ASTM D3800-99(2004)

(Test Method)Standard Test Method for Density of High-Modulus Fibers

Standard Test Method for Density of High-Modulus Fibers

SIGNIFICANCE AND USE

Fiber density is useful in the evaluation of new materials at the research and development level and is one of the material properties normally given in fiber specifications.

Fiber density is used to determine fiber strength and modulus both of a fiber bundle and an individual filament. These properties are based on load or modulus slope over an effective area. Fiber density may be used with lineal mass of the fiber to give an approximation of effective tow area. Tow area divided by the average number of filaments in a tow gives an approximation of the effective area of an individual filament.

Fiber density is used as a constituent property when determining reinforcement volume and void volume based on reinforcement mass and laminate density.

SCOPE

1.1 This test method covers the determination of the density of high-modulus fibers and is applicable to both continuous and discontinuous fibers.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Section 9 for additional information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D3800–99 (Reapproved 2004)

Standard Test Method for

Density of High-Modulus Fibers

This standard is issued under the fixed designation D3800; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3. Terminology

1.1 This test method covers the determination of the density 3.1 Definitions—Terminology D3878 defines terms relating

ofhigh-modulusfibersandisapplicabletobothcontinuousand tocompositematerials.TerminologyE12definestermsrelating

discontinuous fibers. to density. Practice E177 defines terms relating to statistics. In

1.2 The values stated in SI units are to be regarded as theeventofaconflictbetweenterms,TerminologyD3878shall

standard. have precedence over other standards.

1.3 This standard may involve hazardous materials, opera- 3.2 Symbols:

tions, and equipment. This standard does not purport to

address all of the safety concerns, if any, associated with its

r = density of standard

s

use. It is the responsibility of the user of this standard to

r = density of liquid

l

establish appropriate safety and health practices and deter-

r = density of fiber

f

mine the applicability of regulatory limitations prior to use.

r = density of the measured fiber containing sizing

mf

See Section 9 for additional information.

r = density of the measured liquid containing sur-

ml

factant

2. Referenced Documents

r = density of surfactant

sur

2.1 ASTM Standards:

r = density of sizing

sz

D891 Test Methods for Specific Gravity, Apparent, of

r = density of water

w

Liquid Industrial Chemicals

s = standard deviation

D1505 Test Method for Density of Plastics by the Density-

M = weight of suspension wire in air

Gradient Technique

M = weight of suspension wire in liquid (to immer-

D3878 Terminology for Composite Materials sion point)

D5229/D5229M Test Method for Moisture Absorption M = weight of suspension wire plus item whose

density is to be determined (in air)

Properties and Equilibrium Conditioning of Polymer Ma-

M = weight of suspension wire plus item whose

trix Composite Materials

density is to be determined (in liquid)

D6308 Guide for Identification of Composite Materials in

M –M = weight of item for density to be determined in

Computerized Material Property Databases

3 1

air

E12 Terminology Relating to Density and Specific Gravity

M –M = weight of item for density to be determined in

of Solids, Liquids, and Gases 4 2

liquid

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

4. Summary of Test Method

E1471 Guide for Identification of Fibers, Fillers, and Core

4.1 General—Usingrandomselectiontechniques,asuitable

Materials in Computerized Material Property Databases

size sample of high-modulus fiber can be tested by any of the

three procedures described in this test method. Procedure A

This test method is under the jurisdiction of ASTM Committee D30 on

using water with a surfactant as the liquid medium is preferred

Composite Materials and is the direct responsibility of Subcommittee D30.03 on

due to environmental and safety considerations. The other

Constituent/Precursor Properties.

methods shall not be used if Procedure A is adequate. Interim

Current edition approved Oct. 1, 2004. Published October 2004. Originally

approved in 1979. Last previous edition approved in 1999 as D3800 – 99. DOI:

use of Procedures B or C is allowed while a comparison is

10.1520/D3800-99R04.

made to results using Procedure A.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2 Procedure A—Buoyancy (Archimedes) Method:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3800–99 (2004)

4.2.1 The sample is weighed in air and weighed in a liquid

x = mass of sizing as a percentage of the total mass of the

that will thoroughly wet the sample and is of a lower density.

measured fiber.

