ASTM C133-97

(Test Method)Standard Test Methods for Cold Crushing Strength and Modulus of Rupture of Refractories

Standard Test Methods for Cold Crushing Strength and Modulus of Rupture of Refractories

SCOPE

1.1 These test methods cover the determination of the cold crushing strength and the modulus of rupture (MOR) of dried or fired refractory shapes of all types.

1.2 The test methods appear in the following sections: Test Method Sections Cold Crushing Strength 4 to 9 Modulus of Rupture 10 to 15

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 133 – 97

Standard Test Methods for

Cold Crushing Strength and Modulus of Rupture of

Refractories

This standard is issued under the fixed designation C 133; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Approved actions inadvertently omitted were added editorially January 22, 1997.

1. Scope 3.3 Considerable care must be used to compare the results

of different determinations of the cold crushing strength or

1.1 These test methods cover the determination of the cold

modulus of rupture. The specimen size and shape, the nature of

crushing strength and the modulus of rupture (MOR) of dried

the specimen faces (that is, as-formed, sawed, or ground), the

or fired refractory shapes of all types.

orientation of those faces during testing, the loading geometry,

1.2 The test methods appear in the following sections:

and the rate of load application, may all significantly affect the

Test Method Sections

numerical results obtained. Comparisons of the results between

Cold Crushing Strength 4 to 9

different determinations should not be made if one or more of

Modulus of Rupture 10 to 15

these parameters differ between the two determinations.

1.3 The values stated in inch-pound units are to be regarded 3.4 The relative ratio of the largest grain size to the smallest

as the standard. The values given in parentheses are for

specimen dimension may significantly affect the numerical

information only.

results. For example, smaller, cut specimens containing large

1.4 This standard does not purport to address all of the grains may present different results than the bricks from which

safety concerns, if any, associated with its use. It is the

they were cut. Under no circumstances should 6- by 1- by 1-in.

responsibility of the user of this standard to establish appro- (152- by 25- by 25-mm) specimens be prepared and tested for

priate safety and health practices and determine the applica-

materials containing grains with a maximum grain dimension

bility of regulatory limitations prior to use. exceeding 0.25 in. (6.4 mm).

3.5 This test method is useful for research and development,

2. Referenced Documents

engineering application and design, manufacturing process

2.1 ASTM Standards:

control, and for developing purchasing specifications.

C 862 Practice for Preparing Refractory Concrete Speci-

COLD CRUSHING STRENGTH

mens by Casting

C 1054 Practice for Pressing and Drying Refractory Plastic

4. Apparatus

and Ramming Mix Specimens

4.1 Testing Machine—Any form of standard mechanical or

E 4 Practices for Force Verification of Testing Machines

hydraulic compression testing machine conforming to the

3. Significance and Use requirements of Practices E 4 may be used.

3.1 The cold strength of a refractory material is an indica-

NOTE 1—For low-strength materials (such as insulating bricks or

tion of its suitability for use in refractory construction. (It is not

castables), a sensitivity of 20 lbf (67 kN) or less is required. The use of a

a measure of performance at elevated temperatures.) hydraulic testing machine is also preferred over the mechanical type for

these materials.

