ASTM F2160-01

(Specification)Standard Specification for Solid Wall High Density Polyethylene (HDPE) Conduit Based on Controlled Outside Diameter (OD)

Standard Specification for Solid Wall High Density Polyethylene (HDPE) Conduit Based on Controlled Outside Diameter (OD)

SCOPE

1.1 This specification covers material, dimensional, workmanship and performance requirements for polyethylene conduit, duct and innerduct manufactured for use in a non- pressure application with communication, CATV, or power wire and cables.

1.2 HDPE conduit meeting the requirements of this standard shall be made as OD controlled solid wall, with or without internal or external ribs. The sizing shall be Iron Pipe Size (IPS) with noted exceptions in tables. The internal or external surface may contain a coextruded layer provided the finished conduit meets the product requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 2160 – 01

Standard Specification for

Solid Wall High Density Polyethylene (HDPE) Conduit Based

on Controlled Outside Diameter (OD)

This standard is issued under the fixed designation F 2160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 1505 Test Method for Density of Plastics by the Density-

Gradient Technique

1.1 This specification covers material, dimensional, work-

D 1600 Terminology for Abbreviated Terms Relating to

manship and performance requirements for polyethylene con-

Plastics

duit, duct and innerduct manufactured for use in a non-

D 1693 Test Method for Environmental Stress-Cracking of

pressure application with communication, CATV, or power

Ethylene Plastics

wire and cables.

D 2122 Test Method for Determining Dimensions of Ther-

1.2 HDPEconduitmeetingtherequirementsofthisstandard

moplastic Pipe and Fittings

shall be made as OD controlled solid wall, with or without

D 2444 Test Method for Impact Resistance of Thermoplas-

internal or external ribs. The sizing shall be Iron Pipe Size

tic Pipe and Fittings by Means of a Tup (Falling Weight)

(IPS) with noted exceptions in tables. The internal or external

D 2837 Test Method for Obtaining Hydrostatic Design

surface may contain a coextruded layer provided the finished

Basis for Thermoplastic Pipe Materials

conduit meets the product requirements of this specification.

D 3350 Specification for Polyethylene Plastics Pipe and

1.3 The values stated in inch-pound units are to be regarded

Fittings Materials

as the standard. The values given in parentheses are provided

D 3485 Specification for Smooth-Wall Coilable Polyethyl-

for information purposes only.

ene (PE) Conduit (Duct) for Preassembled Wire and

1.4 The following precautionary caveat pertains only to the

Cable

test method portion, Section 6, of this specification. This

D 4883 Test Method for Density of Polyethylene by the

standard does not purport to address all of the safety concerns,

Ultrasound Technique

if any, associated with its use. It is the responsibility of the user

F 412 Terminology Relating to Plastic Piping Systems

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory require-

3. Terminology

ments prior to use.

3.1 Definitions—General terms used in this Specification

2. Referenced Documents are as defined in Terminology F 412, and abbreviations are in

accordance with Terminology D 1600, unless otherwise speci-

2.1 ASTM Standards:

fied.

D 618 Practice for Conditioning Plastics and Electrical

3.2 Definitions of Terms Specific to This Standard:

Insulating Materials for Testing

2 3.2.1 CATV, n—cable television.

D 638 Test Method for Tensile Properties of Plastics

3.2.2 conduit (duct), n—a tubular raceway for carrying

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

power, communications, or other wires and cables

and Reinforced Plastics and Electrical Insulating Materi-

3.2.3 innerduct, n—a conduit installed inside a conduit.

als

3.2.4 kink, n—a crease across the conduit where it has

D 792 TestMethodsforDensityandSpecificGravity(Rela-

folded from excessive bending.

tive Density) of Plastics by Displacement

3.2.5 ribs, n—a series of ridges along the inside or outside

D 1238 Test Method for Flow Rates of Thermoplastics by

surface of a conduit.

