ASTM C1549-09(2014)

(Test Method)Standard Test Method for Determination of Solar Reflectance Near Ambient Temperature Using a Portable Solar Reflectometer

Standard Test Method for Determination of Solar Reflectance Near Ambient Temperature Using a Portable Solar Reflectometer

SIGNIFICANCE AND USE

5.1 The temperatures of opaque surfaces exposed to solar radiation are generally higher than the adjacent air temperatures. In the case of roofs or walls enclosing conditioned spaces, increased inward heat flows result. In the case of equipment or storage containers exposed to the sun, increased operating temperatures usually result. The extent to which solar radiation affects surface temperatures depends on the solar reflectance of the exposed surface. A solar reflectance of 1.0 (100 % reflected) would mean no effect on surface temperature while a solar reflectance of 0 (none reflected, all absorbed) would result in the maximum effect. Coatings of specific solar reflectance are used to change the temperature of surfaces exposed to sunlight. Coatings and surface finishes are commonly specified in terms of solar reflectance. The initial (clean) solar reflectance must be maintained during the life of the coating or finish to have the expected thermal performance.

5.2 The test method provides a means for periodic testing of surfaces in the field or in the laboratory. Monitor changes in solar reflectance due to aging and exposure, or both, with this test method.

5.3 This test method is used to measure the solar reflectance of a flat opaque surface. The precision of the average of several measurements is usually governed by the variability of reflectances on the surface being tested.

5.4 Use the solar reflectance that is determined by this method to calculate the solar energy absorbed by an opaque surface as shown in Eq 1.

5.4.1 Combine the absorbed solar energy with conductive, convective and other radiative terms to construct a heat balance around an element or calculate a Solar Reflectance Index such as that discussed in Practice E1980.

SCOPE

1.1 This test method covers a technique for determining the solar reflectance of flat opaque materials in a laboratory or in the field using a commercial portable solar reflectometer. The purpose of the test method is to provide solar reflectance data required to evaluate temperatures and heat flows across surfaces exposed to solar radiation.

1.2 This test method does not supplant Test Method E903 which measures solar reflectance over the wavelength range 250 to 2500 nm using integrating spheres. The portable solar reflectometer is calibrated using specimens of known solar reflectance to determine solar reflectance from measurements at four wavelengths in the solar spectrum: 380 nm, 500 nm, 650 nm, and 1220 nm. This technique is supported by comparison of reflectometer measurements with measurements obtained using Test Method E903. This test method is applicable to specimens of materials having both specular and diffuse optical properties. It is particularly suited to the measurement of the solar reflectance of opaque materials.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1549 −09(Reapproved 2014)

Standard Test Method for

Determination of Solar Reflectance Near Ambient

Temperature Using a Portable Solar Reflectometer

This standard is issued under the fixed designation C1549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers a technique for determining the

E903 Test Method for Solar Absorptance, Reflectance, and

solar reflectance of flat opaque materials in a laboratory or in

Transmittance of Materials Using Integrating Spheres

the field using a commercial portable solar reflectometer. The

E1980 Practice for Calculating Solar Reflectance Index of

purpose of the test method is to provide solar reflectance data

Horizontal and Low-Sloped Opaque Surfaces

required to evaluate temperatures and heat flows across sur-

2.2 Additional Reference:

faces exposed to solar radiation.

“Instructions for the Solar Spectrum Reflectometer Model

1.2 This test method does not supplant Test Method E903 3

SSR-ER,” Devices and Services Company

which measures solar reflectance over the wavelength range

250 to 2500 nm using integrating spheres. The portable solar

3. Terminology

reflectometer is calibrated using specimens of known solar

3.1 Definitions—For definitions of some terms used in the

reflectance to determine solar reflectance from measurements

test method, refer to Terminology C168.

at four wavelengths in the solar spectrum: 380 nm, 500 nm,

3.2 Definitions of Terms Specific to This Standard:

650 nm, and 1220 nm. This technique is supported by

3.2.1 air mass—airmassisrelatedtothepathlengthofsolar

comparison of reflectometer measurements with measurements

radiation through the Earth’s atmosphere to the site of interest.

obtained using Test Method E903. This test method is appli-

Air mass 1 is for a path of normal solar radiation at the Earth’s

cable to specimens of materials having both specular and

equator while air mass 2 indicates two times this path length.

diffuse optical properties. It is particularly suited to the

measurement of the solar reflectance of opaque materials.

