ASTM D4048-02

(Test Method)Standard Test Method for Detection of Copper Corrosion from Lubricating Grease

Standard Test Method for Detection of Copper Corrosion from Lubricating Grease

SIGNIFICANCE AND USE

This test method measures the tendency of lubricating grease to corrode copper under specific static conditions. It may be of some value in predicting possible chemical attack on lubricated parts, such as bearings that contain copper or copper alloys. Such corrosion, for example, can cause premature bearing failures. However, no correlations with actual field service, most of which are under dynamic conditions, have been established. It does not measure either the ability of the lubricant to inhibit copper corrosion caused by factors other than the lubricant itself nor does it measure the stability of the grease in the presence of copper.

SCOPE

1.1 This test method covers the detection of the corrosiveness to copper of lubricating grease.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 7, 8, and 10.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4048 – 02

Standard Test Method for

1

Detection of Copper Corrosion from Lubricating Grease

This standard is issued under the fixed designation D 4048; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope end of this heating period, the strip is removed, washed, and

compared with the Copper Strip Corrosion Standard.

1.1 This test method covers the detection of the corrosive-

ness to copper of lubricating grease.

5. Significance and Use

1.2 The values stated in SI units are to be regarded as the

5.1 This test method measures the tendency of lubricating

standard. The values given in parentheses are for information

grease to corrode copper under specific static conditions. It

only.

maybeofsomevalueinpredictingpossiblechemicalattackon

1.3 This standard does not purport to address all of the

lubricated parts, such as bearings that contain copper or copper

safety concerns, if any, associated with its use. It is the

alloys. Such corrosion, for example, can cause premature

responsibility of the user of this standard to establish appro-

bearing failures. However, no correlations with actual field

priate safety and heal practices and determine the applicability

service, most of which are under dynamic conditions, have

of regulatory limitations prior to use.For specific hazard

been established. It does not measure either the ability of the

statements, see Sections 7, 8, and 10.

lubricant to inhibit copper corrosion caused by factors other

2. Referenced Documents than the lubricant itself nor does it measure the stability of the

grease in the presence of copper.

2.1 ASTM Standards:

2

D97 Test Method for Pour Point of Petroleum Oils

6. Apparatus

D 130 Test Method for Detection of Copper Corrosion from

2 6.1 Test Jars—Cloud and pour jars, cylindrical jars of clear

Petroleum Products by the Copper Strip Tarnish Test

3 5

glasswithflatbottoms,30mmto33.5-mm(1 ⁄16in.to1 ⁄16in.)

D 2500 Test Method for Cloud Point of Petroleum Prod-

1

2 inside diameter, and 115 mm to 125 mm (4 ⁄2 in. to 5 in.) in

ucts

height as described in Test Methods D 97 and D 2500.

2.2 ASTM Adjuncts:

3 6.2 Test Jar Covers—Beakers, 50-mL; borosilicate glass,

Copper Strip Corrosion Standard

approximately 40 mm (1.6 in.) by 50 mm (2.0 in.) suitable for

3. Terminology covering individual test jars. Small porcelain or glazed silica

crucibles or crucible covers or watch glasses or vented corks

3.1 There are no terms in this test method that require new

that lightly cover the test jars, allowing pressure equalization

or other than dictionary definitions.

between the inside and outside of the jars, yet minimizing

4. Summary of Test Method

exposure of the inside of the jars to foreign vapors present in

the oven will also be satisfactory.

4.1 Aprepared copper strip is totally immersed in a sample

6.3 Oven—A circulating air oven or liquid bath capable of

of grease and heated in an oven or liquid bath at a specified

maintaining a temperature of 100 6 1°C (212 6 2°F) or other

temperature for a definite period of time. Commonly used

desired temperatures with the same precision.

conditionsare100 61°C(212 62°F)for24h 65min.Atthe

6.4 Polishing Vise—For holding the copper strip firmly

without marring the edges while polishing. Any convenient

type of holder (see Appendix X1 of Test Method D 130) may

1

This test method is under the jurisdiction of ASTM Committee D02 on

be used, provided that the strip is held tightly and that the

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

surface of the strip being polished is supported above the

D02.G on Lubricating Grease.

