ASTM F2059-06(2012)e1

(Test Method)Standard Test Method for Laboratory Oil Spill Dispersant Effectiveness Using The Swirling Flask

Standard Test Method for Laboratory Oil Spill Dispersant Effectiveness Using The Swirling Flask

SIGNIFICANCE AND USE

A standard test is necessary to establish a baseline performance parameter so that dispersants can be compared, a given dispersant can be compared for effectiveness on different oils, and at different oil weathering stages, and batches of dispersant or oils can be checked for effectiveness changes with time or other factors.

Dispersant effectiveness varies with oil type, sea energy, oil conditions, salinity, and many other factors. Test results from this test method form a baseline, but are not to be taken as the absolute measure of performance at sea. Actual field effectiveness could be more or less than this value.

Many dispersant tests have been developed around the world. This test has been developed over many years using findings from world-wide testing to use standardized equipment, test procedures, and to overcome difficulties noted in other test procedures.

SCOPE

1.1 This test method covers the procedure to determine the effectiveness of oil spill dispersants on various oils in the laboratory. This test method is not applicable to other chemical agents nor to the use of such products or dispersants in open waters.

1.2 This test method covers the use of the swirling flask test apparatus and does not cover other apparatuses nor are the analytical procedures described in this report directly applicable to such procedures.

1.3 The test results obtained using this test method are intended to provide baseline effectiveness values used to compare dispersants and oil types under conditions analogous to those used in the test.

1.4 The test results obtained using this test method are effectiveness values that should be cited as test values derived from this standard test. Dispersant effectiveness values do not directly relate to effectiveness at sea or in other apparatuses. Actual effectiveness at sea is dependant on sea energy, oil state, temperature, salinity, actual dispersant dosage, and amount of dispersant that enters the oil.

1.5 The decision to use or not use a dispersant on an oil should not be based solely on this or any other laboratory test method.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2059 − 06 (Reapproved 2012)

Standard Test Method for

Laboratory Oil Spill Dispersant Effectiveness Using the

Swirling Flask

This standard is issued under the fixed designation F2059; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—An editorial change was made to Section 6 in February 2012.

1. Scope 2. Summary of Test Method

1.1 This test method covers the procedure to determine the 2.1 Dispersant is pre-mixed with oil and placed on water in

effectiveness of oil spill dispersants on various oils in the a test vessel. The test vessel is agitated on a moving table

laboratory.This test method is not applicable to other chemical shaker. At the end of the shaking period, a settling period is

agents nor to the use of such products or dispersants in open specified and then a sample of water taken.The oil in the water

waters. column is extracted from the water using a pentane/

dichloromethane mixture and analyzed using gas chromatog-

1.2 This test method covers the use of the swirling flask test

raphy.

apparatus and does not cover other apparatuses nor are the

analytical procedures described in this report directly appli- 2.2 The extract is analyzed for oil using a gas chromato-

cable to such procedures. graph equipped with a flame ionization detector, (GC-FID).

Quantification is by means of the internal standard method.

1.3 The test results obtained using this test method are

Effectiveness values are derived by comparison with a cali-

intended to provide baseline effectiveness values used to

brated set of effectiveness values obtained at the same time and

compare dispersants and oil types under conditions analogous

by the same method.

to those used in the test.

3. Significance and Use

1.4 The test results obtained using this test method are

effectiveness values that should be cited as test values derived

3.1 A standard test is necessary to establish a baseline

from this standard test. Dispersant effectiveness values do not

performance parameter so that dispersants can be compared, a

directly relate to effectiveness at sea or in other apparatuses.

given dispersant can be compared for effectiveness on different

Actualeffectivenessatseaisdependantonseaenergy,oilstate,

oils, and at different oil weathering stages, and batches of

temperature, salinity, actual dispersant dosage, and amount of

dispersant or oils can be checked for effectiveness changes

dispersant that enters the oil.

with time or other factors.

1.5 The decision to use or not use a dispersant on an oil

3.2 Dispersant effectiveness varies with oil type, sea energy,

should not be based solely on this or any other laboratory test

oil conditions, salinity, and many other factors. Test results

method.

from this test method form a baseline, but are not to be taken

as the absolute measure of performance at sea. Actual field

1.6 The values stated in SI units are to be regarded as

effectiveness could be more or less than this value.

standard. No other units of measurement are included in this

standard.