3.2.2 solar reflectance—the fraction of incident solar radia-

tion upon a surface that is reflected from the surface.

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.3 Symbols:

standard.

A = area normal to incident radiation, m

Q = rate at which radiant heat is absorbed per m of

1.4 This standard does not purport to address all of the

abs

area, W

safety concerns, if any, associated with its use. It is the

q = solar flux, W/m

responsibility of the user of this standard to establish appro-

solar

r = solar reflectance, dimensionless

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents 4.1 This test method employs a diffuse tungsten halogen

2 lamp to illuminate a flat specimen for two seconds out of a

2.1 ASTM Standards:

ten-second measurement cycle. Reflected light is measured at

C168 Terminology Relating to Thermal Insulation

an angle of 20° from the incident angle with four detectors.

Each detector is equipped with color filters to tailor its

electrical response to a range of wavelengths in the solar

ThistestmethodisunderthejurisdictionofASTMCommitteeC16onThermal

spectrum. Software in the instrument combines the outputs of

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

thefourdetectorsinappropriateproportionstoapproximatethe

Measurement.

Current edition approved Sept. 1, 2014. Published November 2014. Originally

approved in 2002. Last previous edition approved in 2009 as C1549 – 09. DOI:

10.1520/C1549-09R14. The sole source of supply of the apparatus known to the committee at this time

For referenced ASTM standards, visit the ASTM website, www.astm.org, or isDevices&ServicesCompany,10024MonroeDrive,Dallas,TX75229.Ifyouare

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM aware of alternative suppliers, please provide this information to ASTM Interna-

Standards volume information, refer to the standard’s Document Summary page on tional Headquarters.Your comments will receive careful consideration at a meeting

the ASTM website. of the responsible technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1549−09 (2014)

response for incident solar radiation through air mass 0, 1, 1.5, 6.1.1 Measurement Head—The measurement head contains

or 2. The solar reflectance for the desired air mass is selectable atungstenhalogenlampusedastheradiationsource,thefilters

from the instrument’s keypad. The reflectances measured by used to tailor the reflected radiation to specific wavelength

the individual detectors are also available from the keypad and ranges, and detectors for each of the four wavelength ranges.A

digital readout.The instrument is calibrated using a black body 2.5 cm diameter circular opening on the top of the measure-

cavity for a reflectance of zero and one or more surfaces of mentheadservesasaportthroughwhichincidentandreflected

known solar reflectance provided by the manufacturer. A radiation are transmitted to and from the test surface.

surface to be evaluated is placed firmly against the 2.5 cm 6.1.2 Connecting Cable—A connecting cable, connects the

diameter opening on the measurement head and maintained in measurement head to the readout module. The connecting

thispositionuntilconstantreadingsaredisplayedbythedigital cable transmits electrical signals from the four detectors to the

readout. A comparison of techniques for measuring solar readout module.

reflectance is available. 6.1.3 Readout Module—The readout module that is con-

nected to the measurement head includes a keypad for control-

5. Significance and Use

ling the functions of the software, software for interpreting the

signals from the measurement head, and a digital readout for

5.1 The temperatures of opaque surfaces exposed to solar

solar reflectivity or the display of input parameters or calibra-

radiation are generally higher than the adjacent air tempera-

tion information. The resolution of the digital readout is 0.001.

