ASTM E2194-14

(Test Method)Standard Test Method for Multiangle Color Measurement of Metal Flake Pigmented Materials

Standard Test Method for Multiangle Color Measurement of Metal Flake Pigmented Materials

SIGNIFICANCE AND USE

5.1 Instrumental Measurement Angles—This test method is designed to provide color data at specific measurement angles that can be utilized for quality control, color matching, and formulating in the characterization of metal flake pigmented materials.

5.2 Materials—This test method provides meaningful color information for metal flake pigmented materials. This test method has been tested and verified on paint and coatings, and the same principles should apply to plastics containing metallic flake. For materials containing pearlescent materials refer to Test Method E2539.

5.3 Utilization—This test method is appropriate for measurement and characterization of metal flake pigmented materials. These data may be used for quality control, incoming inspection, or color correction purposes.

5.4 Specimen Requirements—Even though a pair of specimens have the same color values at three angles, if there are differences in gloss, orange peel, texture, or flake orientation, they may not be a visual match.

Note 2: Information presented in this test method is based upon data taken on metallic materials coatings. Applicability of this test method to other materials should be confirmed by the user.

SCOPE

1.1 This test method covers the instrumental requirements, standardization procedures, material standards, and parameters needed to make precise instrumental measurements of the colors of gonioapparent materials. This test method is designed to encompass gonioapparent materials; such as, automotive coatings, paints, plastics, and inks.

1.2 This test method addresses measurement of materials containing metal flake and pigments. The measurement of materials containing metal flakes requires three angles of measurement to characterize the colors of the specimen. The optical characteristics of materials containing pearlescent and interference materials are not covered by this test method.

Note 1: Data taken by utilizing this test method are for gonio-appearance quality control purposes. This procedure may not necessarily supply appropriate data for spatial-appearance or pigment identification.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2194 − 14

Standard Test Method for

Multiangle Color Measurement of Metal Flake Pigmented

Materials

This standard is issued under the fixed designation E2194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Surfaces that exhibit different colors depending on the angles of illumination or sensing are said to

be “gonioapparent.” Colorimetric values of reflecting gonioapparent materials are derived from

spectrometric (narrow band) or colorimetric (broad band) measurements of reflectance factor, at

various aspecular angles. When using spectral values, tristimulus values are computed using the CIE

StandardObserverandthespectrumoftheilluminant,asdescribedinPracticeE308.Thistestmethod,

E2194, specifies the measurement of color observed at various aspecular angles.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the instrumental requirements,

E284Terminology of Appearance

standardization procedures, material standards, and parameters

E308PracticeforComputingtheColorsofObjectsbyUsing

needed to make precise instrumental measurements of the

the CIE System

colorsofgonioapparentmaterials.Thistestmethodisdesigned

E805Practice for Identification of Instrumental Methods of

to encompass gonioapparent materials; such as, automotive

Color or Color-Difference Measurement of Materials

coatings, paints, plastics, and inks.

E1345Practice for Reducing the Effect of Variability of

1.2 This test method addresses measurement of materials

Color Measurement by Use of Multiple Measurements

containing metal flake and pigments. The measurement of

E1708Practice for Electronic Interchange of Color and

materials containing metal flakes requires three angles of

Appearance Data

measurement to characterize the colors of the specimen. The E2539Test Method for Multiangle Color Measurement of

optical characteristics of materials containing pearlescent and Interference Pigments

interference materials are not covered by this test method.

2.2 CIE Document:

NOTE 1—Data taken by utilizing this test method are for gonio-

Publication No. 15:2004Colorimetry

appearance quality control purposes. This procedure may not necessarily

2.3 NIST (NBS) Publication:

supply appropriate data for spatial-appearance or pigment identification.

LC-1017StandardsforCheckingtheCalibrationofSpectro-

1.3 The values stated in SI units are to be regarded as

photometers

standard. The values given in parentheses are for information

2.4 ISO Publication:

only.

