ASTM D2007-03(2008)

(Test Method)Standard Test Method for Characteristic Groups in Rubber Extender and Processing Oils and Other Petroleum-Derived Oils by the Clay-Gel Absorption Chromatographic Method

Standard Test Method for Characteristic Groups in Rubber Extender and Processing Oils and Other Petroleum-Derived Oils by the Clay-Gel Absorption Chromatographic Method

SIGNIFICANCE AND USE

The composition of the oil included in rubber compounds has a large effect on the characteristics and uses of the compounds. The determination of the saturates, aromatics, and polar compounds is a key analysis of this composition.

The determination of the saturates, aromatics, and polar compounds and further analysis of the fractions produced is often used as a research method to aid understanding of oil effects in rubber and other uses.

SCOPE

1.1 This test method covers a procedure for classifying oil samples of initial boiling point of at least 260°C (500°F) into the hydrocarbon types of polar compounds, aromatics and saturates, and recovery of representative fractions of these types. This classification is used for specification purposes in rubber extender and processing oils.

Note 1—See Test Method D 2226.

1.2 This test method is not directly applicable to oils of greater than 0.1 mass % pentane insolubles. Such oils can be analyzed after removal of these materials, but precision is degraded (see Appendix X1).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in 6.1, Section 7, A1.4.1, and A1.5.5.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2007–03 (Reapproved 2008)

Standard Test Method for

Characteristic Groups in Rubber Extender and Processing

Oils and Other Petroleum-Derived Oils by the Clay-Gel

Absorption Chromatographic Method

This standard is issued under the fixed designation D2007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a procedure for classifying oil 3.1 Definitions of Terms Specific to This Standard:

samples of initial boiling point of at least 260°C (500°F) into 3.1.1 The following terms refer to the hydrocarbon types

the hydrocarbon types of polar compounds, aromatics and and structural groups as measured by this test method:

saturates, and recovery of representative fractions of these 3.1.2 aromatics—material that, on percolation, passes

types. This classification is used for specification purposes in through a column of adsorbent clay in a n-pentane eluent but

rubber extender and processing oils. adsorbs on silica gel under the conditions specified.

3.1.3 asphaltenes, or n-pentane insolubles—insoluble mat-

NOTE 1—See Test Method D2226.

ter that precipitates from a solution of oil in n-pentane under

1.2 This test method is not directly applicable to oils of

the specified conditions.

greater than 0.1 mass % pentane insolubles. Such oils can be

3.1.4 polar aromatics—synonym for polar compounds.

analyzed after removal of these materials, but precision is

3.1.5 polar compounds—material retained on adsorbent

degraded (see Appendix X1).

clay after percolation of the sample in n-pentane eluent under

1.3 The values stated in SI units are to be regarded as the

the conditions specified.

standard. The values given in parentheses are for information

3.1.6 saturates—materialthat,onpercolationina n-pentane

only.

eluent, is not adsorbed on either the clay or silica gel under the

1.4 This standard does not purport to address all of the

conditions specified.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 The sample is diluted with solvent and charged to a

bility of regulatory limitations prior to use. Specific warning

glass percolation column containing clay in the upper section

statements are given in 6.1, Section 7, A1.4.1, and A1.5.5.

and silica gel plus clay in the lower section. n-pentane is then

charged to the double column until a definite quantity of

2. Referenced Documents

effluenthasbeencollected.Theupper(clay)sectionisremoved

2.1 ASTM Standards:

from the lower section and washed further with n-pentane. A

D2226 Classification for Various Types of Petroleum Oils

toluene-acetone mixture 50 to 50 by volume is then charged to

for Rubber Compounding Use

the clay section for desorption and a specified volume of

D5309 Specification for Cyclohexane 999

effluent collected. The lower (gel) column may be desorbed by

E691 Practice for Conducting an Interlaboratory Study to

recirculation of toluene.

Determine the Precision of a Test Method

4.2 The solvents are completely removed from the recov-

ered n-pentane and the toluene-acetone fractions and the

residues are weighed and calculated as saturate and polar

This test method is under the jurisdiction of ASTM Committee D02 on

compounds contents. Aromatics may be calculated by differ-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

ence, or measured following evaporation of the toluene used

D02.04.0C on Liquid Chromatography.

for desorption of the gel column.

Current edition approved Dec. 1, 2008. Published February 2009. Originally

´1

4.3 When the sample contains more than 0.1 mass % of

approved in 1968. Last previous edition approved in 2003 as D2007–03 . DOI:

10.1520/D2007-03R08.

n-pentane insolubles, this test method cannot be used directly.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Theinsolublemattermustberemovedfromthesamplepriorto

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

charging to the column.Amethod for this removal is given as

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. an appendix.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2007–03 (2008)

4.4 Alternative methods are provided (1) for recovery of 6.9 Condenser, borosilicate (Fig. 3).

3,4

aromatics from the gel column, and (2) for analysis of oil with 6.10 Adapter Tube with Vigreux column (Fig. 3).

high-polar content. 6.11 Flexible Joint, TFE-fluorocarbon and borosilicate,

4,5

24/40 T ground glass joints on each end.

S

5. Significance and Use

7. Reagents and Materials

5.1 The composition of the oil included in rubber com-

7.1 Purity of Reagents, Reagent grade chemicals shall be

pounds has a large effect on the characteristics and uses of the

used in all tests. Unless otherwise indicated, it is intended that

compounds. The determination of the saturates, aromatics, and

all reagents shall conform to the specifications of the commit-

polar compounds is a key analysis of this composition.

tee onAnalytical Reagents of theAmerican Chemical Society,

5.2 The determination of the saturates, aromatics, and polar

where such specifications are available. Other grades may be

compounds and further analysis of the fractions produced is

used, provided it is first ascertained that the reagent is of

often used as a research method to aid understanding of oil

sufficiently high purity to permit its use without lessening the

effects in rubber and other uses.

accuracy of the determination.

