ASTM E1567-93(2001)

(Guide)Standard Guide for Biopharmaceutical Facilities Architectural Design Considerations (Withdrawn 2010)

Standard Guide for Biopharmaceutical Facilities Architectural Design Considerations (Withdrawn 2010)

SIGNIFICANCE AND USE

This guide is intended for use in designing laboratory, pilot plant, commercial production buildings that will use processes involving living organisms to produce products. These products are also manufactured under the FDA and other federal agency regulations.

These guidelines include the layout of facilities, design of containment areas, ventilation and air quality, personnel areas, special processing hazards, controlled environment areas, and other items.

This guide is for use by engineers, architects, and owners of biopharmatechnical manufacturing facilities to consider the special factors in laying out the facilities to meet cGMP requirements and other good engineering principles.

By using these guidelines along with other design criteria required by a variety of regulatory agencies, a validation effort can be achieved more easily to meet agency requirements and obtain operating permits.

This guide is intended to provide general guidelines for consideration and application in a variety of plant operations and processes in which the designers can make specific decisions concerning the exact architectural design features to use.

SCOPE

1.1 This guide covers architectural design considerations for buildings and facilities used in the biological processing industry to make drugs, chemicals, and other products.

1.2 These designs are intended to meet current good manufacturing practices (cGMP) criteria and guidelines published by the U.S. Food and Drug Administration (FDA) for processes and products manufactured under CFR Title 21.

1.3 While the guidelines described are general in nature, they are not expected to apply to all of the possible biotechnical processes used in the industry today. Accordingly, the user of this guide must exercise good engineering judgment in specific design applications to select the proper guidelines that apply.

1.4 In addition to the cGMP guidelines provided herein, other regulations and guides should be considered that are promulgated by other federal agencies such as the Occupational Safety and Health Administration (OSHA), the U.S. Environmental Protection Agency (EPA), the U.S. Drug Administration (USDA), the National Institute of Health (NIH), and so forth.

1.5 While the buildings will be designed to meet specific functional requirements and comply with local zoning ordinances, building codes, handicapped employee standards, and so forth, these considerations are not included in this guide.

1.6 The values stated in SI units are to be regarded as the standard.

1.7 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This guide covers architectural design considerations for buildings and facilities used in the biological processing industry to make drugs, chemicals, and other products.

Formerly under the jurisdiction of Committee E48 on Biotechnology, this guide was withdrawn in July 2010 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1567–93 (Reapproved 2001)

Standard Guide for

Biopharmaceutical Facilities Architectural Design

Considerations

This standard is issued under the fixed designation E1567; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope NIH Guidelines, Containment Area Designations

1.1 Thisguidecoversarchitecturaldesignconsiderationsfor

3. Terminology

buildings and facilities used in the biological processing

3.1 Definition:

industry to make drugs, chemicals, and other products.

3.1.1 cGMP—abbreviation for current good manufacturing

1.2 These designs are intended to meet current good manu-

practices as defined in CFR Title 21, Parts 210 and 211.

facturing practices (cGMP) criteria and guidelines published

bytheU.S.FoodandDrugAdministration(FDA)forprocesses

4. Significance and Use

and products manufactured under CFR Title 21.

4.1 This guide is intended for use in designing laboratory,

1.3 While the guidelines described are general in nature,

pilot plant, commercial production buildings that will use

theyarenotexpectedtoapplytoallofthepossiblebiotechnical

processes involving living organisms to produce products.

processes used in the industry today. Accordingly, the user of

TheseproductsarealsomanufacturedundertheFDAandother

this guide must exercise good engineering judgment in specific

federal agency regulations.

design applications to select the proper guidelines that apply.

4.2 These guidelines include the layout of facilities, design

1.4 In addition to the cGMP guidelines provided herein,

of containment areas, ventilation and air quality, personnel

other regulations and guides should be considered that are

areas, special processing hazards, controlled environment ar-

promulgated by other federal agencies such as the Occupa-

eas, and other items.

tional Safety and Health Administration (OSHA), the U.S.

4.3 This guide is for use by engineers, architects, and

Environmental Protection Agency (EPA), the U.S. Drug Ad-

owners of biopharmatechnical manufacturing facilities to con-

ministration (USDA), the National Institute of Health (NIH),

sider the special factors in laying out the facilities to meet

and so forth.

cGMP requirements and other good engineering principles.

1.5 While the buildings will be designed to meet specific

4.4 By using these guidelines along with other design

functional requirements and comply with local zoning ordi-

criteria required by a variety of regulatory agencies, a valida-

nances, building codes, handicapped employee standards, and

tion effort can be achieved more easily to meet agency

so forth, these considerations are not included in this guide.

requirements and obtain operating permits.

