ASTM G58-85(2023)

(Practice)Standard Practice for Preparation of Stress-Corrosion Test Specimens for Weldments

Standard Practice for Preparation of Stress-Corrosion Test Specimens for Weldments

SIGNIFICANCE AND USE

4.1 The intent of this practice is to indicate standard welded specimens and welding procedures for evaluating the SCC characteristics of weldments in corrosive environments. The practice does not recommend the specific corrosive media that may be selected by the user depending upon the intent of his investigation. Specific corrosive media are included in Practices G35, G36, G37, and G44. Other environments can be used as required.

SCOPE

1.1 This practice covers procedures for the making and utilization of test specimens for the evaluation of weldments in stress-corrosion cracking (SCC) environments.

1.2 Test specimens are described in which (a) stresses are developed by the welding process only, (b) stresses are developed by an externally applied load in addition to the stresses due to welding, and (c) stresses are developed by an externally applied load only with residual welding stresses removed by annealing.

1.3 This practice is concerned only with the welded test specimen and not with the environmental aspects of stress-corrosion testing. Specific practices for the bending and loading of test specimens, as well as the stress considerations involved in preparation of C-rings, U-bend, bent-beam, and tension specimens are discussed in other ASTM standards.

1.4 The actual stress in test specimens removed from weldments is not precisely known because it depends upon the level of residual stress from the welding operation combined with the applied stress. A method for determining the magnitude and direction of residual stress which may be applicable to weldment is described in Test Method E837. The reproducibility of test results is highly dependent on the preparation of the weldment, the type of test specimen tested, and the evaluation criteria used. Sufficient replication should be employed to determine the level of inherent variability in the specific test results that is consistent with the objectives of the test program.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. (For more specific safety hazards information, see Section 7.)

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G58 − 85 (Reapproved 2023)

Standard Practice for

Preparation of Stress-Corrosion Test Specimens for

Weldments

This standard is issued under the fixed designation G58; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.1 This practice covers procedures for the making and

mendations issued by the World Trade Organization Technical

utilization of test specimens for the evaluation of weldments in

Barriers to Trade (TBT) Committee.

stress-corrosion cracking (SCC) environments.

1.2 Test specimens are described in which (a) stresses are 2. Referenced Documents

developed by the welding process only, (b) stresses are 2

2.1 ASTM Standards:

developed by an externally applied load in addition to the

E8 Test Methods for Tension Testing of Metallic Materials

stresses due to welding, and (c) stresses are developed by an

[Metric] E0008_E0008M

externally applied load only with residual welding stresses

E399 Test Method for Linear-Elastic Plane-Strain Fracture

removed by annealing.

Toughness of Metallic Materials

1.3 This practice is concerned only with the welded test E837 Test Method for Determining Residual Stresses by the

specimen and not with the environmental aspects of stress-

Hole-Drilling Strain-Gage Method

corrosion testing. Specific practices for the bending and load- G1 Practice for Preparing, Cleaning, and Evaluating Corro-

ing of test specimens, as well as the stress considerations sion Test Specimens

involved in preparation of C-rings, U-bend, bent-beam, and G30 Practice for Making and Using U-Bend Stress-

tension specimens are discussed in other ASTM standards. Corrosion Test Specimens

G35 Practice for Determining the Susceptibility of Stainless

1.4 The actual stress in test specimens removed from

Steels and Related Nickel-Chromium-Iron Alloys to

weldments is not precisely known because it depends upon the

Stress-Corrosion Cracking in Polythionic Acids

level of residual stress from the welding operation combined

G36 Practice for Evaluating Stress-Corrosion-Cracking Re-

with the applied stress. A method for determining the magni-

sistance of Metals and Alloys in a Boiling Magnesium

tude and direction of residual stress which may be applicable to

Chloride Solution

weldment is described in Test Method E837. The reproducibil-

G37 Practice for Use of Mattsson’s Solution of pH 7.2 to

ity of test results is highly dependent on the preparation of the

Evaluate the Stress-Corrosion Cracking Susceptibility of

weldment, the type of test specimen tested, and the evaluation

Copper-Zinc Alloys

criteria used. Sufficient replication should be employed to

G38 Practice for Making and Using C-Ring Stress-

determine the level of inherent variability in the specific test

Corrosion Test Specimens

results that is consistent with the objectives of the test program.