3.3 Many dispersant tests have been developed around the

world. This test has been developed over many years using

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the findings from world-wide testing to use standardized

equipment, test procedures, and to overcome difficulties noted

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- in other test procedures.

bility of regulatory limitations prior to use.

4. Interferences and Sources of Error

4.1 Interferences can be caused by contaminants, particu-

larly residual oil or surfactants in solvents, on glassware, and

This test method is under the jurisdiction of ASTM Committee F20 on

Hazardous Substances and Oil Spill Response and is the direct responsibility of

other sample processing apparatus that lead to discrete artifacts

Subcommittee F20.13 on Treatment.

or elevated baselines in gas chromatograms. All glassware

Current edition approved Feb. 1, 2012. Published February 2012. Originally

must be thoroughly cleaned. The cleaning process includes

approved in 2000. Last previous edition approved in 2006 as F2059 – 06. DOI:

10.1520/F2059-06R12E01. rinsing with dichloromethane to remove the oil, followed by

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2059 − 06 (2012)

rinsing three times each with tap water, purified water (reverse 4.11 Extreme care should be taken when applying the oil to

osmosis), and acetone. Once cleaned, precautions must be thesurfacesothatmixingdoesnotoccur.Theoilshouldgently

taken to minimize contact of the glassware with surfactants to glide across the water to form a slick. If the oil streams out into

prevent undesired interferences. the water, the agitation can disperse the oil, increasing the

amount of oil dispersed and erroneously raising the final

4.2 Dispersant effectiveness is very susceptible to energy

dispersion result.

levels. Table top shakers generally start and stop slowly.

Shakers that start motion rapidly and stop suddenly impart a 4.12 A slick may form at the water surface in the spout of

high energy to the system and thus cause more dispersion than the swirling flask during mixing and settling. It is important

would be the case with a normal shaker. Furthermore, this thisoildoesnotenterthewatersampledforanalysis.Therefore

variation would not be repeatable. The shaker table used it is important to drain the contents of the spout (about 3 mL)

shouldbeobservedforrapidmovementsorstopstoensurethat prior to sampling, and ensure any adhering droplets do not

it is usable for these tests. The rotational speed of the shaker enter the sample.

should be checked with a tachometer every week.

4.13 The procedure is time critical for the elements of

4.3 The Erlenmeyer flasks used in this test are tapered and mixing, settling, and sampling. Care should be taken to adhere

the energy level varies with the amount of fill. to the times indicated in the procedure for both the mixing and

settling element, as variations in energy input, and especially

4.4 The output is highly sensitive to the volume of oil,

time allowed for droplet creaming, can impact results. Since

water, and extractant delivered. All pipets and dispensers

the water samples cannot be sampled simultaneously, this step

should be calibrated frequently and verified daily.

must be performed with as much careful haste as possible, to

4.5 Theuseofpositivedisplacementpipetsismandatoryfor

reduce the difference in settling times experienced by the

all controlled volumes of microlitre quantities. Use of volume

samples in the test run.

displacement pipets will result in erroneous results due to the

4.14 Analysis of the gas chromatograph-detectable Total

viscosity of the dispersants and oils, the variable viscosity of

Petroleum Hydrocarbon (TPH) content is subject to variability

the oils to be tested (some semi-solid), and the density of

in GC operation and repeatability. Therefore, it is imperative

dichloromethane.

that a rigorous quality assurance program is in place to ensure

4.6 The order of addition of the dispersant and oil has

the GC is functioning properly and valid results are obtained.

effectsontheaccuracyofresults,asthedispersantmayinteract

4.15 Care should be taken to determine the baseline in a

with the vessel walls if added first, thereby reducing the

valid and repeatable manner for both samples and calibration

quantityavailableinthepremix.Itisthereforeimportanttoadd

sets.

oil to the vessel first, and add the dispersant directly to the oil.

Asecondadditionofoilissuggestedsimplybecauseitiseasier 4.16 The accuracy and repeatability of the test can be

to control a large volume of oil than a minute volume of verified and compared using standard oil and dispersant

