ASTM E2480-12(2022)

(Practice)Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method with Multi-Valued Measurands

Standard Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method with Multi-Valued Measurands

SIGNIFICANCE AND USE

5.1 ASTM regulations require precision statements for all test methods in terms of repeatability and reproducibility. This practice may be used in obtaining the information needed to prepare a precision statement in accordance with Practice E177 and the “Blue Book.”

SCOPE

1.1 This practice describes the techniques for planning, conducting, and analyzing the results of an interlaboratory study (ILS) conducted for certain test methods within Committee E12.

1.2 This practice does not concern itself with the development of the test method but rather with the gathering of the information needed for the precision and bias statement after the completion of development of the test method. The data obtained in the ILS may indicate, however, that further effort is needed to improve the test method.

1.3 This practice is concerned exclusively with test methods that derive a multi-valued measurand, such as, but not limited to, spectral reflectance, transmittance function, tristimulus values, or RGB values. Variation in measurements of such multi-valued measurands are usually analyzed by reducing the data to a single-valued parameter, such as color difference, ΔE.

1.4 This practice covers methods of dealing with the non-normal distribution of the variation of sets of color-differences. This is done so that the user may derive valid statistics from such non-normal distributions.

1.5 This practice does not cover test methods, even in Committee E12, whose measurands are single-valued, or whose variations are known to be normally distributed. Task groups involved with such test methods are referred to Practice E691 which contains preferable methods of analyzing data with those properties.

1.6 This practice is not intended to establish a method for estimating possible color-difference tolerances.

1.7 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2480 − 12 (Reapproved 2022)

Standard Practice for

Conducting an Interlaboratory Study to Determine the

Precision of a Test Method with Multi-Valued Measurands

This standard is issued under the fixed designation E2480; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This practice describes the techniques for planning,

mine the applicability of regulatory limitations prior to use.

conducting, and analyzing the results of an interlaboratory

1.9 This international standard was developed in accor-

study (ILS) conducted for certain test methods within Com-

dance with internationally recognized principles on standard-

mittee E12.

ization established in the Decision on Principles for the

1.2 This practice does not concern itself with the develop-

Development of International Standards, Guides and Recom-

ment of the test method but rather with the gathering of the

mendations issued by the World Trade Organization Technical

information needed for the precision and bias statement after

Barriers to Trade (TBT) Committee.

the completion of development of the test method. The data

obtained in the ILS may indicate, however, that further effort is

2. Referenced Documents

needed to improve the test method.

2.1 ASTM Standards:

1.3 Thispracticeisconcernedexclusivelywithtestmethods

E177 Practice for Use of the Terms Precision and Bias in

that derive a multi-valued measurand, such as, but not limited

ASTM Test Methods

to, spectral reflectance, transmittance function, tristimulus

E284 Terminology of Appearance

values, or RGB values. Variation in measurements of such

E691 Practice for Conducting an Interlaboratory Study to

multi-valued measurands are usually analyzed by reducing the

Determine the Precision of a Test Method

data to a single-valued parameter, such as color difference,∆E.

E1345 Practice for Reducing the Effect of Variability of

Color Measurement by Use of Multiple Measurements

1.4 This practice covers methods of dealing with the non-

normal distribution of the variation of sets of color-differences.

3. Terminology

This is done so that the user may derive valid statistics from

such non-normal distributions.

3.1 Definitions—For color and appearance terms, see Ter-

minology E284.

1.5 This practice does not cover test methods, even in

3.2 Definitions of Terms Specific to This Standard:

Committee E12, whose measurands are single-valued, or

3.2.1 precision and bias, n—when a test method is applied

whose variations are known to be normally distributed. Task

to a large number of specimens that are as nearly alike as

groups involved with such test methods are referred to Practice

possible, the test results obtained nevertheless will not all have

E691 which contains preferable methods of analyzing data

the same values.Ameasure of the degree of agreement among

with those properties.

these test results describes the precision of the test method for

1.6 This practice is not intended to establish a method for

that material. This practice is designed only to estimate the

estimating possible color-difference tolerances.

precision of a test method. However, when accepted reference

1.7 The values stated in SI units are to be regarded as the values are known for the materials being tested, the test result

standard. The values given in parentheses are for information data obtained in accordance with this practice may be used to

only. estimate the bias of the test method. For a discussion of bias

estimation, see Practice E177.

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.2.2 repeatability and reproducibility, n—the term repeat-

abilityconcernsthevariabilitybetweenindependenttestresults

This practice is under the jurisdiction of ASTM Committee E12 on Color and

Appearance and is the direct responsibility of Subcommittee E12.02 on Spectro-

photometry and Colorimetry. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2022.PublishedJuly2022.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 2007. Last previous edition approved in 2017 as E2480 – 12 (2017). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2480-12R22. theASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2480 − 12 (2022)

obtained within a single laboratory in the shortest practical PLANNING THE INTERLABORATORY STUDY (ILS)

period of time by a single operator applying the test method

6. ILS Membership

with a specific set of test apparatus using test specimens taken

at random from a single quantity of homogeneous material

6.1 Task Group—Either the task group that developed the

obtained, or prepared, for the ILS. The term reproducibility

test method or a special task group formed specifically for the

concerns the variability between single test results obtained in

purpose must have overall responsibility for the funding,

different laboratories, each by a different operator, each of

staffing, design, and decision-making with regard to data in the

whom has applied the test method to specimens taken at

ILS. The task group should decide on the number of

random from a single quantity of homogeneous material

laboratories, materials, and test results for the ILS. The task

obtained, or prepared, for the ILS.

