ASTM B821-10

(Guide)Standard Guide for Liquid Dispersion of Metal Powders and Related Compounds for Particle Size Analysis

Standard Guide for Liquid Dispersion of Metal Powders and Related Compounds for Particle Size Analysis

SIGNIFICANCE AND USE

The method of powder dispersion in a liquid has a significant effect on the results of a particle size distribution analysis. The analysis will show a too-coarse, unstable, or nonrepeatable distribution if the powder has not been dispersed adequately. It is therefore important that parties wishing to compare their analyses use the same dispersion technique.

This guide provides established powder dispersion techniques for certain materials and the means of deriving techniques for materials not listed. It should be used by all parties performing liquid-dispersed particle size analysis of all of the materials covered by this guide (see 1.1, 1.2, and 4.1).

SCOPE

1.1 This guide covers the dispersion in liquids of metal powders and related compounds for subsequent use in particle size analysis instruments. This guide describes a general procedure for achieving and determining dispersion; it also lists procedures that are currently in general use for certain materials.

1.2 This guide is limited to metal powders and related metal compounds. However, the general procedure described herein may be used, with caution as to its significance, for other particulate materials, such as ceramics, pigments, minerals, etc.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B821 − 10

StandardGuide for

Liquid Dispersion of Metal Powders and Related

1

Compounds for Particle Size Analysis

This standard is issued under the fixed designation B821; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* of Gravity Sedimentation

B822 Test Method for Particle Size Distribution of Metal

1.1 This guide covers the dispersion in liquids of metal

Powders and Related Compounds by Light Scattering

powders and related compounds for subsequent use in particle

size analysis instruments. This guide describes a general

3. Terminology

procedure for achieving and determining dispersion; it also

3.1 Definitions—Definitions of powder metallurgy terms

lists procedures that are currently in general use for certain

can be found in Terminology B243.

materials.

1.2 This guide is limited to metal powders and related metal

4. Significance and Use

compounds. However, the general procedure described herein

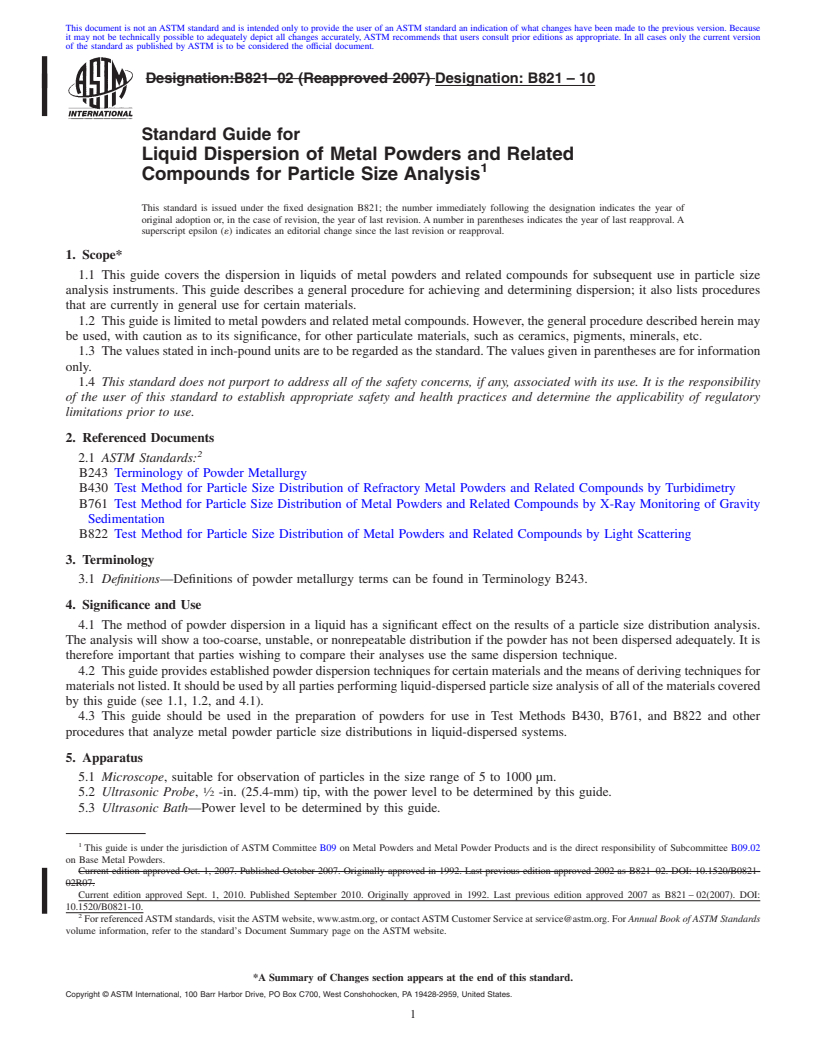

4.1 The method of powder dispersion in a liquid has a

may be used, with caution as to its significance, for other

significant effect on the results of a particle size distribution

particulatematerials,suchasceramics,pigments,minerals,etc.

