ASTM D4304-06

(Specification)Standard Specification for Mineral Lubricating Oil Used in Steam or Gas Turbines

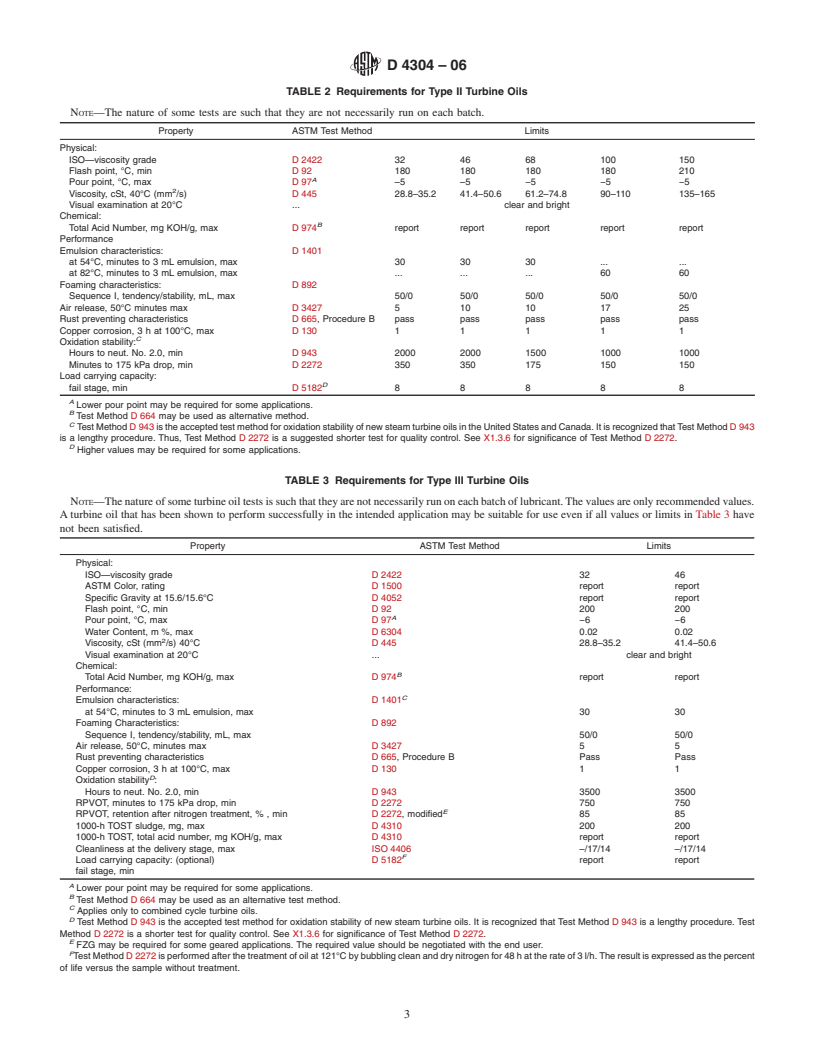

Standard Specification for Mineral Lubricating Oil Used in Steam or Gas Turbines

SCOPE

1.1 This specification covers mineral oils used in steam and gas turbine lubrication systems where the performance requirements demand a highly refined mineral base oil compounded with rust and oxidation inhibitors plus selected additives as needed to control foam, wear, demulsibility, and so forth. This standard may also be applied to "combined cycle" turbine systems, where a single lubricant circulating system is used to supply oil to a steam and gas turbine configured in tandem either on a single or separate shaft for enhanced energy efficiency.

1.2 This specification is intended to define the properties of mineral oil-based turbine lubricating oils that are functionally interchangeable with existing oils of this type, are compatible with most existing machinery components, and with appropriate field maintenance, will maintain their functional characteristics.

