ASTM F2432-12(2018)

(Specification)Standard Specification for Ice Making Machines, Icemaker-Dispensers, and Ice Dispensing Equipment

Standard Specification for Ice Making Machines, Icemaker-Dispensers, and Ice Dispensing Equipment

ABSTRACT

This specification covers the design, performance, and certification requirements pertinent to the construction of commercial automatic ice making machines used in manufacturing and processing ice, including the attached equipment used in storing and dispensing the produced ice for human consumption. This specification does not apply to icemakers of the tray type, ice vending machines, icemakers and icemaker kits used in household refrigerators or freezers, and block ice manufacturing plants. The ice machines covered here are classified into the following types, grades, classes, and styles: Type I—ice machine with or without ice storage bin; Type II—icemaker-dispenser machine; and Type III—ice dispenser; Grade 1—self-contained air-cooled condenser; Grade 2—self-contained water-cooled condenser; Grade 3—remote water-cooled; and Grade 4—remote air-cooled; Class A—cubed ice; Class B—flaked ice; Class C—nugget ice; and Class D—other ice shapes; Style 1—corrosion-resisting steel cabinet; Style 2—carbon steel cabinet; and Style 3—plastic cabinet. Representative production models of the ice making machines shall pass the performance and operational tests, and should function satisfactorily as specified.

SCOPE

1.1 This specification covers requirements for commercial automatic ice making equipment. It covers the equipment and devices used in manufacturing and processing ice for human consumption and the attached equipment used in storing and dispensing ice in connection with this equipment.

1.2 This specification does not apply to icemakers of the tray type, ice vending machines, or icemakers and icemaker kits used in household refrigerators or freezers. This specification is not intended to cover block ice manufacturing plants.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parenthesis are provided for information only.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2432 −12 (Reapproved 2018) An American National Standard

Standard Specification for

Ice Making Machines, Icemaker-Dispensers, and Ice

Dispensing Equipment

This standard is issued under the fixed designation F2432; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F760 Specification for Food Service Equipment Manuals

F1166 Practice for Human Engineering Design for Marine

1.1 This specification covers requirements for commercial

Systems, Equipment, and Facilities

automatic ice making equipment. It covers the equipment and

2.2 ANSI Standard:

devices used in manufacturing and processing ice for human

Z1.4 Sampling Procedures and Tables for Inspection by

consumption and the attached equipment used in storing and

Attributes

dispensing ice in connection with this equipment.

2.3 ANSI/UL Standards:

1.2 This specification does not apply to icemakers of the

No. 563 UL Standard For Ice Makers

tray type, ice vending machines, or icemakers and icemaker

No. 763 UL Standard for Operated Commercial Food Pre-

kits used in household refrigerators or freezers. This specifi-

paring Machines

cation is not intended to cover block ice manufacturing plants.

No. 969 UL Standard for Marking and Labeling Systems

1.3 The values stated in inch-pound units are to be regarded

2.4 ARI Standards:

asthestandard.TheSIvaluesgiveninparenthesisareprovided

Standard No. 810 Standard for Automatic Commercial Ice-

for information only.

makers

1.4 This international standard was developed in accor-

Standard No. 820 Standard for Ice Storage Bins

dance with internationally recognized principles on standard-

2.5 ASHRAE Standard:

ization established in the Decision on Principles for the

Standard No. 29 Methods of Rating and Testing Ice Makers

Development of International Standards, Guides and Recom-

2.6 NSF/ANSI Standards:

mendations issued by the World Trade Organization Technical

No. 12 Automatic Ice making Equipment

Barriers to Trade (TBT) Committee.

No. 18 Manual Food and Beverage Dispensing Equipment

2. Referenced Documents 9

2.7 Federal and Military Standards:

2.1 ASTM Standards: MIL-STD-1399/300 Interface Standard For Shipboard Sys-

A167 Specification for Stainless and Heat-Resisting tems Section 300A Electric Power, Alternating Current

Chromium-Nickel Steel Plate, Sheet, and Strip (With- MIL-STD-167/1 Mechanical Vibrations of Shipboard

drawn 2014) Equipment (Type I—Environmental and Type II—

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled, Internally Excited)

Carbon, Structural, High-Strength Low-Alloy, High- MIL-STD-461 RequirementsFortheControlofElectromag-

Strength Low-Alloy with Improved Formability, Solution netic Interference Characteristics of Subsystems and

Hardened, and Bake Hardenable Equipment

D3951 Practice for Commercial Packaging

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

This specification is under the jurisdiction of ASTM Committee F26 on Food 4th Floor, New York, NY 10036.