Current edition approved April 10, 2002. Published July 2002. Originally

surface of the holder.

published as D 4048–81. Last previous edition D 4048–97.

6.5 Viewing Test Tubes—Flatglasstesttubesmaybeusedto

2

Annual Book of ASTM Standards, Vol 05.01.

3 protect corroded strips for close inspection or storage. (See the

Available from ASTM International Headquarters. Order Adjunct No.

ADJD0130. Appendix X1 of Test Method D 130.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4048–02

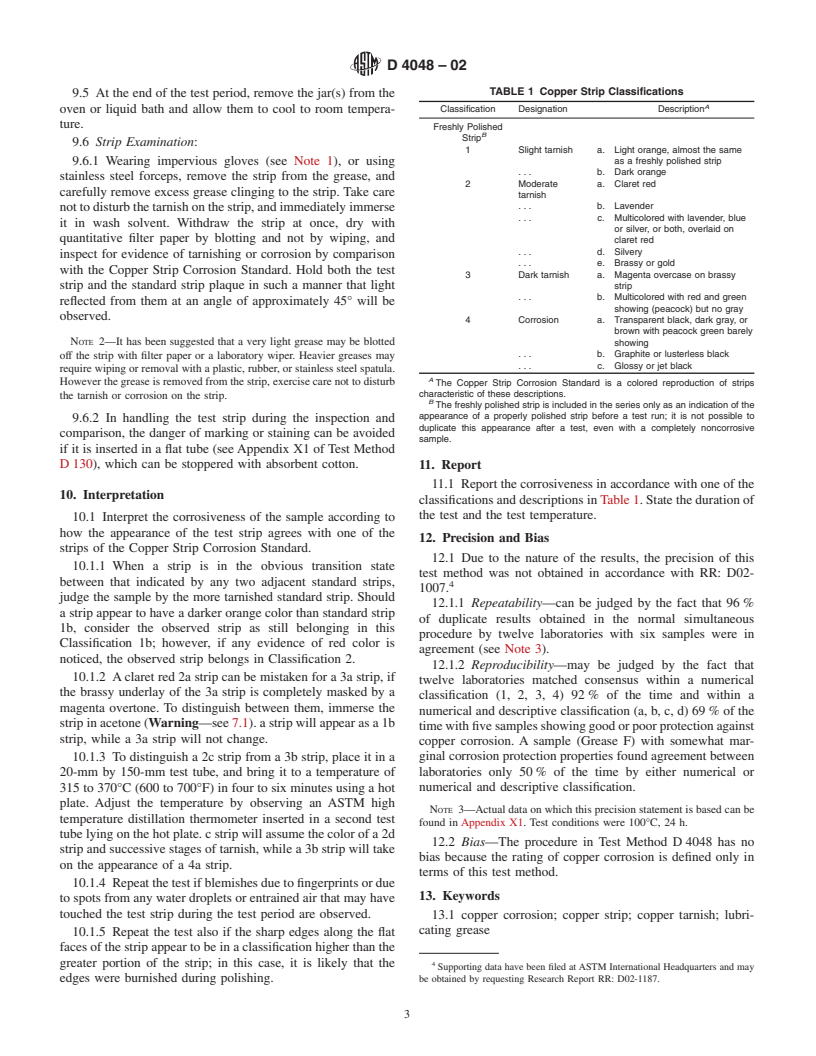

6.6 Copper Strip Corrosion Standard—consists of repro- wash solvent (Warning—see 7.1.) from which it can be

ductions in color of typical strips representing degrees of withdrawnimmediatelyforfinalpolishingorinwhichitcanbe

tarnish and corrosion, the repr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.