ASTM E309-95(2001)

(Practice)Standard Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

Standard Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

SCOPE

1.1 This practice covers a procedure for applying the eddy-current method to detect discontinuities in ferromagnetic pipe and tubing (Note 1) where the article being examined is rendered substantially non-magnetic by the application of a concentrated, strong magnetic field in the region adjacent to the examining coil.

Note 1—For convenience, the term tube or tubular product will hereafter be used to refer to both pipe and tubing.

1.2 The procedure is specifically applicable to eddy-current examination methods using an encircling-coil assembly. However, eddy-current techniques that employ either fixed or rotating probe-coil assemblies may be used to either enhance discontinuity sensitivity on the large diameter tubular products or to maximize the response received from a particular type of discontinuity.

1.3 This practice is intended for use on tubular products having outside diameters from approximately 1/4 to 10 in. (6.35 to 254.0 mm). These techniques have been used for smaller and larger sizes however, and may be specified upon contractural agreement between the purchaser and the supplier.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 309 – 95 (Reapproved 2001)

Standard Practice for

Eddy-Current Examination of Steel Tubular Products Using

1

Magnetic Saturation

This standard is issued under the fixed designation E 309; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This specification has been approved for use by agencies of the Department of Defense.

4

1. Scope Certification of Nondestructive Testing Personnel

2 2.3 Military Standard:

1.1 This practice covers a procedure for applying the

MIL-STD-410E Nondestructive Testing Personnel Qualifi-

eddy-current method to detect discontinuities in ferromagnetic

5

cation and Certification

pipe and tubing (Note 1) where the article being examined is

rendered substantially non-magnetic by the application of a

3. Terminology

concentrated,strongmagneticfieldintheregionadjacenttothe

3.1 General—Standard terminology relating to electromag-

examining coil.

netic examination may be found in Terminology E 1316,

NOTE 1—For convenience, the term tube or tubular product will

Section C, “Electromagnetic Testing.”

hereafter be used to refer to both pipe and tubing.

4. Summary of Practice

1.2 The procedure is specifically applicable to eddy-current

examination methods using an encircling-coil assembly. How- 4.1 The examination is conducted using one of two general

