ASTM F2160-08

(Specification)Standard Specification for Solid Wall High Density Polyethylene (HDPE) Conduit Based on Controlled Outside Diameter (OD)

Standard Specification for Solid Wall High Density Polyethylene (HDPE) Conduit Based on Controlled Outside Diameter (OD)

ABSTRACT

This specification covers material, dimensional, workmanship and performance requirements for polyethylene conduit, duct and innerduct manufactured for use in a nonpressure application with communication, CATV, or power wire and cables. HDPE conduit meeting the requirements of this standard shall be made as OD controlled solid wall, with or without internal or external ribs. The sizing shall be Iron Pipe Size (IPS). The internal or external surface may contain a coextruded layer provided the finished conduit meets the specified product requirements. The product shall be subject to elongation, impact, and ovality tests.

SCOPE

1.1 This specification covers material, dimensional, workmanship and performance requirements for polyethylene conduit, duct and innerduct manufactured for use in a non- pressure application with communication, CATV, or power wire and cables.

1.2 HDPE conduit meeting the requirements of this standard shall be made as OD controlled solid wall, with or without internal or external ribs. The sizing shall be Iron Pipe Size (IPS) with noted exceptions in tables. The internal or external surface may contain a coextruded layer provided the finished conduit meets the product requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: F2160 – 08

Standard Specification for

Solid Wall High Density Polyethylene (HDPE) Conduit Based

1

on Controlled Outside Diameter (OD)

This standard is issued under the fixed designation F2160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

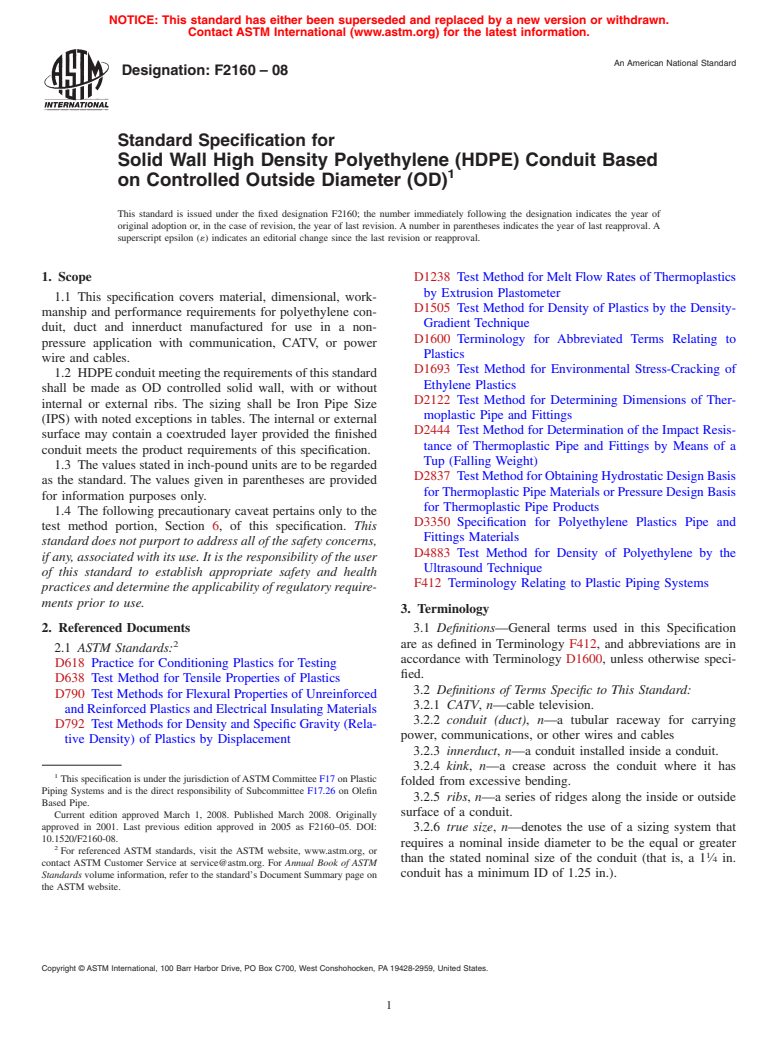

1. Scope D1238 Test Method for Melt Flow Rates of Thermoplastics

by Extrusion Plastometer

1.1 This specification covers material, dimensional, work-

D1505 Test Method for Density of Plastics by the Density-

manship and performance requirements for polyethylene con-

Gradient Technique

duit, duct and innerduct manufactured for use in a non-

D1600 Terminology for Abbreviated Terms Relating to

pressure application with communication, CATV, or power

Plastics

wire and cables.

