ASTM B761-17(2021)

(Test Method)Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by X-Ray Monitoring of Gravity Sedimentation

Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by X-Ray Monitoring of Gravity Sedimentation

SIGNIFICANCE AND USE

4.1 This test method is useful to both producers and purchasers of powders, as outlined in 1.1 and 1.2, in determining particle size distribution for product specifications, manufacturing control, development, and research.

4.2 Users should be aware that sample concentrations used in this test method may not be what is considered ideal by some authorities, and that the range of this test method extends into the region where Brownian movement could be a factor in conventional sedimentation. Within the range of this test method, neither the sample concentration nor Brownian movement are believed to be significant.

4.3 Reported particle size measurement is a function of both the actual particle dimension and shape factor as well as the particular physical or chemical properties being measured. Caution is required when comparing data from instruments operating on different physical or chemical parameters or with different particle size measurement ranges. Sample acquisition, handling, and preparation can also affect reported particle size results.

SCOPE

1.1 This test method covers the determination of particle size distributions of metal powders. Experience has shown that this test method is satisfactory for the analysis of elemental tungsten, tungsten carbide, molybdenum, and tantalum powders, all with an as-supplied estimated average particle size of 6 μm or less, as determined by Test Method B330. Other metal powders (for example, elemental metals, carbides, and nitrides) may be analyzed using this test method with caution as to significance until actual satisfactory experience is developed (see 7.2). The procedure covers the determination of particle size distribution of the powder in the following two conditions:

1.1.1 As the powder is supplied (as-supplied), and

1.1.2 After the powder has been deagglomerated by rod milling as described in Practice B859.

1.2 This test method is applicable to particles of uniform density and composition having a particle size distribution range of 0.1 up to 100 μm.

1.2.1 However, the relationship between size and sedimentation velocity used in this test method assumes that particles sediment within the laminar flow regime. This requires that the particles sediment with a Reynolds number of 0.3 or less. Particle size distribution analysis for particles settling with a larger Reynolds number may be incorrect due to turbulent flow. Some materials covered by this test method may settle with Reynolds number greater than 0.3 if particles greater than 25 μm are present. The user of this test method should calculate the Reynolds number of the largest particle expected to be present in order to judge the quality of obtained results. Reynolds number (Re) can be calculated using the flowing equation

where

D = the diameter of the largest particle expected to be present, ρ = the particle density, ρ0 = the suspending liquid density, g = the acceleration due to gravity, and η = is the suspending liquid viscosity.