analysis. The analysis will show a too-coarse, unstable, or

1.3 The values stated in inch-pound units are to be regarded

nonrepeatabledistributionifthepowderhasnotbeendispersed

as the standard. The values given in parentheses are for

adequately. It is therefore important that parties wishing to

information only.

compare their analyses use the same dispersion technique.

1.4 This standard does not purport to address all of the

4.2 This guide provides established powder dispersion tech-

safety concerns, if any, associated with its use. It is the

niques for certain materials and the means of deriving tech-

responsibility of the user of this standard to establish appro-

niques for materials not listed. It should be used by all parties

priate safety and health practices and determine the applica-

performing liquid-dispersed particle size analysis of all of the

bility of regulatory limitations prior to use.

materials covered by this guide (see 1.1, 1.2, and 4.1).

4.3 This guide should be used in the preparation of powders

2. Referenced Documents

for use in Test Methods B430, B761, and B822 and other

2

2.1 ASTM Standards:

procedures that analyze metal powder particle size distribu-

B243 Terminology of Powder Metallurgy

tions in liquid-dispersed systems.

B430 Test Method for Particle Size Distribution of Refrac-

tory Metal Powders and Related Compounds by Turbidi-

5. Apparatus

metry

5.1 Microscope, suitable for observation of particles in the

B761 Test Method for Particle Size Distribution of Metal

size range of 5 to 1000 µm.

Powders and Related Compounds by X-Ray Monitoring

1

5.2 Ultrasonic Probe, ⁄2 -in. (25.4-mm) tip, with the power

level to be determined by this guide.

1

This guide is under the jurisdiction of ASTM Committee B09 on Metal

Powders and Metal Powder Productsand is the direct responsibility of Subcommit-

5.3 Ultrasonic Bath—Power level to be determined by this

tee B09.02 on Base Metal Powders.

guide.

Current edition approved Sept. 1, 2010. Published September 2010. Originally

approved in 1992. Last previous edition approved 2007 as B821 – 02(2007). DOI:

6. Reagents

10.1520/B0821-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Purity of Reagents—Reagent grade chemicals should be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

used in all tests. Unless otherwise indicated, it is intended that

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. all reagents should conform to the specifications of the

