ASTM E2652-09

(Terminology)Standard Test Method for Behavior of Materials in a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750°C

Standard Test Method for Behavior of Materials in a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750<span class='unicode'>°</span>C

SIGNIFICANCE AND USE

While actual building fire exposure conditions are not duplicated, this test method will assist in indicating those materials which do not act to aid combustion or add appreciable heat to an ambient fire.

This test method does not apply to laminated or coated materials.

This test method is technically equivalent to ISO 1182.

SCOPE

1.1 This fire-test-response test method covers the determination under specified laboratory conditions of combustion characteristics of building materials. It does not apply to laminated or coated materials.

1.2 This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this test method.

1.3 Limitations of the test method are discussed in 1.1 and Annex A1.

1.4 This test method is technically equivalent to ISO 1182.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 2652 – 09

Standard Test Method for

Behavior of Materials in a Tube Furnace with a Cone-shaped

Airflow Stabilizer, at 750°C

This standard is issued under the fixed designation E 2652; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ISO Standards:

ISO 1182 Reaction to Fire Tests for Building Products –

1.1 This fire-test-response test method covers the determi-

Non-combustibility Test

nation under specified laboratory conditions of combustion

ISO 13943 Fire Safety — Vocabulary

characteristics of building materials. It does not apply to

ISO 5725-2:1994 Accuracy (trueness and precision) of

laminated or coated materials.

MeasuredMethodsandResults–Part2:BasicMethodfor

1.2 This test method references notes and footnotes that

the Determination of Repeatability and Reproducibility of

provide explanatory information. These notes and footnotes,

a Standard Measurement Method

excludingthoseintablesandfigures,shallnotbeconsideredas

2.3 Other Standards:

requirements of this test method.

IMO Fire Test Procedures Code

1.3 Limitations of the test method are discussed in 1.1 and

Annex A1.

3. Terminology

1.4 This test method is technically equivalent to ISO 1182.

3.1 Definitions—For definitions of terms found in this test

1.5 The values stated in SI units are to be regarded as

method, refer to Terminology E 176 and ISO 13943. In case of

standard. The values given in parentheses are for information

conflict, the definitions given in Terminology E 176 shall

only.

prevail.

1.6 This standard is used to measure and describe the

3.2 Definitions of Terms Specific to This Standard:

response of materials, products, or assemblies to heat and

3.2.1 homogeneous product, n—a product with nominally

flame under controlled conditions, but does not by itself

uniform density and composition.

incorporate all factors required for fire-hazard or fire-risk

3.2.2 non-homogeneous product, n—a product that does not

assessment of the materials, products, or assemblies under

satisfy the requirements of a homogeneous product.

actual fire conditions.

3.2.2.1 Discussion—Non-homogeneous products are often

1.7 This standard does not purport to address all of the

composed of more than one component.

safety concerns, if any, associated with its use. It is the

3.2.3 substantial component, n—a material that constitutes

responsibility of the user of this standard to establish appro-

a significant part of a non-homogeneous product that consists

priate safety and health practices and determine the applica-

of more than one component.

bility of regulatory limitations prior to use.

3.2.3.1 Discussion—A layer with a weight/unit area larger

2 2

2. Referenced Documents than 1.0 kg/m (0.2 lb/ft ) or a thickness larger than 1 mm (0.04

in.) is often considered to be a substantial component. A layer

2.1 ASTM Standards:

2 2

with a weight per unit area smaller than 1.0 kg/m (0.2 lb/ft )

E 136 Test Method for Behavior of Materials in a Vertical

and a thickness less than 1 mm (0.04 in.) is not considered to

Tube Furnace at 750°C

be a substantial component.

E 176 Terminology of Fire Standards

3.2.4 sustained flaming (for testing at 750°C), n—sustained

flaming for testing at 750°C (1382°F) is the persistence of a

flameonoroveranypartofthevisiblepartofthetestspecimen

This test method is under the jurisdiction of ASTM Committee E05 on Fire

Standards and is the direct responsibility of Subcommittee E05.23 on Combustibil-

lasting5sor longer.

ity.

Current edition approved Aug. 1, 2009. Published August 2009.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Available from International Maritime Origanization, 55 Victoria St., London,

the ASTM website.

SWIH0EU, United Kingdom, http://www.imo.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2652–09

TABLE 1 Furnace Tube Refractory Material for Apparatus

6.2.4.1 Theannularspaceshallbefittedwithtopandbottom

Composition plates, recessed internally to locate the ends of the furnace

Material

% (kg/kg mass)

tube.

