ASTM D2458-69(1975)

(Test Method)Method for Flow Measurement of Industrial Water and Industrial Waste Water by the Venturi Meter Tube (Withdrawn 1981)

Method for Flow Measurement of Industrial Water and Industrial Waste Water by the Venturi Meter Tube (Withdrawn 1981)

General Information

Standards Content (Sample)

~~r~ Designation: o 2458- 69 (Reapproved 19751

Standard Method of

FLOW MEASUREMENT OF WATER BY THE

VENTURI METER TUBE'

~his .~tandtrd_ is ~studd uryder the. fixt:d designatio~ p 2458; the number immediately following the designation indicates

'l'r"'r o ongma a opt1on or, m the case of revJsJon, the year of last revision. A number in parentheses indicates the

year o ast n:approval.

I. Scope ter, d, to the inlet diameter, D. The quantity

dl Dis expressed as a decimal and represented

1.1 This method covers the measurement

by the Greek letter Beta.

of the rate of flow of water in pipelines using

the Herschel Standard Venturi meter tube.

3. General Principles

1.2 VenturF meter tubes are applicable for

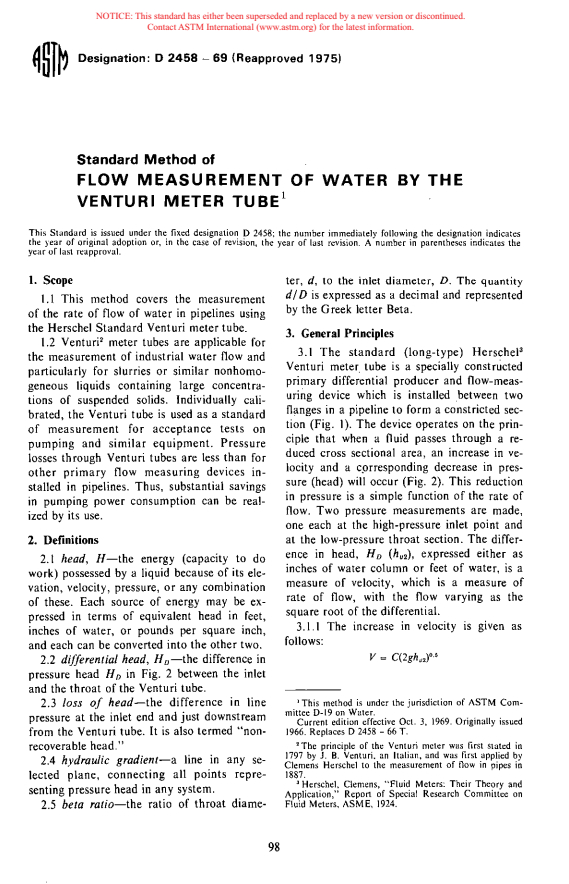

3.1 The standard (long-type) Herschel'

the measurement of industrial water llow and

Venturi meter. tube is a specially constrUcted

particularly for slurries or similar nonhomo

primary differential producer and flow-meas

geneous liquids containing large concentra

uring device which is installed between two

tions of suspended solids. Individually cali

flanges in a pipeline to form a constricted sec

brated, the Venturi tube is used as a standard

tion (Fig. 1). The device operates on the prin

of measurement for acceptance tests on

ciple that when a fluid passes through a re

pumping and similar equipment. Pressure

duced cross sectional area, an increase in ve

losses through Venturi tubes are less than for

locity and a c.orresponding decrease in pres

other primary flow measuring devices in

sure (head) will occur (Fig. 2). This reduction

stalled in pipelines. Thus, substantial savings

in pressure is a simple function of the rate of

in pumping power consumption can be real

flow. Two pressure measurements are made

ized by its use.

one each at the high-pressure inlet point and

at the low-pressure throat section. The differ

2. Definitions

ence in head, H (hu ), expressed either as

0 2

2.1 head, H-the energy (capacity to do

inches of water column or feet of water, is a

work) possessed by a liquid because of its ele

measure of velocity, which is a measure of

vation, velocity, pressure, or any combination

rate of flow, with the flow varying as the

of these. Each source of energy may be ex

square root of the differential.

pressed in terms of equivalent head in feet,

3.1.1 The increase in velocity is given as

inches of water, or pounds per square inch,

follows:

and each can be converted into the other two.