dispersant when attempting to achieve a specific ratio of 25:1. samples

4.7 Following surfactant addition, vigorous mixing is re-

5. Apparatus

quired to thoroughly homogenize the sample. Sharp, manual

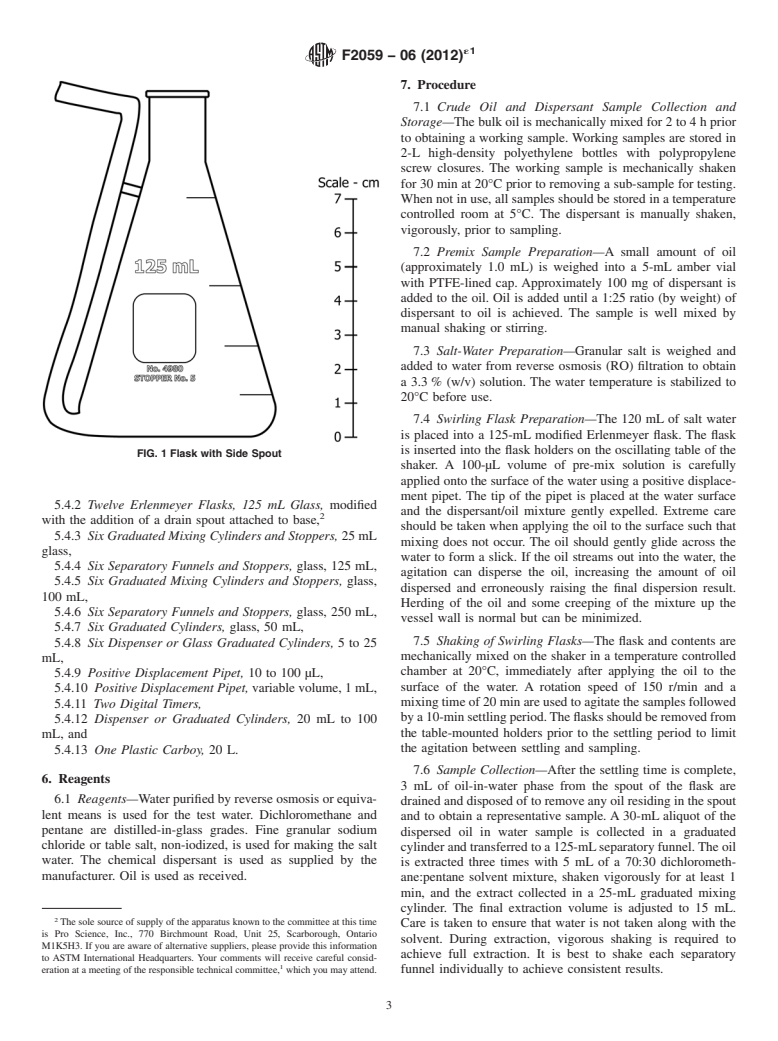

strokes are suggested for light oils, while very heavy oils may 5.1 Modified 120-mL Erlenmeyer Flask, used as the test

require stirring with a clean glass rod or spatula. vessel.Aside spout is added to a standard Erlenmeyer flask to

enable sampling from the water column with minimal distur-

4.8 There are indications that the results for some premixed

bance of resurfaced oil. This vessel is illustrated in Fig. 1.

dispersant/oilcombinationschangeovertime.Itisnecessaryto

take precautions against this potential source of variation. The 5.2 Moving-Table Shaker, with an orbital motion of 1 in.

testing should be concluded as soon as possible after the (25.4 mm) and fitted with flask holders. Ideally such shakers

premix is prepared, generally within a few hours. Results from should be constructed inside temperature-controlled chambers.

samples stored for periods as long as a week should not be Ifsuchanenclosedchamberisnotused,themeasurementmust

considered reliable. be conducted inside temperature-controlled rooms.

4.9 Since the performance of the dispersant is affected by 5.3 Gas Chromatograph (GC), equipped with a flame ion-

salinity, thorough mixing of the salt water is required. Care ization detector is used for analysis. The column is a fused

should also be observed to avoid evaporation from open silica column.

containers of salt water. Over a period of days and weeks, the

5.4 The following is a list of other necessary supplies.

loss of water can significantly increase the salinity.An airtight

Suppliers of suitable units are footnoted. Equivalent supplies

closure is recommended to maintain salinity levels at 3.3 %.

areacceptableineverycase.Quantitiesofsuppliesaregivento

conduct a full set of six samples and calibration set:

4.10 Temperature is a factor in dispersion, so it is important

that all components (salt water, pre-mix, and temperature 5.4.1 Eighteen Crimp Style Vials, with aluminum/PTFE

controlled chamber) are stable at 20°C before starting. (polytetrafluoroethylene) seals, 12 by 32 mm,

´1

F2059 − 06 (2012)

7. Procedure

7.1 Crude Oil and Dispersant Sample Collection and

Storage—The bulk oil is mechanically mixed for 2 to 4 h prior

to obtaining a working sample. Working samples are stored in

2-L high-density polyethylene bottles with polypropylene

screw closures. The working sample is mechanically shaken

for 30 min at 20°C prior to removing a sub-sample for testing.