Extrusion Plastometer

3.2.6 true size, n—denotes the use of a sizing system that

requires a nominal inside diameter to be the equal or greater

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin Annual Book of ASTM Standards, Vol 08.04

Based Pipe. Annual Book of ASTM Standards, Vol 08.02

Current edition approved Dec. 10, 2001. Published February 2002. Annual Book of ASTM Standards, Vol 10.02

2 6

Annual Book of ASTM Standards, Vol 08.01 Annual Book of ASTM Standards, Vol 08.03

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2160–01

than the stated nominal size of the conduit (that is, a 1 ⁄4 in. 4.4.2 Colored Conduit—PE material for colored conduit in

conduit has a minimum ID of 1.25 in.). non-UV exposed applications shall be suitably protected

against UV degradation so that conduit may be stored outside

4. Materials

and uncovered for a period of not less than one year.

4.1 Polyethylene Plastics—The PE materials used to make

5. Requirements

conduit under this Specification shall meet or exceed the

following requirements: 5.1 Workmanship—Each layer of the conduit shall be ho-

mogeneous throughout and essentially uniform in color, opac-

4.1.1 Compound—PE resin compounds shall be classified

in accordance with Specification D 3350 and Table 1. ity, density and other properties. The inside and outside

surfaces shall be free of visible cracks, holes, blisters, voids,

4.1.2 Rework Material—Clean polyethylene compound

from the manufacturers own production may be re-extruded foreign inclusions, or other deleterious defects.

5.2 Dimensions and Tolerances:

into conduit, either alone or blended with virgin compound.

Conduit containing the rework material shall meet all the 5.2.1 Outside Diameters—The outside diameters and toler-

ances shall be as shown in Table 2 for IPS sizes, Table 3 for

material and product requirements of this specification.

Schedules 40 and 80 and Table 4 for “true” sizing, when

4.1.3 Material Physical Properties:

4.1.3.1 Density—Density values shall be determined by measured in accordance with Test Method D 2122.

5.2.2 Wall Thickness—The wall thicknesses and tolerances

Test Methods D 792, D 1505, or D 4883.

4.1.3.2 Melt Index—A melt index of up to 0.55 grams/10 shall be as shown in Tables 5-7 for IPS sizes, Table 8 for

Schedule 40,Table 9 for Schedule 80, andTables 10 and 11 for

minutes as per Test Method D 1238 Condition 190/2.16 is

allowable provided that all other material requirements speci- “True-sized” PE conduit when measured in accordance with

Test Method D 2122.

fied in Table 1 are met.

4.1.3.3 Slow Crack Growth—An ESCR as per Test Method 5.2.3 Special Sizes—When mutually agreeable between the

manufacturer and the purchaser, other sizes and wall thick-

D 1693, condition B, 10 % Igepal requirement of F10 > 96 h is

allowable provided that all other material requirements in nesses shall be acceptable. The tolerance on outside diameter

shall be 6 0.5 percent of the nominal outside diameter. The

Table 1 are met.

4.2 Coextruded Layer—Any material used as a coextruded lowest permissible wall thickness for any conduit outside

diameter shall be 0.062 in. (1.57 mm). For wall thicknesses not

layer on the inside or outside surface of the PE conduit shall

adhere to the surface of the PE and shall not delaminate in listed, the tolerances shall be the same percentage of the

calculated minimum wall thickness as the closest listed mini-

normal use. It shall not degrade or lower the performance of

the PE conduit. mum wall thickness.

5.2.4 Ribbed Conduit—Conduit shall be permitted to con-

4.3 Aerial Applications—PE material for black conduit in

long-term above ground applications, such as aerial suspen- tain either (a) spiral or oscillating spiral HDPE ribs inside of

the conduit or (b) longitudinal ribs on the inside and/or outside

sion, shall be stabilized with a minimum of 2 % by weight

carbon black having an average particle size less than or equal of the conduit. The inside diameter of the conduit relative to

to 20 nanometers. this specification shall be measured between the ribs. For

internally ribbed conduit, the manufacturer shall provide the

4.4 Outdoor Storage Stability:

4.4.1 Black Conduit—PE material for black conduit in maximum inside diameter and tolerance that can be circum-

scribed within the internal rib projections. For externally

non-UV exposed applications shall be stabilized with a mini-

mum of 2 % by weight carbon black in accordance with ribbed conduit, the manufacturer shall provide the minimum

outside diameter and tolerance that circumscribes the external

Specification D 3350.

rib projections.