ISO InternationalVocabulary of Basic and GeneralTerms in

1.4 This standard does not purport to address all of the

Metrology (VIM)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

bility of regulatory limitations prior to use.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

AvailablefromU.S.NationalCommitteeoftheCIE(InternationalCommission

This test method is under the jurisdiction of ASTM Committee E12 on Color on Illumination), http://www.cie-usnc.org or http://www.techstreet.com/cie.

and Appearance and is the direct responsibility of Subcommittee E12.12 on Available from National Institute of Standards and Technology (NIST), 100

Gonioapparent Color. Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Current edition approved Nov. 1, 2014. Published November 2014. Originally ISO/IDE/OIML/BIPM,InternationalVocabularyofBasicandGeneralTermsin

approved in 2003. Last previous edition approved in 2012 as E2194– 12. DOI: Metrology, International Organization for Standardization, Geneva Switzerland,

10.1520/E2194-14. 1984.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2194 − 14

3. Terminology 6.2 Standardization—A standardization plaque with as-

signedspectralreflectancefactorortristimulusvaluestraceable

3.1 Terms and definitions in Terminology E284 are appli-

to a national standardizing laboratory for each specified as-

cable to this test method. See Section “Specialized Terminol-

pecular angle is required to standardize the instrument. The

ogy on Gonioapparent Phenomena.”

instrument manufacturer typically assigns the values to this

3.2 Definitions:

plaque.

3.2.1 Usually the term metallic refers to a metal material.

However,thisstandardemploysthealternativedefinitiongiven

7. Geometric Conditions

in Terminology E284 as:

7.1 Conventional Color Measurement—In general purpose

3.2.2 metallic, adj—pertainingtotheappearanceofagonio-

colorimetry, the common geometry involves illuminating at

apparent material containing metal flakes.

45°andsensingat0°.Thisgeometryisdesignated45:0(45/0).

3.3 Definitions of metrology terms in ISO International

Reverse geometry has the illumination at 0° and the sensing at

Vocabulary of Basic and General Terms in Metrology (VIM) 45°. That is, the illuminator and sensing geometries are

are applicable to this test method.

interchanged. This reciprocal geometry is designated 0:45

(0/45). Either geometry is used.

4. Summary of Test Method

7.1.1 A single bi-directional geometry is specified by illu-

4.1 This test method describes the procedures for the mination and sensing angles with respect to the normal of the

spectrometric and colorimetric measurement of metal flake plane of the specimen. Angles are measured relative to the

pigmented materials. The results are reported in terms of CIE normal. Angles on the same side of the normal as the

illumination beam are written as positive angles; those on the

tristimulus values and other color coordinate systems. Stan-

dardizationoftheinstrumentusedtomeasurethesematerialsis other side are shown as negative, as shown in Fig. 1.

defined. Guidelines are given for the selection of specimens

7.2 Multiangle Uniplanar Measurement—The color of me-

and a measurement protocol given. Characterization of these

tallic materials specimens varies with the angle of view. Thus

materials requires measurement at a near-specular angle, a

measurements must be taken at more than one aspecular angle

mid-specular angle and a far-specular angle. These preferred

to characterize the change of color with angle. The measure-

aspecular angles are 15°, 45°, and 110°.

ment geometry for multiangle measurements is specified by

aspecular angles. The aspecular angle is the viewing angle

5. Significance and Use

measured from the specular direction, in the illuminator plane

5.1 Instrumental Measurement Angles—This test method is

unless otherwise specified. The angle is considered positive

designed to provide color data at specific measurement angles

when measured from the specular direction towards the illu-

that can be utilized for quality control, color matching, and

minator axis.Thus, if the specimen is illuminated at 45° to the

formulating in the characterization of metal flake pigmented

normal the specular reflection will be at -45° (See Fig. 1).

materials.

Sensingat65°fromthenormal,andonthesamesideofnormal

as the illumination, is sensing 110° away from the specular

5.2 Materials—This test method provides meaningful color

direction; that is an aspecular angle of 110°. Thus, the

information for metal flake pigmented materials. This test

aspecular angle is the sum of the anormal illumination and

method has been tested and verified on paint and coatings, and

sensing angles. It has been established that for metallic

thesameprinciplesshouldapplytoplasticscontainingmetallic

materials or colors, a specific aspecular angle gives the same

flake. For materials containing pearlescent materials refer to

measurement regardless of angle of illumination.

Test Method E2539.

7.3 Annular and Circumferential Geometry—Annular illu-

5.3 Utilization—This test method is appropriate for mea-

mination provides incident light to a specimen at all azimuthal

surement and characterization of metal flake pigmented mate-

rials. These data may be used for quality control, incoming

inspection, or color correction purposes.

5.4 Specimen Requirements—Even though a pair of speci-

mens have the same color values at three angles, if there are

differences in gloss, orange peel, texture, or flake orientation,

they may not be a visual match.

