ASTM D4965-96(2002)

(Terminology)Standard Terminology of Seams and Seam Finishes in Home Sewing

Standard Terminology of Seams and Seam Finishes in Home Sewing

SCOPE

1.1 This terminology provides a uniform, easily understood language for the definitions and descriptions of seams and seam finishes used in home sewing.

1.1.1 These seams and seam finishes may be produced on a conventional sewing machine or by hand.

1.1.2 These terms and definitions are not necessarily applicable to the apparel manufacturing industry.

1.2 This terminology provides a common base for use in the preparation of educational materials and pattern guide sheets for home sewing.

1.3 Other seam types or finishes may be more appropriate if equipment other than the conventional sewing machine is available.

1.4 For other terms associated with textiles, refer to Terminology D 123.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4965–96 (Reapproved 2002)

Standard Terminology of

1

Seams and Seam Finishes Used in Home Sewing

This standard is issued under the fixed designation D 4965; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This terminology provides a uniform, easily understood

language for the definitions and descriptions of seams and

seam finishes used in home sewing.

1.1.1 These seams and seam finishes may be produced on a

conventional sewing machine or by hand.

1.1.2 These terms and definitions are not necessarily appli-

cable to the apparel manufacturing industry.

1.2 This terminology provides a common base for use in the

preparation of educational materials and pattern guide sheets

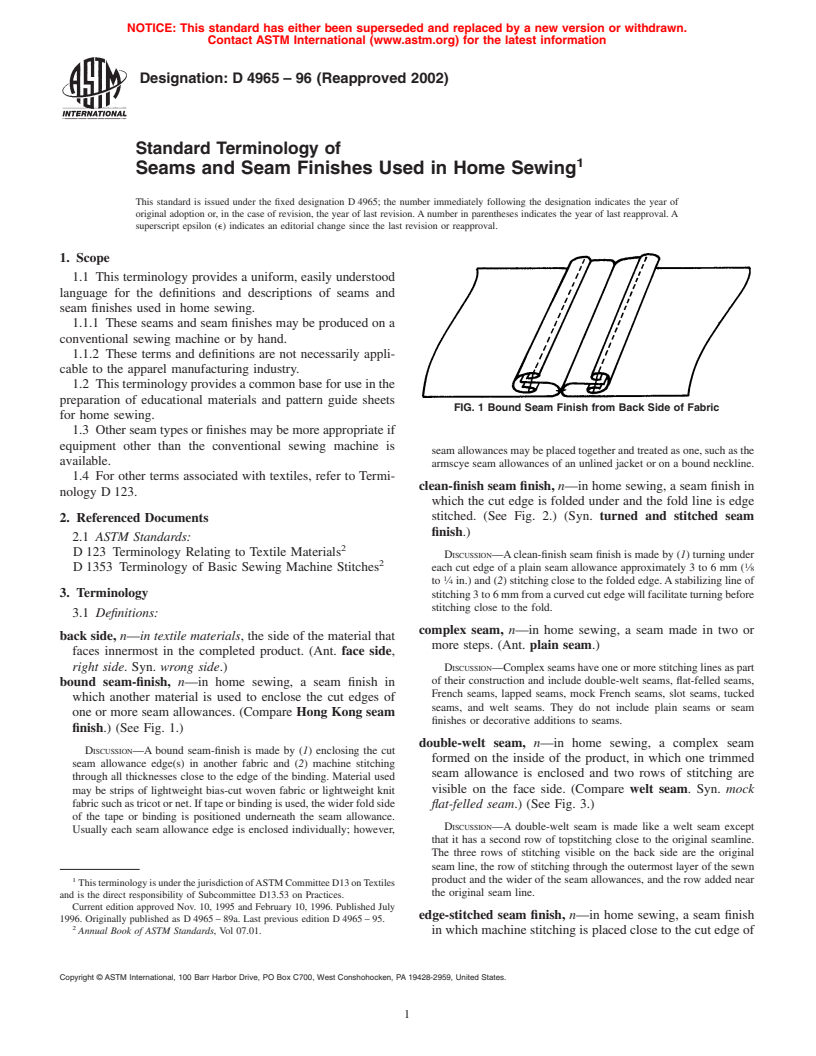

FIG. 1 Bound Seam Finish from Back Side of Fabric

for home sewing.

1.3 Other seam types or finishes may be more appropriate if

equipment other than the conventional sewing machine is

seam allowances may be placed together and treated as one, such as the

available.

armscye seam allowances of an unlined jacket or on a bound neckline.

1.4 For other terms associated with textiles, refer to Termi-

clean-finish seam finish, n—in home sewing, a seam finish in

nology D 123.

which the cut edge is folded under and the fold line is edge

stitched. (See Fig. 2.) (Syn. turned and stitched seam

2. Referenced Documents

finish.)

2.1 ASTM Standards:

2

D 123 Terminology Relating to Textile Materials

DISCUSSION—Aclean-finish seam finish is made by (1) turning under

2

1

D 1353 Terminology of Basic Sewing Machine Stitches each cut edge of a plain seam allowance approximately 3 to 6 mm ( ⁄8

1

to ⁄4 in.) and (2) stitching close to the folded edge.Astabilizing line of

3. Terminology stitching 3 to 6 mm from a curved cut edge will facilitate turning before

stitching close to the fold.