tures. In the case of roofs or walls enclosing conditioned

Detailed instructions for use of the keypad to communicate

spaces, increased inward heat flows result. In the case of

with the software are provided by the manufacturer of the

equipment or storage containers exposed to the sun, increased

apparatus.

operating temperatures usually result. The extent to which

6.1.4 Reference Standards—The calibration of the solar

solar radiation affects surface temperatures depends on the

reflectometer is accomplished with a black body cavity that is

solar reflectance of the exposed surface. A solar reflectance of

supplied by the manufacturer and at least one high-reflectance

1.0 (100 % reflected) would mean no effect on surface tem-

standard. The solar reflectance of the high-reflectance standard

perature while a solar reflectance of 0 (none reflected, all

or standards are programmed into the software to facilitate

absorbed) would result in the maximum effect. Coatings of

calibration. The apparatus accommodates up to eight solar

specific solar reflectance are used to change the temperature of

reflectance standards.

surfaces exposed to sunlight. Coatings and surface finishes are

6.1.5 Test Specimens—Specimens to be tested for solar

commonly specified in terms of solar reflectance. The initial

reflectance shall be relatively flat and shall have a minimum

(clean) solar reflectance must be maintained during the life of

dimension greater than 2.5 cm in order for the specimen to

the coating or finish to have the expected thermal performance.

completely cover the measurement head opening. Test speci-

5.2 The test method provides a means for periodic testing of

mens of sufficient size are placed on top of the measurement

surfaces in the field or in the laboratory. Monitor changes in

head. Position the measurement head against a surface for

solar reflectance due to aging and exposure, or both, with this

in-situ or large area solar reflectance measurements.

test method.

5.3 This test method is used to measure the solar reflectance

7. Procedure

ofaflatopaquesurface.Theprecisionoftheaverageofseveral

7.1 Set-up—The instrument requires 110 volt AC power.

measurements is usually governed by the variability of reflec-

Take into account necessary safety precautions when using the

tances on the surface being tested.

instrument outside of conditioned spaces. Before power is

5.4 Use the solar reflectance that is determined by this

applied and the instrument is turned on, either end of the cable

method to calculate the solar energy absorbed by an opaque

must be connected to the socket on the measurement head.The

surface as shown in Eq 1.

other end must be connected to the socket on the readout and

control module. The instrument powers up, ready to estimate

Q 5 A·q ·~1 2 r! (1)

abs solar

the total solar reflectance through air mass 2.The instrument is

5.4.1 Combine the absorbed solar energy with conductive,

designed to provide solar reflectances for air mass values of 0,

convectiveandotherradiativetermstoconstructaheatbalance

1, 1.5, or 2.0. The instrument shall be calibrated after at least

around an element or calculate a Solar Reflectance Index such

30 min. of warm-up time to avoid drift from the calibration.

as that discussed in Practice E1980.

Leaving the instrument on for extended periods of time with a

cover over the measurement head opening does not cause

6. Apparatus

damage.

6.1 This test method applies to solar reflectance tests con-

7.2 Calibration (gain)—At the end of the warm-up period,

ducted with a portable reflectometer. The instrument consists

check and adjust the zero and gain. A zero reflectance black-

of three major parts.

body cavity and various high reflectance standard specimens

are provided to check zero and gain. If the blackbody cavity

covers the opening of the measurement head and a non-zero

Petrie, T. W., Desjarlais, A. O., Robertson, R. H., and Parker, D. S.,

reading is noted, then depress calibration/zero key. The instru-

“Comparison of Techniques for In Situ Nondamaging Measurement of Solar

ment detects the presence of the zero reflectance cavity and

Reflectances of Low-Slope Roof Membranes,” International Journal of

Thermophysics, Vol 22, No. 5 , 2001, pp. 1613-1628. resets the output reflectance to zero.

