ASTM C702-98(2003)

(Practice)Standard Practice for Reducing Samples of Aggregate to Testing Size

Standard Practice for Reducing Samples of Aggregate to Testing Size

SIGNIFICANCE AND USE

Specifications for aggregates require sampling portions of the material for testing. Other factors being equal, larger samples will tend to be more representative of the total supply. This practice provides procedures for reducing the large sample obtained in the field or produced in the laboratory to a convenient size for conducting a number of tests to describe the material and measure its quality in a manner that the smaller test sample portion is most likely to be a representation of the larger sample, and thus of the total supply. Failure to carefully follow the procedures in this practice could result in providing a nonrepresentative sample to be used in subsequent testing. The individual test methods provide for minimum amount of material to be tested.

Under certain circumstances, reduction in size of the large sample prior to testing is not recommended. Substantial differences between the selected test samples sometimes cannot be avoided, as for example, in the case of an aggregate having relatively few large size particles in the sample. The laws of chance dictate that these few particles may be unequally distributed among the reduced size test samples. Similarly, if the test sample is being examined for certain contaminants occurring as a few discrete fragments in only small percentages, caution should be used in interpreting results from the reduced size test sample. Chance inclusion or exclusion of only one or two particles in the selected test sample may importantly influence interpretation of the characteristics of the original sample. In these cases, the entire original sample should be tested.

SCOPE

1.1 This practice covers three methods for the reduction of large samples of aggregate to the appropriate size for testing employing techniques that are intended to minimize variations in measured characteristics between the test samples so selected and the large sample.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

Designation:C702–98 (Reapproved 2003) Highway and Transportation

Officials Standard: T 248

Standard Practice for

Reducing Samples of Aggregate to Testing Size

This standard is issued under the fixed designation C702; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope convenientsizeforconductinganumberofteststodescribethe

material and measure its quality in a manner that the smaller

1.1 This practice covers three methods for the reduction of

test sample portion is most likely to be a representation of the

large samples of aggregate to the appropriate size for testing

larger sample, and thus of the total supply. Failure to carefully

employing techniques that are intended to minimize variations

follow the procedures in this practice could result in providing

in measured characteristics between the test samples so se-

a nonrepresentative sample to be used in subsequent testing.

lected and the large sample.

The individual test methods provide for minimum amount of

1.2 The values stated in SI units are to be regarded as the

material to be tested.

standard.

4.2 Under certain circumstances, reduction in size of the

1.3 This standard does not purport to address all of the

large sample prior to testing is not recommended. Substantial

safety concerns, if any, associated with its use. It is the

differences between the selected test samples sometimes can-

responsibility of the user of this standard to establish appro-

not be avoided, as for example, in the case of an aggregate

priate safety and health practices and determine the applica-

having relatively few large size particles in the sample. The

bility of regulatory limitations prior to use.

laws of chance dictate that these few particles may be

2. Referenced Documents

unequally distributed among the reduced size test samples.

Similarly, if the test sample is being examined for certain

2.1 ASTM Standards:

contaminants occurring as a few discrete fragments in only

C125 Terminology Relating to Concrete and Concrete Ag-

small percentages, caution should be used in interpreting

gregates

results from the reduced size test sample. Chance inclusion or

C128 Test Method for Density, Relative Density (Specific

exclusion of only one or two particles in the selected test

Gravity), and Absorption of Fine Aggregate

sample may importantly influence interpretation of the charac-

D75 Practice for Sampling Aggregates

teristics of the original sample. In these cases, the entire

3. Terminology

original sample should be tested.

3.1 Definitions—The terms used in this practice are defined

5. Selection of Method

in Terminology C125.

5.1 Fine Aggregate—Reduce the size of samples of fine

4. Significance and Use

aggregate that are drier than the saturated-surface-dry condi-

tion (Note 1) using a mechanical splitter according to Method

4.1 Specifications for aggregates require sampling portions

A. Reduce the size of samples having free moisture on the

of the material for testing. Other factors being equal, larger

particle surfaces by quartering according to Method B, or by

samples will tend to be more representative of the total supply.

treating as a miniature stockpile as described in Method C.