6. Apparatus

7.2 Acetone, reagent grade, minimum purity. (Warning—

6.1 Beakers, Anticreep, 150-mL capacity, as illustrated in Acetone is extremely flammable.)

Fig. 1.(Warning—Beakers should be examined for sharp 7.3 Calcium Chloride, anhydrous granules.

edges and fire polished, if necessary.) 7.4 Clay Adsorbent, 500 to 250 µm (30 to 60 mesh)

4,7

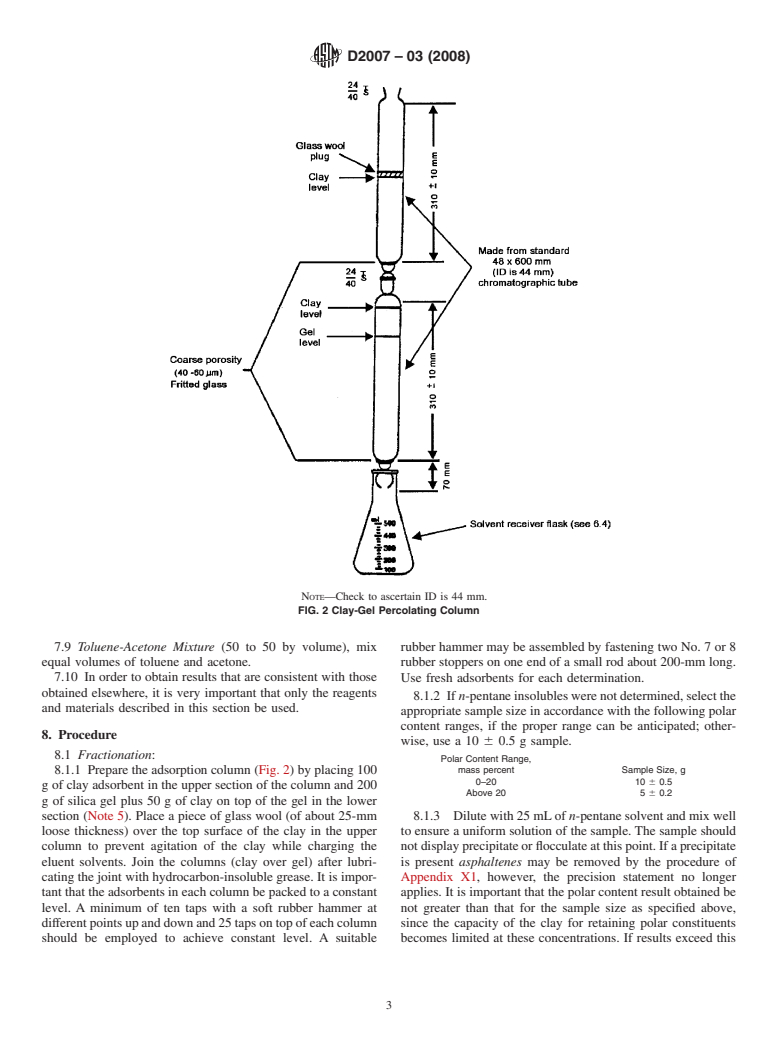

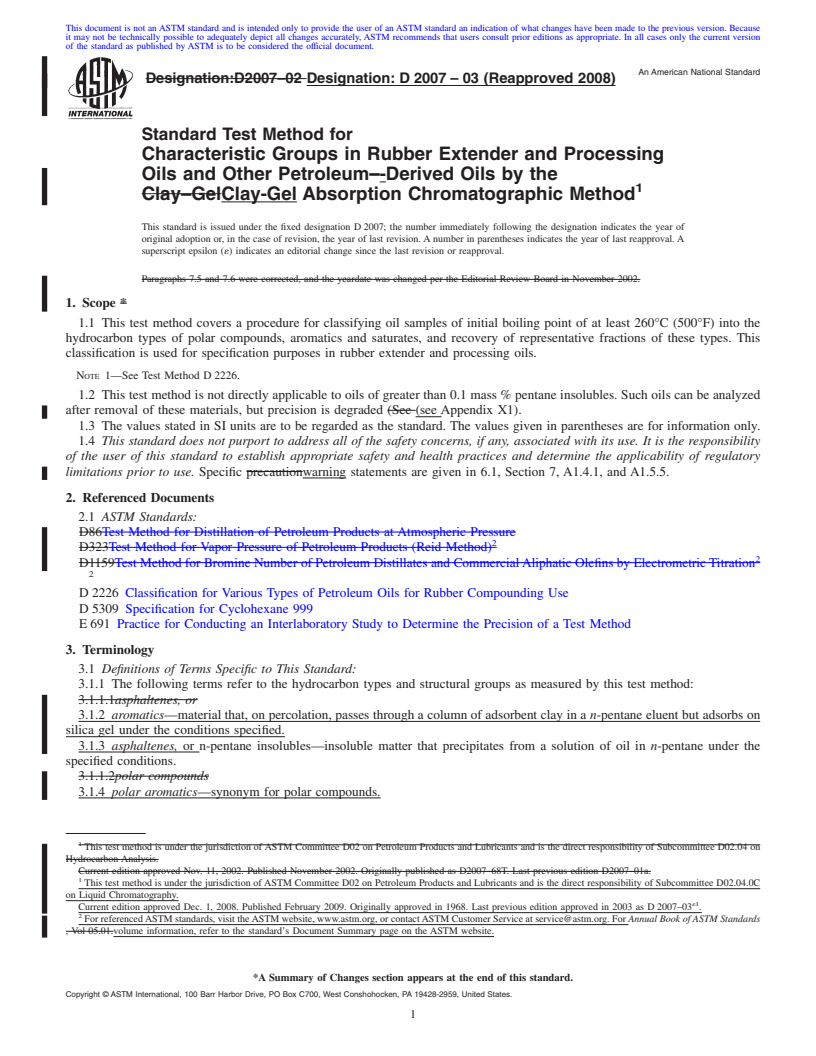

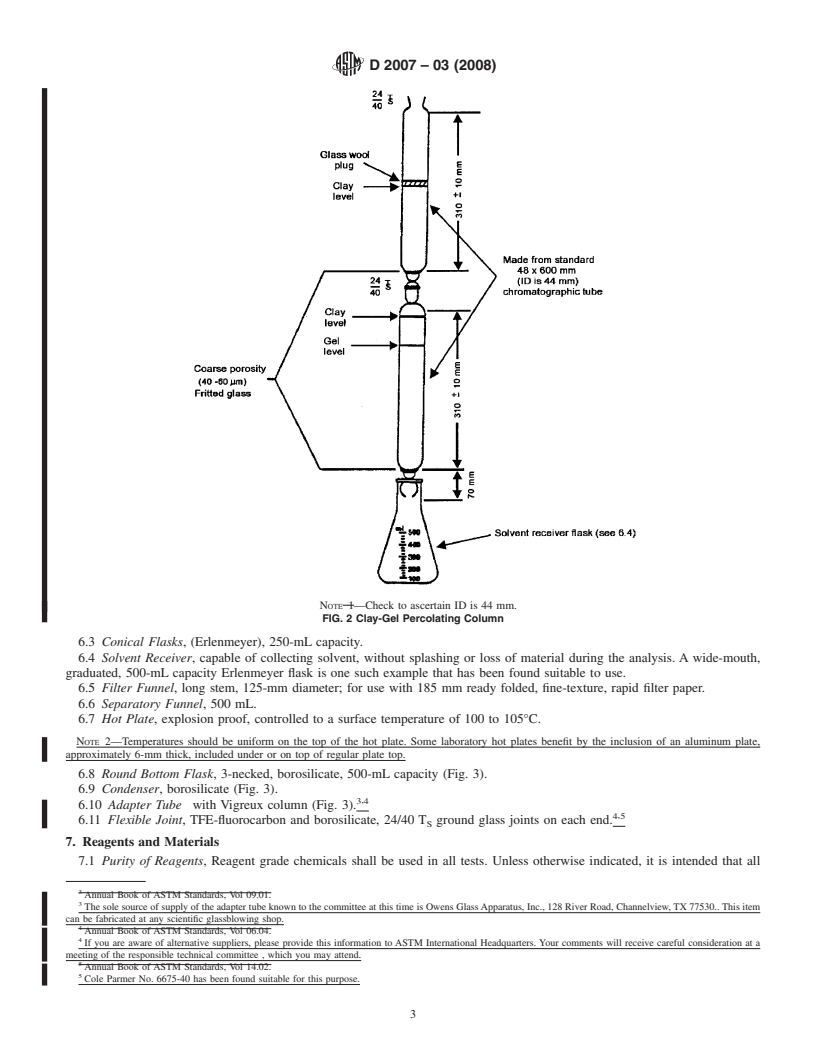

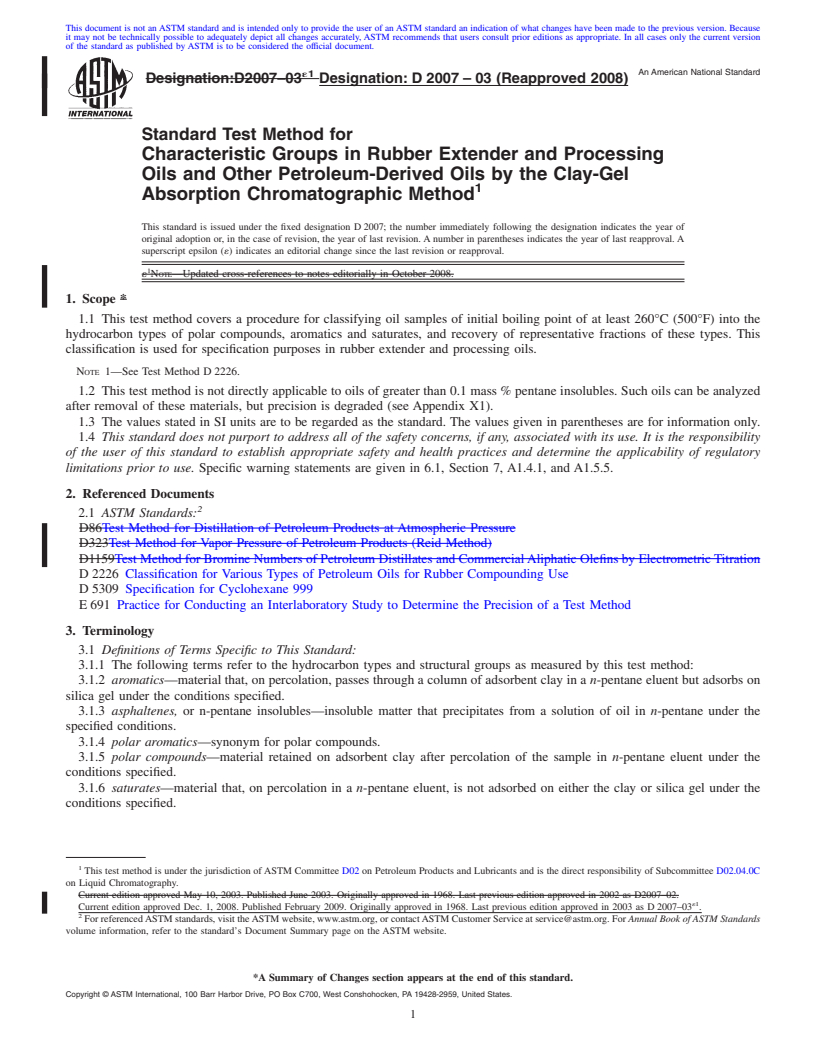

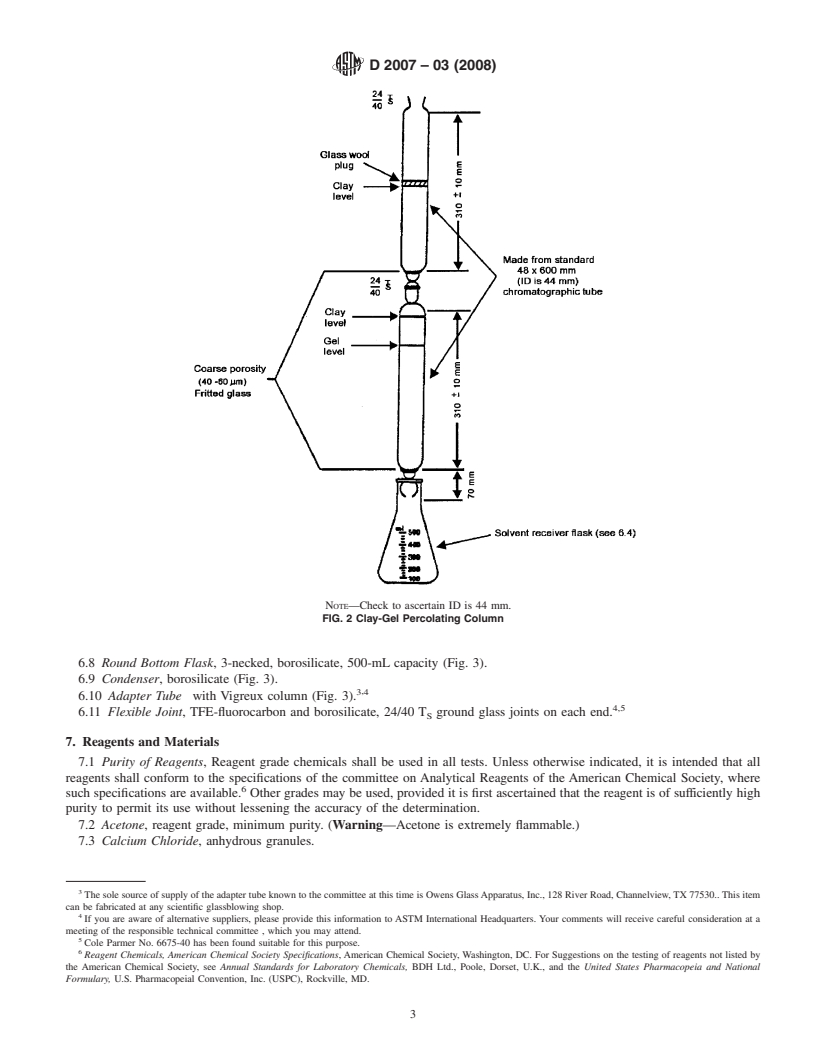

6.2 Clay-Gel Column, constructed as illustrated in Fig. 2. Attapulgus. Clay quality may be determined using the

6.3 Conical Flasks, (Erlenmeyer), 250-mL capacity. azobenzene equivalence test shown inAnnexA1. The azoben-

6.4 Solvent Receiver, capable of collecting solvent, without zene activity test measures the adsorptive characteristics of the

splashing or loss of material during the analysis. A wide- clay. Azobenzene equivalence value should be 30 to 35. Clay

mouth, graduated, 500-mL capacity Erlenmeyer flask is one outside of these limits should be discarded.

such example that has been found suitable to use.

7.5 Cyclohexane, conforming to Specification D5309. (Op-

6.5 Filter Funnel,longstem,125-mmdiameter;forusewith tional, see 8.1.9.) (Warning—Cyclohexane is extremely flam-

185 mm ready folded, fine-texture, rapid filter paper.

mable. Harmful if inhaled.)

4,8

6.6 Separatory Funnel, 500 mL. 7.6 Pentane, reagent grade minimum purity.

6.7 Hot Plate, explosion proof, controlled to a surface (Warning—n-Pentane is extremely flammable. Harmful if

temperature of 100 to 105°C. inhaled.)

7.7 Silica Gel, activated, conforming to the following in-

NOTE 2—Temperatures should be uniform on the top of the hot plate.

4,9

spections:

Some laboratory hot plates benefit by the inclusion of an aluminum plate,

Sieve analysis >30 sieve size, 5 % (mass) maximum;

approximately 6-mm thick, included under or on top of regular plate top.

