ASTM E662-06e1

(Test Method)Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials

Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials

SIGNIFICANCE AND USE

This test method provides a means for determining the specific optical density of the smoke generated by specimens of materials and assemblies under the specified exposure conditions. Values determined by this test are specific to the specimen or assembly in the form and thickness tested and are not to be considered inherent fundamental properties of the material tested. Thus, it is likely that closely repeatable or reproducible experimental results are not to be expected from tests of a given material when specimen thickness, density, or other variables are involved.

The photometric scale used to measure smoke by this test method is similar to the optical density scale for human vision. However, physiological aspects associated with vision are not measured by this test method. Correlation with measurements by other test methods has not been established.

At the present time no basis is provided for predicting the density of smoke generated by the materials upon exposure to heat and flame under other fire conditions.

The test method is of a complex nature and the data obtained are sensitive to variations which in other test methods might be considered to be insignificant (see Section 6). A precision statement based on the results of a roundrobin test by a prior draft version of this test method is given in 14.1

In this procedure, the specimens are subjected to one or more specific sets of laboratory test conditions. If different test conditions are substituted or the end-use conditions are changed, it is not always possible by or from this test method to predict changes in the fire-test-response characteristics measured. Therefore, the results are valid only for the fire test exposure conditions described in this procedure.

SCOPE

1.1 This fire-test-response standard covers determination of the specific optical density of smoke generated by solid materials and assemblies mounted in the vertical position in thicknesses up to and including 1 in. (25.4 mm).

1.2 Measurement is made of the attenuation of a light beam by smoke (suspended solid or liquid particles) accumulating within a closed chamber due to nonflaming pyrolytic decomposition and flaming combustion.

1.3 Results are expressed in terms of specific optical density which is derived from a geometrical factor and the measured optical density, a measurement characteristic of the concentration of smoke.

1.4 This test method is intended for use in research and development and not as a basis for ratings for regulatory purposes.

1.5 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 The values stated in inch-pound units are to be regarded as standard. Values stated in parentheses are for information only.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

´1

Designation: E 662 – 06

Standard Test Method for

Specific Optical Density of Smoke Generated by Solid

1

Materials

This standard is issued under the fixed designation E662; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Added research report footnote to Section 14 editorially in September 2008.

1. Scope 2. Referenced Documents

2

1.1 This fire-test-response standard covers determination of 2.1 ASTM Standards:

the specific optical density of smoke generated by solid D2843 Test Method for Density of Smoke from the Burn-

materials and assemblies mounted in the vertical position in ing or Decomposition of Plastics

thicknesses up to and including 1 in. (25.4 mm). E176 Terminology of Fire Standards

1.2 Measurement is made of the attenuation of a light beam

3. Terminology

by smoke (suspended solid or liquid particles) accumulating

within a closed chamber due to nonflaming pyrolytic decom- 3.1 Definitions—For definitions of terms found in this test

method refer to Terminology E176.

position and flaming combustion.

1.3 Resultsareexpressedintermsofspecificopticaldensity

4. Summary of Test Method

which is derived from a geometrical factor and the measured

4.1 This test method employs an electrically heated radiant-

optical density, a measurement characteristic of the concentra-

energy source mounted within an insulated ceramic tube and

tion of smoke.

positioned so as to produce an irradiance level of 2.2 Btu/

1.4 This test method is intended for use in research and

2 2

s·ft (2.5 W/cm ) averaged over the central 1.5-in. (38.1-mm)

development and not as a basis for ratings for regulatory

diameter area of a vertically mounted specimen facing the

purposes.

radiant heater. The nominal 3 by 3-in. (76.2 by 76.2-mm)

1.5 This standard measures and describes the response of

specimen is mounted within a holder which exposes an area

materials, products, or assemblies to heat and flame under

9 9

measuring 2 ⁄16 by 2 ⁄16 in. (65.1 by 65.1 mm). The holder is

controlled conditions, but does not by itself incorporate all

able to accommodate specimens up to 1 in. (25.4 mm) thick.

factors required for fire hazard or fire risk assessment of the

This exposure provides the nonflaming condition of the test.

materials, products or assemblies under actual fire conditions.

4.2 For the flaming condition, a six-tube burner is used to

1.6 This standard does not purport to address all of the

apply a row of equidistant flamelets across the lower edge of

safety concerns, if any, associated with its use. It is the

the exposed specimen area and into the specimen holder

responsibility of the user of this standard to establish appro-

trough. This application of flame in addition to the specified

priate safety and health practices and determine the applica-

irradiance level from the heating element constitutes the

bility of regulatory limitations prior to use.

flaming combustion exposure.

