ASTM F1252-89(2002)

(Test Method)Standard Test Method for Measuring Optical Reflectivity of Transparent Materials

Standard Test Method for Measuring Optical Reflectivity of Transparent Materials

SIGNIFICANCE AND USE

Reflections from aircraft transparencies of instrument lights and other cockpit objects have been a concern to many pilots. Attempts to reduce these reflections have been hampered by the lack of a repeatable measurement method and variances in reflection measuring instrumentation. The problem with measuring instrumentation is that different brands will often give significant value differences using the same specimen surface.

This test method reduces the instrument variations by standardizing the light source, calculation method, and area of specimen surface being measured; a brand of instrumentation is not specified. Since the reflectivity is defined as the ratio of two luminance measurements and does not depend on an absolute measurement, dependence upon the accuracy of the measuring instrument is reduced.

The test method may be used to objectively compare the reflection characteristics of various transparent materials. Furthermore, the test method may be used to evaluate reflections of a specified spectral source by using that source in place of the standard light source.

Provisions are made to check for polarization effects of the sample and to record the reflectivity of a standard specimen. These provisions are offered as an option to the tester; it is up to the user or the requiring agency to determine the significance and use of these data.

Since the reflections are measured photopically, the results are representative of what the pilot would visually perceive.

SCOPE

1.1 This test method covers a procedure for measuring the reflectivity of transparent materials, hereafter known as specimens. The results are repeatable without specifying a particular brand name of instrumentation.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 1252 – 89 (Reapproved 2002)

Standard Test Method for

Measuring Optical Reflectivity of Transparent Materials

This standard is issued under the fixed designation F 1252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a procedure for measuring the

reflectivity of transparent materials, hereafter known as speci-

mens.The results are repeatable without specifying a particular

brand name of instrumentation.