1.6 The values stated in SI units are to be regarded as the

4.5 This guide is intended to provide general guidelines for

standard.

consideration and application in a variety of plant operations

1.7 This standard does not purport to address all of the

and processes in which the designers can make specific

safety problems, if any, associated with its use. It is the

decisions concerning the exact architectural design features to

responsibility of the user of this standard to establish appro-

use.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Summary of Guide

5.1 This guide provides architectural design principles to

2. Referenced Documents

consider when applying federal regulations to biopharmatech-

2.1 Code of Federal Regulations:

2 nical plant facilities construction and functions. Check lists for

CFR Title 21, Parts 58, 210, 211, 212, 606, 809, 820

specific plant operation activity areas presented with criteria

2.2 Other Document:

for their design and layout considerations. Environmental

considerations are also included for aseptic and special laminar

ThisguideisunderthejurisdictionofASTMCommitteeE48onBiotechnology flow zones of operation. Fermenter area layout and space

and is the direct responsibility of Subcommittee E48.03 on Unit Processes and

considerations are presented. When containment and closed

Validation.

Current edition approved Aug. 15, 1993. Published October 1993. DOI:

10.1520/E1567-93R01.

2 3

Available from Standardization Documents Order Desk, Bldg. 4, Section D, Available from National Institutes of Health, (NIH), 9000 Rockville Pike,

700 Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. Bethesda, MD 20892.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1567–93 (2001)

area operations are necessary, the general criteria to be consid- entering the controlled environment area must use appropriate

ered by the designer is presented based on NIH Guidelines and non-linting garments inside it that are not to be used outside it,

good engineering practices. including in the changing area. This means that the design of

5.2 Plant layout considerations are included for all normal facilitieswillincludeagowningareaandgarmentstorageareas

sections of a biotechnical operating plant. adjacent to the controlled environment area.

6.7.1 Gowning Area Design Considerations:

6. Guidelines

6.7.1.1 Sole means of personnel entry and exit, except for

6.1 First, establish which regulations apply to the specific

emergency exit.

project design. Review 21 CFR, Parts 210, 211, 212, and so

6.7.1.2 Located immediately adjacent to work areas.

forth; NIH Guidelines; and other specific information from

6.7.1.3 Equipped with containers for the disposal of used

federal agencies that applies to the functions intended in these

clothing and protective equipment.

facilities. For example, 21 CFR, Part 606, relates to cGMP for

6.7.1.4 Clean air supplied to the gowning area will have a

blood and blood components; Part 809 to in-vitro diagnostic

negative air pressure relative to the contained work area and

products for human use; Part 820 to medical devices; Part 58

positive air pressure relative to the adjacent non-controlled

to nonclinical laboratories; NIH guidelines to containment

areas. Differential pressures may be 1.3 to 3.8 mm water gage.

requirements, and so forth.

6.7.1.5 Provide hand washing facilities and warm-air drying

6.2 Adequate laboratory facilities must be provided for the

equipment within the gowning area similar to surgical room

testing of process intermediates and products (see section 21

washing facilities operated by foot or knee.

CFR, Part 211.22). The quality control function of the site

6.7.1.6 The gowning room should have a higher pressure

requires adequate laboratory space and facilities.

than the wash room and have loading changers to insert

6.3 Manufacturing employees must have education and

personnel clothing items into the room. Air showers and air

frequent training (see section 21 CFR, Part 211.25), which

locks should be considered.

requires training space or dedicated rooms for the cGMP

6.7.1.7 Finishes within the gowning room should be of the

training.This space can sometimes be combined with an eating

same quality as those in the controlled environment work area.

area or conference room.

6.7.1.8 The use of HEPAfilters and ultraviolet lights should

6.4 Personnelmustwearappropriateclothingandprotective

be considered for garment lockers.

items (see 21 CFR, part 211.28), which implies storage area

6.7.1.9 Doors should remain closed when not in use; con-

lockers for clean and dirty work clothes and change lockers for

sider using automatic door closure and interlocks.

street clothes. Change rooms, laundry rooms, clothing staging

6.7.2 The air quality for controlled environment areas is

areas, and storage rooms may also apply.

described in 21 CFR, Parts 212.221 to 222. Consider the

6.5 Personnel sanitation and health activities require ad-

following:

equate wash rooms, showers, toilets, and storage areas for

6.7.2.1 Temperature Range—22 6 3°C.

supplies, according to Part 211.28.

6.7.2.2 Humidity Range—30 to 50 % relative humidity.

6.6 Building design and construction features in Part 211.42

6.7.2.3 Pressure Differential—0.05 in. (1.27 mm) of water,

require adequate space for the manufacturing, processing,

minimum, with all doors closed relative to the adjacent less

packing, or holding of a drug product. These areas include the

clean area.

following:

6.7.2.4 Sterility, HEPA Filtration—Not to exceed a particle

6.6.1 Receipt and identification of raw materials,

count (0.5 µm size) of 100 000/ft when measured with

6.6.2 Storage offtest and ontest raw materials,

automatic counters, or 700 particles of 5.0 µm size using a

6.6.3 Sample preparation and testing,

manual microscopic method. For sterile air over filling lines, a

6.6.4 In-process Materials—Ontest and offtest,

100 count is maximum for 0.5 µm particles at the point of use.