3.2 These test methods are for determining the room tem-

perature flexural strength in 3-point bending (cold modulus of

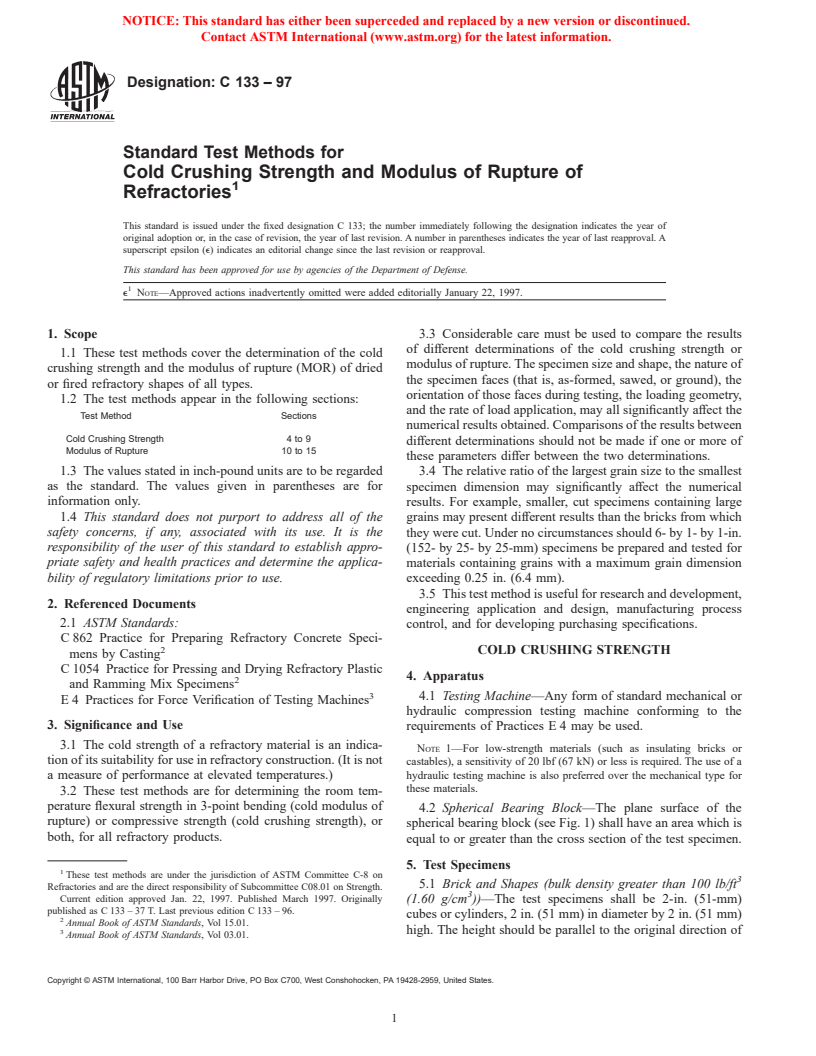

4.2 Spherical Bearing Block—The plane surface of the

rupture) or compressive strength (cold crushing strength), or

spherical bearing block (see Fig. 1) shall have an area which is

both, for all refractory products.

equal to or greater than the cross section of the test specimen.

5. Test Specimens

These test methods are under the jurisdiction of ASTM Committee C-8 on

5.1 Brick and Shapes (bulk density greater than 100 lb/ft

Refractories and are the direct responsibility of Subcommittee C08.01 on Strength.

Current edition approved Jan. 22, 1997. Published March 1997. Originally

(1.60 g/cm ))—The test specimens shall be 2-in. (51-mm)

published as C 133 – 37 T. Last previous edition C 133 – 96.

cubes or cylinders, 2 in. (51 mm) in diameter by 2 in. (51 mm)

Annual Book of ASTM Standards, Vol 15.01.

3 high. The height should be parallel to the original direction of

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 133–97

NOTE 2—For relatively weak specimens like insulating castables or

insulating firebricks, a minimum sample size of ten specimens is pre-

ferred.

6.2 Brick and Shapes—Place a cellulose fiber wall board

(for example, Masonite ) 0.25 in. (6.4 mm) in thickness and

extending 0.5 in. (12.7 mm) or more beyond the edges of the

loaded faces of the specimen. Apply the load parallel to the

direction in which the brick was originally pressed.

6.3 Regular and High Strength Castables—Place a cellulose

fiber wall board 0.25 in. (6.4 mm) in thickness and extending

0.5 in. (12.7 mm) or more beyond the edges of the loaded faces

of the specimen. Apply the load on the 2- by 2-in. (51- by

51-mm) or 2-in. (51-mm) diameter face and perpendicular to

the depth of the specimen as originally cast or gunned.