D1693 Test Method for Environmental Stress-Cracking of

1.2 HDPEconduitmeetingtherequirementsofthisstandard

Ethylene Plastics

shall be made as OD controlled solid wall, with or without

D2122 Test Method for Determining Dimensions of Ther-

internal or external ribs. The sizing shall be Iron Pipe Size

moplastic Pipe and Fittings

(IPS) with noted exceptions in tables. The internal or external

D2444 Test Method for Determination of the Impact Resis-

surface may contain a coextruded layer provided the finished

tance of Thermoplastic Pipe and Fittings by Means of a

conduit meets the product requirements of this specification.

Tup (Falling Weight)

1.3 The values stated in inch-pound units are to be regarded

D2837 TestMethodforObtainingHydrostaticDesignBasis

as the standard. The values given in parentheses are provided

forThermoplastic Pipe Materials or Pressure Design Basis

for information purposes only.

for Thermoplastic Pipe Products

1.4 The following precautionary caveat pertains only to the

D3350 Specification for Polyethylene Plastics Pipe and

test method portion, Section 6, of this specification. This

Fittings Materials

standard does not purport to address all of the safety concerns,

D4883 Test Method for Density of Polyethylene by the

if any, associated with its use. It is the responsibility of the user

Ultrasound Technique

of this standard to establish appropriate safety and health

F412 Terminology Relating to Plastic Piping Systems

practices and determine the applicability of regulatory require-

ments prior to use.

3. Terminology

2. Referenced Documents 3.1 Definitions—General terms used in this Specification

2

are as defined in Terminology F412, and abbreviations are in

2.1 ASTM Standards:

accordance with Terminology D1600, unless otherwise speci-

D618 Practice for Conditioning Plastics for Testing

fied.

D638 Test Method for Tensile Properties of Plastics

3.2 Definitions of Terms Specific to This Standard:

D790 Test Methods for Flexural Properties of Unreinforced

3.2.1 CATV, n—cable television.

and Reinforced Plastics and Electrical Insulating Materials

3.2.2 conduit (duct), n—a tubular raceway for carrying

D792 Test Methods for Density and Specific Gravity (Rela-

power, communications, or other wires and cables

tive Density) of Plastics by Displacement

3.2.3 innerduct, n—a conduit installed inside a conduit.

3.2.4 kink, n—a crease across the conduit where it has

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

folded from excessive bending.

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

3.2.5 ribs, n—a series of ridges along the inside or outside

Based Pipe.

surface of a conduit.

Current edition approved March 1, 2008. Published March 2008. Originally

approved in 2001. Last previous edition approved in 2005 as F2160–05. DOI:

3.2.6 true size, n—denotes the use of a sizing system that

10.1520/F2160-08.

requires a nominal inside diameter to be the equal or greater

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

than the stated nominal size of the conduit (that is, a 1 ⁄4 in.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

conduit has a minimum ID of 1.25 in.).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

