ASTM D1217-93(2007)

(Test Method)Standard Test Method for Density and Relative Density (Specific Gravity) of Liquids by Bingham Pycnometer

Standard Test Method for Density and Relative Density (Specific Gravity) of Liquids by Bingham Pycnometer

SIGNIFICANCE AND USE

Density is a fundamental physical property which can be used in conjunction with other properties to characterize pure hydrocarbons and their mixtures.

This test method was originally developed for the determination of the density of the ASTM Knock Test Reference Fuels n-heptane and isooctane, with an accuracy of 0.00003 g/mL. Although it is no longer employed extensively for this purpose, this test method is useful whenever accurate densities of pure hydrocarbons or petroleum fractions with boiling points between 90 and 110°C are required.

SCOPE

1.1 This test method covers the measurement of the density of pure hydrocarbons or petroleum distillates boiling between 90 and 110°C that can be handled in a normal fashion as a liquid at the specified test temperatures of 20 and 25°C.

1.2 This test method provides a calculation procedure for the conversion of density to relative density (specific gravity).

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1217 −93(Reapproved 2007)

Standard Test Method for

Density and Relative Density (Specific Gravity) of Liquids by

Bingham Pycnometer

This standard is issued under the fixed designation D1217; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope density of water is unity, relative density (specific gravity) and

density are numerically equal.

1.1 This test method covers the measurement of the density

of pure hydrocarbons or petroleum distillates boiling between

4. Summary of Test Method

90 and 110°C that can be handled in a normal fashion as a

liquid at the specified test temperatures of 20 and 25°C. 4.1 The liquid sample is introduced into a pycnometer,

equilibrated to the desired temperature, and weighed. The

1.2 This test method provides a calculation procedure for

relative density (specific gravity) or density is then calculated

the conversion of density to relative density (specific gravity).

from this weight and the previously determined weight of

1.3 The values stated in SI units are to be regarded as

water that is required to fill the pycnometer at the same

standard. The values given in parentheses are for information

temperature, both weights being corrected for the buoyancy of

only.

air.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Densityisafundamentalphysicalpropertywhichcanbe

priate safety and health practices and determine the applica-

used in conjunction with other properties to characterize pure

bility of regulatory limitations prior to use. Specific warning

hydrocarbons and their mixtures.

statements are given in Section 7.

5.2 This test method was originally developed for the

2. Referenced Documents

determination of the density of the ASTM Knock Test Refer-

2 ence Fuels n-heptane and isooctane, with an accuracy of

2.1 ASTM Standards:

0.00003 g/mL. Although it is no longer employed extensively

E1 Specification for ASTM Liquid-in-Glass Thermometers

for this purpose, this test method is useful whenever accurate

densities of pure hydrocarbons or petroleum fractions with

3. Terminology

boiling points between 90 and 110°C are required.

3.1 Definitions:

3.1.1 density—the weight in vacuo, (that is, the mass) of a

6. Apparatus

unit volume of the material at any given temperature.