G39 Practice for Preparation and Use of Bent-Beam Stress-

1.5 This standard does not purport to address all of the

Corrosion Test Specimens

safety concerns, if any, associated with its use. It is the

G44 Practice for Exposure of Metals and Alloys by Alternate

responsibility of the user of this standard to establish appro-

Immersion in Neutral 3.5 % Sodium Chloride Solution

priate safety, health, and environmental practices and deter-

G49 Practice for Preparation and Use of Direct Tension

mine the applicability of regulatory limitations prior to use.

Stress-Corrosion Test Specimens

(For more specific safety hazards information, see Section 7.)

1.6 This international standard was developed in accor-

3. Summary of Practice

dance with internationally recognized principles on standard-

3.1 The following summarizes the test objectives that may

be evaluated:

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen-

tally Assisted Cracking. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2023. Published January 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1985. Last previous edition approved in 2015 as G58 – 85 (2015). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/G0058-85R23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G58 − 85 (2023)

Procedure:

(a) Specimen size—as required.

(b) Note grain direction and weld longitudinally or across grain.

(c) For multiple-pass welds, grind between passes. Use back gouging from

opposite side to attain 100 % weld penetration.

(d) Discard weld ends.

(e) Remove test sections as required. Sections may be taken across the weld or

longitudinally with the weld.

FIG. 1 Flat Weldment

3.1.1 Resistance to SCC of a total weldment (weld, heat- recommended size. The welding procedure involves one cir-

affected zone, and parent metal) as produced by a specific cular stringer bead deposit of weld metal.

