ASTM D6874-03(2009)e1

(Test Method)Standard Test Methods for Nondestructive Evaluation of Wood-Based Flexural Members Using Transverse Vibration

Standard Test Methods for Nondestructive Evaluation of Wood-Based Flexural Members Using Transverse Vibration

SIGNIFICANCE AND USE

The dynamic modulus of elasticity provided by these test methods is a fundamental property for the configuration tested. This value can be related to static and other dynamic moduli of elasticity as measured on the same configuration.

The rapidity and ease of application of these test methods facilitate its use as a substitute for static measurements.

Dynamic modulus of elasticity is often used for surveys, for segregation of lumber for test purposes, and to provide indication of environmental or processing effect.

The modulus of elasticity, whether measured statically or dynamically, is often a useful predictor variable to suggest or explain property relationships.

SCOPE

1.1 These test methods cover the determination of the flexural stiffness and modulus of elasticity properties of wood-based materials by nondestructive testing using transverse vibration in the vertical direction.

1.2 The test methods are limited to specimens having solid, rectangular sections.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6874 − 03 (Reapproved 2009)

StandardTest Methods for

Nondestructive Evaluation of Wood-Based Flexural

Members Using Transverse Vibration

This standard is issued under the fixed designation D6874; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—A units of measurement statement was editorially added in December 2009.

INTRODUCTION

Nondestructive testing methods are used to determine the physical and mechanical properties of

wood-based materials. These test methods help ensure structural performance of products manufac-

turedfromavarietyofwoodspeciesandqualitylevelsofrawmaterials.Thesetestmethodsalsoassist

in evaluating the influence of environmental conditions on product performance.

These test methods for transverse vibration nondestructive testing of wood-based materials adopt

methods used by various testing and research organizations. These test methods will yield results

comparable to traditional methods, permitting standardization of results, interchange and correlation

of data, and establishment of a cumulative body of information on wood species and products of the

world.

1. Scope 2. Referenced Documents

1.1 These test methods cover the determination of the 2.1 ASTM Standards:

flexural stiffness and modulus of elasticity properties of wood- D9Terminology Relating to Wood and Wood-Based Prod-

based materials by nondestructive testing using transverse ucts

vibration in the vertical direction. D198Test Methods of Static Tests of Lumber in Structural

Sizes

1.2 The test methods are limited to specimens having solid,

D1990Practice for Establishing Allowable Properties for

rectangular sections.

Visually-Graded Dimension Lumber from In-Grade Tests

1.3 Thevaluesstatedininch-poundunitsaretoberegarded

of Full-Size Specimens

as standard. The values given in parentheses are mathematical

D2915Practice for Sampling and Data-Analysis for Struc-

conversions to SI units that are provided for information only

tural Wood and Wood-Based Products

and are not considered standard.

D4442Test Methods for Direct Moisture Content Measure-

1.4 This standard does not purport to address all of the

ment of Wood and Wood-Base Materials

safety concerns, if any, associated with its use. It is the D4444Test Method for Laboratory Standardization and

responsibility of the user of this standard to establish appro-

Calibration of Hand-Held Moisture Meters

priate safety and health practices and determine the applica- D4761Test Methods for Mechanical Properties of Lumber

bility of regulatory limitations prior to use.

and Wood-Base Structural Material

E4Practices for Force Verification of Testing Machines

E1267GuideforAstmStandardSpecificationQualityState-

ments (Withdrawn 1996)

1 2

These test methods are under the jurisdiction of ASTM Committee D07 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

WoodandisthedirectresponsibilityofSubcommitteeD07.01onFundamentalTest contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Methods and Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Dec. 1, 2009. Published December 2009. Originally the ASTM website.

approved in 2003. Last previous edition approved in 2003 as D6874–03. DOI: The last approved version of this historical standard is referenced on

10.1520/D6874-03R09E01. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6874 − 03 (Reapproved 2009)

2.2 Other Standard: 5.2 The modulus of elasticity, whether measured statically

ISO7626/1Vibration and Shock-Experimental Determina- or dynamically, is often a useful predictor variable to suggest

tion of Mechanical Mobility—Part 1: Basic Definitions or explain property relationships.

and Transducers

6. Apparatus

3. Terminology

6.1 The testing equipment shall consist of three essential

elements:

3.1 Definitions—See Terminology D9 and Test Methods

6.1.1 A support apparatus,

D198.