NOTE 1—Acceptable cell for Color and UV resistance properties in

5.2.5 Friction Reduction—Internal lubrication or a coex-

Table 1 may be achieved by utilizing a precompounded material or by

truded layer on the inner wall of conduit for reducing frictional

blending a base natural material with a color concentrate.

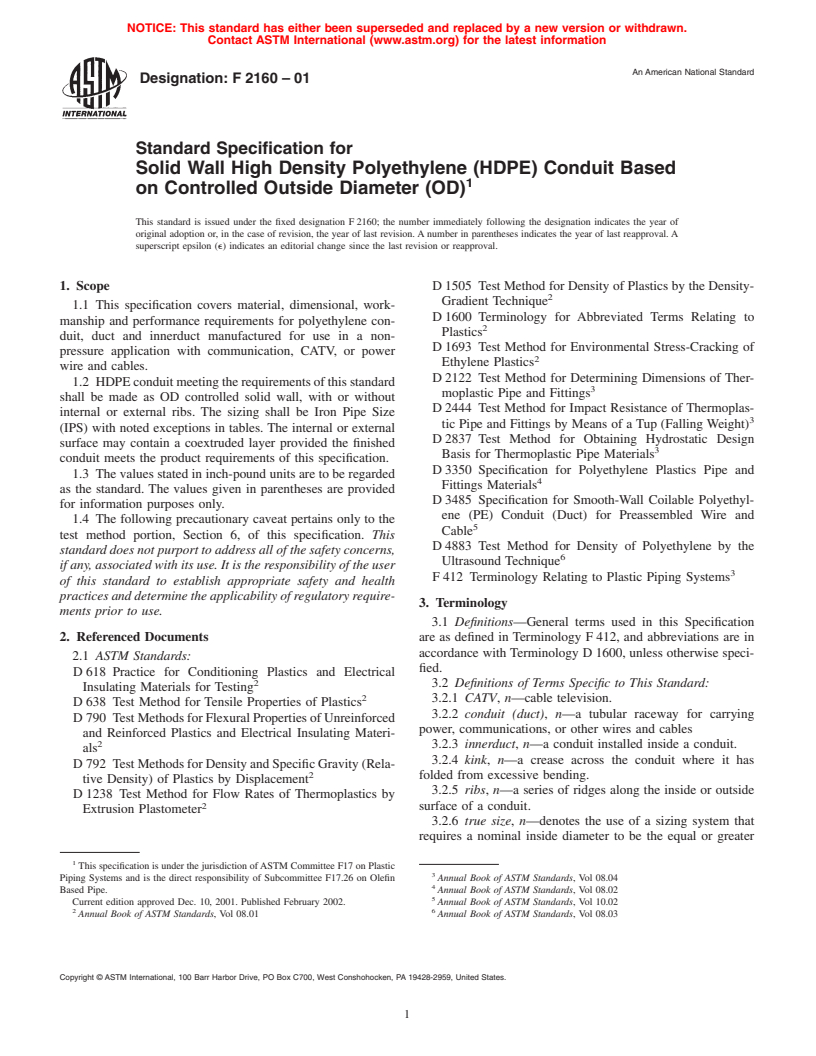

TABLE 2 Outside Diameter and Tolerance for PE Conduit, IPS

TABLE 1 D 3350 Cell Classification Material Requirement for PE

Outside Diameter Tolerance

Conduit

Nominal

Size, in.

in. (mm) in. (mm)

ASTM

Properties Acceptable Cell

Test Method

⁄2 0.840 (21.34) 6 0.004 (6 0.11)

Density D 1505, D 792, 3 ⁄4 1.050 (26.67) 6 0.005 (6 0.13)

1 1.315 (33.40) 6 0.007 (6 0.17)

or D 4883

Melt index (190/2.16) D 1238 3 or 4 or 2 in accordance 1 ⁄4 1.660 (42.16) 6 0.008 (6 0.21)