C1549−09 (2014)

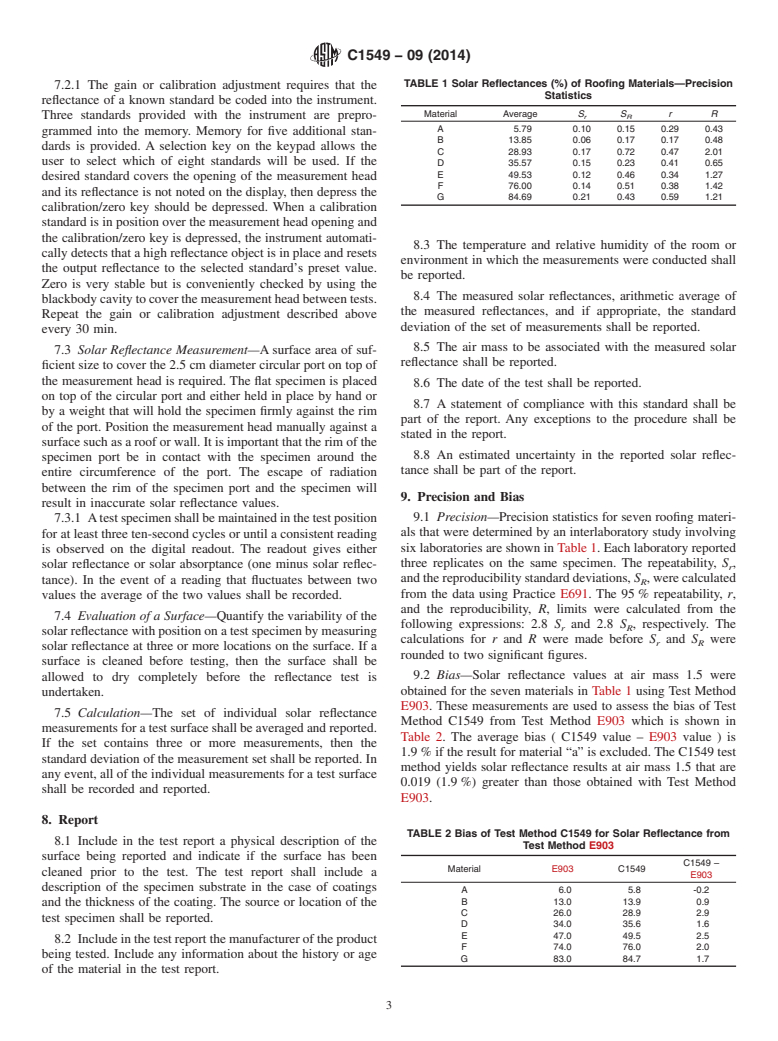

TABLE 1 Solar Reflectances (%) of Roofing Materials—Precision

7.2.1 The gain or calibration adjustment requires that the

Statistics

reflectance of a known standard be coded into the instrument.

Material Average S S rR

Three standards provided with the instrument are prepro- r R

A 5.79 0.10 0.15 0.29 0.43

grammed into the memory. Memory for five additional stan-

B 13.85 0.06 0.17 0.17 0.48

dards is provided. A selection key on the keypad allows the

C 28.93 0.17 0.72 0.47 2.01

user to select which of eight standards will be used. If the

D 35.57 0.15 0.23 0.41 0.65

E 49.53 0.12 0.46 0.34 1.27

desired standard covers the opening of the measurement head

F 76.00 0.14 0.51 0.38 1.42

and its reflectance is not noted on the display, then depress the

G 84.69 0.21 0.43 0.59 1.21

calibration/zero key should be depressed. When a calibration

standard is in position over the measurement head opening and

the calibration/zero key is depressed, the instrument automati-

8.3 The temperature and relative humidity of the room or

cally detects that a high reflectance object is in place and resets

environment in which the measurements were conducted shall

the output reflectance to the selected standard’s preset value.

be reported.

Zero is very stable but is conveniently checked by using the

8.4 The measured solar reflectances, arithmetic average of

blackbodycavitytocoverthemeasurementheadbetweentests.

the measured reflectances, and if appropriate, the standard

Repeat the gain or calibration adjustment described above

deviation of the set of measurements shall be reported.

every 30 min.