6.4 Insulating Brick or Shapes—Apply the load directly to

1 1

the 4 ⁄2-by4 ⁄2-in. (114- by 114-mm) surface of the test

FIG. 1 Recommended Design for Crushing Test Assembly,

specimen.

Including Bearing Block

6.5 Insulating Castables (typical bulk density of 100 lb/ft

(1.60 g/cm ), or greater than 45 % total porosity, or both)—

pressing of the brick or shape. In the case of special shapes,

Apply the load directly to the 2- by 2-in. (51- by 51-mm) face

only one specimen shall be cut from a single shape and as

and perpendicular to the depth of the specimen as originally

many of the original surfaces as possible shall be preserved. In

cast or gunned.

preparing specimens from irregular or large refractory shapes,

6.6 Use the bearing block on top of the test specimen, and

any method involving the use of abrasives, such as a high-

position it so that the center of the sphere is in alignment with

speed abrasion wheel, core drill, or rubbing bed, that will

the vertical axis of the specimen (see Fig. 1). Keep the

produce a specimen with approximately plane and parallel

spherical bearing block thoroughly lubricated to ensure accu-

sides without weakening the structure of the specimen may be

rate adjustment which may be made by hand under a small

used.

initial load for each specimen.

5.2 Insulating Brick or Shapes (typical bulk density of 100

3 3

NOTE 3—The spherical bearing block may not be necessary on test

lb/ft (1.60 g/cm ), or greater than 45 % total porosity, or

machines having mechanical linkages which ensure that the stress applied

1 1 1

both)—The test specimens shall be 4 ⁄2 by 4 ⁄2 by 2 ⁄2 or 3 in.

is colinear with the axis of the specimen.

(114 by 114 by 64 or 76 mm), each taken from a different brick.

6.7 For dense refractories with sufficient strength to require

It is permissible to prepare these specimens from the half-brick

greater than about 3 min per test, initial loading to one-half of

resulting from the modulus of rupture test (see Sections 10-15).

the anticipated failure load may be accomplished at any

The selected compression test section shall be free of cracks,

convenient rate exceeding the specified rate. Subsequently,

chipped surfaces, and other obvious defects. The test surfaces

each specimen shall be crushed with a compressive load

shall be approximately parallel planes.

applied at the standard rates specified in Table 1. The rates shall

5.3 Castable Refractories—The test specimens shall be 2-

not vary by more than 610 % of the specified rate for the type

by 2- by 2-in. (51- by 51- by 51-mm) cubes or cylinders 2 in.

of refractory being tested.

(51 mm) in diameter by 2 in. (51 mm) high, prepared by

6.8 When using a mechanical testing machine, keep the

casting or gunning. It is permissible to prepare one specimen

balance beam in a constantly floating position.

from each 9- by 2- by 2-in. (230- by 51- by 51-mm) bar after

6.9 Specimens are loaded, as specified, to failure. Failure is

the modulus of rupture test (see Sections 10-15). The selected

defined as the collapse of the specimen (failure to support the

compression test section shall be free of cracks, chipped

load), or the reduction of the specimen height to 90 % of its

surfaces, and other obvious defects. The loaded surfaces shall

original value. The maximum applied load is recorded.

be approximately parallel planes. All samples must be dried at

220 to 230°F (105 to 110°C) for 18 h (overnight). Upon

7. Calculation

removal from the oven, allow the sample to cool naturally until

7.1 Calculate the cold crushing strength using Eq 1:

cool to the touch. Complete testing within2hof removal from

the drying oven. (See Practices C 862 and C 1054.) S 5 W/A (1)

6. Procedure

6.1 At least five specimens from an equivalent number of

refractory shapes compose a sample. Masonite has been found satisfactory for this purpose.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 133–97