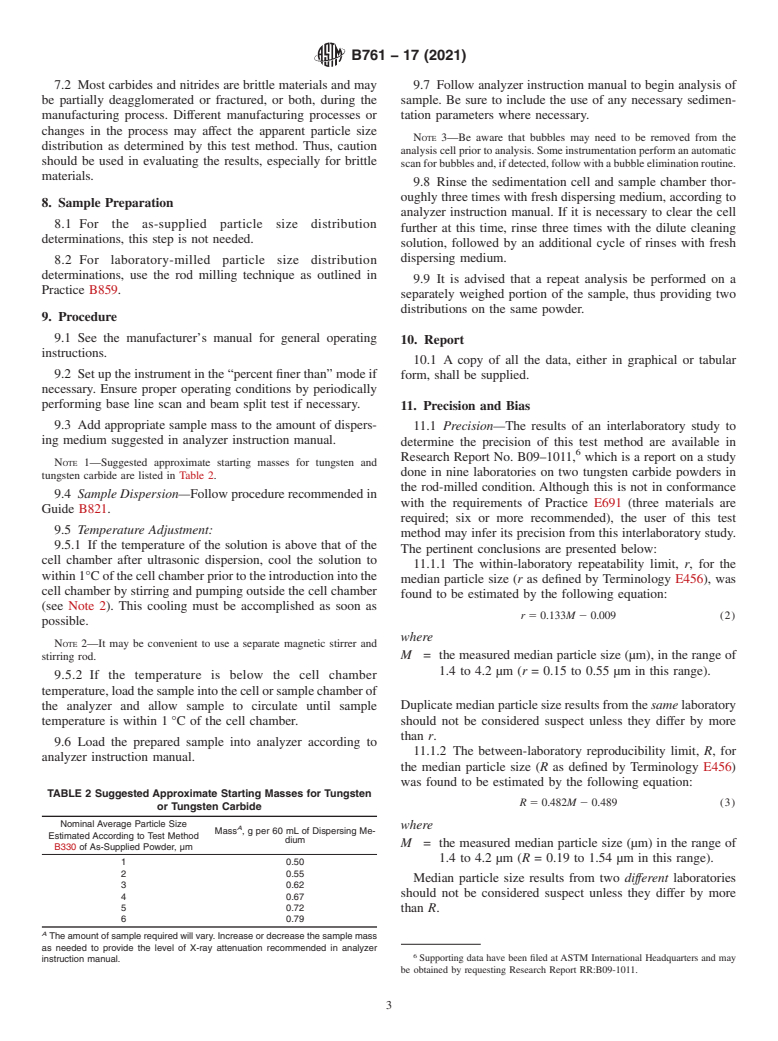

A table of the largest particles that can be analyzed with Reynolds number of 0.3 or less in water at 35°C is given for a number of metals in Table 1. A column of the Reynolds number calculated for a 30–μm particle sedimenting in the same liquid system is given for each material also.

1.3 Units—With the exception of the values for density and the mass used to determine density, for which the use of the gram per cubic centimetre (g/cm3) and gram (g) units is the longstanding industry practice, the values in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific hazard information is given in Section 7.

1.5 ...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B761 − 17 (Reapproved 2021)

Standard Test Method for

Particle Size Distribution of Metal Powders and Related

Compounds by X-Ray Monitoring of Gravity Sedimentation

This standard is issued under the fixed designation B761; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

D = the diameter of the largest particle expected to be

present,

1.1 This test method covers the determination of particle

ρ = the particle density,

size distributions of metal powders. Experience has shown that

ρ = the suspending liquid density,

this test method is satisfactory for the analysis of elemental

g = the acceleration due to gravity, and

tungsten, tungsten carbide, molybdenum, and tantalum

η = is the suspending liquid viscosity.

powders,allwithanas-suppliedestimatedaverageparticlesize

of 6 µm or less, as determined by Test Method B330. Other

A table of the largest particles that can be analyzed with

metal powders (for example, elemental metals, carbides, and

Reynolds number of 0.3 or less in water at 35°C is given for a

nitrides) may be analyzed using this test method with caution

numberofmetalsinTable1.AcolumnoftheReynoldsnumber

as to significance until actual satisfactory experience is devel-

calculated for a 30–µm particle sedimenting in the same liquid

oped (see 7.2). The procedure covers the determination of

system is given for each material also.

particle size distribution of the powder in the following two

conditions:

1.3 Units—With the exception of the values for density and

1.1.1 As the powder is supplied (as-supplied), and

the mass used to determine density, for which the use of the

1.1.2 After the powder has been deagglomerated by rod

gram per cubic centimetre (g/cm ) and gram (g) units is the

milling as described in Practice B859.

longstanding industry practice, the values in SI units are to be

regarded as standard.

1.2 This test method is applicable to particles of uniform

density and composition having a particle size distribution

1.4 This standard does not purport to address all of the

range of 0.1 up to 100 µm.

safety concerns, if any, associated with its use. It is the

1.2.1 However, the relationship between size and sedimen-

responsibility of the user of this standard to establish appro-

tation velocity used in this test method assumes that particles

priate safety, health, and environmental practices and deter-

sediment within the laminar flow regime.This requires that the

mine the applicability of regulatory limitations prior to use.

particles sediment with a Reynolds number of 0.3 or less.

Specific hazard information is given in Section 7.

Particle size distribution analysis for particles settling with a

1.5 This international standard was developed in accor-

largerReynoldsnumbermaybeincorrectduetoturbulentflow.

dance with internationally recognized principles on standard-

Some materials covered by this test method may settle with

ization established in the Decision on Principles for the

Reynolds number greater than 0.3 if particles greater than 25

Development of International Standards, Guides and Recom-

µm are present. The user of this test method should calculate

mendations issued by the World Trade Organization Technical

the Reynolds number of the largest particle expected to be

Barriers to Trade (TBT) Committee.

present in order to judge the quality of obtained results.