>50 sieve size, 45 % (mass) min

6.8 Round Bottom Flask, 3-necked, borosilicate, 500-mL

>100 sieve size, 80 % (mass) min

>200 sieve size, 94 % (mass) min

capacity (Fig. 3).

7.7.1 Gel should be activated for4hinanair oven at 190°C

in a shallow pan.

7.8 Toluene, reagent grade minimum purity. (Warning—

Toluene is flammable. Vapor harmful.)

The sole source of supply of the adapter tube known to the committee at this

time is Owens Glass Apparatus, Inc., 128 River Road, Channelview, TX 77530.

This item can be fabricated at any scientific glassblowing shop.

If you are aware of alternative suppliers, please provide this information to

ASTM International Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee , which you may attend.

Cole Parmer No. 6675-40 has been found suitable for this purpose.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

listed by the American Chemical Society, see Annual Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD.

Thesolesourceofsupplyofclayadsorbentknowntothecommitteeatthistime

is Forcoven Products, 22010 East Martin Dr., Porter, TX 77365. Packaged in

moisture resistant twinned packets of 50 and 100 g (sufficient for one determina-

tion). These packets are packed 50 sets per case. It is important that extremes of

temperature be avoided on stored clay samples.

The sole source of supply of pentane known to the committee at this time is

Special Products Div., Phillips Petroleum Co., Bartlesville, OK.

The sole source of supply of silica gel meeting these specifications known to

the committee at this time is Forcoven Products, 22010 East Martin Dr., Porter, TX

77365, packaged in 200 g moisture resistant packets. Sieve analysis should be

FIG. 1 Anticreep Beaker checked on other sources of gel.

D2007–03 (2008)

NOTE—Check to ascertain ID is 44 mm.

FIG. 2 Clay-Gel Percolating Column

7.9 Toluene-Acetone Mixture (50 to 50 by volume), mix rubber hammer may be assembled by fastening two No. 7 or 8