group should obtain a statement of willingness to participate

3.2.2.1 Discussion—The above single operator and single

fromeachoftheparticipatinglaboratories.Inaddition,thetask

apparatus requirement, as specified in 3.2.2, means that for a

group should obtain, randomize, and distribute the specimens

particular step in the measurement process the same combina-

to be tested.

tionofoperatorandapparatusisusedtoobtaineverytestresult

6.2 ILS Coordinator—The task group must appoint one

on every specimen. Thus, one operator could prepare and

individual to act as overall coordinator of the ILS. This person

mount the specimen, another actuate the measurements, and

hasresponsibilityfordistributingthematerialsandprotocolsto

still another record the value of the result.

the laboratories, and for receiving the test result reports from

3.2.2.2 Discussion—The shortest practical period of time

the laboratories.

means that the test results are obtained in a time not less than

6.3 Statistician:

normal testing and not so long as to permit significant changes

6.3.1 The test method task group should obtain the assis-

in material, equipment, calibration, or environment.

tance of a person familiar with the statistical procedures of this

3.2.2.3 Discussion—Therequirementthatthemeasurements

practice and with the materials being tested. When no such

be independent means that a single test determination begins

person is available, the task group should obtain the assistance

with the mounting of the specimen on the sample port or in the

of a statistician who has experience in practical work with data

transmission compartment, and ends with the removal of the

from materials. Task group members need not be members of

test specimen from the port or compartment.All measurements

ASTM.

are made with replacement.

6.3.2 The calculation of the statistics for each material may

3.2.2.4 Discussion—The requirement for different laborato-

be readily done by persons not having knowledge of statistics,

ries does not exclude the case where more than one instrument

but having basic knowledge of calculating and computers.

resides in the same company, laboratory, or room, provided

that each has an independent and separate calibration traceabil-

6.4 Laboratory ILS Supervisor—Each participating labora-

ity path from each other.

tory must have an ILS supervisor to oversee the conduct of the

ILS within the laboratory and to communicate with the ILS

3.2.3 test method and protocol, n—in this practice, the term

Coordinator. This supervisor’s name should be obtained at the

testmethodappliestoboththeactualmeasurementprocessand

the written description of the process, while the term protocol time that the laboratory states its willingness to participate.

refers to the written instructions given the participants for

7. Basic Design

conducting the ILS.

7.1 Keep the design as simple as possible in order to obtain

3.2.4 test specimens, n—the portion of the material being

estimates of within- and between-laboratory variability that are

tested needed for obtaining a single test determination is called

free of secondary effects. The basic design is represented by a

a test specimen.Asingle test specimen may be measured more

two-way classification table, in which the rows represent the

than once and the results combined to produce a test result if

laboratories, and the columns represent the materials, and each

the protocol or test method so specifies.

cell (the intersection of a row and a column) contains a test

4. Summary of Practice result made by a particular laboratory on a particular material.

4.1 The procedure presented in this practice consists of

8. Test Method

three steps: planning the interlaboratory study, guiding the

8.1 A written version of the test method (but not one

testing phase of the study, and analyzing the test result data.

necessarily as yet published as an ASTM standard) must have

The analysis includes the calculation of the numerical mea-

been developed and be distributed with the protocol if other-

sures of precision of the test method applying to both within-

wise unavailable to the participating laboratories.

laboratory repeatability and between-laboratory reproducibil-

ity.

8.2 The test method should have been subjected to a

screening procedure, in order that some experience with the

5. Significance and Use

test method has been obtained before an ILS is conducted.Test

5.1 ASTM regulations require precision statements for all conditionsthataffectthetestresults,ifany,shouldbeidentified

test methods in terms of repeatability and reproducibility. This and a statement of the needed degree of control of these

practice may be used in obtaining the information needed to conditions should be provided. In addition, the test method, or

prepareaprecisionstatementinaccordancewithPracticeE177 the protocol, should specify to how many digits of precision

and the “Blue Book.” each test result is to be measured.

E2480 − 12 (2022)

8.3 The test method should specify the calibration proce- 11. Number of Test Results per Material

dure and the frequency of calibration.