8.5 The air mass to be associated with the measured solar

7.3 Solar Reflectance Measurement—A surface area of suf-

reflectance shall be reported.

ficient size to cover the 2.5 cm diameter circular port on top of

the measurement head is required. The flat specimen is placed

8.6 The date of the test shall be reported.

on top of the circular port and either held in place by hand or

8.7 A statement of compliance with this standard shall be

by a weight that will hold the specimen firmly against the rim

part of the report. Any exceptions to the procedure shall be

of the port. Position the measurement head manually against a

stated in the report.

surface such as a roof or wall. It is important that the rim of the

8.8 An estimated uncertainty in the reported solar reflec-

specimen port be in contact with the specimen around the

tance shall be part of the report.

entire circumference of the port. The escape of radiation

between the rim of the specimen port and the specimen will

9. Precision and Bias

result in inaccurate solar reflectance values.

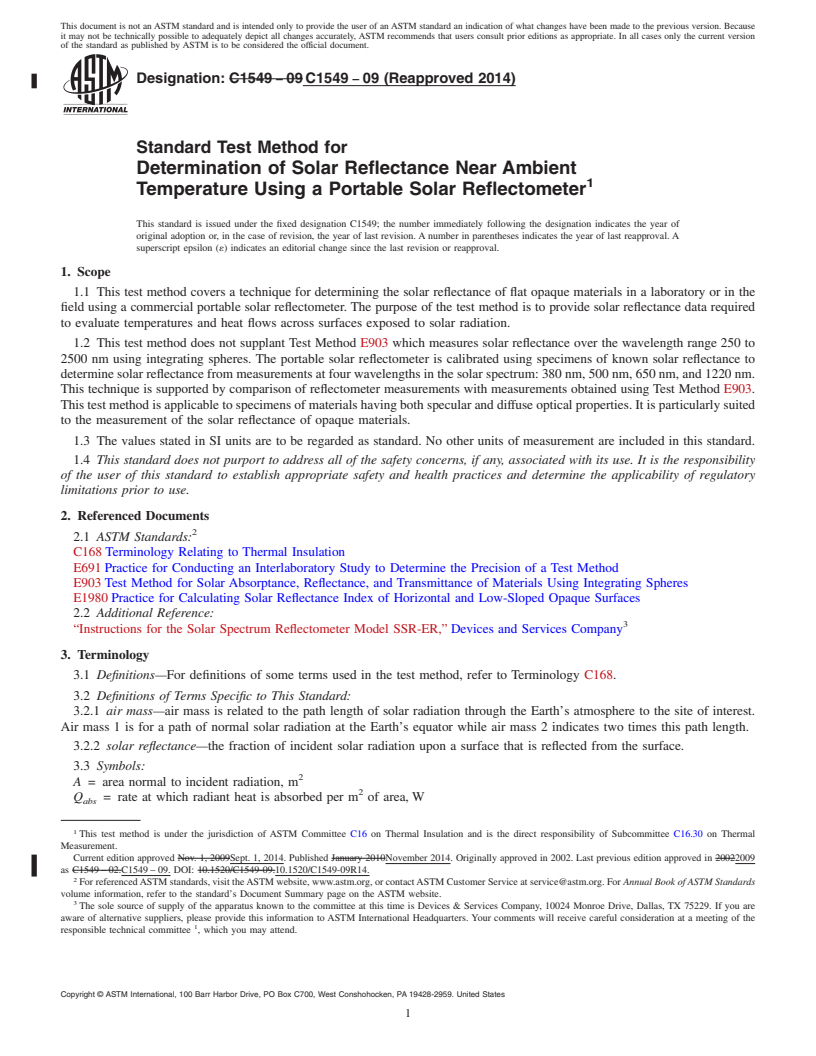

9.1 Precision—Precision statistics for seven roofing materi-

7.3.1 Atestspecimenshallbemaintainedinthetestposition

als that were determined by an interlaboratory study involving

for at least three ten-second cycles or until a consistent reading

six laboratories are shown in Table 1. Each laboratory reported

is observed on the digital readout. The readout gives either

three replicates on the same specimen. The repeatability, S ,

solar reflectance or solar absorptance (one minus solar reflec-

r

andthereproducibilitystandarddeviations, S ,werecalculated

tance). In the event of a reading that fluctuates between two

R

from the data using Practice E691. The 95 % repeatability, r,

values the average of the two values shall be recorded.

and the reproducibility, R, limits were calculated from the

7.4 Evaluation of a Surface—Quantify the variability of the

following expressions: 2.8 S and 2.8 S , respectively. The

r R

solarreflectancewithpositiononatestspecimenbymeasuring

calculations for r and R were made before S and S were

r R

solar reflectance at three or more locations on the surface. If a

rounded to two significant figures.

surface is cleaned before testing, then the surface shall be

9.2 Bias—Solar reflectance values a

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1549 − 09 C1549 − 09 (Reapproved 2014)

Standard Test Method for

Determination of Solar Reflectance Near Ambient

Temperature Using a Portable Solar Reflectometer

This standard is issued under the fixed designation C1549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a technique for determining the solar reflectance of flat opaque materials in a laboratory or in the

field using a commercial portable solar reflectometer. The purpose of the test method is to provide solar reflectance data required

to evaluate temperatures and heat flows across surfaces exposed to solar radiation.

