ASTM D4618-92(2010)

(Specification)Standard Specification for Design and Fabrication of Flue Gas Desulfurization System Components for Protective Lining Application

Standard Specification for Design and Fabrication of Flue Gas Desulfurization System Components for Protective Lining Application

ABSTRACT

This specification covers the design and fabrication of metal components for flue gas desulfurization equipment, including absorber, tanks, chimney liners, ductwork, and associated equipment intended for use in protective lining applications, that are to be lined for corrosion or abrasion resistance, or both. It does not however cover the structural performance of the components and the use of metallic linings. Each of the components shall be designed in such a way that it conforms to the engineering requirements for rigidity wherein the effects of pressure, wind, seismic, and other design loads shall be considered; accessability to welding, grinding, surface preparation, and lining application; shell penetrations; appurtenances inside components such as agitators, anti-swirl baffles, gaging devices, internal piping, ladders, and support brackets; and structural reinforcement members and supports. All internal welds shall be continuous without imperfections and the degree of weld preparation prior to lining shall depend on the type of lining to be applied. Riveted joints and internal bolted joints shall not be used while lap bolted joints shall be avoided whenever possible. Intermittent or spot welding shall not be permitted as well.

SCOPE

1.1 This specification covers the design and fabrication of metal components for Flue Gas Desulfurization (FGD) equipment, including absorbers, tanks, chimney liners, ductwork and associated equipment that are to be lined for corrosion or abrasion resistance, or both.

1.2 Limitations:

1.2.1 This specification is intended only to define the design considerations for successful application and performance of protective linings for FGD system components.

1.2.2 It does not cover structural performance of FGD components.

1.2.3 It does not cover use of metallic linings.

1.3 This specification represents the minimum requirements for lining work. In cases where the manufacturer's instructions and recommendations differ from this specification, these differences must be resolved before fabrication is started.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4618 – 92 (Reapproved 2010)

Standard Specification for

Design and Fabrication of Flue Gas Desulfurization System

Components for Protective Lining Application

This standard is issued under the fixed designation D4618; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.2 The weight of the lining system shall be considered in

the structural design of the component.

1.1 This specification covers the design and fabrication of

2.1.3 Thedesignshallconsidertheeffectsofpressure,wind,

metal components for Flue Gas Desulfurization (FGD) equip-

seismic and other design loads.

ment,includingabsorbers,tanks,chimneyliners,ductworkand

2.1.4 Vibration may cause flexing or high surface strains on

associated equipment that are to be lined for corrosion or

the lining. This is of particular concern to rigid lining materials

abrasion resistance, or both.

and shall be minimized.

1.2 Limitations:

2.1.5 Special consideration shall be given to all conditions

1.2.1 This specification is intended only to define the design

of potentially excessive strain such as unsupported bottom

considerations for successful application and performance of

areas, oil-canning, out of roundness, sidewall-to-bottom joints,

protective linings for FGD system components.

etc.

1.2.2 It does not cover structural performance of FGD

2.1.5.1 Where a component is on a concrete foundation,

components.

grouting shall be done if necessary to correct unsupported

1.2.3 It does not cover use of metallic linings.

bottom areas.

1.3 This specification represents the minimum requirements

2.1.5.2 Sand fill shall not be used for bottom support unless

for lining work. In cases where the manufacturer’s instructions

provisions are made to ensure that the sand cannot be lost due

and recommendations differ from this specification, these

to erosion.

differences must be resolved before fabrication is started.

2.2 Accessibility:

1.4 The values stated in inch-pound units are to be regarded

2.2.1 All interior surfaces of the components shall be

as standard. The values given in parentheses are mathematical

designed to be readily accessible for welding, grinding, surface

conversions to SI units that are provided for information only

preparation, and lining application.

and are not considered standard.

2.2.2 The minimum manway size for a working entrance

1.5 This standard does not purport to address all of the

during lining application shall be 36 in. (900 mm) in diameter

safety concerns, if any, associated with its use. It is the

or 24 in. (600 mm) width by 36 in. (900 mm) height.

responsibility of the user of this standard to establish appro-

2.2.2.1 Closed components shall have a minimum of two

priate safety and health practices and determine the applica-

manways, one near the top and one near the bottom, preferably

bility of regulatory limitations prior to use.

located 180° apart to facilitate adequate ventilation for work-

2. Design/Engineering Requirements

ers.

2.2.2.2 Additional or larger openings may be required to

2.1 Rigidity:

facilitate ventilation and material handling. The lining material

2.1.1 The components shall be designed so that the interior

applicator should be consulted for specific requirements.

metal surfaces are sufficiently rigid for the intended lining

2.3 Shell Penetrations:

materials. Manufacturer’s recommendations for maximum

2.3.1 Openings such as, inlets, manholes, and outlet nozzles

strains or deflection limits for the lining material shall be

shall be flush with the interior wall.

followed.

2.3.1.1 Inlet nozzles may extend into vessels if incoming

fluids will be detrimental to lining materials.