1.7 The values stated in inch-pound units are to be regarded

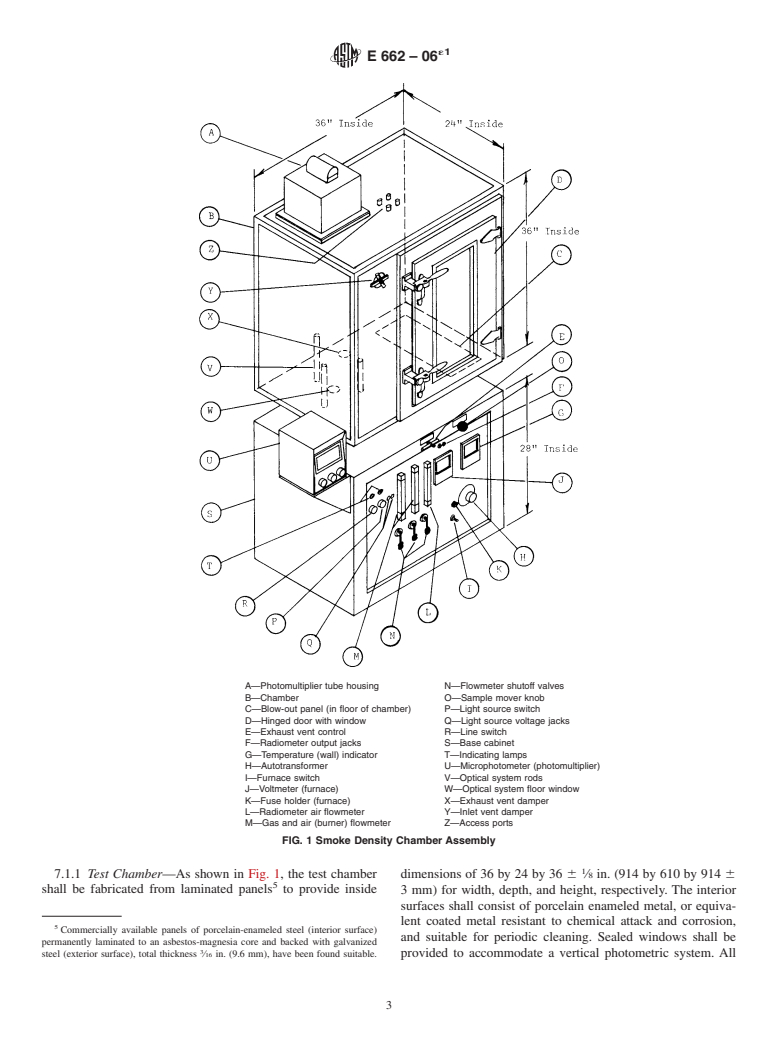

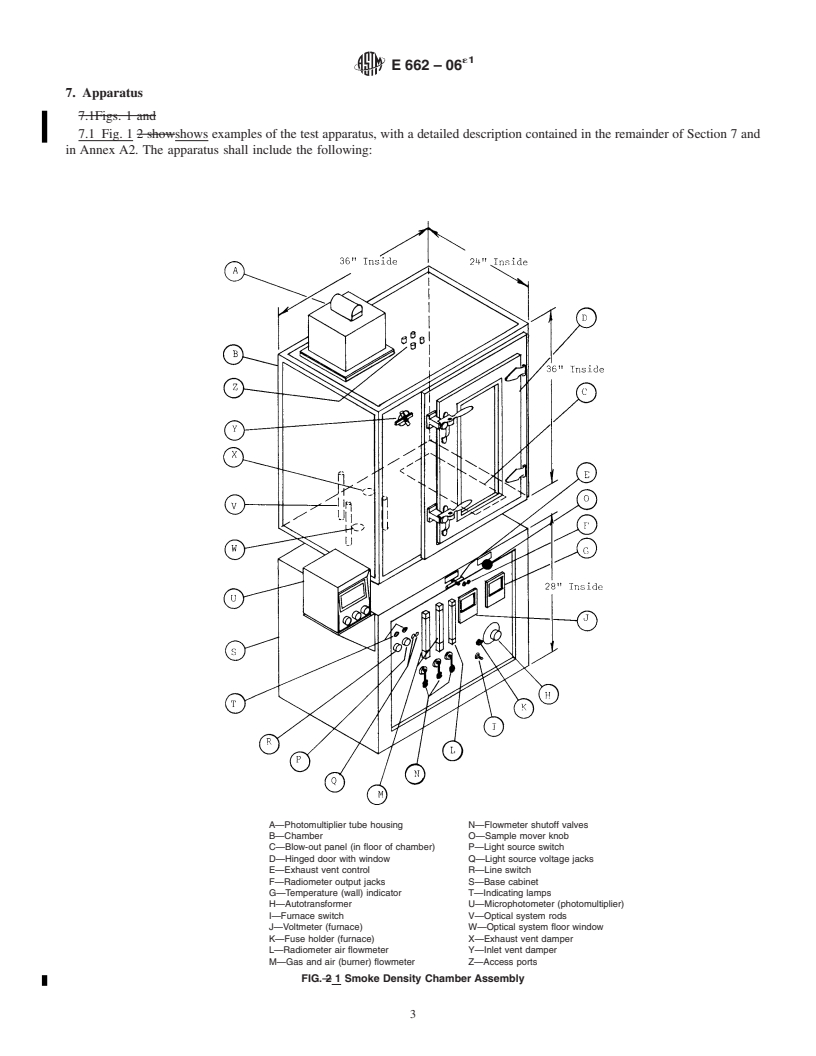

4.3 The test specimens are exposed to the flaming and

as standard. Values stated in parentheses are for information

nonflaming conditions within a closed chamber.Aphotometric

only.

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire

2

Standards and is the direct responsibility of Subcommittee E05.21 on Smoke and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Combustion Products. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved July 15, 2006. Published August 2006. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1979. Last previous edition approved in 2005 as E662–05. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

E662–06

systemwithaverticallightpathisusedtomeasurethevarying reported. The test method is not suitable if more than three of

light transmission as smoke accumulates. The light transmit- the six replicates tested show these characteristics.

tance measurements are used to calculate specific optical

6.2 Thetestmethodhasprovensensitivetosmallvariations

density of the smoke generated during the time period to reach in sample geometry, surface orientation, thickness (either

3

the maximum value.

overall or individual layer), weight, and composition. It is,

therefore, critical that the replicate samples

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:E662–05 Designation: E 662 – 06

Standard Test Method for

Specific Optical Density of Smoke Generated by Solid

1

Materials

This standard is issued under the fixed designation E662; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Added research report footnote to Section 14 editorially in September 2008.

1. Scope

1.1 This fire-test-response standard covers determination of the specific optical density of smoke generated by solid materials

and assemblies mounted in the vertical position in thicknesses up to and including 1 in. (25.4 mm).

1.2 Measurementismadeoftheattenuationofalightbeambysmoke(suspendedsolidorliquidparticles)accumulatingwithin

a closed chamber due to nonflaming pyrolytic decomposition and flaming combustion.

1.3 Results are expressed in terms of specific optical density which is derived from a geometrical factor and the measured

optical density, a measurement characteristic of the concentration of smoke.

1.4 This test method is intended for use in research and development and not as a basis for ratings for regulatory purposes.