Alumina (Al O ) >89

2 3 6.2.4.2 The annular space shall be insulated with a 25 mm

Silica and alumina (SiO ,Al O ) >98

2 2 3

(1 in.) mm layer of an insulating material having a thermal

Ferric oxide (Fe O) <0,45

conductivity of 0.04 6 0.01 W/(m K) (0.00077 6 0.00019

Titanium dioxide (TiO ) <0,25

Manganese oxide (Mn O ) <0,1

3 4

BTU in./(s ft °F)) at a mean temperature of 20°C (68°F).

Other trace oxides (sodium, potassium, The balance

Magnesium oxide powder of a nominal bulk density of 170 6

calcium and magnesium oxides)

3 3

30 kg/m (10.6 6 1.9 lb/ft ) is a suitable material for this use.

6.2.5 The furnace tube shall be provided with a single

4. Summary of Test Method

winding of 80/20 nickel/chromium electrical resistance tape,

3mm 6 0.1 mm (0.12 6 4/1000 in.) wide and 0.2 6 0.01 mm

4.1 This test method uses a furnace to expose homogeneous

(8/1000 6 0.4/1000 in.) thick.

products or substantial components of non homogeneous

products for at least 30 min to a temperature of 750°C 6.2.5.1 Wind the electrical resistance tape as specified in

(1382ºF). Fig. 2.

4.2 The furnace consists of an enclosed refractory tube 6.2.5.2 Cut grooves into the furnace tube so as to allow

surrounded by a heating coil with a cone-shaped airflow

accurate winding of the electrical tape.

stabilizer.

6.2.6 An open-ended cone-shaped air-flow stabilizer shall

4.3 Thermocouples are used to assess the temperature in-

be attached to the underside of the furnace.

creases resulting from combustion of the product.

6.2.6.1 The air-flow stabilizer shall be 500 mm (19.7 in.)

4.4 Weight loss and flaming combustion of the product is

long and shall be reduced uniformly from an internal diameter

also assessed.

of 75 6 1mm (2.9 6 0.04 in.) at the top to an internal diameter

of 10.0 6 0.5 mm (0.4 6 0.4 in.) at the bottom.

5. Significance and Use

6.2.6.2 The air flow stabilizer shall be manufactured from

5.1 While actual building fire exposure conditions are not

1 mm thick sheet steel, with a smooth finish on the inside. The

duplicated, this test method will assist in indicating those

joint between the air flow stabilizer and the furnace shall have

materials which do not act to aid combustion or add appre-

an airtight fit, with an internal smooth finish.

ciable heat to an ambient fire.

6.2.6.3 The upper half of the air flow stabilizer shall be

5.2 This test method does not apply to laminated or coated

insulated with a 25 mm (1 in.) layer of an insulating material

materials.

having a thermal conductivity of 0.04 6 0.01 W/(m K)

5.3 This test method is technically equivalent to ISO 1182.

(0.00077 6 0.00019 BTU in./(s ft °F)) at a mean temperature

of 20°C (68°F). Mineral fiber insulating material with a

6. Test Apparatus

nominal thermal conductivity of 0.04 6 0.01 W/(m K)

6.1 General:

(0.00077 60.00019BTUin./(sft °F)atameantemperatureof

6.1.1 Theapparatusshallconsistofarefractorytubefurnace

20°C (68°F) is a suitable material for this use.

insulated and surrounded by a heating coil. A cone-shaped

6.2.7 Adraft shield, constructed of the same material as the

airflow stabilizer shall be attached to the base of the furnace

air flow stabilizer, shall be provided at the top of the furnace.

and a draft shield to its top. Details are shown in Fig. 1.

It shall be 50 mm (2 in.) high and have an internal diameter of

6.1.2 Thermocouples shall be provided for measuring the

75 6 1 mm (2.9 6 0.04 in.)

furnace temperature and the furnace wall temperature. Op-

6.2.7.1 The draft shield and its joint with the top of the

tional additional thermocouples shall be used if the specimen

furnace shall have smooth internal finish.

surface temperature and the specimen center temperature are

6.2.7.2 The exterior shall be insulated with a 25 mm (1 in.)

required.

layer of an insulating material having a thermal conductivity of

6.1.3 Athermal sensor shall be used to measure the furnace

0.04 6 0.01 W/(m K) (0.00077 6 0.00019 BTU in./(s ft °F))

temperature along its central axis.

at a mean temperature of 20°C (68°F). Mineral fiber insulating

6.1.4 Unless stated otherwise, all dimensions shall have a

material with a nominal thermal conductivity of 0.04 6 0.01

5 % tolerance.