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B821 − 10

Committee on Analytical Reagents of the American Chemical

1

---------------------- Page: 2 ----------------------

B821 − 10

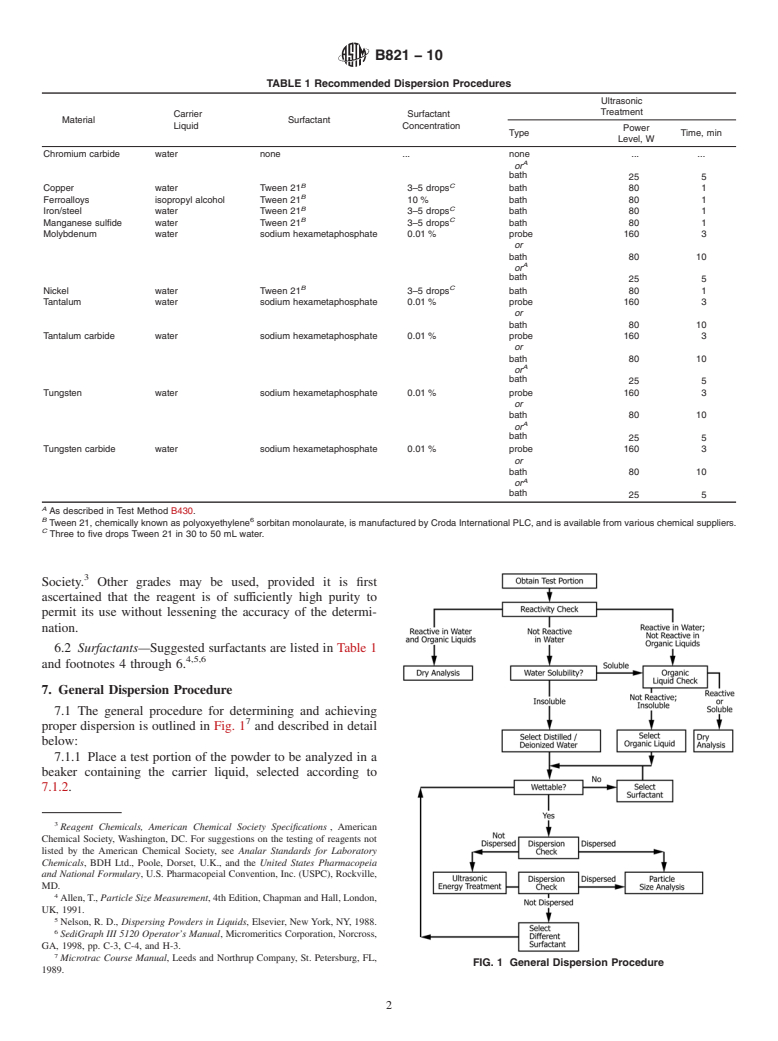

TABLE 1 Recommended Dispersion Procedures

Ultrasonic

Treatment

Carrier Surfactant

Material Surfactant

Liquid Concentration

Power

Type Time, min

Level, W

Chromium carbide water none . none . .

A

or

bath

25 5

B C

Copper water Tween 21 3–5 drops bath 80 1

B

Ferroalloys isopropyl alcohol Tween 21 10 % bath 80 1

B C

Iron/steel water Tween 21 3–5 drops bath 80 1

B C

Manganese sulfide water Tween 21 3–5 drops bath 80 1

Molybdenum water sodium hexametaphosphate 0.01 % probe 160 3

o

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B821–02 (Reapproved 2007) Designation:B821–10

Standard Guide for

Liquid Dispersion of Metal Powders and Related

1

Compounds for Particle Size Analysis

This standard is issued under the fixed designation B821; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This guide covers the dispersion in liquids of metal powders and related compounds for subsequent use in particle size

analysis instruments. This guide describes a general procedure for achieving and determining dispersion; it also lists procedures

that are currently in general use for certain materials.

1.2 This guide is limited to metal powders and related metal compounds. However, the general procedure described herein may

be used, with caution as to its significance, for other particulate materials, such as ceramics, pigments, minerals, etc.

1.3 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

B243 Terminology of Powder Metallurgy

B430 Test Method for Particle Size Distribution of Refractory Metal Powders and Related Compounds by Turbidimetry

B761 Test Method for Particle Size Distribution of Metal Powders and Related Compounds by X-Ray Monitoring of Gravity

Sedimentation

B822 Test Method for Particle Size Distribution of Metal Powders and Related Compounds by Light Scattering

3. Terminology

3.1 Definitions—Definitions of powder metallurgy terms can be found in Terminology B243.

4. Significance and Use

4.1 The method of powder dispersion in a liquid has a significant effect on the results of a particle size distribution analysis.

The analysis will show a too-coarse, unstable, or nonrepeatable distribution if the powder has not been dispersed adequately. It is

therefore important that parties wishing to compare their analyses use the same dispersion technique.

4.2 This guide provides established powder dispersion techniques for certain materials and the means of deriving techniques for

materialsnotlisted.Itshouldbeusedbyallpartiesperformingliquid-dispersedparticlesizeanalysisofallofthematerialscovered

by this guide (see 1.1, 1.2, and 4.1).

4.3 This guide should be used in the preparation of powders for use in Test Methods B430, B761, and B822 and other

procedures that analyze metal powder particle size distributions in liquid-dispersed systems.

5. Apparatus

5.1 Microscope, suitable for observation of particles in the size range of 5 to 1000 µm.

1

5.2 Ultrasonic Probe, ⁄2 -in. (25.4-mm) tip, with the power level to be determined by this guide.

5.3 Ultrasonic Bath—Power level to be determined by this guide.

1

This guide is under the jurisdiction of ASTM Committee B09 on Metal Powders and Metal Powder Products and is the direct responsibility of Subcommittee B09.02

on Base Metal Powders.

Current edition approved Oct. 1, 2007. Published October 2007. Originally approved in 1992. Last previous edition approved 2002 as B821–02. DOI: 10.1520/B0821-

02R07.

Current edition approved Sept. 1, 2010. Published September 2010. Originally approved in 1992. Last previous edition approved 2007 as B821 – 02(2007). DOI:

10.1520/B0821-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B821–10

TABLE 1 Recommended Dispersion Procedures

Ultrasonic

Treatment

Carrier Surfactant

Material Surfactant

Liquid Concentration

Power

Type Time, min

Level, W

Chromium carbide water none . none . .

A

or

bath 25 5

B C

Copper water Tween 21 3–5 drops bath 80 1

B

Ferroalloys isopropyl alcohol Tween 21 10 % bath 80 1

B C

Iron/steel water Tween 21

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.