Service Equipment and is the direct responsibility of Subcommittee F26.03 on Available from Underwriters Laboratories (UL), Corporate Progress, 333

Storage and Dispensing Equipment. Pfingsten Rd., Northbrook, IL 60062.

Current edition approved Oct. 1, 2018. Published November 2018. Originally Available from Air-Conditioning & Refrigeration Institute (ARI) 4100 N.

approved in 2004. Last previous edition approved in 2012 as F2432 – 12. DOI: Fairfax Drive, Suite 200 Arlington, VA 22203.

10.1520/F2432-12R18. Available from American Society of Heating, Refrigerating, and Air-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 30329.

Standards volume information, refer to the standard’s Document Summary page on Available from NSF International, P.O. Box 130140, 789 N. Dixboro Rd.,Ann

the ASTM website. Arbor, MI 48113-0140.

3 9

The last approved version of this historical standard is referenced on Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

www.astm.org. Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2432 − 12 (2018)

3. Terminology

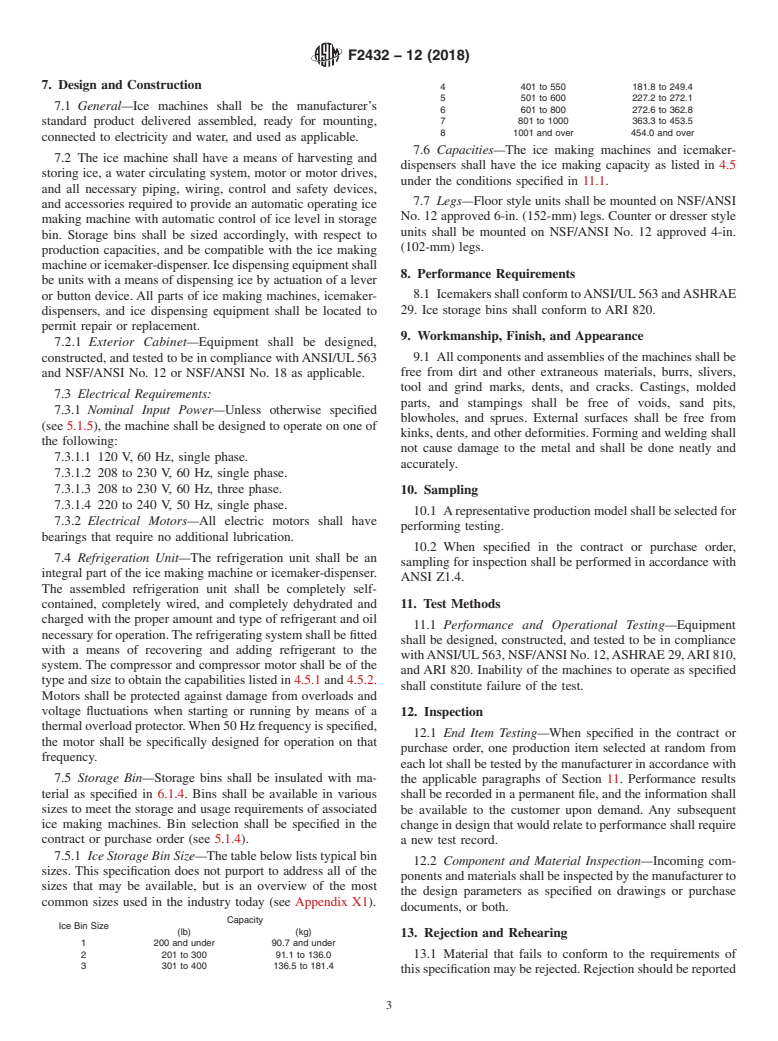

2 201 to 300 91.1 to 136.0

3 301 to 400 136.5 to 181.4

3.1 Definitions:

4 401 to 550 181.8 to 249.4

3.1.1 Capacity: 5 551 to 700 249.9 to 317.5

6 701 to 1000 317.9 to 453.5

3.1.1.1 ice maker—quantity of ice produced during a 24-h

7 1001 to 1200 454.0 to 544.3

period at standard rating conditions defined by ARI 810.

8 1201 to 2000 544.7 to 907.1

9 2001 and over 907.6 and over

3.1.1.2 ice storage bin—theoretical amount of ice, which

can be contained within an ice storage bin at standard rating

NOTE 1—This specification does not purport to address all of the sizes

conditions defined by ARI 820. that may be available, but is an overview of the most common sizes used

in the industry today (see Appendix X1).

3.1.2 harvest—function of removing or separating the

manufactured ice from the evaporator.

4.6 Style:

4.6.1 Style 1—Corrosion-resisting steel cabinet.

3.1.3 remote icemaker—icemaker intended to be connected

4.6.2 Style 2—Carbon steel cabinet.

to a field-installed condenser located remote from the ice-

4.6.3 Style 3—Plastic.

maker.