4.2.2 The difference in weight of the sample in the two

6.1.5 Effect of Surfactant Density—The addition of a sur-

media is the buoyancy force. This force is converted to sample

factant to a liquid may produce bias if not considered. The

volume by dividing it by the liquid density. The sample weight

effect may be shown by the following equation:

in air divided by the sample volume equals the sample density.

~100 – x! r 1 x~r !

l sur

r 5 (2)

4.3 Procedure B—Sink-Float Technique:

ml

4.3.1 The sample is placed in a container containing a liquid

where

that will thoroughly wet the sample and is of a lower density.

x = mass of surfactant as a percentage of total mass of the

A liquid of higher density than the sample and miscible with

measured liquid.

the first liquid is then added slowly to the container under

6.2 (Method A):

constant gentle mixing until the sample is suspended in the

6.2.1 Immersion Point—The distance the sample is lowered

mixture.

into the liquid and the overall liquid level should be the same

4.3.2 The density of the resulting mixed liquid is deter-

throughout determinations for Procedure A. This may be done

mined using either a hydrometer or a pycnometer. The density

by putting a line for the desired liquid level on the outside of

of the sample is equal to the density of the liquid in which the

the container. The sample size should be within a few grams

sample is suspended.

from one sample to another.

4.4 Procedure C—For an alternative method, which may be

used, see Test Method D1505.

7. Apparatus

7.1 General:

5. Significance and Use

7.1.1 Thermometer, capable of reading the test temperature

5.1 Fiberdensityisusefulintheevaluationofnewmaterials

during the test to 0.1°C.

attheresearchanddevelopmentlevelandisoneofthematerial

7.1.2 Agitator—Stirrer or mixing propeller capable of

properties normally given in fiber specifications.

slowly agitating solution without test interference.

5.2 Fiber density is used to determine fiber strength and

7.2 Procedure A:

modulus both of a fiber bundle and an individual filament.

7.2.1 Balance, analytical, capable of weighing to 0.0001 g,

These properties are based on load or modulus slope over an

adapted for suspension weighing.