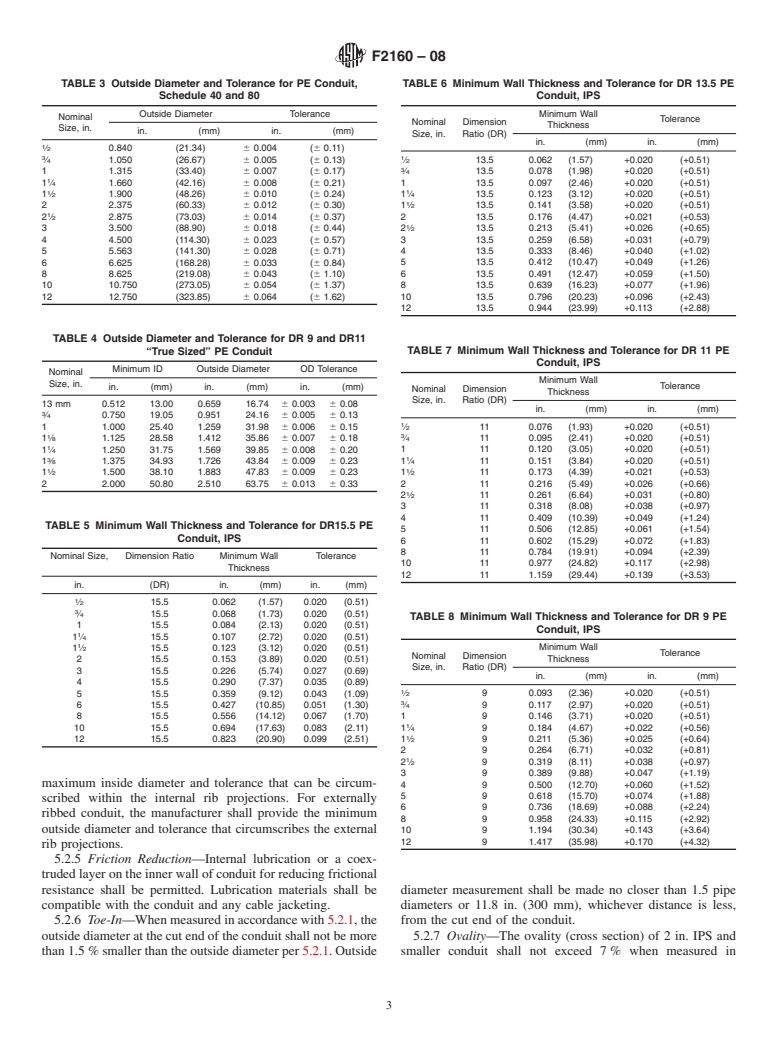

F2160 – 08

4. Materials against UV degradation so that conduit may be stored outside

anduncoveredforaperiodofnotlessthanoneyear.Permanent

4.1 Polyethylene Plastics—The PE materials used to make

color identification shall be permitted to be as solid color, as

conduit under this Specification shall meet or exceed the

stripes, as a

...

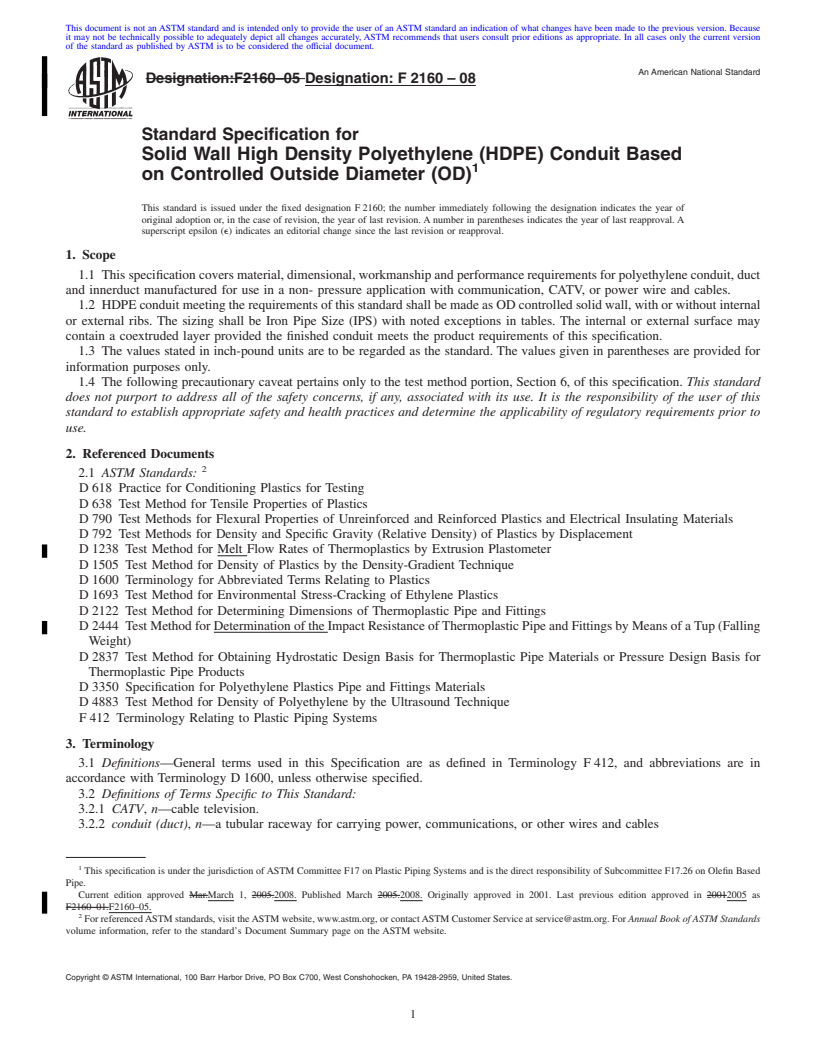

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F2160–05 Designation: F 2160 – 08

Standard Specification for

Solid Wall High Density Polyethylene (HDPE) Conduit Based

1

on Controlled Outside Diameter (OD)

This standard is issued under the fixed designation F 2160; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers material, dimensional, workmanship and performance requirements for polyethylene conduit, duct

and innerduct manufactured for use in a non- pressure application with communication, CATV, or power wire and cables.

1.2 HDPE conduit meeting the requirements of this standard shall be made as OD controlled solid wall, with or without internal

or external ribs. The sizing shall be Iron Pipe Size (IPS) with noted exceptions in tables. The internal or external surface may

contain a coextruded layer provided the finished conduit meets the product requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for

information purposes only.