equal volumes of toluene and acetone. rubber stoppers on one end of a small rod about 200-mm long.

7.10 In order to obtain results that are consistent with those Use fresh adsorbents for each determination.

obtained elsewhere, it is very important that only the reagents

8.1.2 If n-pentaneinsolubleswerenotdetermined,selectthe

and materials described in this section be used.

appropriate sample size in accordance with the following polar

content ranges, if the proper range can be anticipated; other-

8. Procedure

wise, use a 10 6 0.5 g sample.

8.1 Fractionation:

Polar Content Range,

mass percent Sample Size, g

8.1.1 Prepare the adsorption column (Fig. 2) by placing 100

0–20 10 6 0.5

g of clay adsorbent in the upper section of the column and 200

Above 20 5 6 0.2

g of silica gel plus 50 g of clay on top of the gel in the lower

section (Note 5). Place a piece of glass wool (of about 25-mm 8.1.3 Dilute with 25 mLof n-pentane solvent and mix well

loose thickness) over the top surface of the clay in the upper to ensure a uniform solution of the sample. The sample should

column to prevent agitation of the clay while charging the notdisplayprecipitateorflocculateatthispoint.Ifaprecipitate

eluent solvents. Join the columns (clay over gel) after lubri- is present asphaltenes may be removed by the procedure of

cating the joint with hydrocarbon-insoluble grease. It is impor- Appendix X1, however, the precision statement no longer

tant that the adsorbents in each column be packed to a constant applies. It is important that the polar content result obtained be

level. A minimum of ten taps with a soft rubber hammer at not greater than that for the sample size as specified above,

differentpointsupanddownand25tapsontopofeachcolumn since the capacity of the clay for retaining polar constituents

should be employed to achieve constant level. A suitable becomes limited at these concentrations. If results exceed this

D2007–03 (2008)

n-pentane effluent from the column in a graduated, 500-mL

wide-mouth conical flask.