1.3 This specification is intended to define only new lubricating oil before it is installed in the machinery.

1.4 This specification is intended to be used as a guide. It is possible that oils that do not meet this specification may perform satisfactorily in some turbines.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4304 – 06

Standard Specification for

1

Mineral Lubricating Oil Used in Steam or Gas Turbines

This standard is issued under the fixed designation D 4304; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* by Potentiometric Titration

D 665 Test Method for Rust-Preventing Characteristics of

1.1 This specification covers mineral oils used in steam and

Inhibited Mineral Oil in the Presence of Water

gasturbinelubricationsystemswheretheperformancerequire-

D 892 Test Method for Foaming Characteristics of Lubri-

ments demand a highly refined mineral base oil compounded

cating Oils

with rust and oxidation inhibitors plus selected additives as

D 943 Test Method for Oxidation Characteristics of Inhib-

needed to control foam, wear, demulsibility, and so forth. This

ited Mineral Oils

standard may also be applied to “combined cycle” turbine

D 974 Test Method for Acid and Base Number by Color-

systems, where a single lubricant circulating system is used to

Indicator Titration

supply oil to a steam and gas turbine configured in tandem

D 1401 Test Method for Water Separability of Petroleum

either on a single or separate shaft for enhanced energy

Oils and Synthetic Fluids

efficiency.

D 1500 Test Method for ASTM Color of Petroleum Prod-

1.2 This specification is intended to define the properties of

ucts (ASTM Color Scale)

mineral oil-based turbine lubricating oils that are functionally

D 2272 Test Method for Oxidation Stability of Steam Tur-

interchangeable with existing oils of this type, are compatible

bine Oils by Rotating Pressure Vessel

with most existing machinery components, and with appropri-

D 2422 Classification of Industrial Fluid Lubricants by

ate field maintenance, will maintain their functional character-

Viscosity System

istics.

D 3339 Test Method for Acid Number of Petroleum Prod-

1.3 This specification is intended to define only new lubri-

ucts by Semi-Micro Color Indicator Titration

cating oil before it is installed in the machinery.

D 3427 Test Method for Air Release Properties of Petro-

1.4 This specification is intended to be used as a guide. It is

leum Oils

possible that oils that do not meet this specification may

D 4052 Test Method for Density and Relative Density of

perform satisfactorily in some turbines.

Liquids by Digital Density Meter

2. Referenced Documents

D 4057 Practice for Manual Sampling of Petroleum and

2

Petroleum Products

2.1 ASTM Standards:

D 4310 Test Method for Determination of the Sludging and

D92 Test Method for Flash and Fire Points by Cleveland

Corrosion Tendencies of Inhibited Mineral Oils

Open Cup Tester

D 5182 Test Method for Evaluating the Scuffing Load

D97 Test Method for Pour Point of Petroleum Products

Capacity of Oils (FZG Visual Method)

D 130 Test Method for Corrosiveness to Copper from

D 6304 Test Method for Determination of Water in Petro-

Petroleum Products by Copper Strip Test

leum Products, Lubricating Oils, and Additives by Coulo-

D 445 Test Method for Kinematic Viscosity of Transparent

metric Karl Fischer Titration

and Opaque Liquids (and the Calculation of Dynamic

2.2 ISO Standards:

Viscosity)

ISO 4406 Particle Count Analysis

D 664 Test Method forAcid Number of Petroleum Products

3. Terminology

3.1 Definitions:

1

This specification is under the jurisdiction of ASTM Committee D02 on

3.1.1 Type I mineral oils, n—oils for steam and gas turbine

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

lubricating systems where the machinery does not require

D02.C0 on Turbine Oils.

lubricants with enhanced load carrying capacity.

Current edition approved May 1, 2006. Published May 2006. Originally

approved in 1984. Last previous edition approved in 2000 as D 4304–00.

3.1.1.1 Discussion—Type I oils usually are available in ISO

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

VG 32, 46, 68 and 100 (see Classification D 2422). Such oils

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

normally contain rust and oxidation inhibitors in addition to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4304–06

other additives as required to meet the specified performance selection of oils that contain additional anti-wear additives to

characteristic. Type I oils are generally s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.