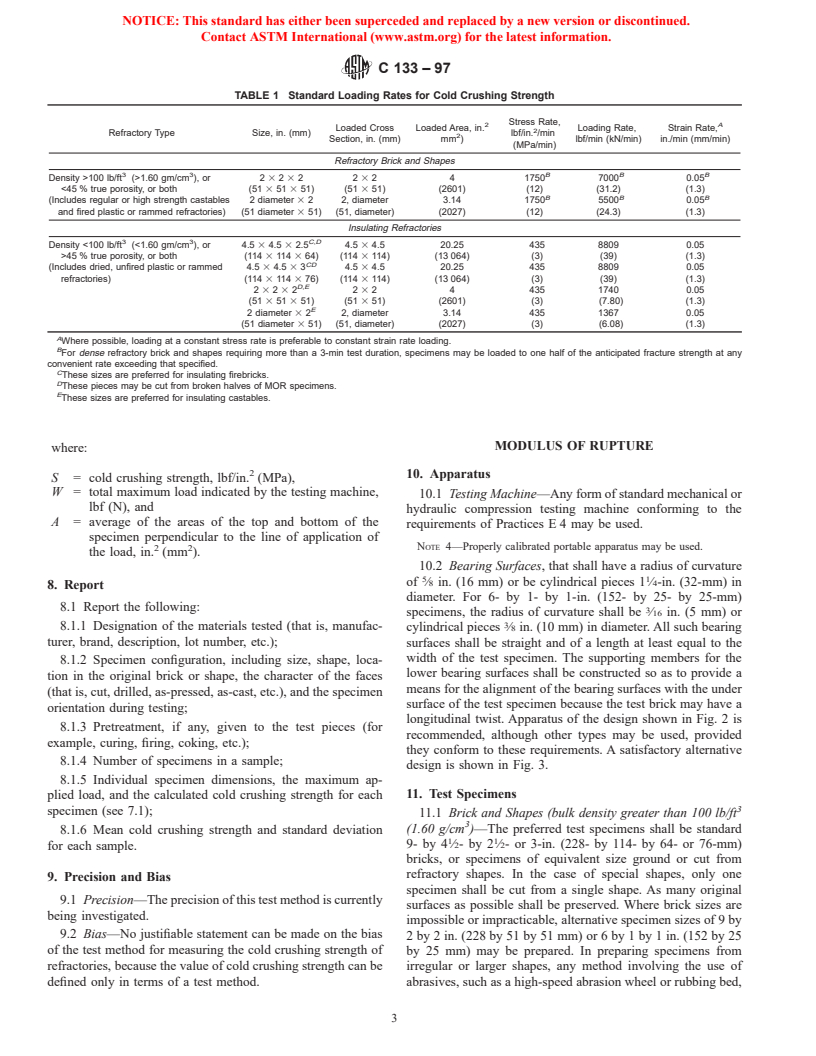

TABLE 1 Standard Loading Rates for Cold Crushing Strength

Stress Rate,

2 A

Loaded Cross Loaded Area, in. Loading Rate, Strain Rate,

Refractory Type Size, in. (mm) lbf/in. /min

Section, in. (mm) mm ) lbf/min (kN/min) in./min (mm/min)

(MPa/min)

Refractory Brick and Shapes

3 3 B B B

Density >100 lb/ft (>1.60 gm/cm ), or 2 3 2 3 2 2 3 2 4 1750 7000 0.05

<45 % true porosity, or both (51 3 51 3 51) (51 3 51) (2601) (12) (31.2) (1.3)

B B B

(Includes regular or high strength castables 2 diameter 3 2 2, diameter 3.14 1750 5500 0.05

and fired plastic or rammed refractories) (51 diameter 3 51) (51, diameter) (2027) (12) (24.3) (1.3)

Insulating Refractories

3 3 C,D

Density <100 lb/ft (<1.60 gm/cm ), or 4.5 3 4.5 3 2.5 4.5 3 4.5 20.25 435 8809 0.05

>45 % true porosity, or both (114 3 114 3 64) (114 3 114) (13 064) (3) (39) (1.3)

CD

(Includes dried, unfired plastic or rammed 4.5 3 4.5 3 3 4.5 3 4.5 20.25 435 8809 0.05

refractories) (114 3 114 3 76) (114 3 114) (13 064) (3) (39) (1.3)

D,E

2 3 2 3 2 2 3 2 4 435 1740 0.05

(51 3 51 3 51) (51 3 51) (2601) (3) (7.80) (1.3)

E

2 diameter 3 2 2, diameter 3.14 435 1367 0.05

(51 diameter 3 51) (51, diameter) (2027) (3) (6.08) (1.3)

A

Where possible, loading at a constant stress rate is preferable to constant strain rate loading.