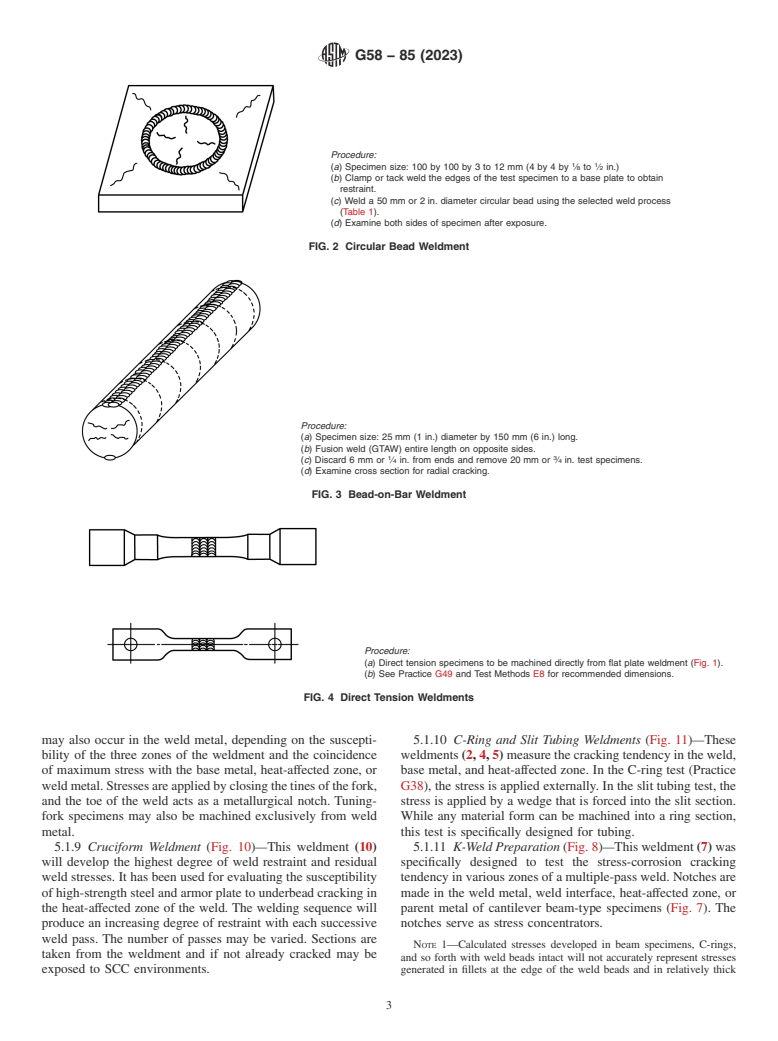

welding process; 5.1.3 Bead-on-Bar Weldment (Fig. 3)—This weldment (2)

3.1.2 Resistance to SCC of deposited weld metal; measures the tendency for SCC of the base metal. The

3.1.3 Determination of a stress level or stress intensity that longitudinal fusion welds develop residual stresses on the bar.

will produce SCC in a weldment; It is applicable to materials that can be machined to approxi-

3.1.4 Evaluation of SCC failure in the specific zones of a mately a 25 mm or 1 in. round.

weld (weld metal, partially melted zone, weld interface,

5.1.4 Direct Tension Weldments (Fig. 4)—These weldments

heat-affected zone, and base metal); and

(3, 4, 5) measure the cracking tendency in weld metal, base

3.1.5 Evaluation of the effect of notches and stress raisers in

metal, or heat-affected zone. The applied stress is developed in

weldments.

uniaxially loaded tension specimens. Notches may be intro-

duced into the weld metal, base metal, or heat-affected zone.

4. Significance and Use

The tension specimens are machined from welded plate or cast

4.1 The intent of this practice is to indicate standard welded

sections (Fig. 1) and may be made exclusively from weld

specimens and welding procedures for evaluating the SCC

metal.

characteristics of weldments in corrosive environments. The

5.1.5 U-Bend Weldment (Fig. 5)—This weldment (5, 6)

practice does not recommend the specific corrosive media that

measures crack tendency in the weld, base metal, and heat-

may be selected by the user depending upon the intent of his

affected zone. The bending operation after welding creates high

investigation. Specific corrosive media are included in Prac-

levels of elastic and plastic strain resulting in a wide range of

tices G35, G36, G37, and G44. Other environments can be

stresses in a single specimen. The presence of residual welding

used as required.

stresses make this a most severe test procedure. It is applicable

to any material that can be formed into a U-shape without

5. Types of Specimens and Specific Applications

mechanical cracking or localized bending in the heat-affected

5.1 This practice covers the following procedures for the zone.

preparation of test weldments. The form of the material to be 5.1.6 Bent-Beam Weldment (Fig. 6)—This weldment (4, 5,

evaluated (plate, bar, tubing, casting, or forging) may deter- 6) measures cracking tendency in the weld bead, the weld base

mine whether its usage is applicable in a given test. Residual metal interface, and heat-affected zone due to stress concen-

welding stresses may be left intact or they may be fully or tration. The specimen will contain residual welding stresses

partially removed by an appropriate heat treatment. and stresses due to elastic strain produced by bending. This

5.1.1 Flat Welding (Fig. 1)—This weldment (1) is appli- specimen is particularly applicable to materials that cannot be

cable for all tension and bend specimens. The size of the bent into a U-shape.

weldment may be varied according to the needs of the user or

5.1.7 Precracked Cantilever Beam Weldment (Fig. 7)—This

the demands of welding practice being evaluated. It is appli-

weldment (5) measures the level of stress intensity to produce

cable to any welding procedure and can involve single- or

crack initiation or propagation in various areas of a weldment.

multiple-pass welds.

