ASTM F2176-17

(Specification)Standard Specification for Mechanical Couplings Used on Polyethylene Conduit, Duct and Innerduct

Standard Specification for Mechanical Couplings Used on Polyethylene Conduit, Duct and Innerduct

ABSTRACT

This specification establishes requirements for the qualification of mechanical couplings of particular range of sizes that connect to particular types of polyethylene conduit, duct and innerduct. The couplings covered by this specification are typically designed to join between conduit ends (in-line coupling). The same coupling-to-conduit joint design may be used as a part of other coupling joint designs that telescope, or connect to bulkheads, or other adapter fitting designs. The requirements of this standard apply only to the coupling-to-conduit joint design. The performance requirements of other coupling joint designs are not a part of this standard. The couplings shall conform to the specified pressure and tensile strength requirements.

SCOPE

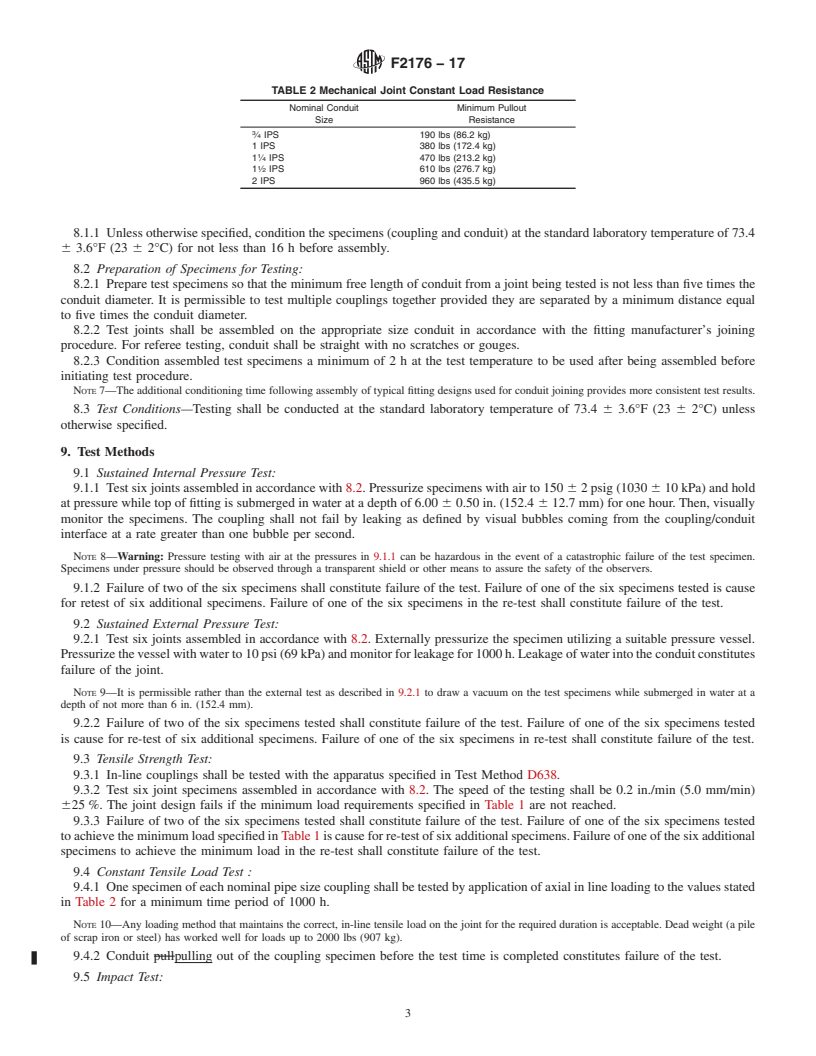

1.1 This specification establishes requirements for material, performance, workmanship and test methods for the qualification of 2 in. and smaller mechanical couplings that connect to SDR 13.5, DR 15.5, Schedule 40 and Schedule 80 polyethylene conduit, duct and innerduct covered by Specification F2160. Throughout this standard, “conduit” refers to “conduit, duct or innerduct” manufactured in accordance with Specification F2160.

Note 1: F2176 fittings are not applicable to True-sized and ID-controlled conduit per F2160.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The couplings covered by this specification are typically designed to join between conduit ends (in-line coupling). The same coupling-to-conduit joint design may be used as a part of other coupling joint designs that telescope, or connect to bulkheads, or other adapter fitting designs. The requirements of this standard apply only to the coupling-to-conduit joint design. The performance requirements of other coupling joint designs are not a part of this standard.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 9 of this specification.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2176 −17 An American National Standard

Standard Specification for

Mechanical Couplings Used on Polyethylene Conduit, Duct

1

and Innerduct

This standard is issued under the fixed designation F2176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification establishes requirements for material, 2.1 ASTM Standards:

performance, workmanship and test methods for the qualifica- D638Test Method for Tensile Properties of Plastics

tion of 2 in. and smaller mechanical couplings that connect to D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

SDR 13.5, DR 15.5, Schedule 40 and Schedule 80 polyethyl- tics

ene conduit, duct and innerduct covered by Specification D2444Test Method for Determination of the Impact Resis-