1.2 This test method does not supplant Test Method E903 which measures solar reflectance over the wavelength range 250 to

2500 nm using integrating spheres. The portable solar reflectometer is calibrated using specimens of known solar reflectance to

determine solar reflectance from measurements at four wavelengths in the solar spectrum: 380 nm, 500 nm, 650 nm, and 1220 nm.

This technique is supported by comparison of reflectometer measurements with measurements obtained using Test Method E903.

This test method is applicable to specimens of materials having both specular and diffuse optical properties. It is particularly suited

to the measurement of the solar reflectance of opaque materials.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C168 Terminology Relating to Thermal Insulation

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E903 Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres

E1980 Practice for Calculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque Surfaces

2.2 Additional Reference:

“Instructions for the Solar Spectrum Reflectometer Model SSR-ER,” Devices and Services Company

3. Terminology

3.1 Definitions—For definitions of some terms used in the test method, refer to Terminology C168.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 air mass—air mass is related to the path length of solar radiation through the Earth’s atmosphere to the site of interest.

Air mass 1 is for a path of normal solar radiation at the Earth’s equator while air mass 2 indicates two times this path length.

3.2.2 solar reflectance—the fraction of incident solar radiation upon a surface that is reflected from the surface.

3.3 Symbols:

A = area normal to incident radiation, m

Q = rate at which radiant heat is absorbed per m of area, W

abs

This test method is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurement.

Current edition approved Nov. 1, 2009Sept. 1, 2014. Published January 2010November 2014. Originally approved in 2002. Last previous edition approved in 20022009

as C1549 – 02.C1549 – 09. DOI: 10.1520/C1549-09.10.1520/C1549-09R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The sole source of supply of the apparatus known to the committee at this time is Devices & Services Company, 10024 Monroe Drive, Dallas, TX 75229. If you are

aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1549 − 09 (2014)

q = solar flux, W/m

solar

r = solar reflectance, dimensionless

4. Summary of Test Method

4.1 This test method employs a diffuse tungsten halogen lamp to illuminate a flat specimen for two seconds out of a ten-second

measurement cycle. Reflected light is measured at an angle of 20° from the incident angle with four detectors. Each detector is

equipped with color filters to tailor its electrical response to a range of wavelengths in the solar spectrum. Software in the

instrument combines the outputs of the four detectors in appropriate proportions to approximate the response for incident solar

radiation through air mass 0, 1, 1.5, or 2. The solar reflectance for the desired air mass is selectable from the instrument’s keypad.