3.1.4 self-contained icemaker—unitary equipment consist-

5. Ordering Information

ing of a complete factory assembled and tested refrigerating

5.1 Ordering Data—Purchasers shall select the ice making

system in which all refrigerant-containing parts are perma-

machines, icemaker-dispensers, and ice dispensing equipment

nently connected at the factory.

and any preferred options and include the following informa-

3.1.5 unitary icemaker—equipment consisting of a com-

tion in the purchasing document:

plete factory assembled and tested refrigeration system com-

5.1.1 Title, number, and date of this specification,

prising one or more assemblies that may be shipped separately

5.1.2 Type,grade,class,size,andstyleofmachinerequired,

but are intended to be used together.

5.1.3 Quantity to be furnished,

5.1.4 Ice storage bin size,

4. Classification

5.1.5 Electrical power supply characteristics: voltage,

4.1 General—Icemachinescoveredbythisspecificationare

phase, frequency (see 7.3.1),

classified by types, grades, classes, sizes and styles.

5.1.6 Accessory equipment such as water/beverage dispens-

ing heads, spare parts, maintenance parts required, or other

4.2 Type:

options available by the manufacturer, or a combination

4.2.1 Type I—Ice machine with or without ice storage bin.

thereof,

4.2.2 Type II—Icemaker-dispenser machine.

5.1.7 When Federal/Military procurement is required, re-

4.2.3 Type III—Ice dispenser.

view and implement the applicable supplementary require-

4.3 Grade:

ments (see S1.1 through S8.8.3),

4.3.1 Grade 1—Air-cooled condenser (self-contained).

5.1.8 When specified, the purchaser shall be furnished

4.3.2 Grade 2—Water-cooled condenser (self-contained).

certificationthatsamplesrepresentingeachlothavebeeneither

4.3.3 Grade 3—Remote water-cooled.

tested or inspected as directed in this specification and the

4.3.4 Grade 4—Remote air-cooled.

requirements have been met.When specified, a copy of the test

4.4 Class:

results shall be furnished (see 14.1 through 14.3),

4.4.1 Class A—Cubed ice.

5.1.9 Level of preservation and packing required if other

4.4.2 Class B—Flaked ice.

than as stated in Practice D3951 (see 17.1), and

4.4.3 Class C—Nugget ice.

5.1.10 Labeling requirements (if different than 15.1).

4.4.4 Class D—Other ice shapes.

6. Materials and Manufacture

4.5 Size:

4.5.1 Cube Ice Makers: 6.1 General—Ice making machines, icemaker-dispensers,

and ice dispensing equipment shall conform to NSF/ANSI No.

Production Capacity

Ice Maker Size

(lb) (kg)

12. Materials used shall be new and free from defects, or

1 100 and under 45.3 and under

reclaimed and recycled conforming to the same quality stan-

2 101 to 150 45.8 to 68.0

dards for new materials.

3 151 to 200 68.5 to 90.7

4 201 to 250 91.1 to 113.4

6.1.1 Stainless Steel—Stainless steel shall conform to the

5 251 to 350 113.8 to 158.7

300 series of Specification A167 as applicable.

6 351 to 450 159.2 to 204.1

6.1.2 Carbon—Carbon steel sheet or strip shall conform to

7 451 to 550 204.5 to 249.8

8 551 to 650 249.9 to 294.8

Specification A1008/A1008M as applicable.

9 651 to 900 295.2 to 408.2

6.1.3 Ozone-Depleting Compounds—Type one ozone-

10 901 to 1250 408.6 to 566.9

depleting compounds shall not be used as a refrigerant or as a

11 1251 to 1500 567.4 to 680.3

12 1501 and over 680.8 and over

component of foam insulation and shall be the manufacturer’s

standard chemicals.

4.5.2 Flake Ice and Nugget Makers:

6.1.4 Insulation—Insulation used in construction shall be

Production Capacity

Ice Maker Size

(lb) (kg) fabricated to efficiency requirements in accordance with ARI

1 200 and under 90.7 and under

820.

F2432 − 12 (2018)

7. Design and Construction

4 401 to 550 181.8 to 249.4

5 501 to 600 227.2 to 272.1

7.1 General—Ice machines shall be the manufacturer’s

6 601 to 800 272.6 to 362.8

7 801 to 1000 363.3 to 453.5

standard product delivered assembled, ready for mounting,

8 1001 and over 454.0 and over

connected to electricity and water, and used as applicable.