3.1 Definitions:

complex seam, n—in home sewing, a seam made in two or

back side, n—in textile materials, the side of the material that

more steps. (Ant. plain seam.)

faces innermost in the completed product. (Ant. face side,

right side. Syn. wrong side.)

DISCUSSION—Complex seams have one or more stitching lines as part

of their construction and include double-welt seams, flat-felled seams,

bound seam-finish, n—in home sewing, a seam finish in

French seams, lapped seams, mock French seams, slot seams, tucked

which another material is used to enclose the cut edges of

seams, and welt seams. They do not include plain seams or seam

one or more seam allowances. (Compare Hong Kong seam

finishes or decorative additions to seams.

finish.) (See Fig. 1.)

double-welt seam, n—in home sewing, a complex seam

DISCUSSION—A bound seam-finish is made by (1) enclosing the cut

formed on the inside of the product, in which one trimmed

seam allowance edge(s) in another fabric and (2) machine stitching

seam allowance is enclosed and two rows of stitching are

through all thicknesses close to the edge of the binding. Material used

visible on the face side. (Compare welt seam. Syn. mock

may be strips of lightweight bias-cut woven fabric or lightweight knit

fabricsuchastricotornet.Iftapeorbindingisused,thewiderfoldside flat-felled seam.) (See Fig. 3.)

of the tape or binding is positioned underneath the seam allowance.

DISCUSSION—A double-welt seam is made like a welt seam except

Usually each seam allowance edge is enclosed individually; however,

that it has a second row of topstitching close to the original seamline.

The three rows of stitching visible on the back side are the original

seam line, the row of stitching through the outermost layer of the sewn

1

product and the wider of the seam allowances, and the row added near

ThisterminologyisunderthejurisdictionofASTMCommitteeD13onTextiles

the original seam line.

and is the direct responsibility of Subcommittee D13.53 on Practices.

Current edition approved Nov. 10, 1995 and February 10, 1996. Published July

edge-stitched seam finish, n—in home sewing, a seam finish

1996. Originally published as D 4965 – 89a. Last previous edition D 4965 – 95.

2

Annual Book of ASTM Standards, Vol 07.01. in which machine stitching is placed close to the cut edge of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

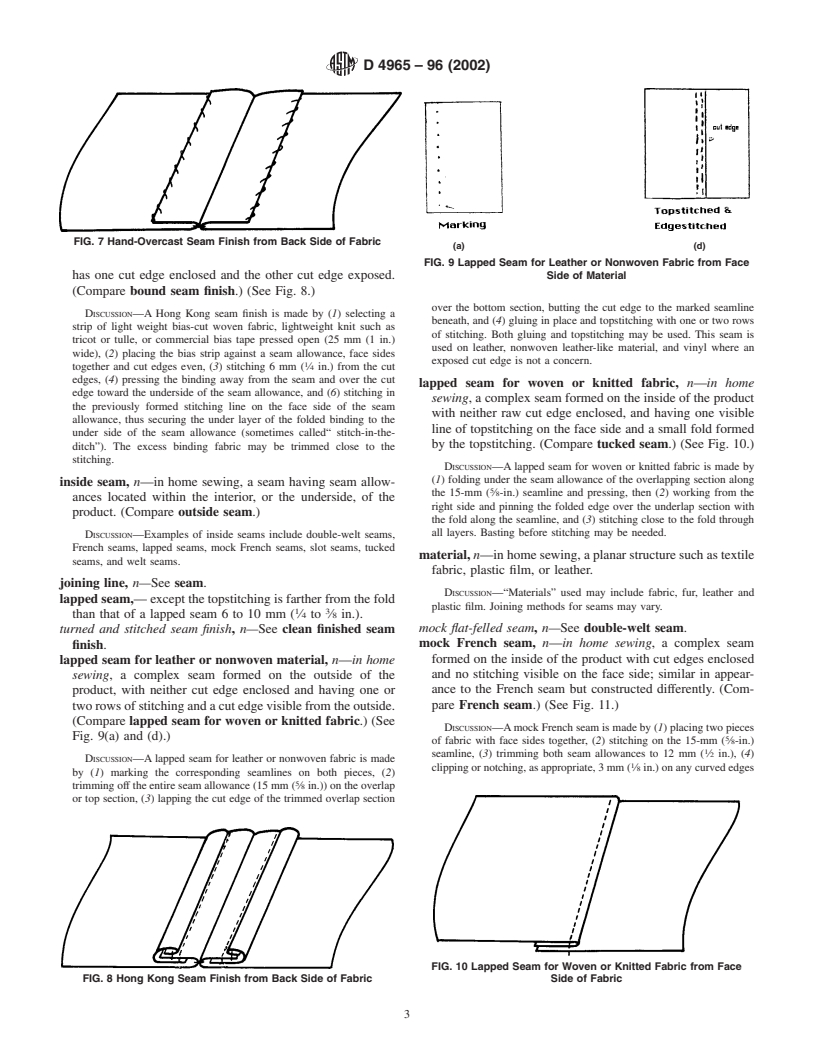

D4965–96 (2002)

FIG. 2 Clean-Finish Seam Finish from Back Side of Fabric

FIG. 5 Flat-Felled Seam from Face Side of Fabric

stitching rows visible on the face side. (Compare mock

French seam.) (See Fig. 6.)

DISCUSSION—A French seam is made by (1) placing two sections of

3

fabric with back sides together, (2) stitching a seam line 10 mm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.