NOTE 2—Information presented in this test method is based upon data

taken on metallic materials coatings. Applicability of this test method to

other materials should be confirmed by the user.

6. Apparatus

6.1 Instrument—This test method requires measurement at

multiple aspecular angles, usually accomplished by the use of

a multiangle spectrometer as specified in this test method to

characterize metal flake pigmented materials. Measurement

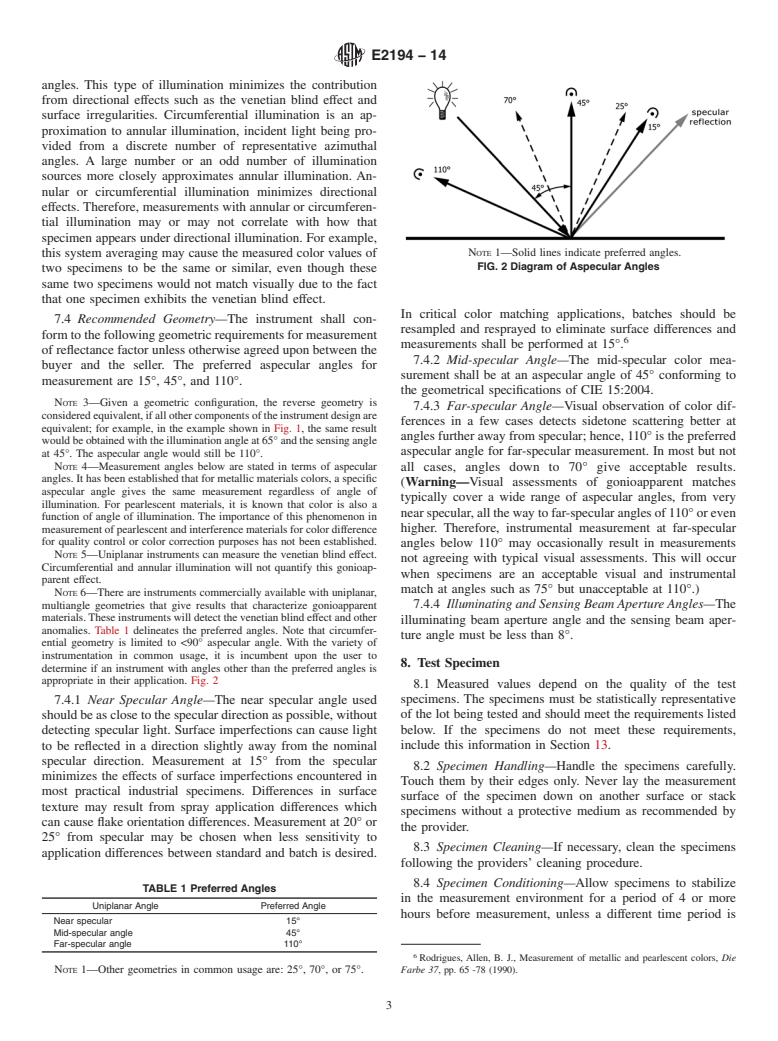

NOTE 1—Anormal illumination angle=45° and anormal sensing

with a single geometry cannot characterize the gonioappear-

angle=65°; therefore, aspecular angle=45+65=110°.