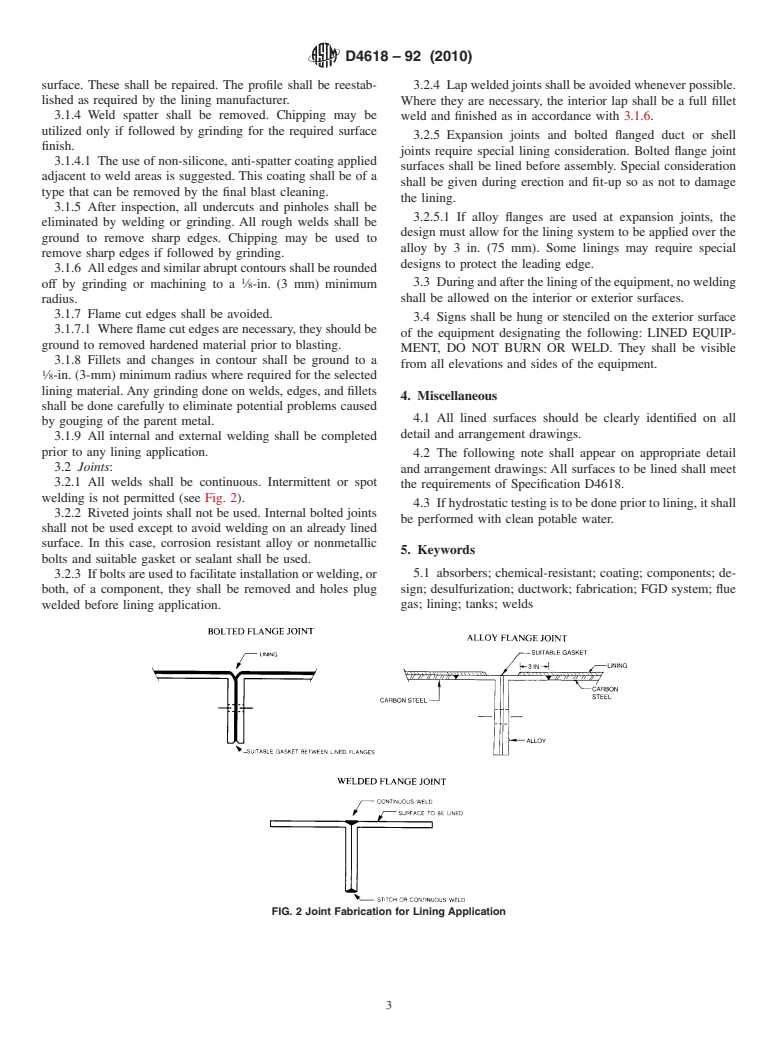

2.3.2 Any exterior or interior connection shall be flanged in

This specification is under the jurisdiction of ASTM Committee D33 on

ProtectiveCoatingandLiningWorkforPowerGenerationFacilitiesandisthedirect

order to facilitate lining.

responsibility of Subcommittee D33.09 on Protective Lining for FGD Systems.

2.3.3 The maximum length of flanged nozzles, 4 in. (100

Current edition approved July 1, 2010. Published July 2010. Originally approved

mm) and greater in diameter, shall not exceed the dimensions

in 1987. Last previous edition approved in 2003 as D4618 – 92 (2003). DOI:

10.1520/D4618-92R10. in Table 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4618 – 92 (2010)

TABLE 1 Maximum Length of Nozzles

operation and possible curing procedures and so that corrosion,

Maximum Nozzle Length— due to localized lining failures, can be observed early.

Nominal Nozzle Size,

Shell to Face of Flange,

in. (mm)

in. (mm)

3. Fabrication

4 (100) 8 (200)

3.1 Welds:

6 (150) 12 (300)

3.1.1 All internal welds to be lined shall be continuous

8–24 (200–600) 16 (400)

26–36 (600–900) 24 (600)

without imperfections such as weld slag, weld spatter, rough

Over 36 (900) any length

surfaces, undercutting, high peaks, porosity, sharp corners,

sharp edges and inadequate thickness shall be corrected (see

Fig. 1).

3.1.2 The degree of weld preparation prior to lining depends

2.3.3.1 Only 4 in. (100 mm) diameter and larger nozzles

on the type of lining to be applied. The lining manufacturer

shall be used for maximum reliability of the lining system.

must be consulted for specific requirements for weld prepara-

2.3.3.2 As an alternative to lined nozzles, compatible pre-

tion during the design of the component and prior to start of

fabricated, reinforced plastic, ceramic or alloy metal inserts

fabrication.

(sleeves) may be used if they offer superior corrosion and

3.1.3 Use of weld display samples before and after grinding

abrasion protection. Lining shall overlap onto prefabricated

may be of help to the component fabricator in supplying

liners.

acceptable welds with a minimum required rework. All welds

2.3.3.3 If an insert is used as an alternate, the lining shall

shall be inspected, corrected, and reinspected prior to blast

overlap unto the insert or some other means of ensuring an

cleaning. Whenever possible, shop welds shall be inspected

adequate seal should be provided.

and imperfections corrected in the fabricator’s shop.

2.3.4 Lining thickness may dictate changes in nozzle di-

3.1.3.1 All weld areas shall be inspected before and after

mensions to achieve design flow rates.

blast cleaning. Pinholes, pits, blind holes, porosity, undercut-

2.4 Appurtenances Inside Components:

ting or similar depressions are not permissible in the finished

2.4.1 The requirements in Sections 2 and 3 apply to any

appurtenances that are being lined and installed inside a li

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.