ASTM F3456-22

(Guide)Standard Guide for Powder Reuse Schema in Powder Bed Fusion Processes for Medical Applications for Additive Manufacturing Feedstock Materials

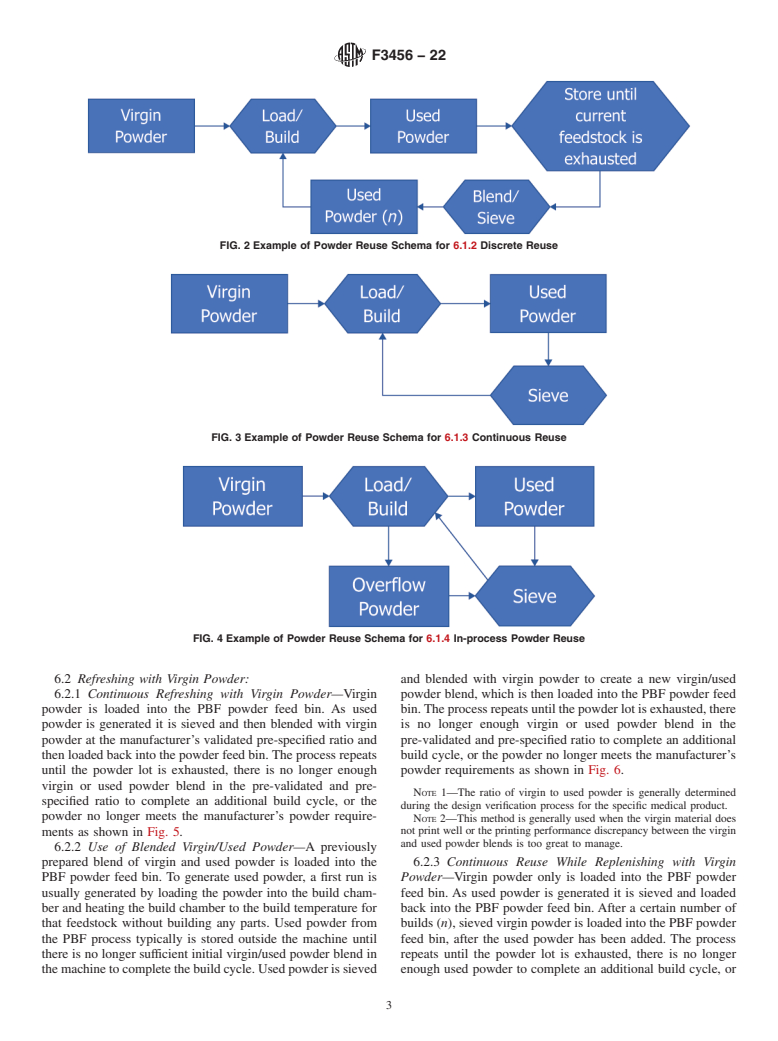

Standard Guide for Powder Reuse Schema in Powder Bed Fusion Processes for Medical Applications for Additive Manufacturing Feedstock Materials

SIGNIFICANCE AND USE

4.1 In PBF systems, powder is often reused to increase feedstock efficiency by reducing waste. While in many applications the customer can rely on the manufacturer’s validation and verification activities to ensure their PBF process produces parts of the appropriate quality, some medical device regulatory bodies ask for the powder reuse schema to ensure that any effect of powder reuse on final device performance is assessed.5 The intention of this guide is to provide manufacturers, customers, and regulatory bodies concise terminology to describe powder feedstock reuse schema for PBF using metal or polymer feedstock. Additionally, a well-defined powder reuse schema may reduce the risk of feedstock contamination and associated defects within the manufacturer’s quality management system. Each schema represents a broad reuse strategy and is intended to be used as the starting point in describing a powder strategy to customers and regulatory bodies. While the focus of this guide is for medical applications, the schema referenced can be used for non-medical applications.

SCOPE

1.1 This guide provides a concise approach for users of powder bed fusion (PBF) processes to communicate the method(s) in which feedstock powders are controlled throughout the feedstock lifecycle.