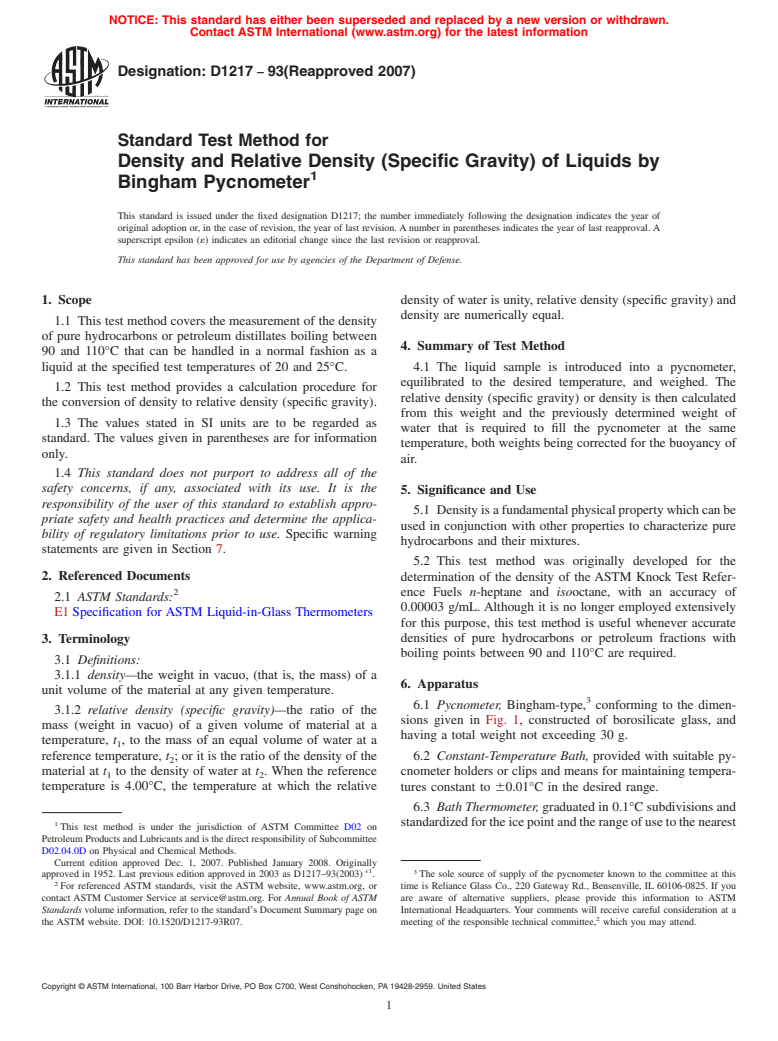

6.1 Pycnometer, Bingham-type, conforming to the dimen-

3.1.2 relative density (specific gravity)—the ratio of the

sions given in Fig. 1, constructed of borosilicate glass, and

mass (weight in vacuo) of a given volume of material at a

having a total weight not exceeding 30 g.

temperature, t , to the mass of an equal volume of water at a

reference temperature, t ; or it is the ratio of the density of the 6.2 Constant-Temperature Bath, provided with suitable py-

material at t to the density of water at t . When the reference

cnometer holders or clips and means for maintaining tempera-

1 2

temperature is 4.00°C, the temperature at which the relative tures constant to 60.01°C in the desired range.

6.3 Bath Thermometer, graduated in 0.1°C subdivisions and

1 standardizedfortheicepointandtherangeofusetothenearest

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.04.0D on Physical and Chemical Methods.

Current edition approved Dec. 1, 2007. Published January 2008. Originally

ϵ1

approved in 1952. Last previous edition approved in 2003 as D1217–93(2003) . The sole source of supply of the pycnometer known to the committee at this

For referenced ASTM standards, visit the ASTM website, www.astm.org, or time is Reliance Glass Co., 220 Gateway Rd., Bensenville, IL 60106-0825. If you

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM are aware of alternative suppliers, please provide this information to ASTM

Standards volume information, refer to the standard’s Document Summary page on International Headquarters. Your comments will receive careful consideration at a

the ASTM website. DOI: 10.1520/D1217-93R07. meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1217−93 (2007)

shall be made by the method of substitution, in which the

calibrated weights and pycnometer are alternately weighed on

the same balance pan. The same balance shall be used for all

related weighings.

6.9 Weights, whose relative values are known to the nearest

0.05 mg or better.The same set of weights shall be used for the

calibration of the pycnometer and the determination of densi-

ties.

7. Reagents and Materials

7.1 Acetone—(Warning— Extremely flammable. Use ad-

equate ventilation.)

7.2 Isopentane—( Warning—Extremely flammable. Avoid

buildupofvaporsandremoveallsourcesofignition,especially

non-explosion proof electrical apparatus.)

7.3 Chromic Acid (Potassium Dichromate/Conc. Sulfuric

Acid)—(Warning—Causes severe burns. A recognized car-

cinogen. Do not get in eyes, or on skin or clothing.)

8. Preparation of Apparatus

8.1 Thoroughly clean the pycnometer with hot chromic acid

cleaning solution by means of the assembly shown in Fig. 4.

Chromic acid solution (Warning—See 7.3) is the most effec-

tive cleaning agent. However, surfactant cleaning fluids have

also been used successfully. Mount the apparatus firmly and

connect the trap to the vacuum.Warm the necessary amount of

cleaning acid in the beaker, place the pycnometer on the

ground joint, and evacuate by opening the stopcock to vacuum.

FIG. 1 Bingham-Type Pycnometer, 25 mL

Fill the pycnometer with acid by turning the stopcock, repeat

several times or remove the filled pycnometer, and allow it to

standforseveralhoursat50to60°C.Removetheacidfromthe

0.01°C. ASTM Saybolt Viscosity Thermometer 17C as pre-

pycnometer by evacuation, empty the acid from the trap, and

scribed in Specification E1, designed for tests at 21.1°C and

flush the pycnometer with water. Cleaning should be made in

25°C, is recommended. A standardized platinum resistance

this manner whenever the pycnometer is to be calibrated or

thermometer may also be used, and offers the best means for

whenever liquid fails to drain cleanly from the walls of the

observing minute temperature changes in the bath. Whichever

pycnometer or its capillary. Ordinarily, the pycnometer may be

means are available, it must be realized that for most hydro-

cleaned between determinations by washing with a suitable

carbons the density coefficient is about 0.0008 units/°C, and

solvent,rinsingwithpure,dryacetone,followedbyisopentane,

therefore an error of 60.013°C would cause an error of

60.00001 in density. and vacuum drying.