B

For dense refractory brick and shapes requiring more than a 3-min test duration, specimens may be loaded to one half of the anticipated fracture strength at any

convenient rate exceeding that specified.

C

These sizes are preferred for insulating firebricks.

D

These pieces may be cut from broken halves of MOR specimens.

E

These sizes are preferred for insulating castables.

MODULUS OF RUPTURE

where:

10. Apparatus

S = cold crushing strength, lbf/in. (MPa),

W = total maximum load indicated by the testing machine,

10.1 Testing Machine—Any form of standard mechanical or

lbf (N), and

hydraulic compression testing machine conforming to the

A = average of the areas of the top and bottom of the

requirements of Practices E 4 may be used.

specimen perpendicular to the line of application of

NOTE 4—Properly calibrated portable apparatus may be used.

2 2

the load, in. (mm ).

10.2 Bearing Surfaces, that shall have a radius of curvature

5 1

of ⁄8 in. (16 mm) or be cylindrical pieces 1 ⁄4-in. (32-mm) in

8. Report

diameter. For 6- by 1- by 1-in. (152- by 25- by 25-mm)

8.1 Report the following:

specimens, the radius of curvature shall be ⁄16 in. (5 mm) or

8.1.1 Designation of the materials tested (that is, manufac-

cylindrical pieces ⁄8 in. (10 mm) in diameter. All such bearing

turer, brand, description, lot number, etc.);

surfaces shall be straight and of a length at least equal to the

width of the test specimen. The supporting members for the

8.1.2 Specimen configuration, including size, shape, loca-

lower bearing surfaces shall be constructed so as to provide a

tion in the original brick or shape, the character of the faces

means for the alignment of the bearing surfaces with the under

(that is, cut, drilled, as-pressed, as-cast, etc.), and the specimen

surface of the test specimen because the test brick may have a

orientation during testing;

longitudinal twist. Apparatus of the design shown in Fig. 2 is

8.1.3 Pretreatment, if any, given to the test pieces (for

recommended, although other types may be used, provided

example, curing, firing, coking, etc.);

they conform to these requirements. A satisfactory alternative

8.1.4 Number of specimens in a sample;

design is shown in Fig. 3.

8.1.5 Individual specimen dimensions, the maximum ap-

11. Test Specimens

plied load, and the calculated cold crushing strength for each

specimen (see 7.1);

11.1 Brick and Shapes (bulk density greater than 100 lb/ft

(1.60 g/cm )—The preferred test specimens shall be standard

8.1.6 Mean cold crushing strength and standard deviation

1 1

9- by 4 ⁄2-by2 ⁄2- or 3-in. (228- by 114- by 64- or 76-mm)

for each sample.

bricks, or specimens of equivalent size ground or cut from

refractory shapes. In the case of special shapes, only one

9. Precision and Bias

specimen shall be cut from a single shape. As many original

9.1 Precision—The precision of this test method is currently

surfaces as possible shall be preserved. Where brick sizes are

being investigated.

impossible or impracticable, alternative specimen sizes of 9 by

9.2 Bias—No justifiable statement can be made on the bias

2 by 2 in. (228 by 51 by 51 mm) or 6 by 1 by 1 in. (152 by 25

of the test method for measuring the cold crushing strength of

by 25 mm) may be prepared. In preparing specimens from

refractories, because the value of cold crushing strength can be irregular or larger shapes, any method involving the use of

defined only in terms of a test method. abrasives, such as a high-speed abrasion wheel or rubbing bed,

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 133–97

NOTE 1—The dimensions appearing in Fig. 2 are in inches. See table below for metric equivalents.

Me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.