ASTM D7855/D7855M-13(2017)

(Test Method)Standard Test Method for Determination of Mold Growth on Coated Building Products Designed for Interior Applications Using an Environmental Chamber and Indirect Inoculation

Standard Test Method for Determination of Mold Growth on Coated Building Products Designed for Interior Applications Using an Environmental Chamber and Indirect Inoculation

SIGNIFICANCE AND USE

5.1 An accelerated test for determining the resistance of interior coated building products to mold growth is useful in estimating the relative performance for use in interior environments under conditions favorable to fungal growth.

5.2 Static or environmental chambers provide controlled laboratory micro-environment conditions. These chambers are not intended to duplicate room conditions, and care must be taken when interpreting the results. Static chambers are not a substitute for dynamic chambers or field studies.

SCOPE

1.1 This test method covers an environmental chamber and the conditions of operation to evaluate in a 4-week period the relative resistance to mold growth and microbial surface defacement on coated building products designed for interior application using an indirect inoculation method. The apparatus is designed so it can be easily built or obtained by any interested party.

1.2 This test method can be used to evaluate the comparative resistance of coated building products to accelerated mold growth. Ratings do not imply a specific time period that the coated building product will be free of fungal growth during installation in an interior environment.

1.3 This test method is not intended for use in the evaluation of public health claims.

1.4 The test method is intended for the accelerated evaluation of mold growth on a coated building product designed for interior use. This method is not intended for evaluation of surfaces designed for exterior applications or uncoated surfaces. Use of this test method for evaluating exterior performance has not been validated, nor have the limitations for such use been determined.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7855/D7855M − 13 (Reapproved 2017)

Standard Test Method for

Determination of Mold Growth on Coated Building Products

Designed for Interior Applications Using an Environmental

1

Chamber and Indirect Inoculation

This standard is issued under the fixed designation D7855/D7855M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method covers an environmental chamber and

ization established in the Decision on Principles for the

the conditions of operation to evaluate in a 4-week period the

Development of International Standards, Guides and Recom-

relative resistance to mold growth and microbial surface

mendations issued by the World Trade Organization Technical

defacement on coated building products designed for interior

Barriers to Trade (TBT) Committee.

application using an indirect inoculation method. The appara-

tus is designed so it can be easily built or obtained by any

2. Referenced Documents

interested party.

2

2.1 ASTM Standards:

1.2 This test method can be used to evaluate the compara-

D16 TerminologyforPaint,RelatedCoatings,Materials,and

tive resistance of coated building products to accelerated mold

Applications

growth. Ratings do not imply a specific time period that the

D1193 Specification for Reagent Water

coated building product will be free of fungal growth during

D6329 Guide for Developing Methodology for Evaluating

installation in an interior environment.

the Ability of Indoor Materials to Support Microbial

1.3 Thistestmethodisnotintendedforuseintheevaluation

Growth Using Static Environmental Chambers

of public health claims.

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.4 The test method is intended for the accelerated evalua-

E691 Practice for Conducting an Interlaboratory Study to

tion of mold growth on a coated building product designed for

Determine the Precision of a Test Method

interior use. This method is not intended for evaluation of

surfaces designed for exterior applications or uncoated sur-

3. Terminology

faces. Use of this test method for evaluating exterior perfor-

mance has not been validated, nor have the limitations for such 3.1 Definitions—For definitions of terms refer to Terminol-

ogy D16.

use been determined.

1.5 The values stated in either SI units or inch-pound units 3.2 Definitions of Terms Specific to This Standard:

3.2.1 chamber control, n—open Petri dish containing appro-

are to be regarded separately as standard. The values stated in

each system may not be exact equivalents; therefore, each priate agar to demonstrate viability of fungal organisms within

the environmental chamber.

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance

3.2.2 coated building product, n—a building material hav-

with the standard.

ing a liquid, liquefiable or mastic composition that is converted

1.6 This standard does not purport to address all of the to a solid protective, decorative, or functional adherent film

after application as a thin layer onto a building fabric.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2.3 interior, n—any surface not exposed to exterior envi-

priate safety, health, and environmental practices and deter-

ronments in end use.

mine the applicability of regulatory limitations prior to use.

3.2.4 interior finish, n—interior wall and ceiling finish and

interior floor finish.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

2

Subcommittee D01.28 on Biodeterioration. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2017. Published December 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2013. Last previous edition approved in 2013 as D7855/D7855M-13. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D7855_D7855M–13R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7855/D7855M − 13 (2017)