The reflectances measured by the individual detectors are also available from the keypad and digital readout. The instrument is

calibrated using a black body cavity for a reflectance of zero and one or more surfaces of known solar reflectance provided by the

manufacturer. A surface to be evaluated is placed firmly against the 2.5 cm diameter opening on the measurement head and

maintained in this position until constant readings are displayed by the digital readout. A comparison of techniques for measuring

solar reflectance is available.

5. Significance and Use

5.1 The temperatures of opaque surfaces exposed to solar radiation are generally higher than the adjacent air temperatures. In

the case of roofs or walls enclosing conditioned spaces, increased inward heat flows result. In the case of equipment or storage

containers exposed to the sun, increased operating temperatures usually result. The extent to which solar radiation affects surface

temperatures depends on the solar reflectance of the exposed surface. A solar reflectance of 1.0 (100 % reflected) would mean no

effect on surface temperature while a solar reflectance of 0 (none reflected, all absorbed) would result in the maximum effect.

Coatings of specific solar reflectance are used to change the temperature of surfaces exposed to sunlight. Coatings and surface

finishes are commonly specified in terms of solar reflectance. The initial (clean) solar reflectance must be maintained during the

life of the coating or finish to have the expected thermal performance.

5.2 The test method provides a means for periodic testing of surfaces in the field or in the laboratory. Monitor changes in solar

reflectance due to aging and exposure, or both, with this test method.

5.3 This test method is used to measure the solar reflectance of a flat opaque surface. The precision of the average of several

measurements is usually governed by the variability of reflectances on the surface being tested.

5.4 Use the solar reflectance that is determined by this method to calculate the solar energy absorbed by an opaque surface as

shown in Eq 1.

Q 5 A·q · 12 r (1)

~ !

abs solar

5.4.1 Combine the absorbed solar energy with conductive, convective and other radiative terms to construct a heat balance

around an element or calculate a Solar Reflectance Index such as that discussed in Practice E1980.

6. Apparatus

6.1 This test method applies to solar reflectance tests conducted with a portable reflectometer. The instrument consists of three

major parts.

6.1.1 Measurement Head—The measurement head contains a tungsten halogen lamp used as the radiation source, the filters used

to tailor the reflected radiation to specific wavelength ranges, and detectors for each of the four wavelength ranges. A 2.5 cm

diameter circular opening on the top of the measurement head serves as a port through which incident and reflected radiation are

transmitted to and from the test surface.

6.1.2 Connecting Cable—A connecting cable, connects the measurement head to the readout module. The connecting cable

transmits electrical signals from the four detectors to the readout module.

6.1.3 Readout Module—The readout module that is connected to the measurement head includes a keypad for controlling the

functions of the software, software for interpreting the signals from the measurement head, and a digital readout for solar

reflectivity or the display of input parameters or calibration information. The resolution of the digital readout is 0.001. Detailed

instructions for use of the keypad to communicate with the software are provided by the manufacturer of the apparatus.

6.1.4 Reference Standards—The calibration of the solar reflectometer is accomplished with a black body cavity that is supplied

by the manufacturer and at least one high-reflectance standard. The solar reflectance of the high-reflectance standard or standards

are programmed into the software to facilitate calibration. The apparatus accommodates up to eight solar reflectance standards.

6.1.5 Test Specimens—Specimens to be tested for solar reflectance shall be relatively flat and shall have a minimum dimension

greater than 2.5 cm in order for the specimen to completely cover the measurement head opening. Test specimens of sufficient size

are placed on top of the measurement head. Position the measurement head against a surface for in-situ or large area solar

reflectance measurements.