1 ⁄2 1.900 (48.26) 6 0.010 (6 0.24)

with 4.1.3.2

Flexural modulus D 790 4 or 5 2 2.375 (60.33) 6 0.012 (6 0.30)

2 ⁄2 2.875 (73.03) 6 0.014 (6 0.37)

Tensile strength D 638 4 or 5

Slow crack growth resistance D 1693 3 or 4 or 7 in accordance 3 3.500 (88.90) 6 0.018 (6 0.44)

with 4.1.3.3 4 4.500 (114.30) 6 0.023 (6 0.57)

Hydrostatic design basis D 2837 0, 1, 2, 3, or 4 5 5.563 (141.30) 6 0.028 (6 0.71)

Color and UV resistance D 3350 C in accordance 6 6.625 (168.28) 6 0.033 (6 0.84)

with 4.3 or 4.4.1, 8 8.625 (219.08) 6 0.043 (6 1.10)

or E in accordance 10 10.750 (273.05) 6 0.054 (6 1.37)

with 4.4.2 12 12.750 (323.85) 6 0.064 (6 1.62)

F2160–01

TABLE 3 Outside Diameter and Tolerance for PE Conduit, TABLE 6 Minimum Wall Thickness and Tolerance for DR 11 PE

Schedule 40 and 80 Conduit, IPS

Outside Diameter Tolerance Minimum Wall

Nominal

Tolerance

Nominal Dimension

Thickness

Size, in.

in. (mm) in. (mm)

Size, in. Ratio (DR)

in. (mm) in. (mm)

⁄2 0.840 (21.34) 6 0.004 (6 0.11)

3 1

⁄4 1.050 (26.67) 6 0.005 (6 0.13) ⁄2 11 0.076 (1.93) +0.020 (+0.51)

⁄4 11 0.095 (2.41) +0.020 (+0.51)

1 1.315 (33.40) 6 0.007 (6 0.17)

1 ⁄4 1.660 (42.16) 6 0.008 (6 0.21) 1 11 0.120 (3.05) +0.020 (+0.51)

1 1

1 ⁄2 1.900 (48.26) 6 0.010 (6 0.24) 1 ⁄4 11 0.151 (3.84) +0.020 (+0.51)

2 2.375 (60.33) 6 0.012 (6 0.30) 1 ⁄2 11 0.173 (4.39) +0.021 (+0.53)

2 ⁄2 2.875 (73.03) 6 0.014 (6 0.37) 2 11 0.216 (5.49) +0.026 (+0.66)

3 3.500 (88.90) 6 0.018 (6 0.44) 2 ⁄2 11 0.261 (6.64) +0.031 (+0.80)

4 4.500 (114.30) 6 0.023 (6 0.57) 3 11 0.318 (8.08) +0.038 (+0.97)

5 5.563 (141.30) 6 0.028 (6 0.71) 4 11 0.409 (10.39) +0.049 (+1.24)

6 6.625 (168.28) 6 0.033 (6 0.84) 5 11 0.506 (12.85) +0.061 (+1.54)

6 11 0.602 (15.29) +0.072 (+1.83)

8 8.625 (219.08) 6 0.043 (6 1.10)

10 10.750 (273.05) 6 0.054 (6 1.37) 8 11 0.784 (19.91) +0.094 (+2.39)

12 12.750 (323.85) 6 0.064 (6 1.62) 10 11 0.977 (24.82) +0.117 (+2.98)

12 11 1.159 (29.44) +0.139 (+3.53)