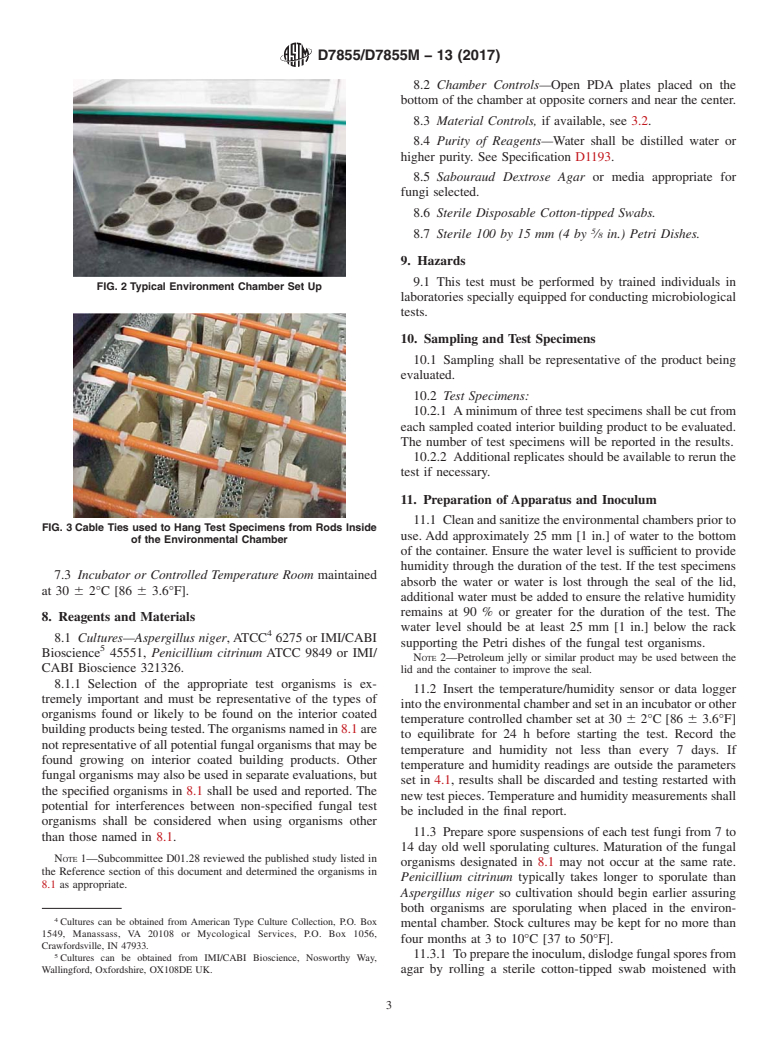

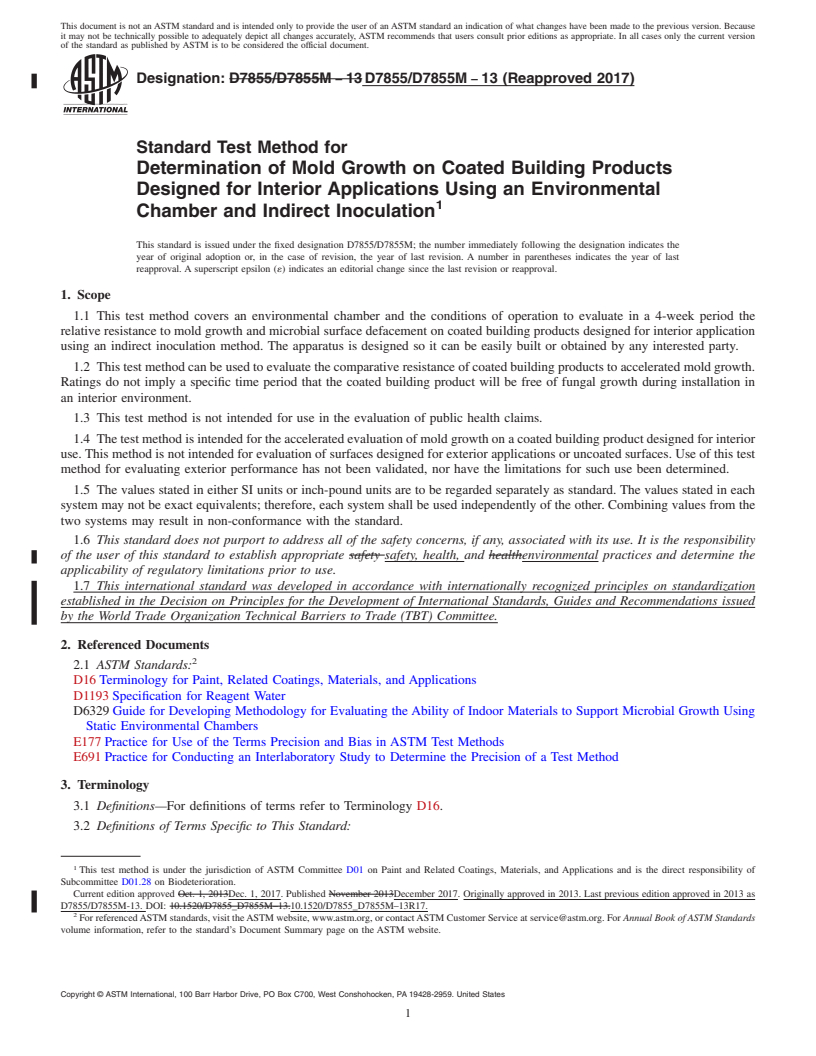

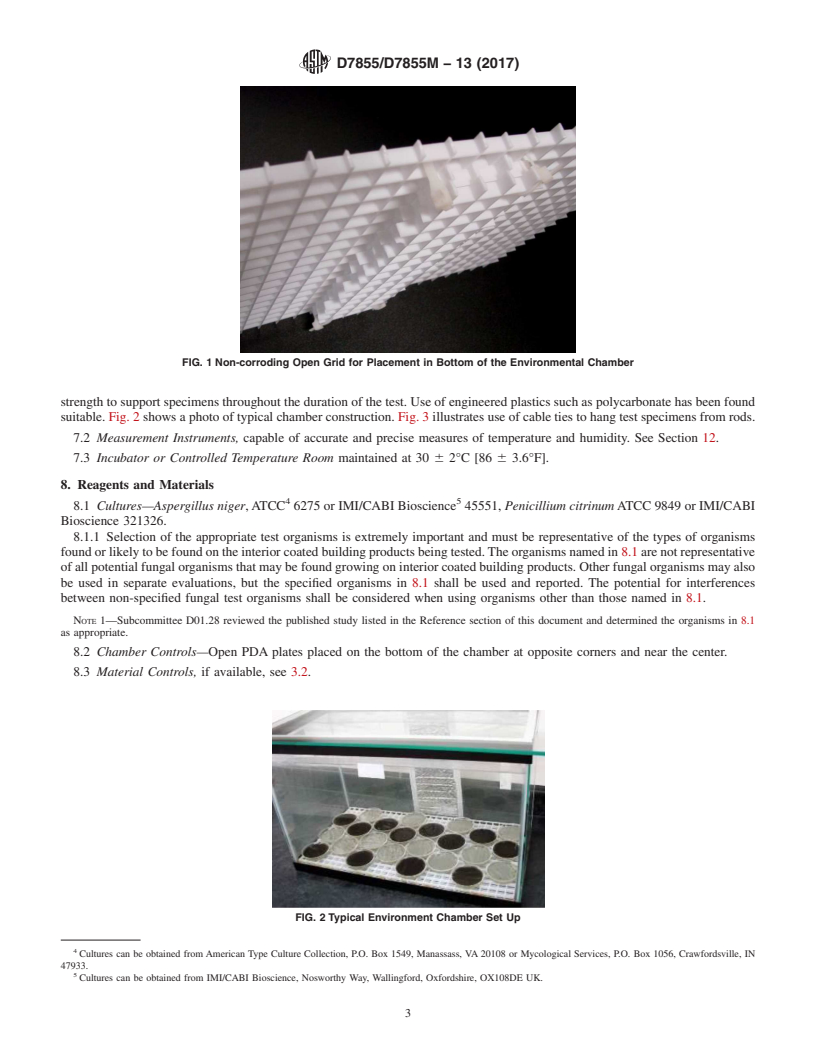

3.2.5 material control, n—untreated representative sub- nineteen liter container measuring approximately 460 mm long

strate. by 300 mm wide by 230 mm high [

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7855/D7855M − 13 D7855/D7855M − 13 (Reapproved 2017)

Standard Test Method for

Determination of Mold Growth on Coated Building Products

Designed for Interior Applications Using an Environmental

1

Chamber and Indirect Inoculation

This standard is issued under the fixed designation D7855/D7855M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers an environmental chamber and the conditions of operation to evaluate in a 4-week period the

relative resistance to mold growth and microbial surface defacement on coated building products designed for interior application

using an indirect inoculation method. The apparatus is designed so it can be easily built or obtained by any interested party.

1.2 This test method can be used to evaluate the comparative resistance of coated building products to accelerated mold growth.

Ratings do not imply a specific time period that the coated building product will be free of fungal growth during installation in

an interior environment.

1.3 This test method is not intended for use in the evaluation of public health claims.

1.4 The test method is intended for the accelerated evaluation of mold growth on a coated building product designed for interior

use. This method is not intended for evaluation of surfaces designed for exterior applications or uncoated surfaces. Use of this test

method for evaluating exterior performance has not been validated, nor have the limitations for such use been determined.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D16 Terminology for Paint, Related Coatings, Materials, and Applications

D1193 Specification for Reagent Water

D6329 Guide for Developing Methodology for Evaluating the Ability of Indoor Materials to Support Microbial Growth Using

Static Environmental Chambers

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—For definitions of terms refer to Terminology D16.

3.2 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.28 on Biodeterioration.

Current edition approved Oct. 1, 2013Dec. 1, 2017. Published November 2013December 2017. Originally approved in 2013. Last previous edition approved in 2013 as

D7855/D7855M-13. DOI: 10.1520/D7855_D7855M–13.10.1520/D7855_D7855M–13R17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7855/D7855M − 13 (2017)

3.2.1 chamber control, n—open Petri dish containing appropriate agar to demonstrate viability of fungal organisms within the

environmental chamber.

3.2.2 coated building product, n—a building material having a liquid, liquefiable or mastic composition that is converted to a

solid protective, decorative, or functional adherent film after application as a thi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.