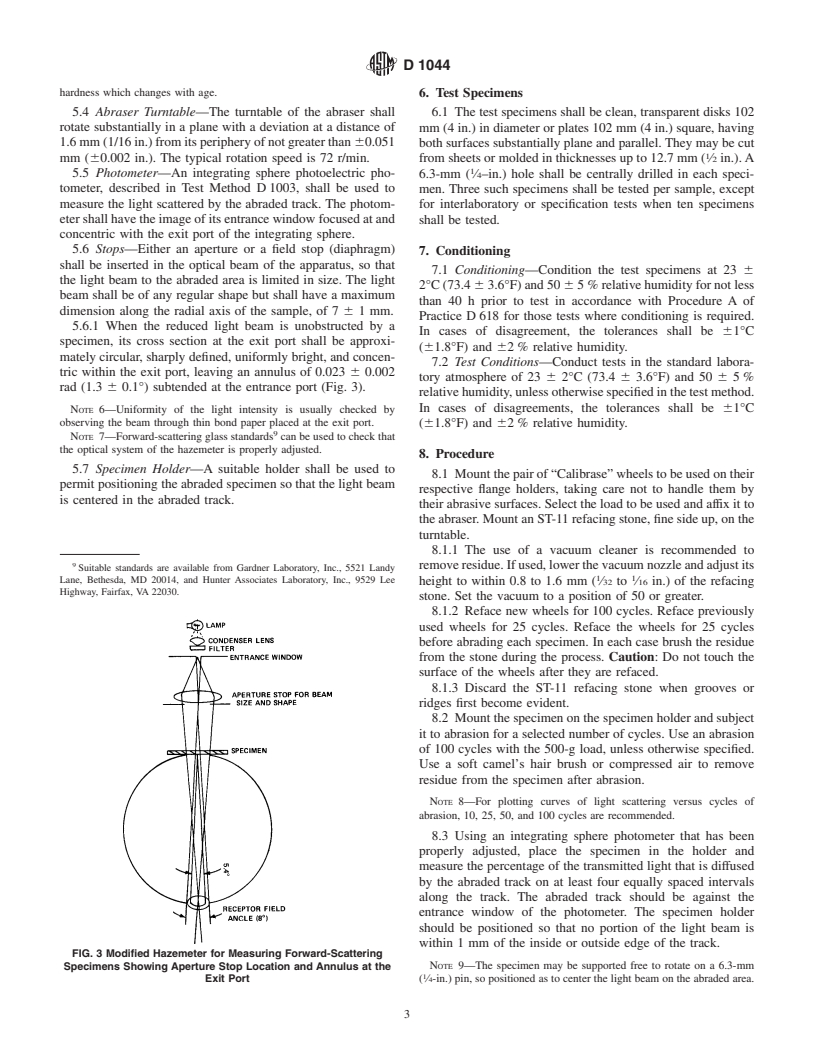

a narrow angle (Fig. 1 and Fig. 2) while light diffused

internally by a specimen is scattered at a wide angle. In many

hazemeters, when a diaphragm is inserted to limit the light

beam to the width of the abraded track, the specular beam at

the exit port becomes smaller. The dark annulus will then be

greater than the 0.023 6 0.002 rad (1.3 6 0.1°) requirements

of Test Method D 1003. Since a large percentage of the

narrow-angle forward-scattered light will not impinge on the

sphere wall,“ haze” readings become smaller. For hazemeters

NOTE 1—This graph shows goniophotometric curves for Taber abraded

that have not been properly adjusted, the magnitude of this tracks. The specular angle of transmission is at 180°.

FIG. 2 Light Scattering from Surface of Abraded Tracks (Graph)

reduction is dependent both on the integrating sphere diameter

and the reduction of the entrance beam.

4.4 For many materials, there may be a specification that

requires the use of this test method, but with some procedural

modifications that take precedence when adhering to the

specification. Therefore, it is advisable to refer to that material

specification before using this test method. Table 1 of Classi-

ficationSystemD 4000liststheASTMmaterialsstandardsthat

currently exist.

5. Apparatus

5.1 Abrader—The Taber abraser or its equivalent, so con-

structed that wheels of several degrees of abrasiveness may be

readily used. Loads of 250, 500, or 1000 g on the wheels may

be obtained by use of changeable weights or counterweights.

5.2 Refacing Stone—An ST-11 refacing stone shall be used

for truing the abrasive wheels.

5.3 Abrasive Wheels—The grade of “Calibrase” wheel des-

ignated CS-10F shall be used. The “Calibrase” wheel shall

meet the following requirements at the time of the test (Note

3):

5.3.1 The wheel shall not be used after the date stamped on

it, and

5.3.2 The durometer hardness of the wheel shall be mea-

sured in accordance with Test Method D 2240, on at least four

points equally spaced on the center of the abrading surface and

one point on each side surface of the wheel. The test on the

abrading surface shall be made with the pressure applied

NOTE 1—This photograph shows light pattern of the scattering from the

surface of aTaber abraded specimen.The circles show how increasing the

vertically along a diameter of the wheel, and the reading taken

1.3° dark annulus dramatically changes the amount of light impacting the

10 s after full application of the pressure. Each wheel shall

sphere wall.

have a durometer hardness of D 72 6 5 at all measured points.

FIG. 1 Light Scattering from Surface of Abraded Tracks

(Photograph) NOTE 5—The abrasive quality of the “Calibrase” wheels varies with

D 1044

hardness which changes with age.

6. Test Specimens

5.4 Abraser Turntable—The turntable of the abraser shall

6.1 The test specimens shall be clean, transparent disks 102

rotate substantially in a plane with a deviation at a distance of mm (4 in.) in diameter or plates 102 mm (4 in.) square, having

1.6mm(1/16in.)fromitsperipheryofnotgreaterthan 60.051

both surfaces substantially plane and parallel. They may be cut

mm (60.002 in.). The typical rotation speed is 72 r/min. from sheets or molded in thicknesses up to 12.7 mm ( ⁄2 in.).A

5.5 Photometer—An integrating sphere photoelectric pho-

6.3-mm ( ⁄4–in.) hole shall be centrally drilled in each speci-

tometer, described in Test Method D 1003, shall be used to men. Three such specimens shall be tested per sample, except

measure the light scattered by the abraded track. The photom-

for interlaboratory or specification tests when ten specimens

eter shall have the image of its entrance window focused at and shall be tested.

concentric with the exit port of the integrating sphere.

5.6 Stops

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.