Notches or cracks may be introduced into the weld metal, base

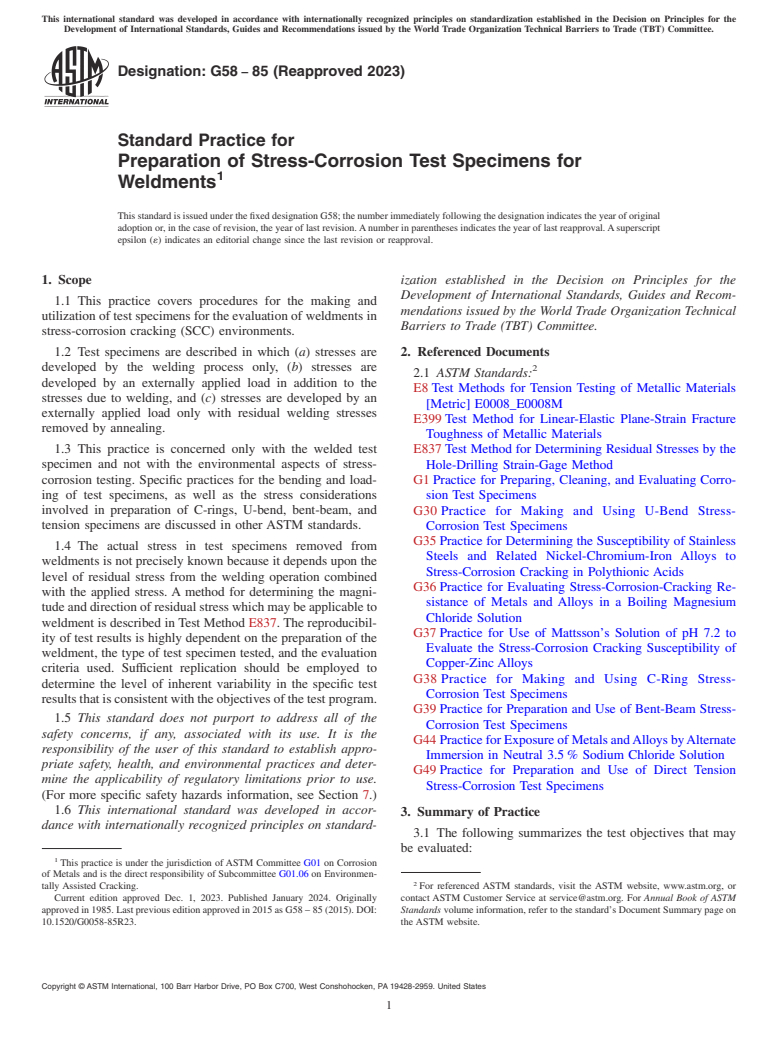

5.1.2 Circular Bead Weldment (Fig. 2)—This weldment (2,

metal, or heat-affected zone. The specimen will contain re-

3, 4, 5) measures the tendency for SCC in the base metal,

sidual welding stresses and applied stresses. Weldments may

heat-affected zone, and deposited weld metal. The circular

be prepared in accordance with Fig. 1 or by means of the

weld develops residual stresses. It is applicable to any material

K-preparation for multiple-pass welds (Fig. 8 and Ref (7)).

form (plate, bar, castings) that can be machined to the

5.1.8 Tuning Fork Weldment (Fig. 9)—This weldment (5, 9)

measures cracking tendency in the base metal, heat-affected

zone, or weld-base metal interface if the weld reinforcement is

The boldface numbers in parentheses refer to a list of references at the end of

this standard. not removed. When the reinforcement is removed, cracking

G58 − 85 (2023)

Procedure:

1 1

(a) Specimen size: 100 by 100 by 3 to 12 mm (4 by 4 by ⁄8 to ⁄2 in.)

(b) Clamp or tack weld the edges of the test specimen to a base plate to obtain

restraint.

(c) Weld a 50 mm or 2 in. diameter circular bead using the selected weld process

(Table 1).

(d) Examine both sides of specimen after exposure.

FIG. 2 Circular Bead Weldment

Procedure:

(a) Specimen size: 25 mm (1 in.) diameter by 150 mm (6 in.) long.

(b) Fusion weld (GTAW) entire length on opposite sides.

1 3

(c) Discard 6 mm or ⁄4 in. from ends and remove 20 mm or ⁄4 in. test specimens.