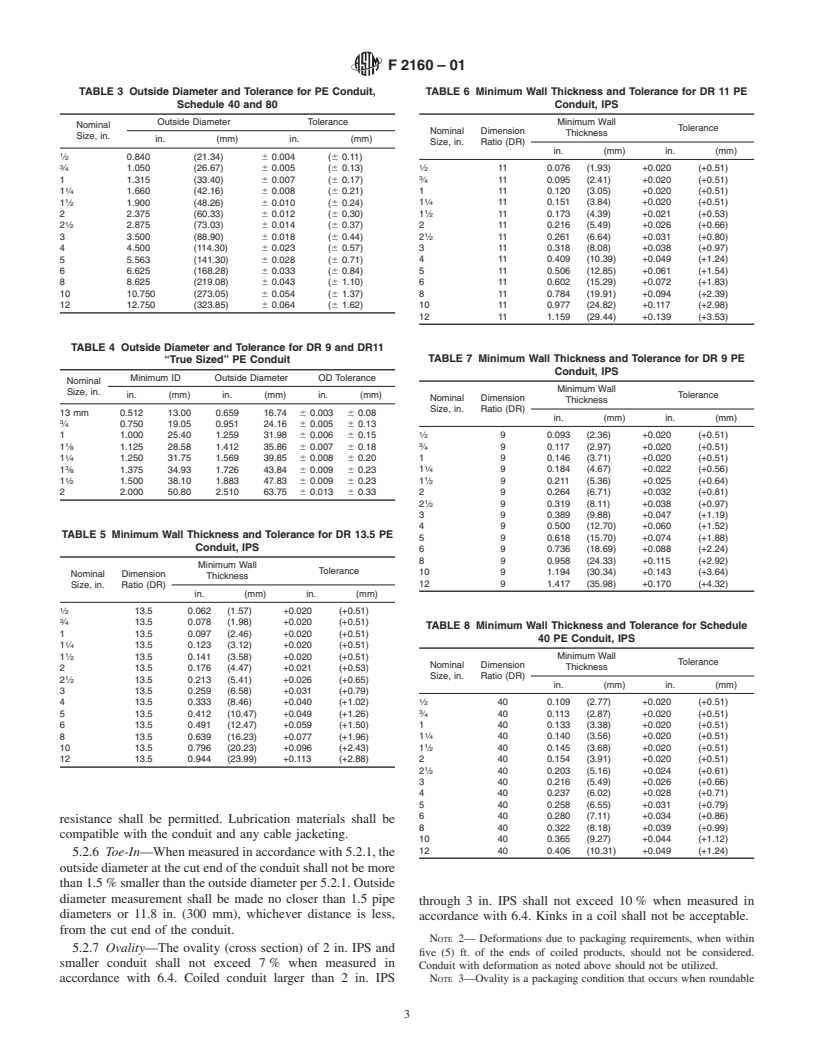

TABLE 4 Outside Diameter and Tolerance for DR 9 and DR11

TABLE 7 Minimum Wall Thickness and Tolerance for DR 9 PE

“True Sized” PE Conduit

Conduit, IPS

Minimum ID Outside Diameter OD Tolerance

Nominal

Minimum Wall

Size, in.

in. (mm) in. (mm) in. (mm) Tolerance

Nominal Dimension

Thickness

Size, in. Ratio (DR)

13 mm 0.512 13.00 0.659 16.74 6 0.003 6 0.08

in. (mm) in. (mm)

⁄4 0.750 19.05 0.951 24.16 6 0.005 6 0.13

1 1.000 25.40 1.259 31.98 6 0.006 6 0.15 ⁄2 9 0.093 (2.36) +0.020 (+0.51)

1 3

1 ⁄8 1.125 28.58 1.412 35.86 6 0.007 6 0.18 ⁄4 9 0.117 (2.97) +0.020 (+0.51)

1 ⁄4 1.250 31.75 1.569 39.85 6 0.008 6 0.20 1 9 0.146 (3.71) +0.020 (+0.51)

3 1

1 ⁄8 1.375 34.93 1.726 43.84 6 0.009 6 0.23 1 ⁄4 9 0.184 (4.67) +0.022 (+0.56)

1 1

1 ⁄2 9 0.211 (5.36) +0.025 (+0.64)

1 ⁄2 1.500 38.10 1.883 47.83 6 0.009 6 0.23

2 2.000 50.80 2.510 63.75 6 0.013 6 0.33 2 9 0.264 (6.71) +0.032 (+0.81)

