ASTM C1113-99(2004)

(Test Method)Standard Test Method for Thermal Conductivity of Refractories by Hot Wire (Platinum Resistance Thermometer Technique)

Standard Test Method for Thermal Conductivity of Refractories by Hot Wire (Platinum Resistance Thermometer Technique)

SIGNIFICANCE AND USE

The k-values determined at one or more temperatures can be used for ranking products in relative order of their thermal conductivities.

Estimates of heat flow, interface temperatures, and cold face temperatures of single, and multi-component linings can be calculated using k-values obtained over a wide temperature range.

The k-values determined are “at temperature” measurements rather than “mean temperature” measurements. Thus, a wide range of temperatures can be measured, and the results are not averaged over the large thermal gradient inherent in water-cooled calorimeters.

The k-values measured are the combination of the k-values for the width and thickness of the sample, as the heat flow from the hot wire is in both of those directions. The water-cooled calorimeter measures k-value in one direction, through the sample thickness.

The test method used should be specified when reporting k-values, as the results obtained may vary with the type of test method that is used. Data obtained by the hot wire method are typically 10 to 30 % higher than data obtained by the water calorimeter method given in Test Method C 201.

SCOPE

1.1 This test method covers the determination of thermal conductivity of non-carbonacious, dielectric refractories.

1.2 Applicable refractories include refractory brick, refractory castables, plastic refractories, ramming mixes, powdered materials, granular materials, and refractory fibers.

1.3 Thermal conductivity k-values can be determined from room temperature to 1500°C (2732°F), or the maximum service limit of the refractory, or to the temperature at which the refractory is no longer dielectric.

1.4 This test method is applicable to refractories with k-values less than 15 W/mK (100 Btuin./hft 2F).

1.5 In general it is difficult to make accurate measurements of anisotropic materials, particularly those containing fibers, and the use of this test method for such materials should be agreed between the parties concerned.

1.6 The values stated in SI units are to be regarded as standard.

This standard does not purport to address the safety concerns, if any, associated with it's use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1113–99 (Reapproved 2004)

Standard Test Method for

Thermal Conductivity of Refractories by Hot Wire (Platinum

1

Resistance Thermometer Technique)

This standard is issued under the fixed designation C 1113; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 691 Practice for Conducting an Interlaboratory Test Pro-

gram to Determine the Precision of Test Methods

1.1 This test method covers the determination of thermal

2.2 ISO Standard:

conductivity of non-carbonacious, dielectric refractories.

DIS*8894-2 Refractory Materials - Determination of Ther-

1.2 Applicable refractories include refractory brick, refrac-

mal Conductivity up to 1250°C of Dense and Insulating

tory castables, plastic refractories, ramming mixes, powdered

Refractory Products According to the Hot Wire Parallel

materials, granular materials, and refractory fibers.

3

Method

1.3 Thermal conductivity k-values can be determined from

room temperature to 1500°C (2732°F), or the maximum

3. Terminology

service limit of the refractory, or to the temperature at which

3.1 Symbols:

the refractory is no longer dielectric.

3.1.1 R —hot wire resistance at any temperature, ohms.

T

1.4 This test method is applicable to refractories with

2

3.1.2 R —hot wire resistance at 0°C (32°F) (from an ice

0

k-values less than 15 W/m·K (100 Btu·in./h·ft ·°F).

bath), ohms.

1.5 In general it is difficult to make accurate measurements

3.1.3 L—hot wire length, cm.

of anisotropic materials, particularly those containing fibers,

3.1.4 T—sample test temperature, °C.

and the use of this test method for such materials should be

3.1.5 V—average voltage drop across hot wire, volts.

agreed between the parties concerned.

3.1.6 V —average voltage drop across standard resistor,

s

1.6 The values stated in SI units are to be regarded as

volts.

standard.

3.1.7 R —average resistance of standard resistor, ohms.

s

1.7 This standard does not purport to address the safety

3.1.8 I—average current through hot wire (V /R ), amperes.

s s

concerns, if any, associated with it’s use. It is the responsibility

3.1.9 Q—average power input to hot wire (I*V*100/L)

of the user of this standard to establish appropriate safety and

during test, watts/m.

health practices and determine the applicability of regulatory

3.1.10 t—time, min.

limitations prior to use.