ance of these materials. FIG. 1 Example of Illuminating and Sensing Geometry

E2194 − 14

angles. This type of illumination minimizes the contribution

from directional effects such as the venetian blind effect and

surface irregularities. Circumferential illumination is an ap-

proximation to annular illumination, incident light being pro-

vided from a discrete number of representative azimuthal

angles. A large number or an odd number of illumination

sources more closely approximates annular illumination. An-

nular or circumferential illumination minimizes directional

effects. Therefore, measurements with annular or circumferen-

tial illumination may or may not correlate with how that

specimen appears under directional illumination. For example,

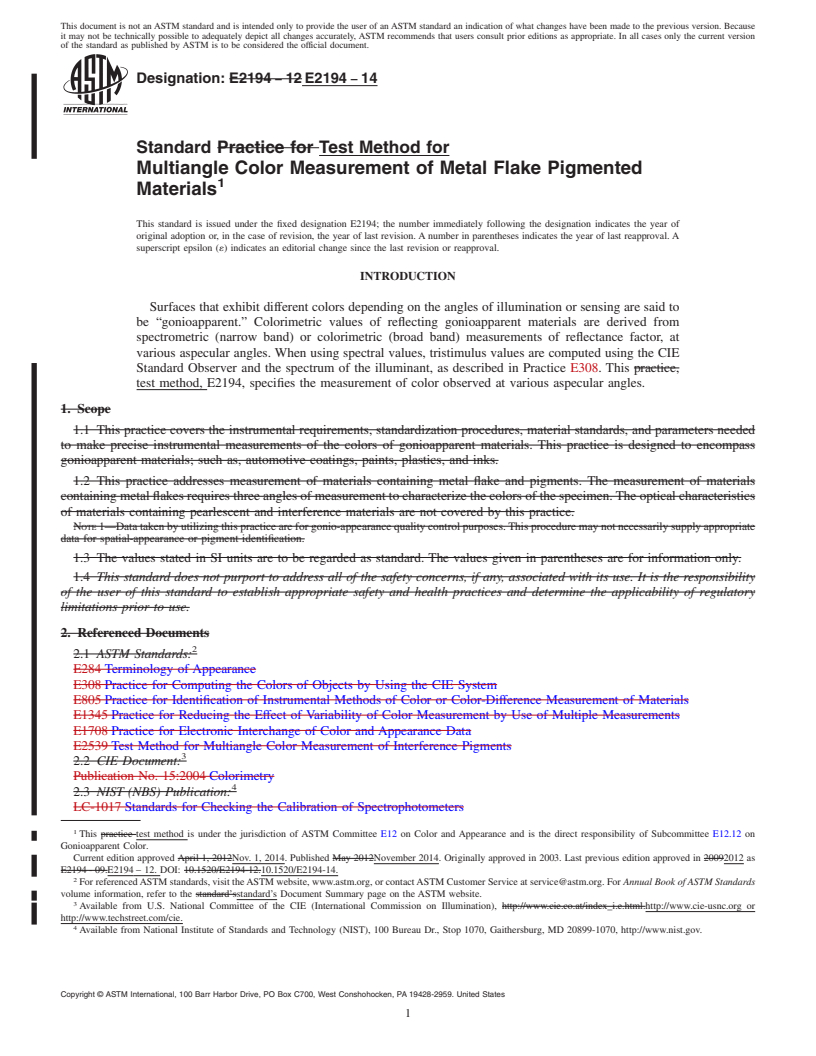

NOTE 1—Solid lines indicate preferred angles.

this system averaging may cause the measured color values of

FIG. 2 Diagram of Aspecular Angles

two specimens to be the same or similar, even though these

same two specimens would not match visually due to the fact

that one specimen exhibits the venetian blind effect.

In critical color matching applications, batches should be

7.4 Recommended Geometry—The instrument shall con-

resampled and resprayed to eliminate surface differences and

formtothefollowinggeometricrequirementsformeasurement

measurements shall be performed at 15°.

of reflectance factor unless otherwise agreed upon between the

7.4.2 Mid-specular Angle—The mid-specular color mea-

buyer and the seller. The preferred aspecular angles for

surement shall be at an aspecular angle of 45° conforming to

measurement are 15°, 45°, and 110°.

the geometrical specifications of CIE 15:2004.

NOTE 3—Given a geometric configuration, the reverse geometry is

7.4.3 Far-specular Angle—Visual observation of color dif-

consideredequivalent,ifallothercomponentsoftheinstrumentdesignare

ferences in a few cases detects sidetone scattering better at

equivalent; for example, in the example shown in Fig. 1, the same result

anglesfurtherawayfromspecular;hence,110°isthepreferred

wouldbeobtainedwiththeilluminationangleat65°andthesensingangle

aspecular angle for far-specular measurement. In most but not

at 45°. The aspecular angle would still be 110°.

NOTE 4—Measurement angles below are stated in terms of aspecular

all cases, angles down to 70° give acceptable results.

angles.Ithasbeenestablishedthatformetallicmaterialscolors,aspecific

(Warning—Visual assessments of gonioapparent matches

aspecular angle gives the same measurement regardless of angle of

typically cover a wide range of aspecular angles, from very

illumination. For pearlescent materials, it is known that color is also a

nearspecular,allthewaytofar-specularanglesof110°oreven

function of angle of illumination. The importance of this phenomenon in

higher. Therefore, instrumental measurement at far-specular

measurementofpearlescentandinterferencematerialsforcolordifference

for quality control or color correction purposes has not been established.

angles below 110° may occasionally result in measurements

NOTE 5—Uniplanar instruments can measure the venetian blind effect.

not agreeing with typical visual assessments. This will occur

Circumferential and annular illumination will not quantify this gonioap-

when specimens are an acceptable visual and instrumental

parent effect.

match at angles such as 75° but unacceptable at 110°.)