2 ⁄2 9 0.319 (8.11) +0.038 (+0.97)

3 9 0.389 (9.88) +0.047 (+1.19)

4 9 0.500 (12.70) +0.060 (+1.52)

TABLE 5 Minimum Wall Thickness and Tolerance for DR 13.5 PE

5 9 0.618 (15.70) +0.074 (+1.88)

Conduit, IPS

6 9 0.736 (18.69) +0.088 (+2.24)

8 9 0.958 (24.33) +0.115 (+2.92)

Minimum Wall

Tolerance

10 9 1.194 (30.34) +0.143 (+3.64)

Nominal Dimension

Thickness

12 9 1.417 (35.98) +0.170 (+4.32)

Size, in. Ratio (DR)

in. (mm) in. (mm)

⁄2 13.5 0.062 (1.57) +0.020 (+0.51)

⁄4 13.5 0.078 (1.98) +0.020 (+0.51)

TABLE 8 Minimum Wall Thickness and Tolerance for Schedule

1 13.5 0.097 (2.46) +0.020 (+0.51)

40 PE Conduit, IPS

1 ⁄4 13.5 0.123 (3.12) +0.020 (+0.51)

1 ⁄2 13.5 0.141 (3.58) +0.020 (+0.51) Minimum Wall

Tolerance

Nominal Dimension

Thickness

2 13.5 0.176 (4.47) +0.021 (+0.53)

Size, in. Ratio (DR)

2 ⁄2 13.5 0.213 (5.41) +0.026 (+0.65)

in. (mm) in. (mm)

3 13.5 0.259 (6.58) +0.031 (+0.79)

⁄2 40 0.109 (2.77) +0.020 (+0.51)

4 13.5 0.333 (8.46) +0.040 (+1.02)

5 13.5 0.412 (10.47) +0.049 (+1.26) ⁄4 40 0.113 (2.87) +0.020 (+0.51)

1 40 0.133 (3.38) +0.020 (+0.51)

6 13.5 0.491 (12.47) +0.059 (+1.50)

8 13.5 0.639 (16.23) +0.077 (+1.96) 1 ⁄4 40 0.140 (3.56) +0.020 (+0.51)

10 13.5 0.796 (20.23) +0.096 (+2.43) 1 ⁄2 40 0.145 (3.68) +0.020 (+0.51)

12 13.5 0.944 (23.99) +0.113 (+2.88) 2 40 0.154 (3.91) +0.020 (+0.51)

2 ⁄2 40 0.203 (5.16) +0.024 (+0.61)

3 40 0.216 (5.49) +0.026 (+0.66)

4 40 0.237 (6.02) +0.028 (+0.71)

5 40 0.258 (6.55) +0.031 (+0.79)

6 40 0.280 (7.11) +0.034 (+0.86)

resistance shall be permitted. Lubrication materials shall be

8 40 0.322 (8.18) +0.039 (+0.99)

compatible with the conduit and any cable jacketing.

10 40 0.365 (9.27) +0.044 (+1.12)

12 40 0.406 (10.31) +0.049 (+1.24)

5.2.6 Toe-In—When measured in accordance with 5.2.1, the

outside diameter at the cut end of the conduit shall not be more

than 1.5 % smaller than the outside diameter per 5.2.1. Outside

diameter measurement shall be made no closer than 1.5 pipe

through 3 in. IPS shall not exceed 10 % when measured in

diameters or 11.8 in. (300 mm), whichever distance is less,

accordance with 6.4. Kinks in a coil shall not be acceptable.

from the cut end of the conduit.

NOTE 2— Deformations due to packaging requirements, when within

5.2.7 Ovality—The ovality (cross section) of 2 in. IPS and

five (5) ft. of the ends of coiled products, should not be considered.

smaller conduit shall not exceed 7 % when measured in

Conduit with deformation as noted above should not be utilized.

accordance with 6.4. Coiled conduit larger than 2 in. IPS NOTE 3—Ovality is a packaging condition that occurs when roundable

F2160–01

TABLE 9 Minimum Wall Thickness and Toleran

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.