1.1.1 Regulatory bodies may require descriptions of used powder reuse schemes in a submission. This is because a medical device's performance can be affected by the condition of the powder feedstock and current regulations are not prescriptive to powder.

1.1.2 This guide is intended for users of both polymer and metal feedstock powders.

1.2 This guide does not cover powder specifications, recycling strategy, blending processes, lot control, or address contamination prevention.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3456 − 22

Standard Guide for

Powder Reuse Schema in Powder Bed Fusion Processes for

Medical Applications for Additive Manufacturing Feedstock

1

Materials

This standard is issued under the fixed designation F3456; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope 2.2 ASTM Standards:

B213 Test Methods for Flow Rate of Metal Powders Using

1.1 This guide provides a concise approach for users of

the Hall Flowmeter Funnel

powder bed fusion (PBF) processes to communicate the

B214 Test Method for Sieve Analysis of Metal Powders

method(s) in which feedstock powders are controlled through-

B215 Practices for Sampling Metal Powders

out the feedstock lifecycle.

B822 Test Method for Particle Size Distribution of Metal

1.1.1 Regulatory bodies may require descriptions of used

Powders and Related Compounds by Light Scattering

powder reuse schemes in a submission. This is because a

B964 Test Methods for Flow Rate of Metal Powders Using

medical device’s performance can be affected by the condition

the Carney Funnel

of the powder feedstock and current regulations are not

3

2.3 ANSI/AAMI/ISO Standard:

prescriptive to powder.

ANSI/AAMI/ISO 13485 Medical devices — Quality man-

1.1.2 This guide is intended for users of both polymer and

agementsystems—Requirementsforregulatorypurposes

metal feedstock powders.

4

2.4 U.S. Food and Drug Administration:

1.2 This guide does not cover powder specifications, recy-

21 CFR 820.60 Quality System Regulation — Identification

cling strategy, blending processes, lot control, or address

contamination prevention.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 Terminology relating to additive manufacturing in

responsibility of the user of this standard to establish appro-

Terminology ISO/ASTM 52900 shall apply.

priate safety, health, and environmental practices and deter-

3.2 Definitions:

mine the applicability of regulatory limitations prior to use.

3.2.1 overflow powder, n—excess powder that does not

1.4 This international standard was developed in accor-

remain in the build volume, but instead is deposited into the

dance with internationally recognized principles on standard-

overflow region of an additive manufacturing machine.

ization established in the Decision on Principles for the

3.2.1.1 Discussion—Because of its exposure to the build

Development of International Standards, Guides and Recom-

volumeandpreviouslyconsolidatedmaterial,overflowpowder

mendations issued by the World Trade Organization Technical

is considered used powder in the context of reuse.

Barriers to Trade (TBT) Committee.

3.2.2 powder lot, n—a lot as defined in ISO/ASTM 52900,

2. Referenced Documents

where the feedstock is powder.

2 3.2.2.1 Discussion—The machine user may develop addi-

2.1 ISO/ASTM Standards:

tional naming/labeling conventions if a single powder lot is

52900 Additive manufacturing — General principles —

permanently subdivided between different machines or to keep

Fundamentals and Vocabulary

track of how many times the powder has been reused. The

machine user can choose the exact naming convention pro-

1 vided the convention maintains appropriate traceability and

This guide is under the jurisdiction of ASTM Committee F42 on Additive

Manufacturing Technologies and is the direct responsibility of Subcommittee does not create ambiguity in the description of the schema.

F42.07 on Applications.

Current edition approved April 1, 2022. Published May 2022. DOI: 10.1520/

F3456-22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Food and Drug Administration (FDA), 10903 New

the ASTM website. Hampshire Ave., Silver Spring, MD 20993, http://www.fda.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3456 − 22

3.2.3 refreshed powder batch, n—powder blend of used and 5.3 Powder Storage—Whenever powder is stored or

virgin powder. handled external to the machine, procedures should be v

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.