NOTE 6—There are instruments commercially available with uniplanar,

multiangle geometries that give results that characterize gonioapparent 7.4.4 Illuminating and Sensing Beam Aperture Angles—The

materials.Theseinstrumentswilldetectthevenetianblindeffectandother

illuminating beam aperture angle and the sensing beam aper-

anomalies. Table 1 delineates the preferred angles. Note that circumfer-

ture angle must be less than 8°.

ential geometry is limited to <90° aspecular angle. With the variety of

instrumentation in common usage, it is incumbent upon the user to

8. Test Specimen

determine if an instrument with angles other than the preferred angles is

appropriate in their application. Fig. 2

8.1 Measured values depend on the quality of the test

specimens. The specimens must be statistically representative

7.4.1 Near Specular Angle—The near specular angle used

shouldbeasclosetothespeculardirectionaspossible,without of the lot being tested and should meet the requirements listed

below. If the specimens do not meet these requirements,

detecting specular light. Surface imperfections can cause light

to be reflected in a direction slightly away from the nominal include this information in Section 13.

specular direction. Measurement at 15° from the specular

8.2 Specimen Handling—Handle the specimens carefully.

minimizes the effects of surface imperfections encountered in

Touch them by their edges only. Never lay the measurement

most practical industrial specimens. Differences in surface

surface of the specimen down on another surface or stack

texture may result from spray application differences which

specimens without a protective medium as recommended by

can cause flake orientation differences. Measurement at 20° or

the provider.

25° from specular may be chosen when less sensitivity to

8.3 Specimen Cleaning—If necessary, clean the specimens

application differences between standard and batch is desired.

following the providers’ cleaning procedure.

8.4 Specimen Conditioning—Allow specimens to stabilize

TABLE 1 Preferred Angles

in the measurement

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2194 − 12 E2194 − 14

Standard Practice for Test Method for

Multiangle Color Measurement of Metal Flake Pigmented

Materials

This standard is issued under the fixed designation E2194; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Surfaces that exhibit different colors depending on the angles of illumination or sensing are said to

be “gonioapparent.” Colorimetric values of reflecting gonioapparent materials are derived from

spectrometric (narrow band) or colorimetric (broad band) measurements of reflectance factor, at

various aspecular angles. When using spectral values, tristimulus values are computed using the CIE

Standard Observer and the spectrum of the illuminant, as described in Practice E308. This practice,

test method, E2194, specifies the measurement of color observed at various aspecular angles.

1. Scope

1.1 This practice covers the instrumental requirements, standardization procedures, material standards, and parameters needed

to make precise instrumental measurements of the colors of gonioapparent materials. This practice is designed to encompass

gonioapparent materials; such as, automotive coatings, paints, plastics, and inks.

1.2 This practice addresses measurement of materials containing metal flake and pigments. The measurement of materials

containing metal flakes requires three angles of measurement to characterize the colors of the specimen. The optical characteristics

of materials containing pearlescent and interference materials are not covered by this practice.

NOTE 1—Data taken by utilizing this practice are for gonio-appearance quality control purposes. This procedure may not necessarily supply appropriate

data for spatial-appearance or pigment identification.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E284 Terminology of Appearance

E308 Practice for Computing the Colors of Objects by Using the CIE System

E805 Practice for Identification of Instrumental Methods of Color or Color-Difference Measurement of Materials

E1345 Practice for Reducing the Effect of Variability of Color Measurement by Use of Multiple Measurements

E1708 Practice for Electronic Interchange of Color and Appearance Data

E2539 Test Method for Multiangle Color Measurement of Interference Pigments

2.2 CIE Document:

Publication No. 15:2004 Colorimetry

2.3 NIST (NBS) Publication:

LC-1017 Standards for Checking the Calibration of Spectrophotometers

This practice test method is under the jurisdiction of ASTM Committee E12 on Color and Appearance and is the direct responsibility of Subcommittee E12.12 on

Gonioapparent Color.