6.1.2 An excitation system, and

3.2 Definitions of Terms Specific to This Standard:

6.1.3 A measurement system.

3.2.1 calibration—the determination of the relationship be-

6.2 Support Apparatus—The support shall provide vertical

tween the response of standardized instrumentation to proper-

support to the ends of the specimen yet permit rotation.

ties of reference material, determined by a standard method.

6.2.1 Reactions—The specimen shall be supported in a

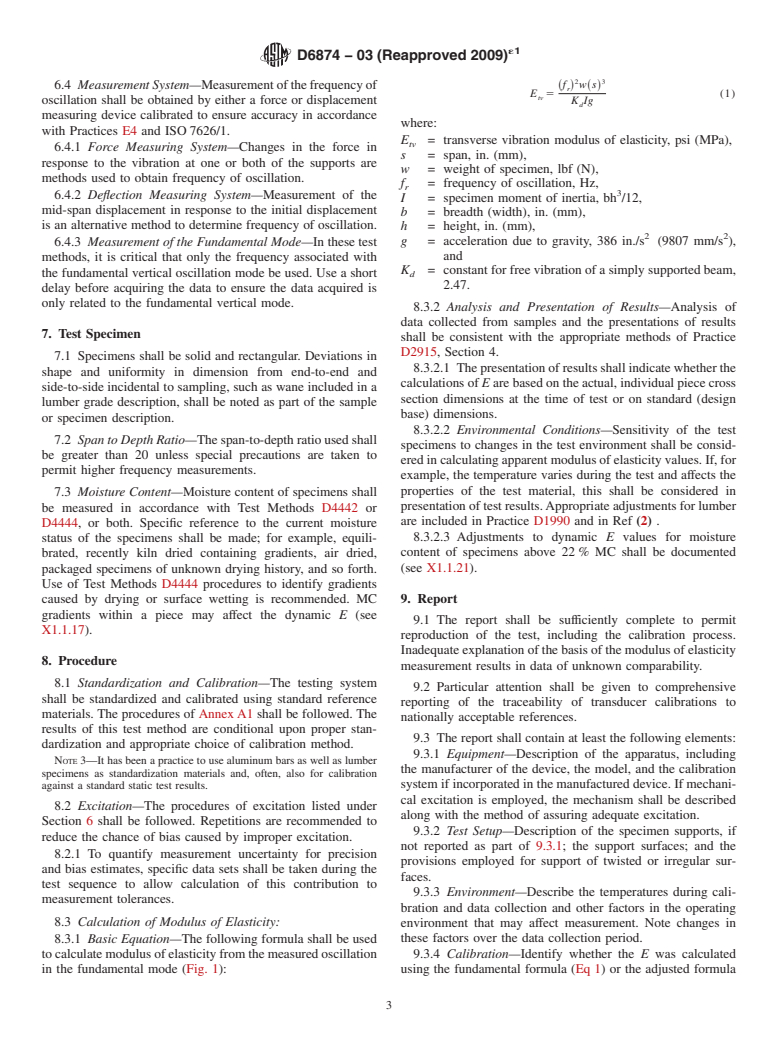

3.2.2 fundamental mode of vibration—the simplest mode of

manner to prevent damage to the specimen at the point of

vibration for a simply supported beam is the vertical motion

contactbetweenitandthereactionsupport.Thereactionsshall

produced from a slight vertical displacement of the member at

be such that change in length of the specimen longitudinal

its mid-span.This is termed its fundamental mode of vibration

movement and rotation of the specimen about the reaction due

(Fig. 1) and is the mode to which this standard applies.

to deflection will be unrestricted.

3.2.3 standardization—the determination of the response of

6.2.2 Reaction Alignment—Provision shall be made at the

the instrumentation to a reference material.

reactionstoallowforinitialtwistinthelengthofthespecimen.