1.2 The values stated in SI units are to be regarded as

standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

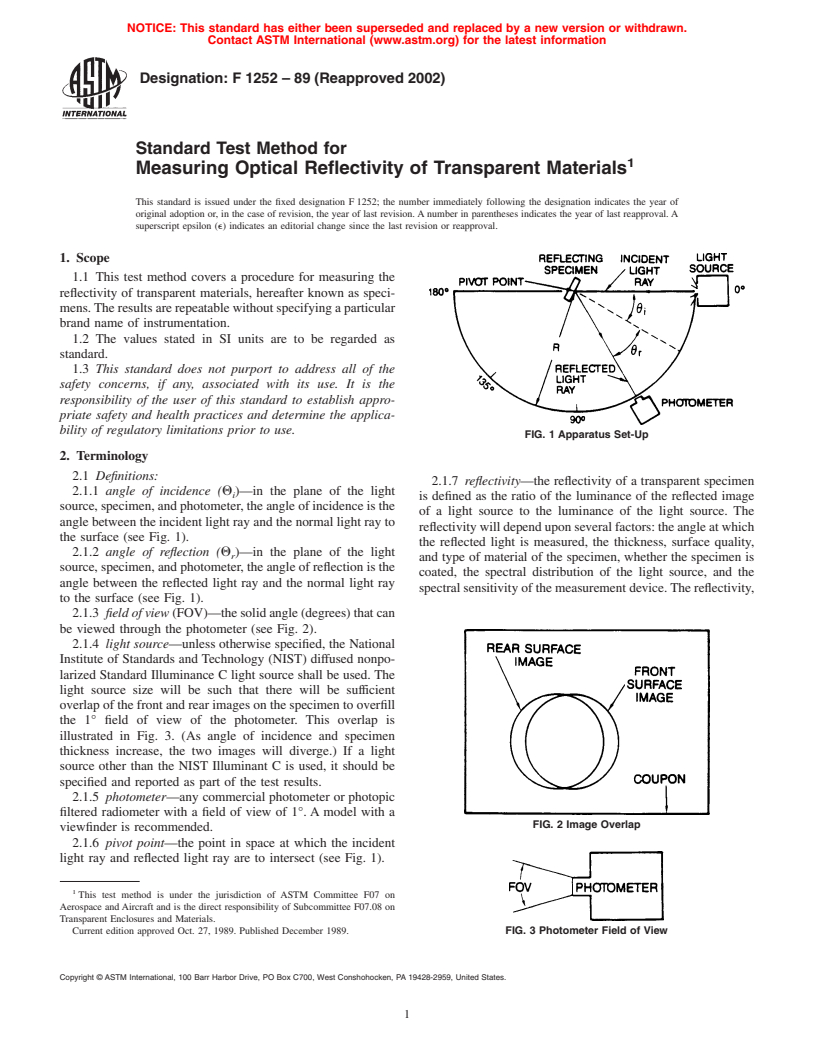

FIG. 1 Apparatus Set-Up

2. Terminology

2.1 Definitions:

2.1.7 reflectivity—the reflectivity of a transparent specimen

2.1.1 angle of incidence (Q)—in the plane of the light

i

is defined as the ratio of the luminance of the reflected image

source, specimen, and photometer, the angle of incidence is the

of a light source to the luminance of the light source. The

angle between the incident light ray and the normal light ray to

reflectivitywilldependuponseveralfactors:theangleatwhich

the surface (see Fig. 1).

the reflected light is measured, the thickness, surface quality,

2.1.2 angle of reflection (Q )—in the plane of the light

r

and type of material of the specimen, whether the specimen is

source, specimen, and photometer, the angle of reflection is the

coated, the spectral distribution of the light source, and the

angle between the reflected light ray and the normal light ray

spectral sensitivity of the measurement device.The reflectivity,

to the surface (see Fig. 1).

2.1.3 field of view(FOV)—thesolidangle(degrees)thatcan

be viewed through the photometer (see Fig. 2).

2.1.4 light source—unless otherwise specified, the National

Institute of Standards and Technology (NIST) diffused nonpo-

larized Standard Illuminance C light source shall be used. The

light source size will be such that there will be sufficient

overlap of the front and rear images on the specimen to overfill

the 1° field of view of the photometer. This overlap is

illustrated in Fig. 3. (As angle of incidence and specimen

thickness increase, the two images will diverge.) If a light

source other than the NIST Illuminant C is used, it should be

specified and reported as part of the test results.

2.1.5 photometer—any commercial photometer or photopic

filtered radiometer with a field of view of 1°. A model with a

FIG. 2 Image Overlap

viewfinder is recommended.

2.1.6 pivot point—the point in space at which the incident

light ray and reflected light ray are to intersect (see Fig. 1).

This test method is under the jurisdiction of ASTM Committee F07 on

Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on

Transparent Enclosures and Materials.

Current edition approved Oct. 27, 1989. Published December 1989. FIG. 3 Photometer Field of View

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1252 – 89 (2002)

as defined here, includes the small amount of scattered light 5.6 A flat black surface (such as black velvet) shall be

that contributes to the luminance of the reflected image. behind the specimen during measurement to prevent second

source reflection.

3. Summary of Test Method

6. Procedure

3.1 The luminance of the standard source is determined by

6.1 Allow the light source and photometer to warm up per

measuring it directly with the photometer. The luminance of

manufacturer’s specification.

the reflection of the source is then measured off the specimen

6.2 The pivot point is the point in space at which the surface

at a specified geometry. The luminance of the reflection is

of the specimen will be placed (6.5) such that the reflection

divided by the luminance of the source to obtain the reflectivity

occurs at the desired geometry. Establish the pivot point by

of the specimen.

marking the point with a small object, such as a piece of

cardboard. Position the light source at a proper distance from

4. Significance and Use

the pivot point (5.3).

4.1 Reflections from aircraft transparencies of instrument

6.3 Locate the photometer at a position equidistant from the

lights and other cockpit objects have been a concern to many

pivot point such that the source, pivot point, and photometer

pilots. Attempts to reduce these reflections have been ham-

are in line (see Fig. 4). Direct the photometer such that its FOV

pered by the lack of a repeatable measurement method and

variances in reflection measuring instrumentation. The prob-

lem with measuring instrumentation is that different brands

will often give significant value differences using the same

specimen surface.

4.2 This test method reduces the instrument variations by

standardizing the light source, calculation method, and area of

specimen surface being measured; a brand of instrumentation

is not specified. Since the reflectivity is defined as the ratio of

two luminance measurements and does not depend on an

absolute measurement, dependence upon the accuracy of the

measuring instrument is reduced.

4.3 The test method may be used to objectively compare the

reflection characteristics of various transparent materials. Fur-

FIG. 4 Apparatus Set-Up for Source Measurement

thermore, the test method may be used to evaluate reflections

of a specified spectral source by using that source in place of

the standard light source.

is centered on the luminance source. Focus the photometer on

4.4 Provisions are made to check for polarization effects of

the source and record the luminance L.

the sample and to record the reflectivity of a standard speci-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.