Current edition approved April 1, 2012Nov. 1, 2014. Published May 2012November 2014. Originally approved in 2003. Last previous edition approved in 20092012 as

E2194 - 09.E2194 – 12. DOI: 10.1520/E2194-12.10.1520/E2194-14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Available from U.S. National Committee of the CIE (International Commission on Illumination), http://www.cie.co.at/index_i.e.html.http://www.cie-usnc.org or

http://www.techstreet.com/cie.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2194 − 14

2.4 ISO Publication:

ISO International Vocabulary of Basic and General Terms in Metrology (VIM)

3. Terminology

3.1 Terms and definitions in Terminology E284 are applicable to this practice. See Section “Specialized Terminology on

Gonioapparent Phenomena.”

3.2 Definitions:

3.2.1 Usually the term metallic refers to a metal material. However, this standard employs the alternative definition given in

Terminology E284 as:

3.2.2 metallic, adj—pertaining to the appearance of a gonioapparent material containing metal flakes.

3.3 Definitions of metrology terms in ISO International Vocabulary of Basic and General Terms in Metrology (VIM) are

applicable to this practice.

4. Summary of Practice

4.1 This practice describes the procedures for the spectrometric and colorimetric measurement of metal flake pigmented

materials. The results are reported in terms of CIE tristimulus values and other color coordinate systems. Standardization of the

instrument used to measure these materials is defined. Guidelines are given for the selection of specimens and a measurement

protocol given. Characterization of these materials requires measurement at a near-specular angle, a mid-specular angle and a

far-specular angle. These preferred aspecular angles are 15°, 45°, and 110°.

5. Significance and Use

5.1 Instrumental Measurement Angles—This practice is designed to provide color data at specific measurement angles that can

be utilized for quality control, color matching, and formulating in the characterization of metal flake pigmented materials.

5.2 Materials—This practice provides meaningful color information for metal flake pigmented materials. This practice has been

tested and verified on paint and coatings, and the same principles should apply to plastics containing metallic flake. For materials

containing pearlescent materials refer to Practice E2539.

5.3 Utilization—This practice is appropriate for measurement and characterization of metal flake pigmented materials. These

data may be used for quality control, incoming inspection, or color correction purposes.

5.4 Specimen Requirements—Even though a pair of specimens have the same color values at three angles, if there are differences

in gloss, orange peel, texture, or flake orientation, they may not be a visual match.

NOTE 2—Information presented in this practice is based upon data taken on metallic materials coatings. Applicability of this practice to other materials

should be confirmed by the user.

6. Apparatus

6.1 Instrument—This practice requires measurement at multiple aspecular angles, usually accomplished by the use of a

multiangle spectrometer as specified in this practice to characterize metal flake pigmented materials. Measurement with a single

geometry cannot characterize the gonioappearance of these materials.

6.2 Standardization—A standardization plaque with assigned spectral reflectance factor or tristimulus values traceable to a

national standardizing laboratory for each specified aspecular angle is required to standardize the instrument. The instrument

manufacturer typically assigns the values to this plaque.

7. Geometric Conditions

7.1 Conventional Color Measurement—In general purpose colorimetry, the common geometry involves illuminating at 45° and

sensing at 0°. This geometry is designated 45:0 (45/0). Reverse geometry has the illumination at 0° and the sensing at 45°. That

is, the illuminator and sensing geometries are interchanged. This reciprocal geometry is designated 0:45 (0/45). Either geometry

is used.

7.1.1 A single bi-directional geometry is specified by illumination and sensing angles with respect to the normal of the plane

of the specimen. Angles are measured relative to the normal. Angles on the same side of the normal as the illumination beam are

written as positive angles; those on the other side are shown as negative, as shown in Fig. 1.

7.2 Multiangle Uniplanar Measurement—The color of metallic materials specimens varies with the angle of view. Thus

measurements must be taken at more than one aspecular angle to characterize the change of color with angle. The measurement

geometry for multiangle measurements is specified by aspecular angles. The aspecular angle is the viewing angle measured from

the specular direction, in the illuminator plane unless otherwise specified. The angle is considered positive when measured from

the specular direction towards the illuminator axis. Thus, if the specimen is illuminated at 45° to the normal the specular reflection

ISO/IDE/OIML/BIPM, International Vocabulary of Basic and General Terms in Metrology, International Organization for Standardization, Geneva Switzerland, 1984.

E2194 − 14

NOTE 1—Anormal illumination angle = 45° and anormal sensing angle = 65°; therefore, aspecular angle = 45 + 65 = 110°.