1.5 This standard measures and describes the response of materials, products, or assemblies to heat and flame under controlled

conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products

or assemblies under actual fire conditions.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.7 The values stated in inch-pound units are to be regarded as standard. Values stated in parentheses are for information only.

2. Referenced Documents

2

2.1 ASTM Standards:

D2843 Test Method for Density of Smoke from the Burning or Decomposition of Plastics

E176 Terminology of Fire Standards

3. Terminology

3.1 Definitions—For definitions of terms found in this test method refer to Terminology E176.

4. Summary of Test Method

4.1 This test method employs an electrically heated radiant-energy source mounted within an insulated ceramic tube and

2 2

positioned so as to produce an irradiance level of 2.2 Btu/s·ft (2.5 W/cm ) averaged over the central 1.5-in. (38.1-mm) diameter

area of a vertically mounted specimen facing the radiant heater. The nominal 3 by 3-in. (76.2 by 76.2-mm) specimen is mounted

9 9

withinaholderwhichexposesanareameasuring2 ⁄16by2 ⁄16in.(65.1by65.1mm).Theholderisabletoaccommodatespecimens

up to 1 in. (25.4 mm) thick. This exposure provides the nonflaming condition of the test.

4.2 For the flaming condition, a six-tube burner is used to apply a row of equidistant flamelets across the lower edge of the

exposed specimen area and into the specimen holder trough. This application of flame in addition to the specified irradiance level

from the heating element constitutes the flaming combustion exposure.

4.3 The test specimens are exposed to the flaming and nonflaming conditions within a closed chamber.Aphotometric system

with a vertical light path is used to measure the varying light transmission as smoke accumulates. The light transmittance

1

ThistestmethodisunderthejurisdictionofASTMCommitteeE05onFireStandardsandisthedirectresponsibilityofSubcommitteeE05.21onSmokeandCombustion

Products.

´2

Current edition approved Dec. 1, 2005. Published December 2005. Originally approved in 1979. Last previous edition approved in 2003 as E662–03 .

Current edition approved July 15, 2006. Published August 2006. Originally approved in 1979. Last previous edition approved in 2005 as E662–05.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

E662–06

measurements are used to calculate specific optical density of the smoke generated during the time period

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.