6.6.5 Manufacturing equipment,

6.7.2.5 Air Change Rate—20/h, minimum.

6.6.6 Equipment holding, cleaning, and staging,

6.7.3 Construction considerations must be designed to pre-

6.6.7 Packaging and labeling,

vent the physical facilities from becoming a source of particu-

6.6.8 Quarantine storage of finished products,

late contamination:

6.6.9 Utilities—Inert gases, steam generators, water for

6.7.3.1 Coating on all surfaces must resist deterioration and

injection (WFI), treated water, air (utility, clean, instrument,

flaking.

and sterile), and so forth,

6.7.3.2 Surfacesshouldbeabletobecleanedeffectivelyand

6.6.10 Sterilization Systems—Clean-in-place and sterilize-

easily.

in-place,

6.7.3.3 Smooth, hard surfaces clean best; use coatings such

6.6.11 Waste treatment,

as epoxy, cove bases flush with wall, covered corners, sealed

6.6.12 Offices, personnel change rooms, and containment

joints, flush fitting doors and windows, wall protection, and

access areas, and

corner guards.

6.6.13 Control room, quality assurance and quality control

areas, and so forth. 6.7.3.4 Conceal all ducts, conduits, piping, etc. above ceil-

ings and behind walls. Exposed pipe and conduits for equip-

6.7 The controlled environment area must be environmen-

tally controlled, with special air quality, lighting, and construc- ment connections should be installed vertically.

tion (see 21 CFR, part 212.3) to minimize contamination from 6.7.3.5 Install insect control units and screens on vents and

air-borne particulates, including microorganisms. Personnel openings, as appropriate.

E1567–93 (2001)

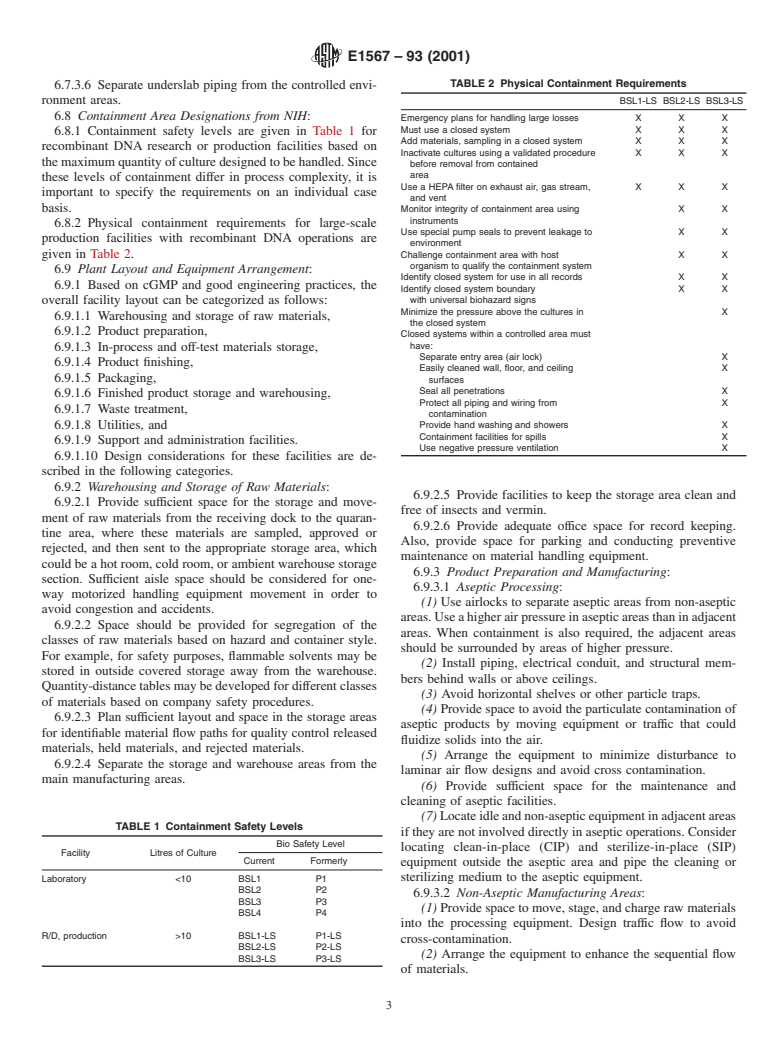

TABLE 2 Physical Containment Requirements

6.7.3.6 Separate underslab piping from the controlled envi-

ronment areas. BSL1-LS BSL2-LS BSL3-LS

6.8 Containment Area Designations from NIH:

Emergency plans for handling large losses X X X

Must use a closed system X X X

6.8.1 Containment

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.