effective area. Fiber density may be used with lineal mass of

7.2.2 Balance Stand,dependingonthetypeofbalanceused;

the fiber to give an approximation of effective tow area. Tow

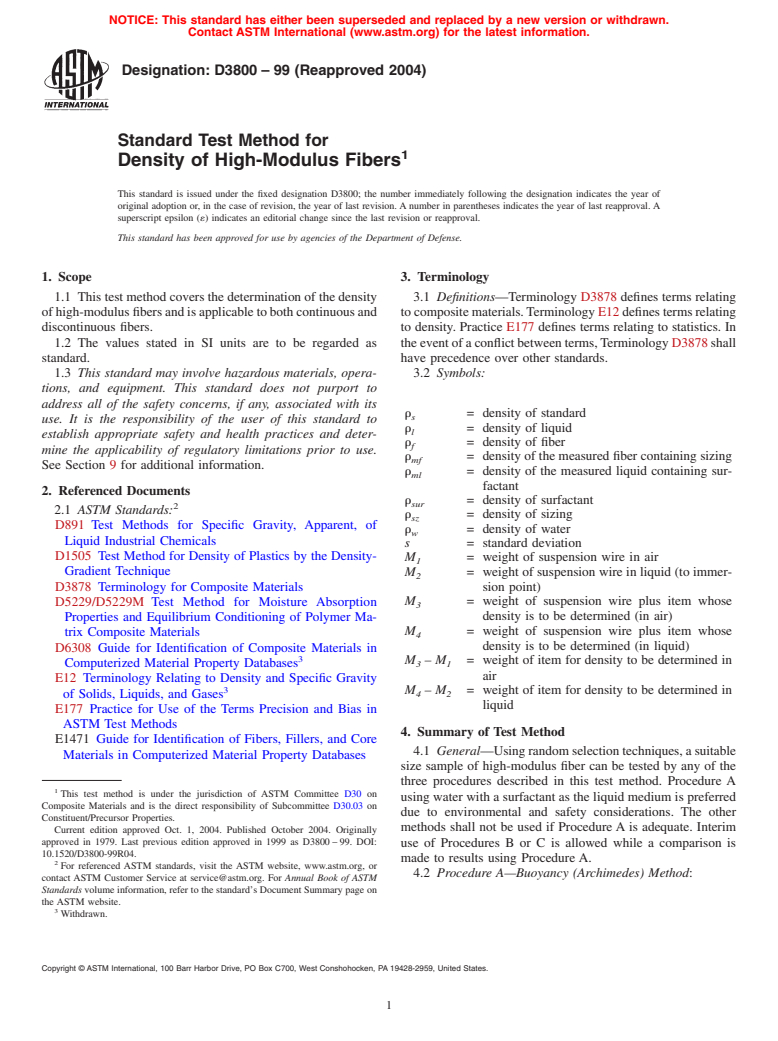

two recommended stands are shown in Figs. 1 and 2.

area divided by the average number of filaments in a tow gives

7.2.3 Laboratory Jack, heavy-duty precision.

an approximation of the effective area of an individual fila-

7.2.4 Suspension Wire, nickel or stainless steel, approxi-

ment.

mately0.4mmindiameter,cutandshapedtomatchthesystem

5.3 Fiber density is used as a constituent property when

used.

determining reinforcement volume and void volume based on

7.2.5 Vacuum Desiccator (with Pump)—An airtight con-

reinforcement mass and laminate density.

tainerinwhichalowvacuum(lessthan75kPa[22in.Hg])can

be maintained.

6. Interferences

7.2.6 Density Standard—A solid piece of borosilicate glass

6.1 General (All Methods): (density approximately 2.2 g/mL) of known density to four

6.1.1 Temperature—The temperature of the liquid shall significant figures as determined by water immersion. ANIST

standard of this type (SRM 1825) is recommended.

remain constant within a tolerance of 61°C, since liquid

7.2.7 Vacuum Pump or Aspirator, used to provide vacuum-

density changes with temperature.

to-vacuum desiccator.

6.1.2 Sample Wetting (Entrapped Air)—Since this test

7.2.8 Container, glass or other transparent container resis-

method is very dependent on buoyancy, any entrapped air in

tant to a liquid medium is recommended.

the sample will change the measured density and not give a

7.2.9 Immersion Liquid—The liquid used shall not dissolve

true material density. Ensure visually that the sample does not

or otherwise affect the specimen, but should wet it and have a

contain entrapped air bubbles.

specific gravity less than that of the specimen. The specific

6.1.3 Homogenous Mixture—The density of the liquid shall

gravity of the immersion liquid shall be determined shortly

be uniform, through suitable agitation.

before and after each use.

6.1.4 Removal of Sizing—A bias will exist if sizing is not

7.3 Procedure B:

removed. In this case, the measured fiber density is a combi-

7.3.1 Container, glass or other transparent container resis-

nation of the density of the fiber and the sizing. The following

tant to liquids used is recommended.

equation may be used to calculate the effect of the sizing on the

density of the material.

~100 – x! r 1 x~r !

f sz

r 5 (1)

ANo. 19 “Pyrex” glass stopper with a 3.175-mm diameter hole bored through

mf

the top for suspension purposes has proved satisfactory.

One suitable surfactant to use with water is Triton X manufactured by Rohm

where

and Haas, Philadelphia, PA.

D3800–99 (2004)

FIG. 1 Density Apparatus (Alternative)

of filter paper, taking care not to draw any liquid from within the capillary.

7.3.2 Immersion Liquids—See Notes 1 and 2. One liquid

Place the cap over the side arm, wipe the outside carefully, and weigh the

should have a density less than the fiber, and the other greater,

filled bottle again to the nearest 0.2 mg. Empty the pycnometer, dry, and

so when mixed they have the same density as the fiber. Two

then fill and weigh with the other liquid in the same manner as was done

suitable liquids are trichloroethylene and dibromomethane

with the water. Calculate the specific gravity at 23°C of the liquid, r,as

f

(having densities of 1.464 and 2.477 g/mL). Both of these

follows:

liquids pose hazards (see Section 8).

r 5 ~b – e!/~w – e! (3)

l

7.3.3 Hydrometer, capable of reading liquid density.

7.4 Procedure C—Use the apparatus described in Test where:

e = apparent weight of empty pycnometer,

Method D1505.