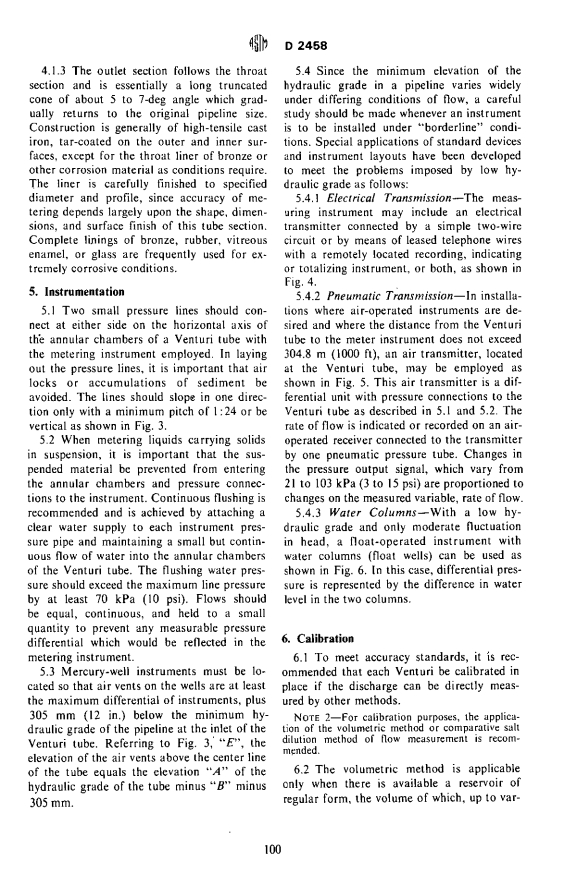

2.2 differential head, H -the difference in

0

pressure head H n in Fig. 2 between the inlet

and the throat of the Venturi tube.

'This method is under the jurisdiction of ASTM Com

2.3 loss of head-the difference in line

mittee D-19 on Water.

pressure at the inlet end and just downstream

Current edition effective Oct. 3, 1969. Originally issued

from the Venturi tube. It is also termed "non 1966. Replaces D 2458- 66 T.

'The principle of th~: Venturi meter was lirst stated in

recoverable head."

1797 by J. B. Venturi. an Italian, and wa~ fir~t upplied by

2.4 hydraulic gradient-a line in any se

Clemens Herschel to the measurement of flow in pipes in

1887.

lected plane, connecting all points repre

a I:~er~che!: Clemens, "Flui~ Meters: Their Theory and

senting pressure head in any system.

Appl1catwn, Report of Spec1al Research Committt:e on

Fluid Mctm, ASME, 1924.

2.5 beta ratio-the ratio of throat diame-

98

---------------------- Page: 1 ----------------------

D 2458

where: 3.3 The formula for Venturi tube measure

ment evolved from consideration of the con

V velocity, theoretical, ft/s,

C discharge coefficient (average value cept of flow, pressure, velocity, and the neces

0.98), sary correction factors becomes:

g acceleration constant of gravity

Q~Ac( .l \x(2gHn)"'

32.16 ft/s', and

_(I - B•)u·~j

hu velocity head, theoretical, ft of water.

2

3

3.1.2 The fluid flow formulas for the Ven

where Q = ft /unit of time. By the use of

turi tube are derived from this basic relation

proper additional numerical factors, this

ship. The flow formula then becomes the fol

equation can be converted into ga.flons per

lowing:

unit of time.

4. Apparatus

where:

4.1 Venturi Meter Tube (Primary Device)

3

Q = ft /unit time, and

-The apparatus shall consist of the Venturi

2

A = area of pipe, ft • meter tube referred to as the primary meas

3.2 In addition to the simple determination uring device suitably constructed in accord

of the differential head, H , there are two

ance with standard dimensions selected to

0

factors to be considered in measurement with

give accurately measurable differential pres

a Venturi tube. These are the velocity of ap

sures over the entire required variation of

proach and friction. Flowing fluid in a pipe quantity flow. At no time should the throat

line as it reaches the inlet section of the Ven pressure drop below atmospheric. The Venturi

turi tube has a certain velocity of approach.

tube should consist of inlet, thr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.