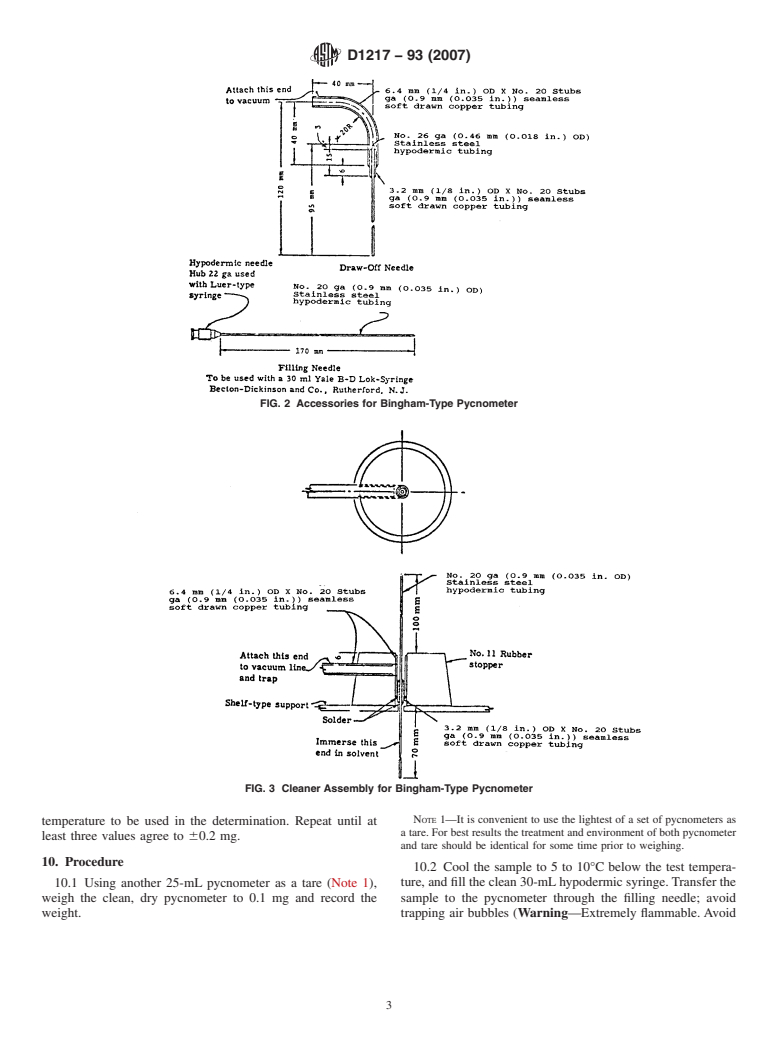

6.4 Hypodermic Syringe, 30-mL capacity, of chemically 8.2 Transfer the pycnometer to the cleaner assembly shown

resistant glass, equipped with a 152-mm (6-in.) needle made of in Fig. 3, with vacuum line and trap attached to the side tube

as indicated. Place the pycnometer on the cleaner with the

stainless steel tubing as shown in Fig. 2.

upper hypodermic needle extending upward into the pycnom-

6.5 Draw-Off Needle, made of stainless steel tubing as

eter, and press the edge of the ground joint on the rubber

shown in Fig. 2.

stopper until the vacuum holds it in place. Draw out all the

6.6 Solvent-Cleaning Assembly, as shown in Fig. 3.

liquid or sample. Immerse the lower end of the hypodermic

tube in a suitable solvent and draw 20 to 25 mL through the

6.7 Chromic Acid Cleaning Apparatus, similar to that

pycnometer.Leavingthepycnometerinplace,drawairthrough

shown in Fig. 4.

it until it is dry. Clean the hypodermic syringe with the same

6.8 Balance, capable of reproducing weighings within 0.1

apparatus.

mg. Mechanical balances should have sensitivity which causes

the pointer to be deflected 2 or 3 scale divisions per 1 mg when

9. Calibration of Pycnometer

carrying a load of 30 g or less on each pan.The balance should

be located in a room shielded from drafts and fumes and in 9.1 Proceeding as directed in Section 10, determine the

which the temperature changes between related weighings weight of freshly-boiled and cooled distilled water (distilled

(empty and filled pycnometer) do not cause a significant from alkaline permanganate through a tin condenser) held by

change in the ratio of the balance arms. Otherwise weighings the pycnometer when equilibrated to volume at the bath

D1217−93 (2007)

FIG. 2 Accessories for Bingham-Type Pycnometer

FIG. 3 Cleaner Assembly for Bingham-Type Pycnometer

NOTE 1—It is convenient to use the lightest of a set of pycnometers as

temperature to be used in the determination. Repeat until at

a tare. For best results the treatment and environment of both pycnometer

least three values agree to 60.2 mg.

and tare should be identical for some time prior to weighing.

10.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.