If the bearing surfaces of the specimen at its reaction are not

3.2.4 transverse vibration—the oscillation of a simply sup-

parallel to the bearing surface of the reactions, the specimen

ported bending member that results from an initial displace-

shall be shimmed or the bearing surfaces rotated about an axis

ment of the member at its mid-span or other means of exciting

parallel to the span to provide adequate bearing across the

its fundamental mode of vibration.

width of the specimen.

6.2.3 Lateral Support—No lateral support shall be applied.

4. Summary of Test Method

Specimens unstable in this mode shall not be tested using this

4.1 The structural member is deflected at its mid-span and

method.

allowed to oscillate in a transverse bending mode. Observa-

6.2.4 Lengthwise Positioning and Overhang of the

tions of frequency of oscillation are used to calculate modulus

Specimen—The specimen shall be positioned such that an

of elasticity.

equal portion of the length overhangs each support. Excessive

overhangmayalterresultsobtained.Ifbasicequation(Eq1)is

5. Significance and Use

used, then the span(s) to length (L) ratio shall exceed 0.98. If

5.1 The dynamic modulus of elasticity provided by these

other s/Lratios are used, more exacting analysis and equations

test methods is a fundamental property for the configuration

shall be used; see Ref (1).

tested. This value can be related to static and other dynamic

NOTE1—Intestingofdimensionlumber,anoverhangofapproximately

moduli of elasticity as measured on the same configuration.

1in.oneachendisoftenused.Theamountofoverhangmaybeinfluenced

5.1.1 The rapidity and ease of application of these test

by the convenience of handling and positioning but should be kept

methods facilitate its use as a substitute for static measure-

uniform from specimen to specimen.

ments.

6.3 Excitation System—The member shall be excited so as

5.1.2 Dynamic modulus of elasticity is often used for

toproduceaverticaloscillationinareproduciblemannerinthe

surveys, for segregation of lumber for test purposes, and to

fundamental mode. The method of analysis is based on

provide indication of environmental or processing effect.

oscillation in this mode (Fig. 1).

6.3.1 Manual Method—A manual deflection of the speci-

men will provide sufficient impetus for oscillation for many

products. The deflection shall be vertical with an effort to

exclude lateral components; neither excessive impact nor

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

prolonged contact with the specimen are recommended.

4th Floor, New York, NY 10036, http://www.ansi.org.

NOTE 2—For example, a manual tap on a 16-foot 2-by-12, supported

flat-wisehavingaMOEof2.0×10 psiwillresultinaverticaloscillation

of between 3 and 4 Hz.

6.3.2 MechanicalMethods—Theguidelinesof6.3.1shallbe

duplicatedwithmechanicalsystems.Specimenswithveryhigh

stiffness require mechanical excitation by a high force or

carefully regulated impact/release.

The boldface numbers in parentheses refer to a list of references at the end of

FIG. 1 Transverse Vibration in the Fundamental Mode this standard.

´1

D6874 − 03 (Reapproved 2009)

2 3

6.4 MeasurementSystem—Measurementofthefrequencyof f w s

~ ! ~ !

r

E 5 (1)

tv

oscillation shall be obtained by either a force or displacement K Ig

d

measuring device calibrated to ensure accuracy in accordance

where:

with Practices E4 and ISO7626/1.

E = transverse vibration modulus of elasticity, psi (MPa),

tv

6.4.1 Force Measuring System—Changes in the force in

s = span, in. (mm),

response to the vibration at one or both of the supports are

w = weight of specimen, lbf (N),

methods used to obtain frequency of oscillation.

f = frequency of oscillation, Hz,

r

6.4.2 Deflection Measuring System—Measurement of the

I = specimen moment of inertia, bh /12,

mid-span displacement in response to the initial displacement

b = breadth (width), in. (mm),

is an alternative method to determine frequency of oscillation.

h = height, in. (mm),

2 2

g = acceleration due to gravity, 386 in./s (9807 mm/s ),

6.4.3 Measurement of the Fundamental Mode—Inthesetest

and

methods, it is critical that only the frequency associated with

K = constantforfreevibrationofasimplysupportedbeam,

the fundamental vertical oscillation mode be used. Use a short

d

2.47.

delay before acquiring the data to ensure the data acquired is

only related to the fundamental vertical mode.