(d) Examine cross section for radial cracking.

FIG. 3 Bead-on-Bar Weldment

Procedure:

(a) Direct tension specimens to be machined directly from flat plate weldment (Fig. 1).

(b) See Practice G49 and Test Methods E8 for recommended dimensions.

FIG. 4 Direct Tension Weldments

may also occur in the weld metal, depending on the suscepti- 5.1.10 C-Ring and Slit Tubing Weldments (Fig. 11)—These

bility of the three zones of the weldment and the coincidence weldments (2, 4, 5) measure the cracking tendency in the weld,

of maximum stress with the base metal, heat-affected zone, or base metal, and heat-affected zone. In the C-ring test (Practice

weld metal. Stresses are applied by closing the tines of the fork, G38), the stress is applied externally. In the slit tubing test, the

and the toe of the weld acts as a metallurgical notch. Tuning- stress is applied by a wedge that is forced into the slit section.

fork specimens may also be machined exclusively from weld While any material form can be machined into a ring section,

metal. this test is specifically designed for tubing.

5.1.9 Cruciform Weldment (Fig. 10)—This weldment (10) 5.1.11 K-Weld Preparation (Fig. 8)—This weldment (7) was

will develop the highest degree of weld restraint and residual specifically designed to test the stress-corrosion cracking

weld stresses. It has been used for evaluating the susceptibility tendency in various zones of a multiple-pass weld. Notches are

of high-strength steel and armor plate to underbead cracking in made in the weld metal, weld interface, heat-affected zone, or

the heat-affected zone of the weld. The welding sequence will parent metal of cantilever beam-type specimens (Fig. 7). The

produce an increasing degree of restraint with each successive notches serve as stress concentrators.

weld pass. The number of passes may be varied. Sections are

NOTE 1—Calculated stresses developed in beam specimens, C-rings,

taken from the weldment and if not already cracked may be

and so forth with weld beads intact will not accurately represent stresses

exposed to SCC environments. generated in fillets at the edge of the weld beads and in relatively thick

G58 − 85 (2023)

Procedure:

(a) U-bend specimens to be machined directly from flat plate weldment (Fig. 1)

(b) See Practice G30 for bending method.

NOTE 1—The welds may be oriented 90° to the direction shown.

FIG. 5 U-Bend Weldment

Procedure:

(a) Bent-beam specimens to be machined directly from flat plate weldment. (Fig. 1).

Fulcrum should be notched so as not to contact weld bead.

(b) Dimensions: as required.

(c) See Practice G39 for stress calculations.

NOTE 1—The welds may be oriented 90° to the direction shown.

FIG. 6 Bent-Beam Weldment

Procedure:

(a) Specimens may be machined from flat plate weldment (Fig. 1) or K-weld

preparation (Fig. 8).

(b) See Test Method E399 and Ref (8).

FIG. 7 Precracked Cantilever Beam Weldment

beads, and strain gages will be needed if precise values of the applied

and monitored since it will be the governing parameter in the

stress are required. The effective stress of course will be the algebraic sum

procedure and may introduce a number of variables that will

of the applied stress and residual welding stresses.

affect test results.

NOTE 2—Calculated stresses also may be erroneous for bead-off

specimens of weldments of dissimilar alloys or in the case of relatively

6.2 Typical welding methods that are applicable to this

soft heat-affected zones.

practice are listed in Table 1.

6. Welding Considerations

6.3 Variables introduced by the welding method are (a) the

amount of heat input introduced by the specific welding

6.1 The choice of a welding method and the application of

process and its effect on microstructure of the weld nugget,

proper welding techniques are major factors influencing the

weld interface, and heat-affected zone of the parent metal, (b)

overall corrosion resistance of a weldment. Each welding

method as described in Refs (11, 12) has its own inherent localized variations in chemical composition developed during

melting and solidification, (c) the possible pick-up of nitrogen,

characteristics which will govern the overall quality of the

weld. The welding method must therefore be carefully selected carbon, silicon, fluorine, or other impurities from

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.