w = apparent weight of pycnometer filled with water at 23°C, and

NOTE 1—Standard deionized or distilled water need not be measured,

b = apparent weight of pycnometer filled with liquid at 23°C.

but can be taken as a value from standard tables. For the determination

If a constant-temperature bath is available, a pycnometer without a

of the specific gravity of the liquid, the use of a standard plummet of

thermometer may be used.

known volume (Note 3) orTest MethodA, C, or D ofTest Methods D891,

NOTE 2—One standard, which has been found satisfactory for this

using the modifications required to give specific gravity at 23°C is

purpose, is the Reimann Thermometer Plummet. These are normally

recommended. One suggested procedure is the following: If a constant

calibrated for measurements at temperatures other than 23/23°C, so that

temperature water bath is not available, determine the weight of the clean,

recalibration is necessary for the purpose of these test methods. Calibra-

dry pycnometer with the thermometer to the nearest 0.1 mg on an

tions at intervals of one week are recommended.

analyticalbalance.Fillthepycnometerwithwatercoolerthan23°C.Insert

8. Reagents

the thermometer stopper causing excess water to be expelled through the

side arm. Permit the filled bottle to warm in air until the thermometer

8.1 Purity of Reagents—As a minimum, a technical grade

reads 23°C. Remove the drop of water at the tip of the side arm with a bit

reagent is required to provide accurate results. However, when

resolving disputes or performing subsequent analysis of extract

or residue, a reagent grade reagent shall be used. Unless

One such reference is in CRC Handbook of Chemistry and Physics, CRC Press

Inc., Boca Raton, FL. otherwise indicated, it is intended that the reagents conform to

D3800–99 (2004)

FIG. 2 Density Apparatus (Alternative)

the specifications of the Committee on Analytical Reagents of cals.Asource of useful information is Prudent Practices in the

the American Chemical Society where such specifications are Laboratory: Handling and Disposal of Chemicals, National

available. Academy Press, 1995, 448 pp., ISBN 0-309-05229-7.

8.1.1 Water,H O, (deionized or distilled and degassed), (Warning—In addition to other warnings, consult the appro-

maycontainawettingagentsuchasglycerinorsurfactant.This priate material safety data sheet for each material used,

is the safest reagent found, and recommended for ProcedureA. including reagent materials and test specimen materials, for

specific recommendations on safety and handling.)

NOTE 3—Reagents in 8.1.2-8.1.6 should be used if water is found to be

unsatisfactory to accurately determine the density of the fiber. Other

10. Test Specimen

reagents are listed in order of known hazard or toxicity.

10.1 A minimum of three test specimens shall be tested for

8.1.2 Acetone (2-Propanone),CH CHOCH .

3 3

each sample.

8.1.3 Methanol (Methyl Alcohol),CH OH.

10.2 The test specimen weight shall be a minimum of 0.5 g.

8.1.4 o-dichlorobenzene,CH Cl.(Warning—o-

4 2

dichlorobenzene has been identified as toxic and an irritant.)

11. Calibration and Standardization

8.1.5 Dibromomethane,CH Br.(Warning—As of the ap-

2 2

11.1 All measuring equipment shall have certified calibra-

proval date of this test method, dibromomethane was listed by

tions that are current at the time of use of the equipment. The

the International Agency for Research on Cancer in Group 2C

calibration documentation shall be available for inspection.

as “toxic.”)

8.1.6 Trichloroethylene, CHClCCl.(Warning—Asofthe

12. Conditioning

approval date of this test method, trichloroethylene was listed

12.1 Test Method D5229/D5229M may be used to deter-

by the International Agency for Research on Cancer in Group

mine equilibrium dryness of a fiber. In general, no special

2D as a “cancer suspect agent” and mutagen.)

conditioning is needed for carbon fiber, less than 1 h at 100°C

9. Hazards

is needed for glass fibers, and approximately4hat 100°C is

9.1 This test method should be used only by laboratory needed for aramid fibers.

workers with general training in the safe handling of chemi- 12.2 Condition liquids to a test temperature, typically 23°C.

13. Procedure

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

13.1 Procedure A—Buoyancy (Archimedes) Method):

listed by the American Chemical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.