ever, eddy-current techniques that employ either fixed or

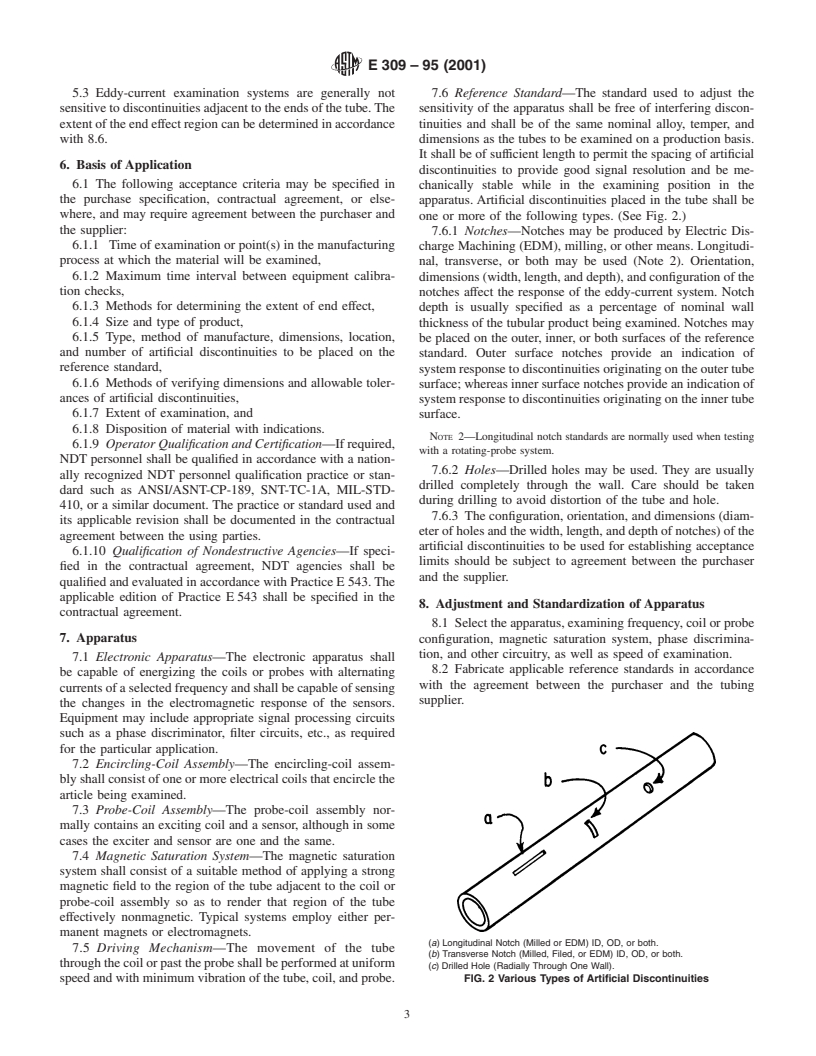

techniques shown in Fig. 1.

rotating probe-coil assemblies may be used to either enhance 4.1.1 Onetechniqueemploysoneormoreexciterandsensor

discontinuity sensitivity on the large diameter tubular products

coils that encircle the tube and through which the tubular

or to maximize the response received from a particular type of product to be examined is passed. Some circuit configurations

discontinuity.

employ one or more coils that concurrently function as both

1.3 This practice is intended for use on tubular products exciters and sensors. Alternating current passes through the

1

having outside diameters from approximately ⁄4 to 10 in. (6.35

exciting coil which, by reason of its proximity, induces

to254.0mm).Thesetechniqueshavebeenusedforsmallerand corresponding currents (eddy currents) to flow in the tubular

larger sizes however, and may be specified upon contractual product. The sensor coil detects the resultant electromagnetic

agreement between the purchaser and the supplier.

flux related to these currents.The presence of discontinuities in

the tubular product will alter the normal flow of currents and

2. Referenced Documents

this change is detected by the sensor. The encircling-coil

2.1 ASTM Standards:

technique is capable of examining the entire circumference of

E 543 Practice for Agencies Performing Nondestructive

a tubular product.

3

Testing

4.1.2 Another technique employs a probe coil with one or

3

E 1316 Terminology for Nondestructive Examinations

more sensors that are in close proximity to the surface of the

2.2 Other Documents:

tubular product to be examined. Since the probe is generally

SNT-TC-1A Recommended Practice for Personnel Qualifi-

small and does not encircle the article being examined, it

4

cation and Certification in Nondestructive Testing

examines only a limited area in the vicinity of the probe. This

ANSI/ASNT CP-189 ASNT Standard for Qualification and

technique is frequently used for examination of welded tubular

productsinwhichonlytheweldisexaminedbyscanningalong

the weld zone.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

4.1.3 The magnetic permeability of ferromagnetic materials

structive Testing, and is the direct responsibility of Subcommittee E07.07 on

severely limits the depth of penetration of induced eddy

Electromagnetic Methods.

currents. Furthermore, the permeability variations inherent in

Current edition approved October 10, 1995. Published December 1995. Origi-

nally published as E 309 – 66 T. Last previous edition E 309 – 93a.

ferromagnetic tubular products often cause anomalous test

2

For ASME Boiler and Pressure Vessel Code applications see related Recom-

mended Practice SE 309 in Section V of that Code.

3

Annual Book of ASTM Standards, Vol 03.03.

4 5

Available from American Society for Nondestructive Testing, 1711 Arlingate Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Plaza, P.O. Box 28518, Columbus, OH 43228-0518. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E 309 – 95 (2001)

(a)Encircling Coil.

(b) Probe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.