8.3.2 Analysis and Presentation of Results—Analysis of

data collected from samples and the presentations of results

7. Test Specimen

shall be consistent with the appropriate methods of Practice

D2915, Section 4.

7.1 Specimens shall be solid and rectangular. Deviations in

8.3.2.1 Thepresentationofresultsshallindicatewhetherthe

shape and uniformity in dimension from end-to-end and

calculationsof Earebasedontheactual,individualpiececross

side-to-side incidental to sampling, such as wane included in a

section dimensions at the time of test or on standard (design

lumber grade description, shall be noted as part of the sample

base) dimensions.

or specimen description.

8.3.2.2 Environmental Conditions—Sensitivity of the test

7.2 Span to Depth Ratio—Thespan-to-depthratiousedshall

specimens to changes in the test environment shall be consid-

be greater than 20 unless special precautions are taken to

eredincalculatingapparentmodulusofelasticityvalues.If,for

permit higher frequency measurements.

example, the temperature varies during the test and affects the

properties of the test material, this shall be considered in

7.3 Moisture Content—Moisture content of specimens shall

presentationoftestresults.Appropriateadjustmentsforlumber

be measured in accordance with Test Methods D4442 or

are included in Practice D1990 and in Ref (2) .

D4444, or both. Specific reference to the current moisture

8.3.2.3 Adjustments to dynamic E values for moisture

status of the specimens shall be made; for example, equili-

content of specimens above 22% MC shall be documented

brated, recently kiln dried containing gradients, air dried,

(see X1.1.21).

packaged specimens of unknown drying history, and so forth.

Use of Test Methods D4444 procedures to identify gradients

9. Report

caused by drying or surface wetting is recommended. MC

gradients within a piece may affect the dynamic E (see

9.1 The report shall be sufficiently complete to permit

X1.1.17).

reproduction of the test, including the calibration process.

Inadequateexplanationofthebasisofthemodulusofelasticity

8. Procedure

measurement results in data of unknown comparability.

8.1 Standardization and Calibration—The testing system

9.2 Particular attention shall be given to comprehensive

shall be standardized and calibrated using standard reference

reporting of the traceability of transducer calibrations to

materials.The procedures of AnnexA1 shall be followed.The

nationally acceptable references.

results of this test method are conditional upon proper stan-

9.3 The report shall contain at least the following elements:

dardization and appropriate choice of calibration method.

9.3.1 Equipment—Description of the apparatus, including

NOTE 3—It has been a practice to use aluminum bars as well as lumber

the manufacturer of the device, the model, and the calibration

specimens as standardization materials and, often, also for calibration

systemifincorporatedinthemanufactureddevice.Ifmechani-

against a standard static test results.

cal excitation is employed, the mechanism shall be described

8.2 Excitation—The procedures of excitation listed under

along with the method of assuring adequate excitation.

Section 6 shall be followed. Repetitions are recommended to

9.3.2 Test Setup—Description of the specimen supports, if

reduce the chance of bias caused by improper excitation.

not reported as part of 9.3.1; the support surfaces; and the

8.2.1 To quantify measurement uncertainty for precision

provisions employed for support of twisted or irregular sur-

and bias estimates, specific data sets shall be taken during the

faces.

test sequence to allow calculation of this contribution to

9.3.3 Environment—Describe the temperatures during cali-

measurement tolerances.

bration and data collection and other factors in the operating

8.3 Calculation of Modulus of Elasticity:

environment that may affect measurement. Note changes in

8.3.1 Basic Equation—The following formula shall be used these factors over the data collection period.

tocalculatemodulusofelasticityfromthemeasuredoscillation 9.3.4 Calibration—Identify whether the E was calculated

in the fundamental mode (Fig. 1): using the fundamental formula (Eq 1) or the adjusted formula

´1

D6874 − 03 (Reapproved 2009)

(see A1.2.4). If the latter was used, describe the source of the 10. Precision and Bias

factors k and z.Acomprehensive description of the materials

s

10.1 The precision and bias are dependent upon equipment

used for standardization and for calibration shall be provided.

used (see Section 6) and the Standardization and Calibration

9.3.5 Test Data—Present the test data in the units compa-

practices applied.

rable to those employed in 7.1. The data presentation shall

include an estimate of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.