W/(m K) (0.00077 6 0.00019 BTU in./(s ft °F) at a mean

6.2 Test Furnace:

temperature of 20°C (68°F) is a suitable material for this use.

6.2.1 The test furnace shall consist primarily of the follow-

6.2.8 The assembly, consisting of the furnace, air flow

ing.

stabilizer cone and draft shield, shall be mounted on a firm

6.2.2 The furnace tube shall be constructed of a refractory

horizontal stand, with a base and draft screen attached to the

material, as specified in Table 1, of density 2800 6 300

3 3

stand, to reduce drafts around the bottom of the stabilizer cone.

kg/m (175 6 19 lb/ft ).

The draft screen shall be 550 mm (21.7 in.) high and the

6.2.3 Thefurnaceshallbe150 61mm(5.9 60.04in.)high

bottom of the air flow stabilizer cone shall be located 250 mm

with an internal diameter of 75 6 1 mm (2.9 6 0.04 in.) and

(9.8 in.) above the base plate.

a wall thickness of 10 6 1 mm (0.4 6 0.04 in.).

6.3 Test Specimen Holder and Insertion Device:

6.2.4 The furnace tube shall be surrounded by an annular

space of the following dimensions: 150 mm (5.9 6 0.04 in.) 6.3.1 The test specimen holder shall be made of nickel/

high and of 10 mm (0.4 6 0.04 in.) wall thickness. chromium or of an alternate heat-resisting steel wire. A fine

E2652–09

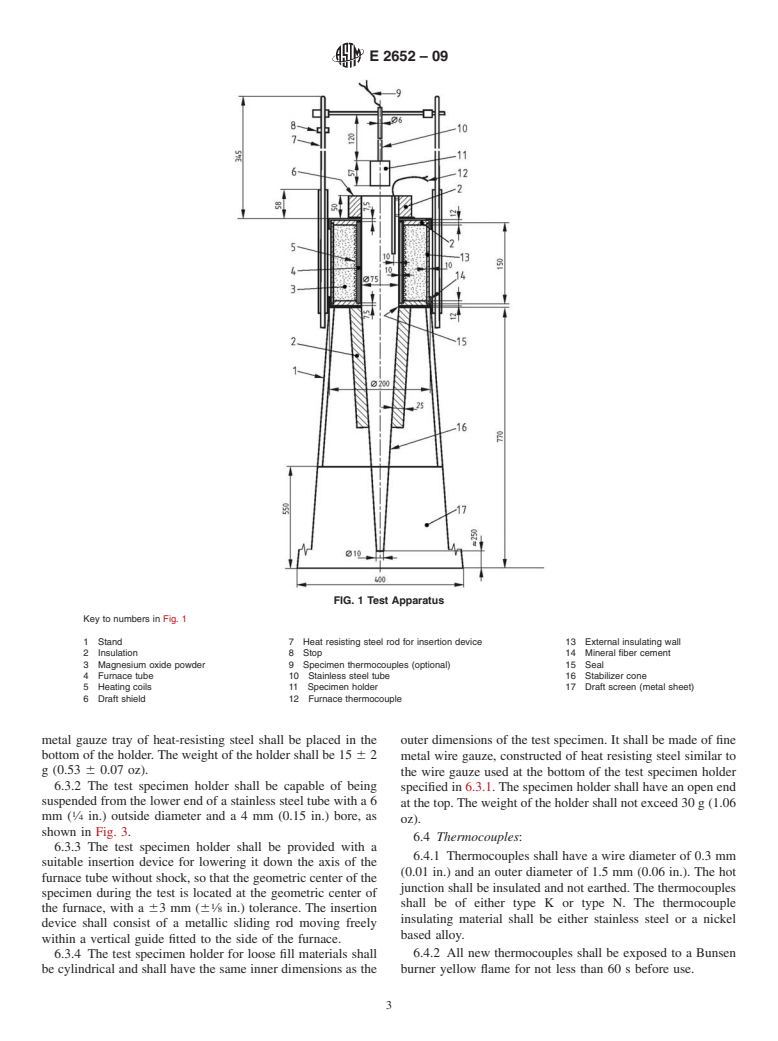

FIG. 1 Test Apparatus

Key to numbers in Fig. 1

1 Stand 7 Heat resisting steel rod for insertion device 13 External insulating wall

2 Insulation 8 Stop 14 Mineral fiber cement

3 Magnesium oxide powder 9 Specimen thermocouples (optional) 15 Seal

4 Furnace tube 10 Stainless steel tube 16 Stabilizer cone

5 Heating coils 11 Specimen holder 17 Draft screen (metal sheet)

6 Draft shield 12 Furnace thermocouple

metal gauze tray of heat-resisting steel shall be placed in the outer dimensions of the test specimen. It shall be made of fine

bottom of the holder. The weight of the holder shall be 15 6 2 metal wire gauze, constructed of heat resisting steel similar to

g (0.53 6 0.07 oz).