1.4 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to

use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

D 638 Test Method for Tensile Properties of Plastics

D 790 Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D 792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

D 1238 Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer

D 1505 Test Method for Density of Plastics by the Density-Gradient Technique

D 1600 Terminology for Abbreviated Terms Relating to Plastics

D 1693 Test Method for Environmental Stress-Cracking of Ethylene Plastics

D 2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D 2444 Test Method for Determination of the Impact Resistance ofThermoplastic Pipe and Fittings by Means of aTup (Falling

Weight)

D 2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

D 3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

D 4883 Test Method for Density of Polyethylene by the Ultrasound Technique

F 412 Terminology Relating to Plastic Piping Systems

3. Terminology

3.1 Definitions—General terms used in this Specification are as defined in Terminology F 412, and abbreviations are in

accordance with Terminology D 1600, unless otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 CATV, n—cable television.

3.2.2 conduit (duct), n—a tubular raceway for carrying power, communications, or other wires and cables

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin Based

Pipe.

Current edition approved Mar.March 1, 2005.2008. Published March 2005.2008. Originally approved in 2001. Last previous edition approved in 20012005 as

F2160–01.F2160–05.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

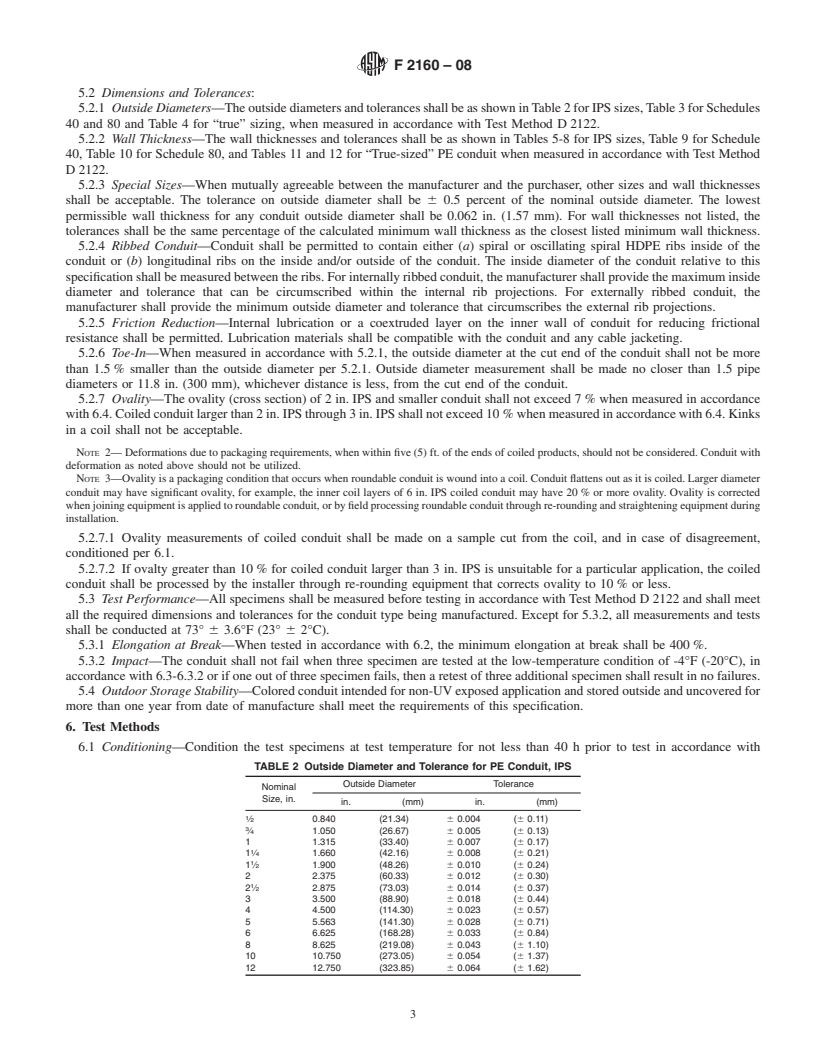

F2160–08

3.2.3 innerduct, n—a conduit installed inside a conduit.

3.2.4 kink, n—a crease across the conduit where it has folded from excessive bending.

3.2.5 ribs, n—a series of ridges along the inside or outside surface of a conduit.

3.2.6 true size, n—denotes the use of a sizing system that requires a nominal inside diameter to be the equal or greater than the

1

stated nominal size of the conduit (that is, a 1 ⁄4 in. conduit has a minimum ID of 1.25 in.).

4. Mat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.