Petrie, T. W., Desjarlais, A. O., Robertson, R. H., and Parker, D. S., “Comparison of Techniques for In Situ Nondamaging Measurement of Solar Reflectances of

Low-Slope Roof Membranes,” International Journal of Thermophysics, Vol 22, No. 5 , 2001, pp. 1613-1628.

C1549 − 09 (2014)

7. Procedure

7.1 Set-up—The instrument requires 110 volt AC power. Take into account necessary safety precautions when using the

instrument outside of conditioned spaces. Before power is applied and the instrument is turned on, either end of the cable must

be connected to the socket on the measurement head. The other end must be connected to the socket on the readout and control

module. The instrument powers up, ready to estimate the total solar reflectance through air mass 2. The instrument is designed to

provide solar reflectances for air mass values of 0, 1, 1.5, or 2.0. The instrument shall be calibrated after at least 30 min. of warm-up

time to avoid drift from the calibration. Leaving the instrument on for extended periods of time with a cover over the measurement

head opening does not cause damage.

7.2 Calibration (gain)—At the end of the warm-up period, check and adjust the zero and gain. A zero reflectance blackbody

cavity and various high reflectance standard specimens are provided to check zero and gain. If the blackbody cavity covers the

opening of the measurement head and a non-zero reading is noted, then depress calibration/zero key. The instrument detects the

presence of the zero reflectance cavity and resets the output reflectance to zero.

7.2.1 The gain or calibration adjustment requires that the reflectance of a known standard be coded into the instrument. Three

standards provided with the instrument are preprogrammed into the memory. Memory for five additional standards is provided. A

selection key on the keypad allows the user to select which of eight standards will be used. If the desired standard covers the

opening of the measurement head and its reflectance is not noted on the display, then depress the calibration/zero key should be

depressed. When a calibration standard is in position over the measurement head opening and the calibration/zero key is depressed,

the instrument automatically detects that a high reflectance object is in place and resets the output reflectance to the selected

standard’s preset value. Zero is very stable but is conveniently checked by using the blackbody cavity to cover the measurement

head between tests. Repeat the gain or calibration adjustment described above every 30 min.

7.3 Solar Reflectance Measurement—A surface area of sufficient size to cover the 2.5 cm diameter circular port on top of the

measurement head is required. The flat specimen is placed on top of the circular port and either held in place by hand or by a weight

that will hold the specimen firmly against the rim of the port. Position the measurement head manually against a surface such as

a roof or wall. It is important that the rim of the specimen port be in contact with the specimen around the entire circumference

of the port. The escape of radiation between the rim of the specimen port and the specimen will result in inaccurate solar reflectance

values.

7.3.1 A test specimen shall be maintained in the test position for at least three ten-second cycles or until a consistent reading

is observed on the digital readout. The readout gives either solar reflectance or solar absorptance (one minus solar reflectance). In

the event of a reading that fluctuates between two values the average of the two values shall be recorded.

7.4 Evaluation of a Surface—Quantify the variability of the solar reflectance with position on a test specimen by measuring solar

reflectance at three or more locations on the surface. If a surface is cleaned before testing, then the surface shall be allowed to dry

completely before the reflectance test is undertaken.

7.5 Calculation—The set of individual solar reflectance measurements for a test surface shall be averaged and reported. If the

set contains three or more measurements, then the standard deviation of the measurement set shall be reported. In any event, all

of the individual measurements for a test surface shall be recorded and reported.

8. Report

8.1 Include in the test report a physical description of the surface being reported and indicate if the surface has been cleaned

prior to the test. The test report shall include a description of the specimen substrate in the case of coatings and the thickness of

the coating. The source or location of the test specimen shall be reported.

8.2 Include in the test report the manufacturer of the product being tested. Include any information about the history or age of

the material in the test report.

8.3 The temperature and relative humidity of the room or environment in which the measurements were conducted shall be

reported.

TABLE 1 Solar Reflectances (%) of Roofing Materials—Precision

Statistics

Material Average S S r R

r R

A 5.79 0.10 0.15 0.29 0.43

B

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.