This practice provides procedures for reducing the large

5.1.1 If the use of Method B or Method C is desired, and the

sample obtained in the field or produced in the laboratory to a

sample does not have free moisture on the particle surfaces,

moisten the sample to obtain free moisture on the particle

This practice is under the jurisdiction of ASTM Committee C09 on Concrete

surfaces, mix thoroughly, and then reduce the sample size.

andConcreteAggregatesandisthedirectresponsibilityofSubcommitteeC09.20on

5.1.2 If use of Method A is desired and the sample has free

Normal Weight Aggregates.

Current edition approved June 10, 2003. Published July 2003. Originally moisture on the particle surfaces, dry the entire sample to at

approved in 1971. Last previous edition approved in 1998 as C702–98. DOI:

least the saturated-surface-dry condition, using temperatures

10.1520/C0702-98R03.

that do not exceed those specified for any of the tests

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contemplated,andthenreducethesamplesize.Alternatively,if

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on the moist sample is very large, make a preliminary split using

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C702–98 (2003)

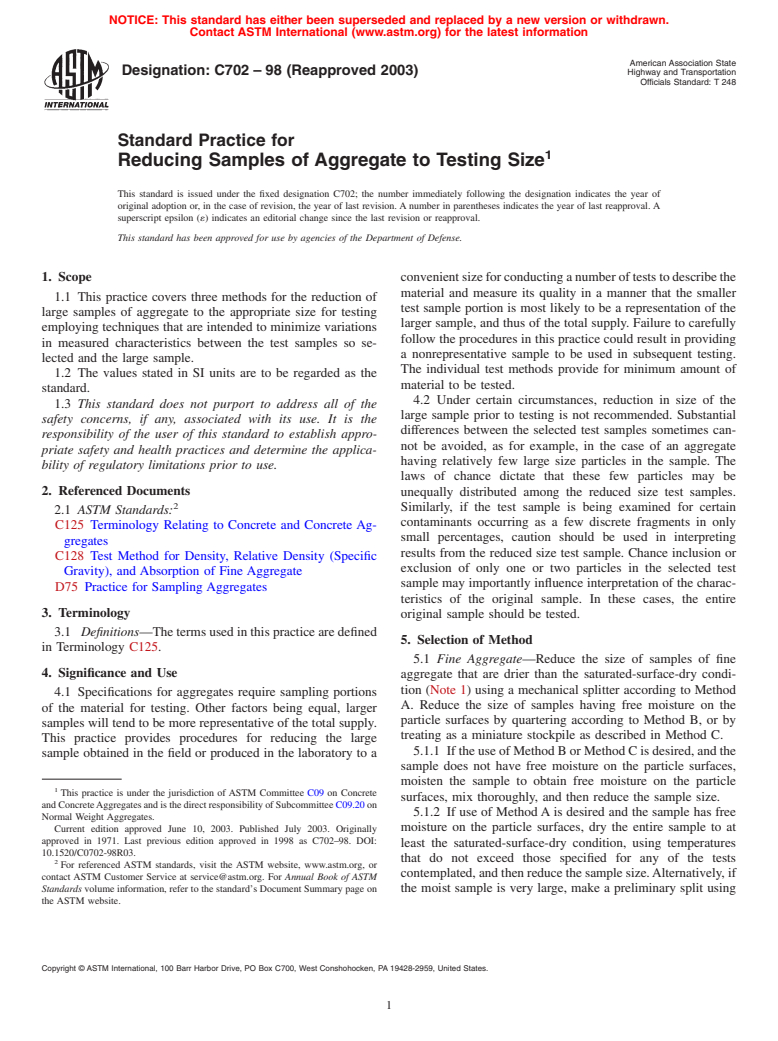

amechanicalsplitterhavingchuteopeningsof38mm(1 ⁄2 in.) receptacles to hold the two halves of the sample following

or more in width to reduce the sample to not less than 5000 g. splitting. It shall also be equipped with a hopper or straight-

Dry the portion so obtained, and reduce it to test sample size edged pan which has a width equal to or slightly less than the

using Method A. over-all width of the assembly of chutes, by which the sample

may be fed at a controlled rate to the chutes. The splitter and

NOTE 1—The method of determining the saturated-surface-dry condi-

accessory equipment shall be so designed that the sample will

tion is described in Test Method C128. As a quick approximation, if the

flow smoothly without restriction or loss of material (see Fig.

fine aggregate will retain its shape when molded in the hand, it may be

considered to be wetter than saturated-surface-dry. 1 and Fig. 2).