FIG. 1 Example of Illuminating and Sensing Geometry

will be at -45° (See Fig. 1). Sensing at 65° from the normal, and on the same side of normal as the illumination, is sensing 110°

away from the specular direction; that is an aspecular angle of 110°. Thus, the aspecular angle is the sum of the anormal

illumination and sensing angles. It has been established that for metallic materials or colors, a specific aspecular angle gives the

same measurement regardless of angle of illumination.

7.3 Annular and Circumferential Geometry—Annular illumination provides incident light to a specimen at all azimuthal angles.

This type of illumination minimizes the contribution from directional effects such as the venetian blind effect and surface

irregularities. Circumferential illumination is an approximation to annular illumination, incident light being provided from a

discrete number of representative azimuthal angles. A large number or an odd number of illumination sources more closely

approximates annular illumination. Annular or circumferential illumination minimizes directional effects. Therefore, measurements

with annular or circumferential illumination may or may not correlate with how that specimen appears under directional

illumination. For example, this system averaging may cause the measured color values of two specimens to be the same or similar,

even though these same two specimens would not match visually due to the fact that one specimen exhibits the venetian blind

effect.

7.4 Recommended Geometry—The instrument shall conform to the following geometric requirements for measurement of

reflectance factor unless otherwise agreed upon between the buyer and the seller. The preferred aspecular angles for measurement

are 15°, 45°, and 110°.

NOTE 3—Given a geometric configuration, the reverse geometry is considered equivalent, if all other components of the instrument design are

equivalent; for example, in the example shown in Fig. 1, the same result would be obtained with the illumination angle at 65° and the sensing angle at

45°. The aspecular angle would still be 110°.

NOTE 4—Measurement angles below are stated in terms of aspecular angles. It has been established that for metallic materials colors, a specific

aspecular angle gives the same measurement regardless of angle of illumination. For pearlescent materials, it is known that color is also a function of

angle of illumination. The importance of this phenomenon in measurement of pearlescent and interference materials for color difference for quality control

or color correction purposes has not been established.

NOTE 5—Uniplanar instruments can measure the venetian blind effect. Circumferential and annular illumination will not quantify this gonioapparent

effect.

NOTE 6—There are instruments commercially available with uniplanar, multiangle geometries that give results that characterize gonioapparent

materials. These instruments will detect the venetian blind effect and other anomalies. Table 1 delineates the preferred angles. Note that circumferential

geometry is limited to <90° aspecular angle. With the variety of instrumentation in common usage, it is incumbent upon the user to determine if an

instrument with angles other than the preferred angles is appropriate in their application. Fig. 2

7.4.1 Near Specular Angle—The near specular angle used should be as close to the specular direction as possible, without

detecting specular light. Surface imperfections can cause light to be reflected in a direction slightly away from the nominal specular

direction. Measurement at 15° from the specular minimizes the effects of surface imperfections encountered in most practical

industrial specimens. Differences in surface texture may result from spray application differences which can cause flake orientation

differences. Measurement at 20° or 25° from specular may be chosen when less sensitivity to application differences between

TABLE 1 Preferred Angles

Uniplanar Angle Preferred Angle

Near specular 15°

Mid-specular angle 45°

Far-specular angle 110°

NOTE 1—Other geometries in common usage are: 25°, 70°, or 75°.

E2194 − 14

NOTE 1—Solid lines indicate preferred angles.

FIG. 2 Diagram of Aspecular Angles

standard and batch is desired. In critical color matching applications, batches should be resampled and resprayed to eliminate

surface differences and measurements shall be performed at 15°.

7.4.2 Mid-specular Angle—The mid-specular color measurement shall be at an aspecular angle of 45° conforming to the

geometrical specifications of CIE 15:2004.

7.4.3 Far-specular Angle—Visual observation of color differences in a few cases detects sidetone scattering better at angles

further away from specular; hence, 110° is the preferred aspecular angle for far-specular measurement. In most but not all cases,

angles down to 70° give acceptable results. (Warning—Visual assessments of gonioapparent matches typically cover a wide range

of aspecular angles, from very near specular, all the way to far-specular angles of 110° or even higher. Therefore, instrumental

measurement at far-specular angles below 110° may occasionally result in measurements not agreeing with typical visual

assessments. This will occur when specimens are an acceptable visual and instrumental match at angles such as 75° but

unacceptable at 110°.)

7.4.4 Illuminating and Sensing Beam Aperture Angles—The illuminating beam aperture angl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.