3.1.11 B—slope of linear region in R vs. ln(t) plot.

T

2. Referenced Documents 3.1.12 k—thermal conductivity, W/m·K.

2 3.1.13 a, b, c—coefficients of a second degree polynomial

2.1 ASTM Standards:

equation relating hot wire resistance and temperature.

C 134 Test Methods for Size and Bulk Density of Refrac-

3.1.14 V, I, and Q are preferably measured in the linear

tory Brick and Insulating Firebrick

region of the R versus ln(t) plot for maximum data accuracy.

T

C 201 Test Methods for Thermal Conductivity of Refracto-

ries

4. Summary of Test Method

C 865 Practice for Firing Refractory Concrete Specimens

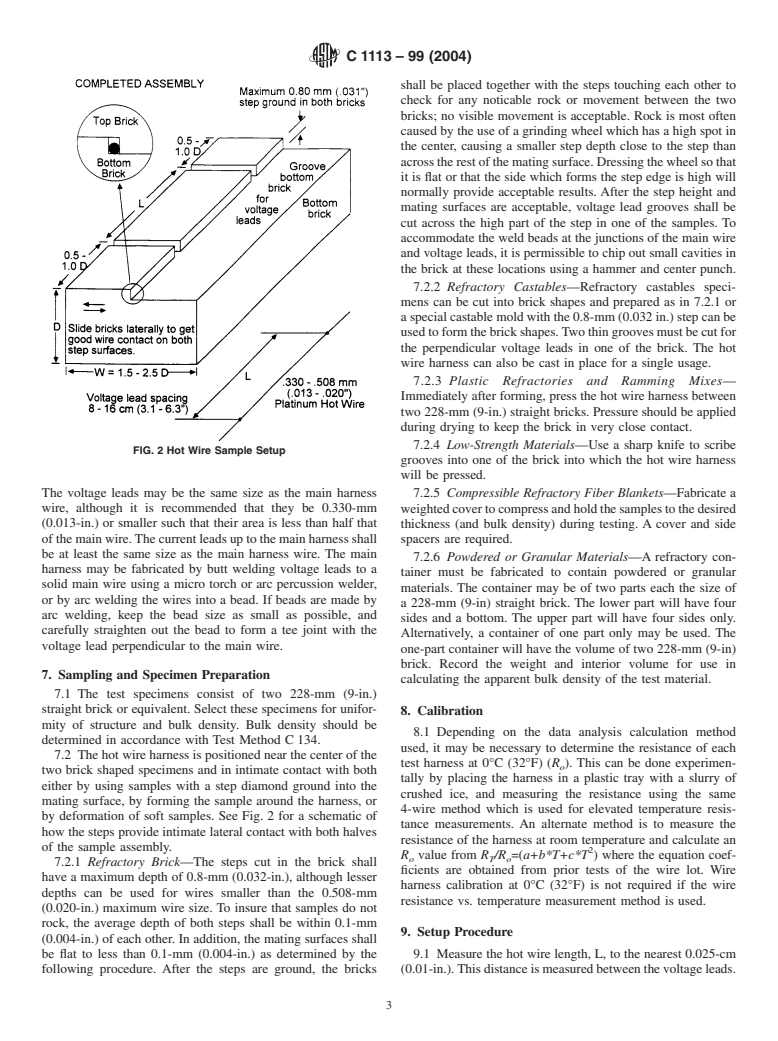

4.1 A constant electrical current is applied to a pure plati-

num wire placed between two brick.The rate at which the wire

heats is dependent upon how rapidly heat flows from the wire

1

This test method is under the jurisdiction of ASTM Committee C08 on

into the constant temperature mass of the refractory brick. The

Refractories and is the direct responsibility of Subcommittee C08.02 on Thermal

rate of temperature increase of the platinum wire is accurately

and Thermochemical Properties.

determined by measuring its increase in resistance in the same

Current edition approved Sept. 1, 2004. Published October 2004. Originally

approved in 1990. Last previous edition approved in 1999 as C 1113–99.

way a platinum resistance thermometer is used. A Fourier

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 11 W. 42nd St., 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1113–99 (2004)

equation is used to calculate the k-value based on the rate of 1°C (1.8°F) precision such that the temperature variation with

4

temperature increase of the wire and power input. time is minimized.Temperature stability measurements are not

required by this test method because small temperature varia-

5. Significance and Use

tions with time are difficult to m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.