the wire gauze used at the bottom of the test specimen holder

6.3.2 The test specimen holder shall be capable of being

specified in 6.3.1. The specimen holder shall have an open end

suspended from the lower end of a stainless steel tube with a 6

at the top.The weight of the holder shall not exceed 30 g (1.06

mm ( ⁄4 in.) outside diameter anda4mm (0.15 in.) bore, as

oz).

shown in Fig. 3.

6.4 Thermocouples:

6.3.3 The test specimen holder shall be provided with a

6.4.1 Thermocouples shall have a wire diameter of 0.3 mm

suitable insertion device for lowering it down the axis of the

(0.01 in.) and an outer diameter of 1.5 mm (0.06 in.). The hot

furnace tube without shock, so that the geometric center of the

junction shall be insulated and not earthed. The thermocouples

specimen during the test is located at the geometric center of

shall be of either type K or type N. The thermocouple

the furnace, with a 63mm(6 ⁄8 in.) tolerance. The insertion

insulating material shall be either stainless steel or a nickel

device shall consist of a metallic sliding rod moving freely

based alloy.

within a vertical guide fitted to the side of the furnace.

6.4.2 All new thermocouples shall be exposed to a Bunsen

6.3.4 The test specimen holder for loose fill materials shall

be cylindrical and shall have the same inner dimensions as the burner yellow flame for not less than 60 s before use.

E2652–09

FIG. 2 Furnace Winding for Test Apparatus

NOTE 1—This will reduce thermocouple reflectivity.

so that its hot junction is located at the geometric center of the

test specimen. This shall be achieved by drillinga2mm (0.08

6.4.3 The furnace thermocouple shall be located with its hot

in.) diameter hole axially in the top of the test specimen.

junction10.0 60.5mm(0.4 60.04in.)fromthetubewalland

6.4.7 Optional Test Specimen Surface Thermocouple—The

ataheightcorrespondingtothegeometriccenterofthefurnace

optional test specimen surface thermocouple shall be posi-

tube.Alocating guide is a useful tool to set the position of the

tioned so that its hot junction is in contact with the test

thermocouple. The correct position shall be maintained with

specimen at mid-height of the test specimen at the start of the

the help of a guide attached to the draft shield.

test. It shall be located diametrically opposite the furnace

6.4.4 In addition to the thermocouple for the measurement

thermocouple.

of the furnace temperature, a similar thermocouple shall be

6.5 Thermal Sensor—The thermal sensor shall be con-

provided for measuring the furnace wall temperature during

structed of a thermocouple of the type specified in 6.4, brazed

calibration.

to a copper cylinder 10.0 6 0.2 mm (0.4 6 0.001 in.) in

6.4.5 If required, thermocouples shall also be provided for

diameter and 15.0 6 0.2 mm (0.6 6 0.001 in.) high.

measurement of the temperature in the geometric center of the

specimen and on the surface of the specimen. 6.6 Mirror—To facilitate observation of sustained flaming

6.4.6 Optional Test Specimen Center Thermocouple—The andforoperatorsafety,itisadvisabletoprovideamirrorabove

optional test specimen center thermocouple shall be positioned the apparatus, positioned so that it will not affect the test. A

E2652–09

FIG. 3 Specimen Holder for Solid Specimens

square mirror, 300 mm (11.8 in.) per side, at an angle of 30° to output from the thermocouple to the nearest 1°C (0.5ºF) or the

the horizontal, and placed 1 m (1.1 yd) above the furnace has millivoltequivalent.Itshallproduceapermanentrecordofthis

been found suitable. at intervals of not greater than 1 s.

6.7 Balance—A balance with an accuracy of 0.01 g (0.004

NOTE 2—A digital device or a multirange chart recorder with an

oz) is required.

operating range of 10 mV full scale deflection with a “zero” of approxi-

6.8 Voltage Stabilizer—A single-phase automatic voltage

mately 700°C (1292ºF) have been found suitable instruments

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.