11.1 The minimum number of test results per laboratory on

each material shall be four.The number may rise to as many as

9. Laboratories

ten when test results are apt to vary considerably. The number

9.1 Number of Laboratories—An ILS should be run with no

of test results in any one ILS will be determined by the Task

fewer than 8 laboratories. It is recommended that the number

Group, based upon the desired level of tolerance and the

of laboratories be set at 10, and it is desirable that more

anticipated variation of test results from the test method.

laboratories be included if available in order that the ILS is

conducted with a reasonable cross-section of competent labo-

12. Protocol

ratories. Under no circumstances, allowing for attrition, should

12.1 Prepare a written protocol containing instructions for

the final statement of precision of a test method be based on

the participating laboratories to follow. Clearly identify the

fewer than 6 laboratories when the requisite three materials are

specific version of the test method being studied. If the test

employed.

method allows options in apparatus or procedure, clearly

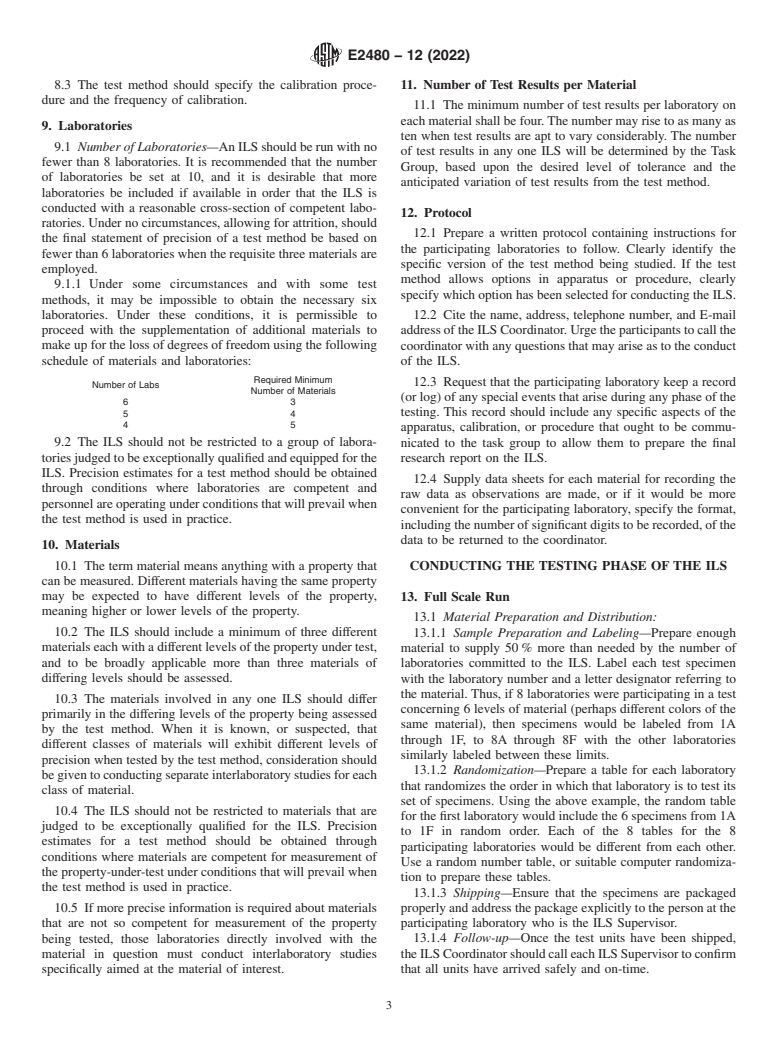

9.1.1 Under some circumstances and with some test

specify which option has been selected for conducting the ILS.

methods, it may be impossible to obtain the necessary six

laboratories. Under these conditions, it is permissible to 12.2 Cite the name, address, telephone number, and E-mail

proceed with the supplementation of additional materials to addressoftheILSCoordinator.Urgetheparticipantstocallthe

make up for the loss of degrees of freedom using the following coordinator with any questions that may arise as to the conduct

schedule of materials and laboratories:

of the ILS.

Required Minimum

12.3 Request that the participating laboratory keep a record

Number of Labs

Number of Materials

(or log) of any special events that arise during any phase of the

testing. This record should include any specific aspects of the

apparatus, calibration, or procedure that ought to be commu-

9.2 The ILS should not be restricted to a group of labora- nicated to the task group to allow them to prepare the final

toriesjudgedtobeexceptionallyqualifiedandequippedforthe research report on the ILS.

ILS. Precision estimates for a test method should be obtained

12.4 Supply data sheets for each material for recording the

through conditions where laboratories are competent and

raw data as observations are made, or if it would be more

personnelareoperatingunderconditionsthatwillprevailwhen

convenient for the participating laboratory, specify the format,

the test method is used in practice.

includingthenumberofsignificantdigitstoberecorded,ofthe

data to be returned to the coordinator.

10. Materials

10.1 The term material means anything with a property that CONDUCTING THE TESTING PHASE OF THE ILS

can be measured. Different materials having the same property

may be expected to have different levels of the property,

13. Full Scale Run

meaning higher or lower levels of the property.

13.1 Material Preparation and Distribution:

10.2 The ILS should include a minimum of three different

13.1.1 Sample Preparation and Labeling—Prepare enough

materials each with a different levels of the property under test, material to supply 50 % more than needed by the number of

and to be broadly applicable more than three materials of

laboratories committed to the ILS. Label each test specimen

differing levels should be assessed. with the laboratory number and a letter designator referring to

the material. Thus, if 8 laboratories were participating in a test

10.3 The materials involved in any one ILS should di

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.