ASTM D808-05

(Test Method)Standard Test Method for Chlorine in New and Used Petroleum Products (Bomb Method)

Standard Test Method for Chlorine in New and Used Petroleum Products (Bomb Method)

SIGNIFICANCE AND USE

This test method may be used to measure the level of chlorine-containing compounds in petroleum products. This knowledge can be used to predict performance or handling characteristics of the product in question.

This test method can also serve as a qualitative tool for the presence or non-detection of chlorine in petroleum products. In light of the efforts in the industry to prepare chlorine free products, this test method would provide information regarding the chlorine levels, if any, in such products.

SCOPE

1.1 This test method covers the determination of chlorine in lubricating oils and greases, including new and used lubricating oils and greases containing additives, and in additive concentrates. Its range of applicability is 0.1 to 50 m% chlorine. The procedure assumes that compounds containing halogens other than chlorine will not be present.

1.2 The preferred units are mass percent. The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Attention is called to specific warning statements incorporated in the test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D808–05

Standard Test Method for

Chlorine in New and Used Petroleum Products (Bomb

1

Method)

This standard is issued under the fixed designation D808; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* mechanical condition. It is desirable, however, that the bomb

1

be enclosed in a shield of steel plate at least 13 mm ( ⁄2 –in.)

1.1 This test method covers the determination of chlorine in

thick, or equivalent protection be provided against unforesee-

lubricating oils and greases, including new and used lubricat-

ablecontingencies.)Thechlorinecompoundsthusliberatedare

ing oils and greases containing additives, and in additive

absorbed in a sodium carbonate solution and the amount of

concentrates. Its range of applicability is 0.1 to 50 m% chlo-

chlorine present is determined gravimetrically by precipitation

rine. The procedure assumes that compounds containing halo-

as silver chloride.

gens other than chlorine will not be present.

1.2 The preferred units are mass percent. The values stated

4. Significance and Use

in SI units are to be regarded as standard. No other units of

4.1 This test method may be used to measure the level of

measurement are included in this standard.

chlorine-containing compounds in petroleum products. This

1.3 This standard does not purport to address all of the

knowledge can be used to predict performance or handling

safety concerns, if any, associated with its use. It is the

characteristics of the product in question.

responsibility of the user of this standard to establish appro-

4.2 This test method can also serve as a qualitative tool for

priate safety and health practices and determine the applica-

the presence or non-detection of chlorine in petroleum prod-

bility of regulatory limitations prior to use. Attention is called

ucts. In light of the efforts in the industry to prepare chlorine

to specific warning statements incorporated in the test method.

free products, this test method would provide information

2. Referenced Documents regarding the chlorine levels, if any, in such products.

2

2.1 ASTM Standards:

5. Apparatus

D1193 Specification for Reagent Water

5.1 Bomb, having a capacity of not less than 300 mL, so

D4057 Practice for Manual Sampling of Petroleum and

constructed that it will not leak during the test, and that

Petroleum Products

quantitative recovery of the liquids from the bomb may be

D6299 Practice for Applying Statistical Quality Assurance

readily achieved. The inner surface of the bomb may be made

and Control Charting Techniques to Evaluate Analytical

of stainless steel or any other material that will not be affected

Measurement System Performance

by the combustion process or products. Materials used in the

3. Summary of Test Method bomb assembly, such as the head gasket and lead-wire insula-

tion,shallberesistanttoheatandchemicalaction,andshallnot

3.1 The sample is oxidized by combustion in a bomb

undergo any reaction that will affect the chlorine content of the

containing oxygen under pressure. (Warning—Strict adher-

liquid in the bomb.

ence to all of the provisions prescribed hereinafter ensures

5.2 Sample Cup, platinum, 24 mm in outside diameter at the

against explosive rupture of the bomb, or a blow-out, provided

bottom, 27 mm in outside diameter at the top, 12 mm in height

the bomb is of proper design and construction and in good

outside, and weighing 10 to 11 g.

5.3 Firing Wire, platinum, No. 26 B & S gage 0.41 (16

1

This test method is under the jurisdiction of ASTM Committee D02 on

thou), 27 SWG or equivalent.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

5.4 Ignition Circuit, capable of supplying sufficient current

D02.03 on Elemental Analysis.

toignitethenylonthreadorcottonwickingwithoutmeltingthe

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1944. Last previous edition approved in 2000 as D808–00. DOI:

wire.

10.1520/D0808-05.

5.4.1 Theswitchintheignitioncircuitshallbeofatypethat

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

remains open, except when held in closed position by the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

operator.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

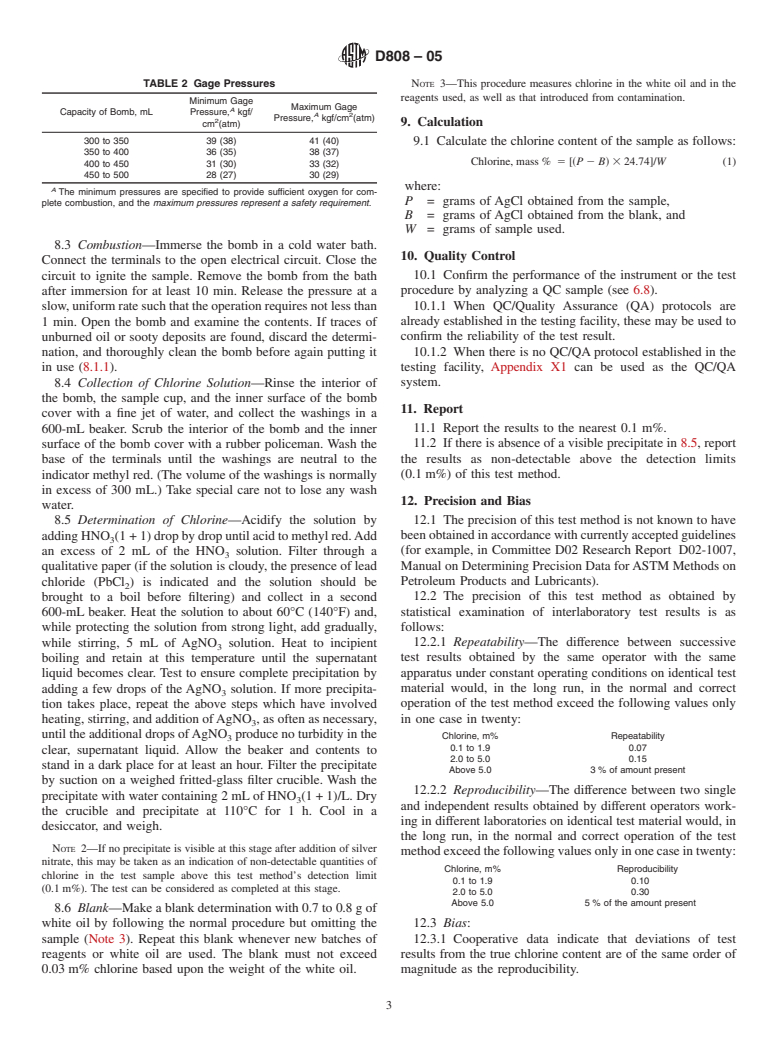

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.