7.6 Capacities—The ice making machines and icemaker-

7.2 The ice machine shall have a means of harvesting and

dispensers shall have the ice making capacity as listed in 4.5

storing ice, a water circulating system, motor or motor drives,

under the conditions specified in 11.1.

and all necessary piping, wiring, control and safety devices,

7.7 Legs—Floor style units shall be mounted on NSF/ANSI

and accessories required to provide an automatic operating ice

No. 12 approved 6-in. (152-mm) legs. Counter or dresser style

making machine with automatic control of ice level in storage

units shall be mounted on NSF/ANSI No. 12 approved 4-in.

bin. Storage bins shall be sized accordingly, with respect to

(102-mm) legs.

production capacities, and be compatible with the ice making

machineoricemaker-dispenser.Icedispensingequipmentshall

8. Performance Requirements

be units with a means of dispensing ice by actuation of a lever

8.1 IcemakersshallconformtoANSI/UL563andASHRAE

or button device. All parts of ice making machines, icemaker-

29. Ice storage bins shall conform to ARI 820.

dispensers, and ice dispensing equipment shall be located to

permit repair or replacement.

9. Workmanship, Finish, and Appearance

7.2.1 Exterior Cabinet—Equipment shall be designed,

9.1 All components and assemblies of the machines shall be

constructed, and tested to be in compliance withANSI/UL563

free from dirt and other extraneous materials, burrs, slivers,

and NSF/ANSI No. 12 or NSF/ANSI No. 18 as applicable.

tool and grind marks, dents, and cracks. Castings, molded

7.3 Electrical Requirements:

parts, and stampings shall be free of voids, sand pits,

7.3.1 Nominal Input Power—Unless otherwise specified

blowholes, and sprues. External surfaces shall be free from

(see 5.1.5), the machine shall be designed to operate on one of

kinks, dents, and other deformities. Forming and welding shall

the following:

not cause damage to the metal and shall be done neatly and

7.3.1.1 120 V, 60 Hz, single phase.

accurately.

7.3.1.2 208 to 230 V, 60 Hz, single phase.

7.3.1.3 208 to 230 V, 60 Hz, three phase.

10. Sampling

7.3.1.4 220 to 240 V, 50 Hz, single phase.

10.1 Arepresentativeproductionmodelshallbeselectedfor

7.3.2 Electrical Motors—All electric motors shall have

performing testing.

bearings that require no additional lubrication.

10.2 When specified in the contract or purchase order,

7.4 Refrigeration Unit—The refrigeration unit shall be an

sampling for inspection shall be performed in accordance with

integral part of the ice making machine or icemaker-dispenser.

ANSI Z1.4.

The assembled refrigeration unit shall be completely self-

contained, completely wired, and completely dehydrated and 11. Test Methods

charged with the proper amount and type of refrigerant and oil

11.1 Performance and Operational Testing—Equipment

necessaryforoperation.Therefrigeratingsystemshallbefitted

shall be designed, constructed, and tested to be in compliance

with a means of recovering and adding refrigerant to the

withANSI/UL563,NSF/ANSINo.12,ASHRAE29,ARI810,

system. The compressor and compressor motor shall be of the

and ARI 820. Inability of the machines to operate as specified

type and size to obtain the capabilities listed in 4.5.1 and 4.5.2.

shall constitute failure of the test.

Motors shall be protected against damage from overloads and

voltage fluctuations when starting or running by means of a

12. Inspection

thermaloverloadprotector.When50Hzfrequencyisspecified,

12.1 End Item Testing—When specified in the contract or

the motor shall be specifically designed for operation on that

purchase order, one production item selected at random from

frequency.

each lot shall be tested by the manufacturer in accordance with

7.5 Storage Bin—Storage bins shall be insulated with ma- the applicable paragraphs of Section 11. Performance results

terial as specified in 6.1.4. Bins shall be available in various

shall be recorded in a permanent file, and the information shall

sizes to meet the storage and usage requirements of associated be available to the customer upon demand. Any subsequent

ice making machines. Bin selection shall be specified in the

change in design that would relate to performance shall require

contract or purchase order (see 5.1.4). a new test record.

7.5.1 Ice Storage Bin Size—The table below lists typical bin

12.2 Component and Material Inspection—Incoming com-

sizes. This specification does not purport to address all of the

ponentsandmaterialsshallbeinspectedbythemanufacturerto

sizes that may be available, but is an overview of the most

the design parameters as specified on drawings or purchase

common sizes used in the industry today (see Appendix X1).

documents, or both.

Capacity

Ice Bin Size

(lb) (kg)

13. Rejection and Rehearing

1 200 and under 90.7 and under

2 201 to 300 91.1 to 136.0

13.1 Material that fails to conform to the requirements of

3 301 to 400 136.5 to 181.4

thisspecificationmayberejected.Rejectionshouldbereported

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.