NOTE 4—Columns may be briefly separated, if necessary, to give a

solvent head 5- to 10-mm deep in the second (lower) column. Loss of the

head will give channeling in the lower column, with inaccurate results.

NOTE 5—With long use, the frits in the absorption columns become

progressively less porous. If the time for percolation doubles over that for

a new column, the slow columns are to be discarded.

NOTE 6—If only saturates are to be determined, proceed to 8.3 and

subsequent calculation of saturates.

8.1.6 Disconnect the two sections. Allow the lower section

to drain into a receiver. Continue washing the upper clay

section with n-pentane. Maintain a moderate liquid head level

above the clay during this wash and adjust n-pentane additions

so that the level is about 25 mm when 150 mL have been

collectedinthereceiver.Discontinueadditionsatthispointand

allow the liquid to essentially drain from the column. The

quantity in the receiver should then be about 200 mL. The

n-pentane from this step and from the draining of the lower

column should be discarded if aromatics are to be determined

by difference. This n-pentane should be added to the aromatics

solution from the gel column during solvent evaporation (8.3)

if aromatics are to be recovered.

NOTE 7—This extra n-pentane washing of the clay section is necessary

in order to ensure complete removal of aromatics from the clay.

8.1.7 After n-pentane effluent has essentially drained from

the column, charge a 50 to 50 volume mixture of toluene–ac-

etone. Collect the effluent in a 500-mL separatory funnel.

Collect250mLofthetoluene-acetone(plus n-pentane)effluent

or until the effluent is practically colorless (only in exceptional

cases will more than 300 mL of effluent be required).

8.1.8 Stopper the separatory funnel containing the toluene-

acetone fraction and swirl it a few times to aid in settling the

FIG. 3 Extraction Apparatus

water. Then let it stand for about 5 min. Drain off and discard

the lower (aqueous) layer. Add approximately 10 g of anhy-

specification, repeat the test using a smaller sample. Partition- drouscalciumchloridegranulestothefractionremaininginthe

ing between aromatics and polar compounds is affected by

separatory funnel and shake for about 30 s; vent frequently

sample size. Results using different sample size may not be during the shaking period. Allow the mixture to settle for at

equivalent.

least 10 min.

8.1.9 Filter the fraction through a rapid folded filter paper

NOTE 3—For viscous oils, dilutions of the sample with 25 mL of

catching the filtrate in a 500-mL conical flask. Rinse the

cyclohexane is more convenient and does not affect the results. Cyclo-

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:D2007–02 Designation:D2007–03 (Reapproved 2008)

Standard Test Method for

Characteristic Groups in Rubber Extender and Processing

Oils and Other Petroleum–-Derived Oils by the

Clay–GelClay-Gel Absorption Chromatographic Method

This standard is issued under the fixed designation D 2007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

Paragraphs 7.5 and 7.6 were corrected, and the yeardate was changed per the Editorial Review Board in November 2002.

1. Scope *

1.1 This test method covers a procedure for classifying oil samples of initial boiling point of at least 260°C (500°F) into the

hydrocarbon types of polar compounds, aromatics and saturates, and recovery of representative fractions of these types. This

classification is used for specification purposes in rubber extender and processing oils.

NOTE 1—See Test Method D 2226.

1.2 This test method is not directly applicable to oils of greater than 0.1 mass % pentane insolubles. Such oils can be analyzed

after removal of these materials, but precision is degraded (See (see Appendix X1).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific precautionwarning statements are given in 6.1, Section 7, A1.4.1, and A1.5.5.

2. Referenced Documents

2.1 ASTM Standards:

D86Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D323Test Method for Vapor Pressure of Petroleum Products (Reid Method)

D1159Test Method for Bromine Number of Petroleum Distillates and CommercialAliphatic Olefins by ElectrometricTitration

D 2226 Classification for Various Types of Petroleum Oils for Rubber Compounding Use

D 5309 Specification for Cyclohexane 999

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 The following terms refer to the hydrocarbon types and structural groups as measured by this test method:

3.1.1.1asphaltenes, or

3.1.2 aromatics—material that, on percolation, passes through a column of adsorbent clay in a n-pentane eluent but adsorbs on

silica gel under the conditions specified.

3.1.3 asphaltenes, or n-pentane insolubles—insoluble matter that precipitates from a solution of oil in n-pentane under the

specified conditions.

3.1.1.2polar compounds

3.1.4 polar aromatics—synonym for polar compounds.

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.04 on

Hydrocarbon Analysis.

Current edition approved Nov. 11, 2002. Published November 2002. Originally published as D2007–68T. Last previous edition D2007–01a.

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.04.0C

on Liquid Chromatography.

´1

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1968. Last previous edition approved in 2003 as D 2007–03 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 05.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2007–03 (2008)

3.1.5 polar compounds—material retained on adsorbent clay after percolation of the sample in n-pentane eluent under the

conditions specified.

3.1.1.3polar aromatics—synonym for polar compounds.

3.1.1.4aromatics—material that, on percolation, passes through a column of adsorbent clay in a n-pentane eluent but adsorbs on

silica gel under the conditions specified.

3.1.1.5saturates

3.1.6 saturates—material that, on percolation in a n-pentane eluent, is not adsorbed on either the clay or silica gel under the

conditions specified.

4. Summary of Test Method

4.1 The sample is diluted with solvent and charged to a glass percolation column containing clay in the upper section and silica

gel plus clay in the lower section. n-Pentane-pentane is then charged to the double column until a definite quantity of effluent has

been collected. The upper (clay) section is removed from the lower section and washed further with n-pentane.Atoluene-acetone

mixture 50 to 50 by volume is then charged to the clay section for desorption and a specified volume of effluent collected. The

lower (gel) column may be desorbed by recirculation of toluene.

4.2 The solvents are completely removed from the recovered n-pentane and the toluene-acetone fractions and the residues are

weighed and calculated as saturate and polar compounds contents. Aromatics may be calculated by difference, or measured

following evaporation of the toluene used for desorption of the gel column.

4.3 When the sample contains more than 0.1 mass % of n-pentane insolubles, this test method cannot be used directly. The

insoluble matter must be removed from the sample prior to charging to the column. A method for this removal is given as an

appendix.

4.4 Alternative methods are provided ( a1) for recovery of aromatics from the gel column, and ( b2) for analysis of oil with

high-polar content.