2. Referenced Documents

Reynolds number (Re) can be calculated using the flowing

equation

2.1 ASTM Standards:

B330 Test Methods for Estimating Average Particle Size of

D ~ρ 2 ρ !ρ g

0 0

Re 5 (1)

Metal Powders and Related Compounds Using Air Per-

18η

meability

where

B821 Guide for Liquid Dispersion of Metal Powders and

Related Compounds for Particle Size Analysis

This test method is under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Products and is the direct responsibility of Subcom-

mittee B09.03 on Refractory Metal Powders. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2021. Published October 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1986. Last previous edition approved in 2017 as B761 – 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0761-17R21. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B761 − 17 (2021)

TABLE 1 Maximum Diameter of Metal Powders and Related Compounds That Can Be Analyzed with Reynolds Number of 0.3 or Less in

Waterat35°C

A

Particle Composition Particle Density Maximum Particle Diameter Reynolds Number for 30 µm

Cobalt 8.90 33.19 0.22

Copper 8.92 33.16 0.22

Iron 7.86 34.79 0.19

Molybdenum 10.20 31.55 0.26

Nickel 8.90 33.19 0.22

Tantalum 16.60 26.46 0.44

Tantalum carbide 13.90 28.19 0.36

Titanium carbide 4.93 41.88 0.11

Tungsten 19.35 25.06 0.51

Tungsten carbide 15.63 27.03 0.41

Vanadium 6.11 38.37 .014

Vanadium carbide 5.77 39.26 0.13

A 3

Reynolds number calculated for 30 µm particle sedimenting in water at 35°C, with a density of 0.9941 g/cm and viscosity of 0.7225 cp.

B859 Practice for De-Agglomeration of Refractory Metal 5. Apparatus

Powders and Their Compounds Prior to Particle Size

5.1 Gravitational sedimentation particle size analyzer utiliz-

Analysis 3

ing X-ray extinction to determine particle concentration.

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to

6. Reagents and Materials

Determine the Precision of a Test Method

6.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

3. Summary of Test Method

all reagents conform to the specifications of the Committee on

3.1 A carefully dispersed homogeneous suspension of the

Analytical Reagents of the American Chemical Society where

powder is permitted to settle in a cell scanned by a collimated 4

such specifications are available. Other grades may be used,

X-ray beam of constant intensity. The net X-ray signal is

provided it is first ascertained that the reagent is of sufficiently

inversely proportional to the sample concentration in the

high purity to permit its use without lessening the accuracy of

dispersing medium, and the particle diameter is related to the

the determination.

position of the X-ray beam relative to the top of the cell.

6.2 Dispersing Medium—Dissolve0.10gofsodiumhexam-

Cumulative mass percent versus equivalent spherical diameter

etaphosphate [(NaPO ) ] in 1000 mL of distilled or deionized

3 6

are recorded to yield a particle size distribution curve.

water.

4. Significance and Use

6.3 Cleaning Solution—Dissolve 0.5 g of laboratory deter-

4.1 This test method is useful to both producers and

gent in 1000 mL of distilled or deionized water, or prepare a

purchasers of powders, as outlined in 1.1 and 1.2, in determin- 0.1 % solution by volume of Triton X-100 using distilled or

ing particle size distribution for product specifications, manu-

deionized water.

facturing control, development, and research.

7. Hazards

4.2 Users should be aware that sample concentrations used

7.1 Precautions applying to the use of low intensity X-ray

inthistestmethodmaynotbewhatisconsideredidealbysome

units should be observed.

authorities, and that the range of this test method extends into

the region where Brownian movement could be a factor in

conventional sedimentation. Within the range of this test 3

The sole instrument of this type known to the committee as this time is the

SediGraph X-ray gravity sedimentation particle size analyzer, available from

method, neither the sample concentration nor Brownian move-

Micromeritics Instrument Corporation, 4356 Communications Drive, Norcross, GA

ment are believed to be significant.

30093. If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

4.3 Reportedparticlesizemeasurementisafunctionofboth

ation at a meeting of the responsible technical committee, which you may attend.

the actual particle dimension a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.