F2160. Throughout this standard, “conduit” refers to “conduit, tance of Thermoplastic Pipe and Fittings by Means of a

duct or innerduct” manufactured in accordance with Specifi- Tup (Falling Weight)

cation F2160. F412Terminology Relating to Plastic Piping Systems

F2160Specification for Solid Wall High Density Polyethyl-

NOTE 1—F2176 fittings are not applicable to True-sized and ID-

ene (HDPE) Conduit Based on Controlled Outside Diam-

controlled conduit per F2160.

eter (OD)

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

3. Terminology

conversions to SI units that are provided for information only

3.1 Definitions are in accordance with Terminology F412

and are not considered standard.

and abbreviations are in accordance with Terminology D1600,

1.3 Thecouplingscoveredbythisspecificationaretypically

unless otherwise specified.

designed to join between conduit ends (in-line coupling). The

3.2 Definitions of Terms Specific to This Standard:

same coupling-to-conduit joint design may be used as a part of

3.2.1 coupling joint, n—the connection between the cou-

other coupling joint designs that telescope, or connect to

pling and a conduit end.

bulkheads,orotheradapterfittingdesigns.Therequirementsof

3.2.2 duct, n—a conduit (see Terminology F412, conduit).

this standard apply only to the coupling-to-conduit joint

design. The performance requirements of other coupling joint 3.2.3 inline mechanical couplings, n—a device used to join

designs are not a part of this standard.

two conduit ends.

1.4 The following safety hazards caveat pertains only to the 3.2.4 innerduct, n—a conduit installed inside a conduit.

test methods portion, Section 9 of this specification.This

4. Materials and Manufacture

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

4.1 Thephysicalpropertiesofeachmaterialusedtoproduce

of this standard to establish appropriate safety, health, and

mechanical couplings shall be available from the coupling

environmental practices and determine the applicability of

manufacturer upon request.

regulatory limitations prior to use.

4.2 Specifications outlining all the physical properties and

1.5 This international standard was developed in accor-

effects of environmental conditions for materials of manufac-

dance with internationally recognized principles on standard-

ture shall be available from the coupling manufacturer upon

ization established in the Decision on Principles for the

request.

Development of International Standards, Guides and Recom-

NOTE 2—Materials should have a demonstrated resistance to environ-

mendations issued by the World Trade Organization Technical

mental stress cracking when exposed, under stress, to chemical com-

Barriers to Trade (TBT) Committee. pounds encountered in or external to conduit systems and a demonstrated

resistancetobacteriologicaldecomposition.Suchcompoundsinclude,but

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2017. Published September 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved 2002. Last previous edition approved in 2009 as F2176–02(2009). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2176-17. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2176 − 02 (Reapproved 2009) F2176 − 17 An American National Standard

Standard Specification for

Mechanical Couplings Used on Polyethylene Conduit, Duct

1

and Innerduct

This standard is issued under the fixed designation F2176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification establishes requirements for material, performance, workmanship and test methods for the qualification

of 2 in. and smaller mechanical couplings that connect to DR 15.5 and lower SDR 13.5, DR 15.5, Schedule 40 and Schedule 80

polyethylene conduit, duct and innerduct covered by Specification F2160. Throughout this standard, “conduit” refers to “conduit,

duct or innerduct” manufactured in accordance with Specification F2160.

NOTE 1—F2176 fittings are not applicable to True-sized and ID-controlled conduit per F2160.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The couplings covered by this specification are typically designed to join between conduit ends (in-line coupling). The same

coupling-to-conduit joint design may be used as a part of other coupling joint designs that telescope, or connect to bulkheads, or

other adapter fitting designs. The requirements of this standard apply only to the coupling-to-conduit joint design. The performance

requirements of other coupling joint designs are not a part of this standard.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 9 of this specification.The following

safety hazards caveat pertains only to the test methods portion, Section 9 of this specification.This standard does not purport to

address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish

appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory requirement-

slimitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D638 Test Method for Tensile Properties of Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2444 Test Method for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

F412 Terminology Relating to Plastic Piping Systems

F2160 Specification for Solid Wall High Density Polyethylene (HDPE) Conduit Based on Controlled Outside Diameter (OD)

3. Terminology

3.1 Definitions are in accordance with Terminology F412 and abbreviations are in accordance with Terminology D1600, unless

otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 coupling joint, n—the connection between the coupling and a conduit end.

3.2.2 duct, n—a conduit (see Terminology F412, conduit).

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.10 on Fittings.

Current edition approved March 1, 2009Sept. 1, 2017. Published March 2009September 2017. Originally approved 2002. Last previous edition approved in 20022009 as

F2176F2176–02(2009).–02. DOI: 10.1520/F2176-02R09.10.1520/F2176-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2176 − 17

3.2.3 inline mechanical couplings, n—a device used to join two conduit ends.

3.2.4 innerduct, n—a conduit installed inside a conduit.

4. Materials and Manufacture

4.1 The physical properties of each material us

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.