5.2 Coarse Aggregates and Mixtures of Coarse and Fine

NOTE 2—Mechanical splitters are commonly available in sizes ad-

equate for coarse aggregate having the largest particle not over 37.5 mm

Aggregates—Reduce the sample using a mechanical splitter in

(1 ⁄2 in.).

accordance with MethodA(preferred method) or by quartering

in accordance with Method B. The miniature stockpile Method

8. Procedure

C is not permitted for coarse aggregates or mixtures of coarse

8.1 Place the original sample in the hopper or pan and

and fine aggregates.

uniformly distribute it from edge to edge, so that when it is

introduced into the chutes, approximately equal amounts will

6. Sampling

flow through each chute. Introduce the sample at a rate so as to

6.1 Obtain samples of aggregate in the field in acco

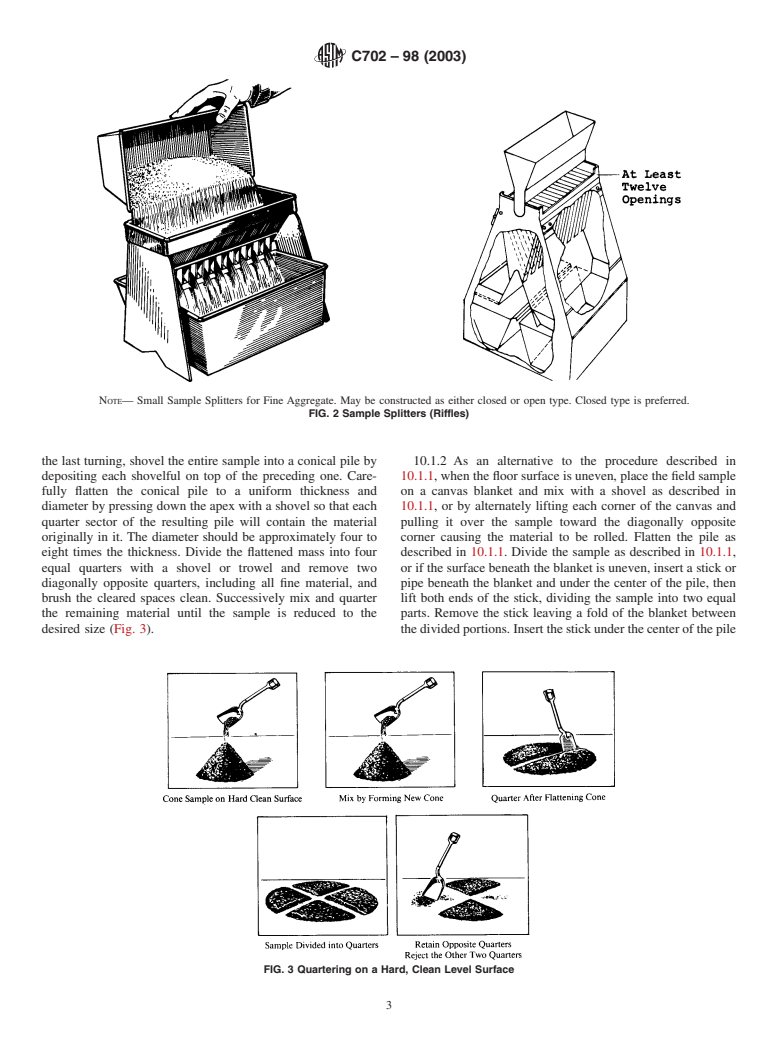

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.