When not in use, all samples should be stored in a temperature

controlled room at 5°C. The dispersant is manually shaken,

vigorously, prior to sampling.

7.2 Premix Sample Preparation—A small amount of oil

(approximately 1.0 mL) is weighed into a 5-mL amber vial

with PTFE-lined cap. Approximately 100 mg of dispersant is

added to the oil. Oil is added until a 1:25 ratio (by weight) of

dispersant to oil is achieved. The sample is well mixed by

manual shaking or stirring.

7.3 Salt-Water Preparation—Granular salt is weighed and

added to water from reverse osmosis (RO) filtration to obtain

a 3.3 % (w/v) solution. The water temperature is stabilized to

20°C before use.

7.4 Swirling Flask Preparation—The 120 mL of salt water

is placed into a 125-mL modified Erlenmeyer flask. The flask

is inserted into the flask holders on the oscillating table of the

FIG. 1 Flask with Side Spout

shaker. A 100-µL volume of pre-mix solution is carefully

applied onto the surface of the water using a positive displace-

ment pipet. The tip of the pipet is placed at the water surface

5.4.2 Twelve Erlenmeyer Flasks, 125 mL Glass, modified

and the dispersant/oil mixture gently expelled. Extreme care

with the addition of a drain spout attached to base,

should be taken when applying the oil to the surface such that

5.4.3 Six Graduated Mixing Cylinders and Stoppers, 25 mL

mixing does not occur. The oil should gently glide across the

glass,

water to form a slick. If the oil streams out into the water, the

5.4.4 Six Separatory Funnels and Stoppers, glass, 125 mL,

agitation can disperse the oil, increasing the amount of oil

5.4.5 Six Graduated Mixing Cylinders and Stoppers, glass,

dispersed and erroneously raising the final dispersion result.

100 mL,

Herding of the oil and some creeping of the mixture up the

5.4.6 Six Separatory Funnels and Stoppers, glass, 250 mL,

vessel wall is normal but can be minimized.

5.4.7 Six Graduated Cylinders, glass, 50 mL,

7.5 Shaking of Swirling Flasks—The flask and contents are

5.4.8 Six Dispenser or Glass Graduated Cylinders,5to25

mechanically mixed on the shaker in a temperature controlled

mL,

chamber at 20°C, immediately after applying the oil to the

5.4.9 Positive Displacement Pipet, 10 to 100 µL,

surface of the water. A rotation speed of 150 r/min and a

5.4.10 Positive Displacement Pipet, variable volume, 1 mL,

mixing time of 20 min are used to agitate the samples followed

5.4.11 Two Digital Timers,

bya10-minsettlingperiod.Theflasksshouldberemovedfrom

5.4.12 Dispenser or Graduated Cylinders, 20 mL to 100

the table-mounted holders prior to the settling period to limit

mL, and

the agitation between settling and sampling.

5.4.13 One Plastic Carboy, 20 L.

7.6 Sample Collection—After the settling time is complete,

6. Reagents

3 mL of oil-in-water phase from the spout of the flask are

6.1 Reagents—Water purified by reverse osmosis or equiva-

drained and disposed of to remove any oil residing in the spout

lent means is used for the test water. Dichloromethane and

and to obtain a representative sample. A 30-mL aliquot of the

pentane are distilled-in-glass grades. Fine granular sodium

dispersed oil in water sample is collected in a graduated

chloride or table salt, non-iodized, is used for making the salt

cylinder and transferred to a 125-mLseparatory funnel.The oil

water. The chemical dispersant is used as supplied by the

is extracted three times with 5 mL of a 70:30 dichlorometh-

manufacturer. Oil is used as received.

ane:pentane solvent mixture, shaken vigorously for at least 1

min, and the extract collected in a 25-mL graduated mixing

cylinder. The final extraction volume is adjusted to 15 mL.

The sole source of supply of the apparatus known to the committee at this time

Care is taken to ensure that water is not taken along with the

is Pro Science, Inc., 770 Birchmount Road, Unit 25, Scarborough, Ontario

solvent. During extraction, vigorous shaking is required to

M1K5H3. If you are aware of alter

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.