5. Significance and Use

5.1 Thecompositionoftheoilincludedinrubbercompoundshasalargeeffectonthecharacteristicsandusesofthecompounds.

The determination of the saturates, aromatics, and polar compounds is a key analysis of this composition.

5.2 The determination of the saturates, aromatics, and polar compounds and further analysis of the fractions produced is often

used as a research method to aid understanding of oil effects in rubber and other uses.

6. Apparatus

6.1 Beakers, Anticreep, 150-mLcapacity, as illustrated in Fig. 1. (Warning—Beakers should be examined for sharp edges and

fire polished, if necessary.)

6.2 Clay-Gel Column, constructed as illustrated in Fig. 2.

FIG. 1 Anticreep Beaker

D2007–03 (2008)

NOTE 1—Check to ascertain ID is 44 mm.

FIG. 2 Clay-Gel Percolating Column

6.3 Conical Flasks, (Erlenmeyer), 250-mL capacity.

6.4 Solvent Receiver, capable of collecting solvent, without splashing or loss of material during the analysis. A wide-mouth,

graduated, 500-mL capacity Erlenmeyer flask is one such example that has been found suitable to use.

6.5 Filter Funnel, long stem, 125-mm diameter; for use with 185 mm ready folded, fine-texture, rapid filter paper.

6.6 Separatory Funnel, 500 mL.

6.7 Hot Plate, explosion proof, controlled to a surface temperature of 100 to 105°C.

NOTE 2—Temperatures should be uniform on the top of the hot plate. Some laboratory hot plates benefit by the inclusion of an aluminum plate,

approximately 6-mm thick, included under or on top of regular plate top.

6.8 Round Bottom Flask, 3-necked, borosilicate, 500-mL capacity (Fig. 3).

6.9 Condenser, borosilicate (Fig. 3).

3,4

6.10 Adapter Tube with Vigreux column (Fig. 3).

,

4 5

6.11 Flexible Joint, TFE-fluorocarbon and borosilicate, 24/40 T ground glass joints on each end.

S

7. Reagents and Materials

7.1 Purity of Reagents, Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

Annual Book of ASTM Standards, Vol 09.01.

The sole source of supply of the adapter tube known to the committee at this time is Owens GlassApparatus, Inc., 128 River Road, Channelview, TX 77530. This item

can be fabricated at any scientific glassblowing shop.

Annual Book of ASTM Standards, Vol 06.04.

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee , which you may attend.

Annual Book of ASTM Standards, Vol 14.02.

Cole Parmer No. 6675-40 has been found suitable for this purpose.

D2007–03 (2008)

FIG. 3 Extraction Apparatus

reagents shall conform to the specifications of the committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

7.2 Acetone, reagent grade, minimum purity. (Warning—Acetone is extremely flammable.)

7.3 Calcium Chloride, anhydrous granules.

,

4 7

7.4 Clay Adsorbent, 500 to 250 µm (30 to 60 mesh) Attapulgus. Clay quality may be determined using the azobenzene

equivalence test shown inAnnexA1. The azobenzene activity test measures the adsorptive characteristics of the clay.Azobenzene

equivalence value should be 30 to 35. Clay outside of these limits should be discarded.

7.5 Cyclohexane, conforming to Specification D 5309. (Optional, see 8.1.9.) (Warning—Cyclohexane is extremely flammable.

Harmful if inhaled.)

4 ,8

7.6 Pentane, reagent grade minimum purity:purity. (Warning—n-Pentane is extremely flammable. Harmful if inhaled.)

,

4 9

7.7 Silica Gel, activated, conforming to the following inspections:

Temperaturesshouldbeuniformonthetopofthehotplate.Somelaboratoryhotplatesbenefitbytheinclusionofanaluminumplate,approximately6-mmthick,included

under or on top of regular plate top.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

This item can be fabricated at any scientific glassblowing shop. It is also available from Owens Glass Apparatus, Inc., 128 River Road, Channelview, TX 77530.

The sole source of supply of clay adsorbent known to the committee at this time is Forcoven Products, 22010 East Martin Dr., Porter, TX 77365. Packaged in moisture

resistant twinned packets of 50 and 100 g (sufficient for one determination).These packets are packed 50 sets per case. It is important that extremes of temperature be avoided

on stored clay samples.

Cole Parmer No. 6675-40 has been found suitable for this purpose.

The sole source of supply of pentane known to the committee at this time is Special Products Div., Phillips Petroleum Co., Bartlesville, OK.

D2007–03 (2008)

Sieve analysis >30 sieve size, 5 % (mass) maximum;

>50 sieve size, 45 % (mass) min

>100 sieve size, 80 % (mass) min

>200 sieve size, 94 % (mass) min

7.7.1 Gel should be activated for4hinanair oven at 190°C in a shallow pan.

7.8 Toluene, reagent grade minimum purity. (Warning—Toluene is flammable. Vapor harmful.)

7.9 Toluene-Acetone Mixture (50 to 50 by volume), mix equal volumes of toluene and acetone.

7.10 In order to obtain results that are consistent with those obtained elsewhere, it is very important that only the reagents and

materials described in this section be used.

8. Procedure

8.1 Fractionation:

8.1.1 Prepare the adsorption column (Fig. 2) by placing 100 g of clay adsorbent in the upper section of the column and 200 g

of silica gel plus 50 g of clay on top of the gel in the lower section (Note 4).(Note 5). Place a piece of glass wool (of about 25-mm

loose thickness) over the top surface of the clay in the upper column to prevent agitation of the clay while charging the eluent

solvents. Join the columns (clay over gel) after lubricating the joint with hydrocarbon-insoluble grease. It is important that the

adsorbents in each column be packed to a constant level.Aminimum of ten taps with a soft rubber hammer at different points up

and down and 25 taps on top of each column should be employed to achieve constant level. A suitable rubber hammer may be

assembled by fastening two No. 7 or 8 rubber stoppers on one end of a small rod about 200-mm long. Use fresh adsorbents for

each determination.

8.1.2 If n-pentane insolubles were not determined, select the appropriate sample size in accordance with the following polar

content ranges, if the proper range can be anticipated; otherwise, use a 10 6 0.5 g sample.

Polar Content Range,

mass percent Sample Size, g

0–20 10 6 0.5

Above 20 5 6 0.2

8.1.3 Dilute with 25 mLof n-pentane solvent and mix well to ensure a uniform solution of the sample. The sample should not

display precipitate or flocculate at this point. If a precipitate is present asphaltenes may be removed by the procedure ofAppendix

X1, however, the precision statement no longer applies. It is important that the polar content result obtained be not greater than

that for the sample size as specified above, since the capacity of the clay for retaining polar constituents becomes limited at these

concentrations. If results exceed this specification, repeat the test using a smaller sample. Partitioning between aromatics and polar

compounds is affected by sample size. Results using different sample size may not be equivalent.

NOTE2—For 3—For viscous oils, dilutions of the sample with 25 mL of cyclohexane is more convenient and does not affect the results. Cyclohexane

used in this manner will not detect small quantities of asphaltenes, however.

8.1.4 Add 25 mL of n-pentane to the top of the clay portion of the assembled column and allow to percolate into the clay. As

soon as nearly all of the n-pentane has entered the clay, charge to the column the diluted sample of 8.1.3. Wash the sample beaker

(or flask) with n-pentane and add the washings to the column.After nearly all of this material has entered the clay, wash the walls

of the column above the clay free of sample with n-pentane. The sample and eluent solvent can be added to the column throu

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

´1

Designation:D2007–03 Designation:D2007–03 (Reapproved 2008)

Standard Test Method for

Characteristic Groups in Rubber Extender and Processing

Oils and Other Petroleum-Derived Oils by the Clay-Gel

Absorption Chromatographic Method

This standard is issued under the fixed designation D 2007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Updated cross-references to notes editorially in October 2008.

1. Scope *

1.1 This test method covers a procedure for classifying oil samples of initial boiling point of at least 260°C (500°F) into the

hydrocarbon types of polar compounds, aromatics and saturates, and recovery of representative fractions of these types. This

classification is used for specification purposes in rubber extender and processing oils.

NOTE 1—See Test Method D 2226.

1.2 This test method is not directly applicable to oils of greater than 0.1 mass % pentane insolubles. Such oils can be analyzed

after removal of these materials, but precision is degraded (see Appendix X1).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Specific warning statements are given in 6.1, Section 7, A1.4.1, and A1.5.5.

2. Referenced Documents

2.1 ASTM Standards:

D86Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D323Test Method for Vapor Pressure of Petroleum Products (Reid Method)

D1159Test Method for Bromine Numbers of Petroleum Distillates and CommercialAliphatic Olefins by ElectrometricTitration

D 2226 Classification for Various Types of Petroleum Oils for Rubber Compounding Use

D 5309 Specification for Cyclohexane 999

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 The following terms refer to the hydrocarbon types and structural groups as measured by this test method:

3.1.2 aromatics—material that, on percolation, passes through a column of adsorbent clay in a n-pentane eluent but adsorbs on

silica gel under the conditions specified.

3.1.3 asphaltenes, or n-pentane insolubles—insoluble matter that precipitates from a solution of oil in n-pentane under the

specified conditions.

3.1.4 polar aromatics—synonym for polar compounds.

3.1.5 polar compounds—material retained on adsorbent clay after percolation of the sample in n-pentane eluent under the

conditions specified.

3.1.6 saturates—material that, on percolation in a n-pentane eluent, is not adsorbed on either the clay or silica gel under the

conditions specified.

This test method is under the jurisdiction ofASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.04.0C

on Liquid Chromatography.

Current edition approved May 10, 2003. Published June 2003. Originally approved in 1968. Last previous edition approved in 2002 as D2007–02.

´1

Current edition approved Dec. 1, 2008. Published February 2009. Originally approved in 1968. Last previous edition approved in 2003 as D 2007–03 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2007–03 (2008)

4. Summary of Test Method

4.1 The sample is diluted with solvent and charged to a glass percolation column containing clay in the upper section and silica

gel plus clay in the lower section. n-pentane is then charged to the double column until a definite quantity of effluent has been

collected. The upper (clay) section is removed from the lower section and washed further with n-pentane. A toluene-acetone

mixture 50 to 50 by volume is then charged to the clay section for desorption and a specified volume of effluent collected. The

lower (gel) column may be desorbed by recirculation of toluene.

4.2 The solvents are completely removed from the recovered n-pentane and the toluene-acetone fractions and the residues are

weighed and calculated as saturate and polar compounds contents. Aromatics may be calculated by difference, or measured

following evaporation of the toluene used for desorption of the gel column.

4.3 When the sample contains more than 0.1 mass % of n-pentane insolubles, this test method cannot be used directly. The

insoluble matter must be removed from the sample prior to charging to the column. A method for this removal is given as an

appendix.

4.4 Alternative methods are provided ( 1) for recovery of aromatics from the gel column, and ( 2) for analysis of oil with

high-polar content.

5. Significance and Use

5.1 Thecompositionoftheoilincludedinrubbercompoundshasalargeeffectonthecharacteristicsandusesofthecompounds.

The determination of the saturates, aromatics, and polar compounds is a key analysis of this composition.

5.2 The determination of the saturates, aromatics, and polar compounds and further analysis of the fractions produced is often

used as a research method to aid understanding of oil effects in rubber and other uses.

6. Apparatus

6.1 Beakers, Anticreep, 150-mLcapacity, as illustrated in Fig. 1. (Warning—Beakers should be examined for sharp edges and

fire polished, if necessary.)

6.2 Clay-Gel Column, constructed as illustrated in Fig. 2.

6.3 Conical Flasks, (Erlenmeyer), 250-mL capacity.

6.4 Solvent Receiver, capable of collecting solvent, without splashing or loss of material during the analysis. A wide-mouth,

graduated, 500-mL capacity Erlenmeyer flask is one such example that has been found suitable to use.

6.5 Filter Funnel, long stem, 125-mm diameter; for use with 185 mm ready folded, fine-texture, rapid filter paper.

6.6 Separatory Funnel, 500 mL.

6.7 Hot Plate, explosion proof, controlled to a surface temperature of 100 to 105°C.

NOTE 2—Temperatures should be uniform on the top of the hot plate. Some laboratory hot plates benefit by the inclusion of an aluminum plate,

approximately 6-mm thick, included under or on top of regular plate top.

FIG. 1 Anticreep Beaker

D2007–03 (2008)

NOTE—Check to ascertain ID is 44 mm.

FIG. 2 Clay-Gel Percolating Column

6.8 Round Bottom Flask, 3-necked, borosilicate, 500-mL capacity (Fig. 3).

6.9 Condenser, borosilicate (Fig. 3).

,

3 4

6.10 Adapter Tube with Vigreux column (Fig. 3).

,

4 5

6.11 Flexible Joint, TFE-fluorocarbon and borosilicate, 24/40 T ground glass joints on each end.

S

7. Reagents and Materials

7.1 Purity of Reagents, Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all

reagents shall conform to the specifications of the committee on Analytical Reagents of the American Chemical Society, where

such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high

purity to permit its use without lessening the accuracy of the determination.

7.2 Acetone, reagent grade, minimum purity. (Warning—Acetone is extremely flammable.)

7.3 Calcium Chloride, anhydrous granules.

The sole source of supply of the adapter tube known to the committee at this time is Owens GlassApparatus, Inc., 128 River Road, Channelview, TX 77530. This item

can be fabricated at any scientific glassblowing shop.

If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a

meeting of the responsible technical committee , which you may attend.

Cole Parmer No. 6675-40 has been found suitable for this purpose.

Reagent Chemicals, American Chemical Society Specifications, American Chemical Society, Washington, DC. For Suggestions on the testing of reagents not listed by

the American Chemical Society, see Annual Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia and National

Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D2007–03 (2008)

FIG. 3 Extraction Apparatus

,

4 7

7.4 Clay Adsorbent, 500 to 250 µm (30 to 60 mesh) Attapulgus. Clay quality may be determined using the azobenzene

equivalence test shown inAnnexA1. The azobenzene activity test measures the adsorptive characteristics of the clay.Azobenzene

equivalence value should be 30 to 35. Clay outside of these limits should be discarded.

7.5 Cyclohexane, conforming to Specification D 5309. (Optional, see 8.1.9.) (Warning—Cyclohexane is extremely flammable.

Harmful if inhaled.)

4 ,8

7.6 Pentane, reagent grade minimum purity. (Warning—n-Pentane is extremely flammable. Harmful if inhaled.)

,

4 9

7.7 Silica Gel, activated, conforming to the following inspections:

Sieve analysis >30 sieve size, 5 % (mass) maximum;

>50 sieve size, 45 % (mass) min

>100 sieve size, 80 % (mass) min

>200 sieve size, 94 % (mass) min

7.7.1 Gel should be activated for4hinanair oven at 190°C in a shallow pan.

7.8 Toluene, reagent grade minimum purity. (Warning—Toluene is flammable. Vapor harmful.)

7.9 Toluene-Acetone Mixture (50 to 50 by volume), mix equal volumes of toluene and acetone.

7.10 In order to obtain results that are consistent with those obtained elsewhere, it is very important that only the reagents and

materials described in this section be used.

The sole source of supply of clay adsorbent known to the committee at this time is Forcoven Products, 22010 East Martin Dr., Porter, TX 77365. Packaged in moisture

resistant twinned packets of 50 and 100 g (sufficient for one determination).These packets are packed 50 sets per case. It is important that extremes of temperature be avoided

on stored clay samples.

The sole source of supply of pentane known to the committee at this time is Special Products Div., Phillips Petroleum Co., Bartlesville, OK.

The sole source of supply of silica gel meeting these specifications known to the committee at this time is Forcoven Products, 22010 East Martin Dr., Porter, TX 77365,

packaged in 200 g moisture resistant packets. Sieve analysis should be checked on other sources of gel.

D2007–03 (2008)

8. Procedure

8.1 Fractionation:

8.1.1 Prepare the adsorption column (Fig. 2) by placing 100 g of clay adsorbent in the upper section of the column and 200 g

of silica gel plus 50 g of clay on top of the gel in the lower section (Note 5). Place a piece of glass wool (of about 25-mm loose

thickness) over the top surface of the clay in the upper column to prevent agitation of the clay while charging the eluent solvents.

Join the columns (clay over gel) after lubricating the joint with hydrocarbon-insoluble grease. It is important that the adsorbents

in each column be packed to a constant level.Aminimum of ten taps with a soft rubber hammer at different points up and down

and 25 taps on top of each column should be employed to achieve constant level. A suitable rubber hammer may be assembled

by fastening two No. 7 or 8 rubber stoppers on one end of a small rod about 200-mm long. Use fresh adsorbents for each

determination.

8.1.2 If n-pentane insolubles were not determined, select the appropriate sample size in accordance with the following polar

content ranges, if the proper range can be anticipated; otherwise, use a 10 6 0.5 g sample.

Polar Content Range,

mass percent Sample Size, g

0–20 10 6 0.5

Above 20 5 6 0.2

8.1.3 Dilute with 25 mLof n-pentane solvent and mix well to ensure a uniform solution of the sample. The sample should not

display precipitate or flocculate at this point. If a precipitate is present asphaltenes may be removed by the procedure ofAppendix

X1, however, the precision statement no longer applies. It is important that the polar content result obtained be not greater than

that for the sample size as specified above, since the capacity of the clay for retaining polar constituents becomes limited at these

concentrations. If results exceed this specification, repeat the test using a smaller sample. Partitioning between aromatics and polar

compounds is affected by sample size. Results using different sample size may not be equivalent.

NOTE 3—For viscous oils, dilutions of the sample with 25 mL of cyclohexane is more convenient and does not affect the results. Cyclohexane used

in this manner will not detect small quantities of asphaltenes, however.

8.1.4 Add 25 mL of n-pentane to the top of the clay portion of the assembled column and allow to percolate into the clay. As

soon as nearly all of the n-pentane has entered the clay, charge to the column the diluted sample of 8.1.3. Wash the sample beaker

(or flask) with n-pentane and add the washings to the column.After nearly all of this material has entered the clay, wash the walls

of the column above the clay free of sample with n-pentane. The sample and eluent solvent can be added to the column through

a 65-mm diameter, wide-stem funnel (the funnel can be left on top of the column).At no time during the run should air be allowed

to enter the clay bed.

8.1.5 When nearly all of the washings have entered the clay, charge n-pentane to the column and maintain a head level well

above the clay beds (Note 4) to wash the saturate portion of the sample from the adsorbents. Recover 280 6 10 mL of the first

n-pentane effluent from the column in a graduated, 500-mL wide-mouth conical flask.

NOTE 4—Columns may be briefly separated, if necessary, to give a solvent head 5- to 10-mm deep in the second (lower) column. Loss of the head

will give channeling in the lower column, with inaccurate results.

NOTE 5—With long use, the frits in the absorption columns become progressively less porous. If the time for percolation doubles over that for a ne

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.